Centrifuges

A centrifuge system is designed to separate different elements within a particular substance by way of a high speed rotation known as centrifugal force. The simplest and perhaps crudest demonstration of centrifugal force can be witnessed in a laundry washer or dryer that is typically found in a residential home. As the washer spins, dirt is separated from the clothing.

Quick links to Centrifuges Information

The History of Centrifuges

The earliest centrifuges were hand-driven milk separators used during the 15th century, although the first modern centrifuge was not officially invented until the 19th century, when German cafe owner Antonin Prandtl refined the basic design to help purify milk of its fat for his customers. The updated design was displayed at the 1875 World Exhibition in Frankfurt. In 1926, Theodor Svedberg won the Nobel Prize for his invention of the world’s first ultracentrifuge, which could rotate substances at 10 to the sixth power of gravity. Svedberg’s design was driven by a scientific curiosity; he was attempting to study colloids, which are a medley of both liquid and gas, and needed a method to quickly separate the different particle densities. Suitably, the next major advances in the field were driven by scientific need. In the 1950s, Gernot Zippe invented the Zippe-Type Centrifuge, which is now essentially classified as a gas centrifuge. In our contemporary world, most centrifuges are controlled by microprocessors, which allow for specific calibration of force and speed.

Centrifuge Design

Centrifuges traditionally are made out of plastic, metal alloy, and metal, and are powered by an electric motor that uses a rotor. The substances placed within a centrifuge can be either liquid or solid, and include those found in the medical field, such as blood, as well as industrial solutions, products, and fuels. In some cases, centrifuges are also used to create or refine certain food products. In general, centrifuges work by creating a temporary but very strong gravitational well that separates elements based on their density. In most cases, the process must be a continual one that is synced to a particular cycle of varying speeds; if the cycle is interrupted, the separation will not be complete, and may damage the equipment. There are numerous types of centrifuges designed for specific environments, including laboratory centrifuges, industrial centrifuges, and decanter centrifuges. However, the two principal types of centrifuges are referred to as preparative and analytical. An analytical centrifuge is traditionally used for research applications where the components of a particular substance are being identified, while a preparative centrifuge is used to separate particles from a given slurry or liquid.

