Electronic Enclosures

Electrical enclosures are boxes that shield electronic equipment such as conduits, connections and switches from the environment and from tampering.

Quick Links to Electronic Enclosures Information

The History of Electronic Enclosures

Electronic enclosures were born out of need, to shield early switches, known as cut-outs. Cut-outs featured copper bars and an insulated "T" handle made for the person to grasp for operation. The cut-out was mounted with screws or bolts onto a slate, wood or mica surface. Like the switch itself, its open live parts were visible and accessible. Likewise, switchboards were vertically mounted on boards with open copper busbars and exposed live parts. Eventually, people discovered the danger of this arrangement. To keep people safe from the perils of live electricity, manufacturers installed them inside wooden cut-out boxes.

For a number of years, this style of protective enclosure kept users safe. So, when electrical power was brought into the home, they used the same strategy, installing live parts in a wood cabinet. This worked until they added electricity for taps to the system. Once they did this, homeowners discovered that occasional overheating and loose connections led to fires. To solve this problem, manufacturers switched from wooden cabinets to flame retardant metal cabinets.

Since their creation, electronic enclosures have morphed and advanced with the technology and materials of the day. For example, today, while enclosures can be made from sheet metal types like stainless steel, they’re just as frequently produced using thermoplastic and composite materials that did not exist 100 years ago. Electronic enclosures are more important than ever, and the foreseeable future does not suggest this changing, as, in our world, we use ever more powerful electronics.

Enclosure Benefits

Electronic enclosures are more than beneficial—they’re essential. Without electronic enclosures, both people and equipment would be in constant danger of harm; systems could easily fail from anything from water damage to EMI.

Even better, with so many different materials and designs that manufacturers can use, there’s an enclosure for every situation. Plus, there’s an enclosure for every price point.

Electronic Enclosure Design and Customization

When designing electronic enclosures, manufacturers must make decisions regarding material and configuration.

- Material Design

- Some of the most common electronic instrument enclosure materials include: stainless steel sheet, aluminum sheet, fiberglass, Kevlar, high strength polymer plastics and composites. Materials are chosen based on their ability to protect and shelter the electronics inside and keep intrusive materials (and people) out.

- Common material requirements include: protection from vandalism, weather and corrosion. Other requirements manufacturers look to accommodate include: thermal insulation and transfer, protection from the demands of the location (ex. enclosure inside a mine must be made from explosion proof material), durability, aesthetic appeal and price point.

- The durability of an enclosure is determined by the installation location. For instance, you can label a plastic enclosure durable if it will not be exposed to extreme environmental conditions. The general rule is, if you need an enclosure for the outdoors, and durability is the only factor, always select sheet metal fabrication options.

- Size and Shape

- Manufacturers produce enclosures ranging in size from one square inch to the size of an entire room. Most often, their shape is rectangular and box-like, although they may also be round or have sloping sides. The choice of what size and shape to make an electronic enclosure depends entirely on the application. For example, some enclosures need only contain a small push button assemblage, while others must contain large computer networks and wiring. Still others must be circular in order to protect head-mount style instruments.

- Features and Customization

- Manufacturers can customize enclosures by adding all sorts of extra features. Once again, this depends entirely on the application at hand. For instance, for safety and security, they may choose to include a locking mechanism. For heat control, they may configure some electrical cabinets with ventilation fans. Examples of other custom enclosure features they made include: lids, removable panels, access points, vents and recessed tops for labels and keypads.

- Also, they custom size them to precisely fit just about any space. While most enclosures snap together, manufacturers can offer you an even tighter and more impermeable seal using lap joint or tongue and groove construction.

Electronic Enclosures Images, Diagrams and Visual Concepts

Electronic enclosures, box-like structures that are designed to protect, contain, and enclose electronic components.

Electronic enclosures, box-like structures that are designed to protect, contain, and enclose electronic components.

NEMA enclosures are boxes that are designed to protect electrical components from the surrounding environment and depending on the specific NEMA rating.

NEMA enclosures are boxes that are designed to protect electrical components from the surrounding environment and depending on the specific NEMA rating.

Structures made from aluminum to protect electronic components from damage.

Structures made from aluminum to protect electronic components from damage.

Protective structures designed to secure and protect computer hardware components.

Protective structures designed to secure and protect computer hardware components.

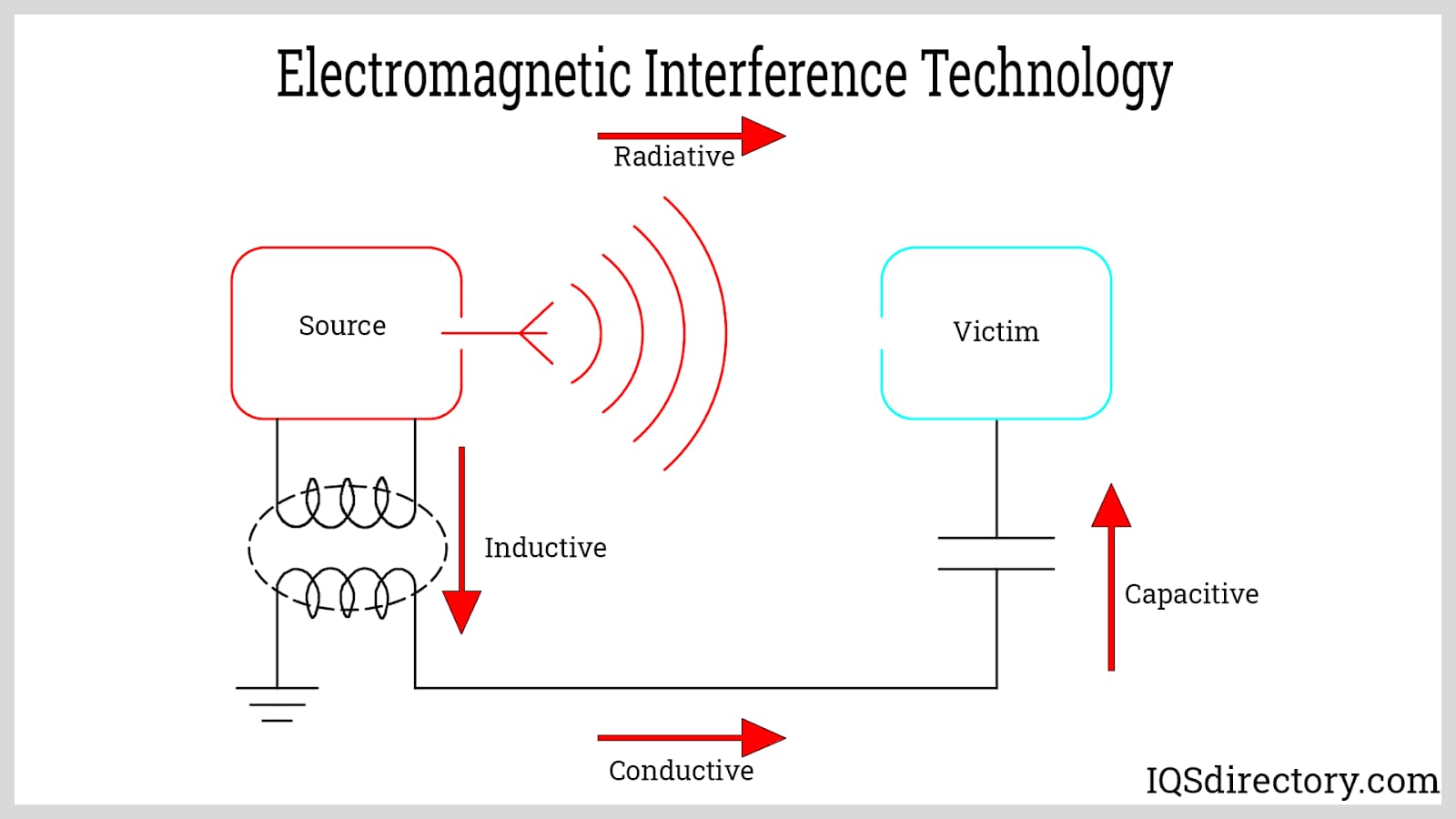

The diagram shows the different ways in which emissions are spread in electrical and electronic devices.

The diagram shows the different ways in which emissions are spread in electrical and electronic devices.

Types of Electronic Enclosures

- Aluminum Enclosure

- Good thermal and electrical conductors. Typically, they’re made from diecast aluminum. Aluminum offers the best of both worlds–while tough and durable, aluminum is also malleable and very lightweight. For indoor use, where exposure to moisture can be reduced, aluminum enclosures are considered ideal. You can connect with aluminum enclosure manufacturers here.

- Stainless Steel Enclosure

- Also durable and corrosion resistant, having properties similar to aluminum. When electrical components generate too much energy and require heat transfer, metal boxes made from stainless steel are the best choice.