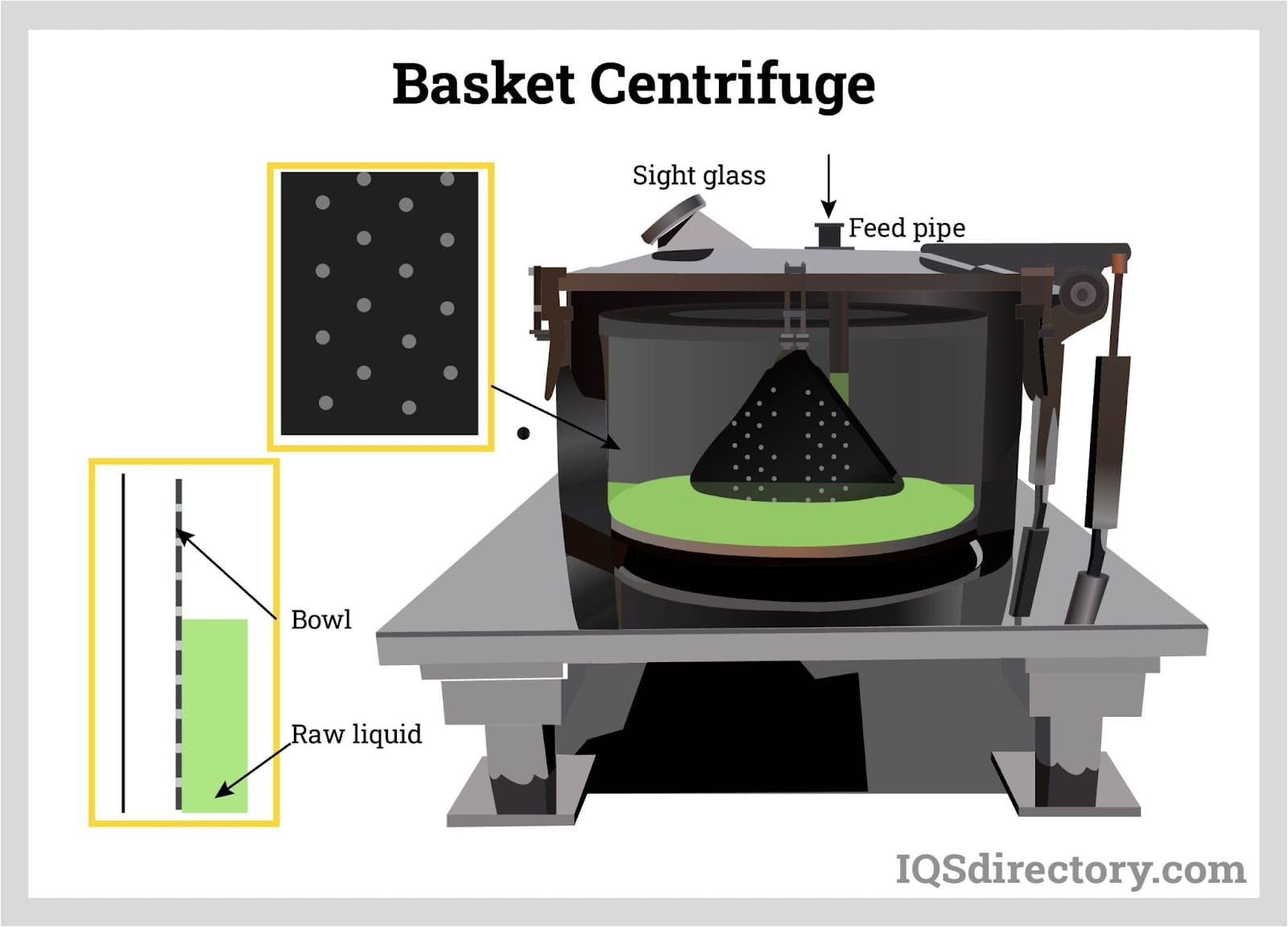

A basket centrifuge performs separation by spinning an enclosed space, typically in the shape of a basket, rapidly around a fixed vertical axis, creating a centrifugal force that is approximately 20,000 times stronger than normal earth gravity. Instead of a central enclosure, other centrifuges rotate an arm-like tool around a central axis to create the powerful gravitational separation. In most cases, after processing the denser material adheres to the wall of the enclosure, while the lighter, purified substance remains in the center. A centrifuge tube utilizes a tubular enclosure, while a chamber centrifuge uses a number of differently sized bowls to gradually filter the components of a substance. A chamber centrifuge can be especially helpful when dealing with large particulate matter, such as a sample of dirt that contains smaller amounts of a given mineral. A decanter centrifuge is used to quickly separate liquids from slurry, and is therefore primed for industrial, although not medical, uses. This is because the decanter centrifuge generally lacks the ability to separate particles on a microscopic basis. An industrial centrifuge can take a variety of different forms in terms of the style of its enclosure, but distinguishes itself by virtue of being appropriate for use in tasks such as large scale industrial purification or extraction.