- Computer Enclosure

- Are made specifically to enclose computer components. Usually they’re made from aluminum or steel. Although electromagnetic interference can travel through these metals, they can be coated with a substance to screen their contents from the rays.

- Polycarbonate Enclosure

- Choose a polycarbonate box enclosure design when they are looking to reduce heat interference. This type of plastic enclosure works especially well with low exterior temperatures. Molded polycarbonate plastic enclosures are usually small and complex.

- ABS Enclosure

- Enclosures made from acrylonitrile butadiene styrene, or ABS, a common thermoplastic, are popular for use with pocket and handheld devices. ABS is popular not only with handheld enclosure designs, but many others as well. It offers superior electrical insulation properties and impact resistance, and it’s lightweight and shock absorbent.

- Mounted Enclosure

- Are just as they sound; they’re made to be mounted. To mount them, install screws or fasteners through designated holes in the back or bottom of the housing.

- NEMA Enclosure

- Certified by the National Electronic Manufacturers Association. They range from Type 1 to 13 and identify whether the enclosure is intended for indoor or outdoor use, in non-hazardous or dangerous situations and what it can protect from.

- Fiberglass Enclosure

- Heat resistant, impact resistant, chemical resistant and corrosion resistant. In addition, they have excellent electrical properties and can withstand high tensile loads. Fiberglass enclosures are great for outdoor applications, including salt and chemical environments, corrosive environments and continuously wet environments.

- Rack Mount Enclosure

- Accommodate multiple equipment modules that are 19 inches wide. Protruding edges allow the module to be fastened to the frame, which is usually steel or aluminum because of their strength and load-bearing properties. Professional audio equipment, computer servers and other electronics are stored inside the rack mount enclosure.

- This enclosure is usually a metal enclosure encased in reinforced plastic, and many models have a door that can be shut and locked.

- EMI Enclosures

- A type of disturbance caused by external forces that interfere with electrical circuits and signals. EMI enclosures, named after electromagnetic interference, are a type of housing designed specifically to insulate susceptible devices against exposure to electromagnetic fields and radiation, and the damage they can do.

Electronic Enclosure Applications

Because of their sensitive circuitry, manufacturers must seek to protect electronic products, like wiring, from dirt, water and accidental contact. That’s why electronic enclosures are standard in most industrial and manufacturing settings.

Being kept in an enclosure prevents the intrusion of solid foreign objects, as well as, to a certain extent, liquids. Not only do electronic instrument enclosures protect the products they contain from pollutants and moisture, they also shield the internal equipment from electromagnetic interference, or EMI.

Sometimes referred to as "electrical cabinets" or electronic instrument enclosures, electronic enclosures are widely used in the medical, communication, automotive and agricultural industries, but can be found in any electronic component application. They are found everywhere, from public places such as street corners or parks, to private buildings and residences.

Standards and Specifications for Electric Enclosures

Make sure that your electronic enclosure is NEMA certified. NEMA helps manufacturers and distributors get exactly what they need and ensures that the electronics inside will be able to function properly and safely.

Also make sure that you get an electronic enclosure with the right NEMA grade for you, as they are all different. Type 1, for example, is for general indoor use to prevent accidental contact with the enclosed equipment. Type 4X can be used indoors or outdoors and protects against corrosion, windblown dust and rain, sleet, snow, splashing or hose-directed water and the formation of ice on the enclosure. NEMA Type 12 is for industrial use indoors to protect from lint, dust, dirt, fibers, dripping, seepage and dripping non-corrosive liquids. Type 12 enclosures may not have any knockouts (partially punched holes) or openings, except for oil and dust-tight gasket mechanisms.

Things to Consider When Choosing an Enclosure

Factors to consider during enclosure selection include: application, size, construction materials, mounting, security and NEMA type.

In addition, you need to consider: control of liquid water movement, control of heat flow, strength and rigidity, control of water vapor flow, and control of air flow.

The features that you need to look for in an electrical enclosure are: impact shock shielding, static shielding, magnetic shielding, dirt and dust proofing, and heat shielding. Let’s go over those in a little more detail.

- Impact Shielding

- Pieces of modern electronic equipment, unlike their bulky predecessors, are, to some degree fragile and can lose efficiency after being exposed to physical impact. So, any electrical enclosure that you install needs to have impact shock shielding, which protects or minimizes the implication of physical impact and vibration to the equipment housed in the enclosure.

- Static Shielding

- Some electric components can be damaged by static current; therefore, static shielding from external sources is an important attribute for an enclosure to offer. Static shielding also provides protection from unexpected or abrupt electrical surges and charge interferences.

- Heat Shielding

- When electricity passes through electrical components, heat dissipates. Because most electronic equipment is heat sensitive, they require shielding to work efficiently. It’s important, therefore, to make sure that the enclosure you buy provides this. For example, some enclosures have in-built heat sinks, which do not allow temperature built up inside the enclosure and push the heat outside. However, heat sinks are normally used and are installed only when there is a special requirement.

- Dirt and Waterproofing

- Almost all electrical components need protection from dirt and water, so before buying, determine your unique requirements and make sure your enclosure offers such protection.

- Some electronic enclosures are dirt resistant, while some provide absolute proofing, even from windblown dirt. Similarly, some models offer water-resistant properties, whereas some are resistant even to ice.

- Magnetic Shielding

- Your enclosure should also protect your electronic components against electromagnetic pulses, as they can be quite damaging. While electromagnetic bursts are very uncommon, it’s still worthwhile to shield your equipment from them.

- The string that ties your whole search together is your manufacturer. Even if you know all of your specifications, you won’t get a quality enclosure unless you work with a quality supplier. You’ll know which company is right for you when you find one that can not only perform the task at hand, but do it while providing you the best customer service possible. Find a supplier that's right for you by checking out our list of recommended enclosure companies near the top of this page. Browse their respective websites, pick three or four that interest you, and reach out to them with your questions. When you talk to them, make sure to go over the considerations we outlined above.

Electronic Enclosures Terms

- Attenuation

- A reduction in signal strength. Attenuation can occur naturally during normal signal transmission, or it may be produced intentionally by inserting a device in the path of the signal to reduce signal strength.

- Bounding Surface

- The outer surface of the electrical enclosure.

- Instrument Cabinet

- Often used interchangeably with either enclosure or rack. It is a piece of equipment designed to house or enclose something, such as electrical or process equipment.

- Cable Glands

- Seals that prevent water, dust, etc. from entering the enclosure at the point at which the cable is brought through the enclosure wall. Often, cable glands are installed via a gland plate.

- EMI (Electromagnetic Interference) Emission

- The unintentional or undesired exiting of potentially interfering electromagnetic energy from electrical/electronic sources.

- Flame Retardancy

- The ability of a material to resist burning, sparking, sputtering or dripping when brought into contact with a naked flame. Not all enclosures are flame retardant.

- Gear Tray

- Also called a "mounting plate" or "mounting pan," it is a shelf that allows the mounting of equipment inside the enclosure. Gear trays are typically located at the rear of the enclosure, though some may be movable.

- Gland Plate

- Removable section of the enclosure, usually located on the bottom. The gland plate can be removed to allow the easy fitting of cable glands.

- Permeability

- The extent to which a material can be magnetized.

- Plinth

- Term used to describe various styles of mounting bases for floor-mounted enclosures.

- Shielded Cables

- Cables that have shields, such as braids or foils, to prevent EMI from entering or exiting the cable.

- Rated Current

- The input current of the equipment as declared by the manufacturer.

- Shielding Vents

- Vents that are used for HVAC or simple ventilation of shielded products, such as cabinets, rooms or enclosures. Some shielding vents also provide high shielding or air filtering.

- Shielded Windows

- Shielding consisting of a thin conductive film on the glass or a fine-wire mesh or metalized open-mesh textile.

- Shielding Gasket

- A material that maintains shielding effectiveness across a seam or gap in an electronic enclosure.

- Type 1

- A NEMA rating indicating that the enclosures are intended for indoor, non-hazardous locations. Type 1 enclosures are mainly used to provide protection against limited amounts of falling dirt.

- Type 3R

- A NEMA rating indicating that the enclosures are intended for use in outdoor, non-hazardous locations. Type 3R enclosures are mainly used to provide protection against falling rain and external ice formation.

- Type 4

- A NEMA rating indicating that the enclosures are intended for indoor or outdoor use in non-hazardous locations. Type 4 enclosures are mainly used to provide protection against splashing or hose-directed water, damage from external ice formation and windblown dust or rain.

- Type 12

- A NEMA rating indicating that the enclosures are intended for indoor use in non-hazardous locations. Type 12 enclosures are mainly used to provide protection against dripping, non-corrosive liquids, circulating dust and falling dirt.