Centrifuge Images, Diagrams and Visual Concepts

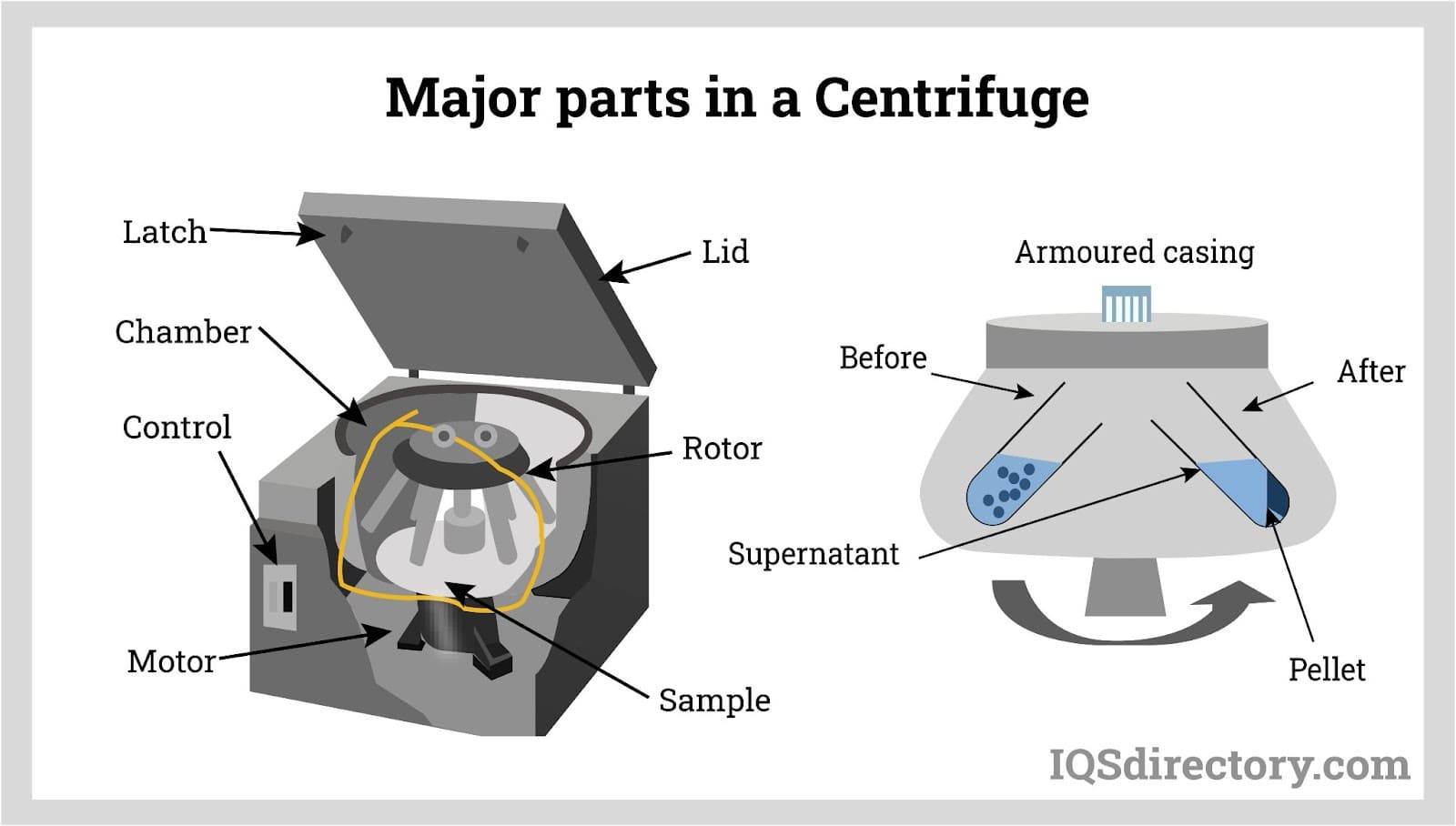

Centrifuge, a scientific device used to separate gasses or liquids based on the density of the subject.

Centrifuge, a scientific device used to separate gasses or liquids based on the density of the subject.

There are two basic components in all centrifuges which are the rotor assembly which generating and transfers the rotational motion and the electrical motor which converts electrical energy into mechanical energy and kinetic energy.

There are two basic components in all centrifuges which are the rotor assembly which generating and transfers the rotational motion and the electrical motor which converts electrical energy into mechanical energy and kinetic energy.

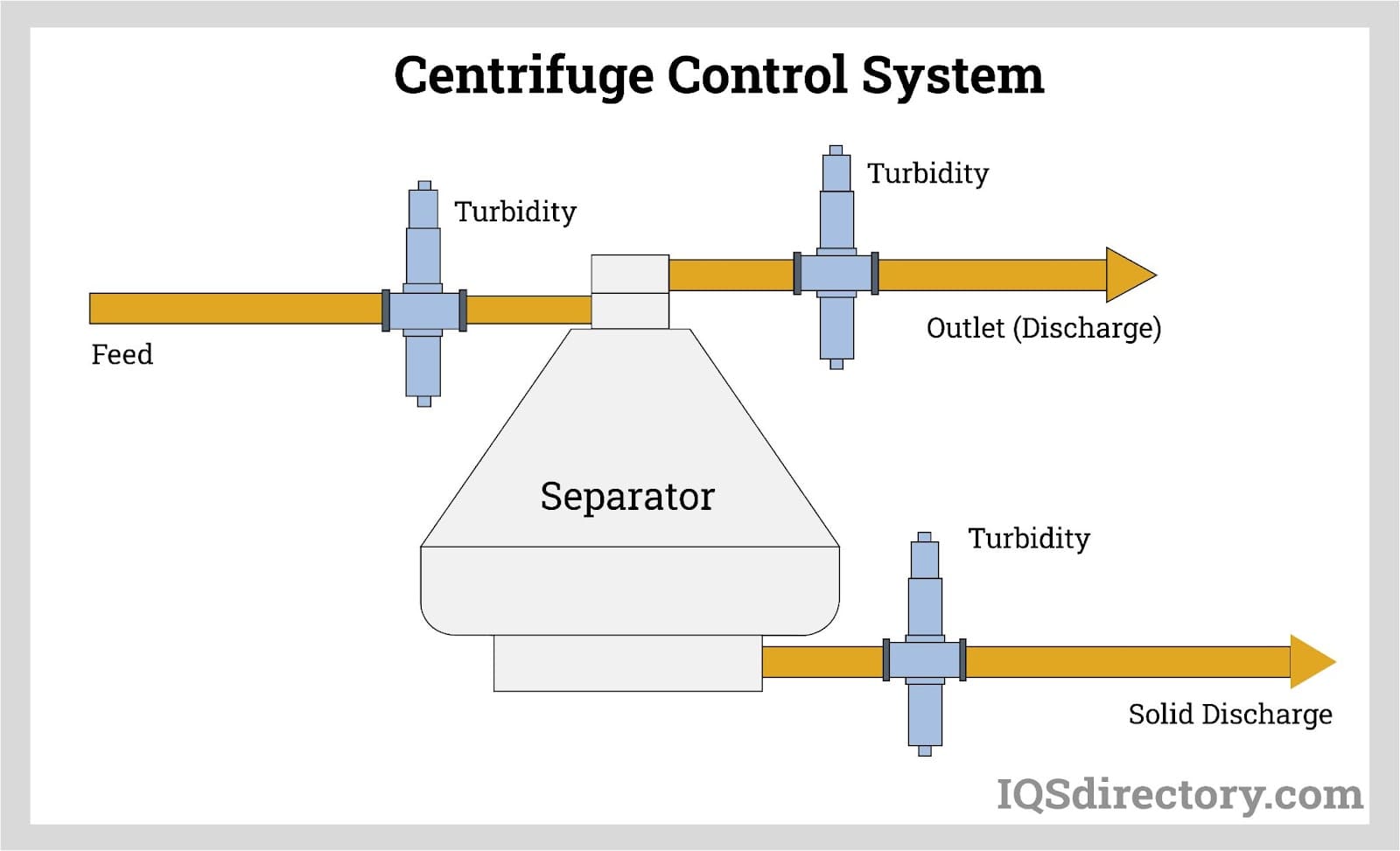

The control system achieves this through a microcomputer with a touch panel and a digital display allows to set rotation speed and centrifugal force.

The control system achieves this through a microcomputer with a touch panel and a digital display allows to set rotation speed and centrifugal force.

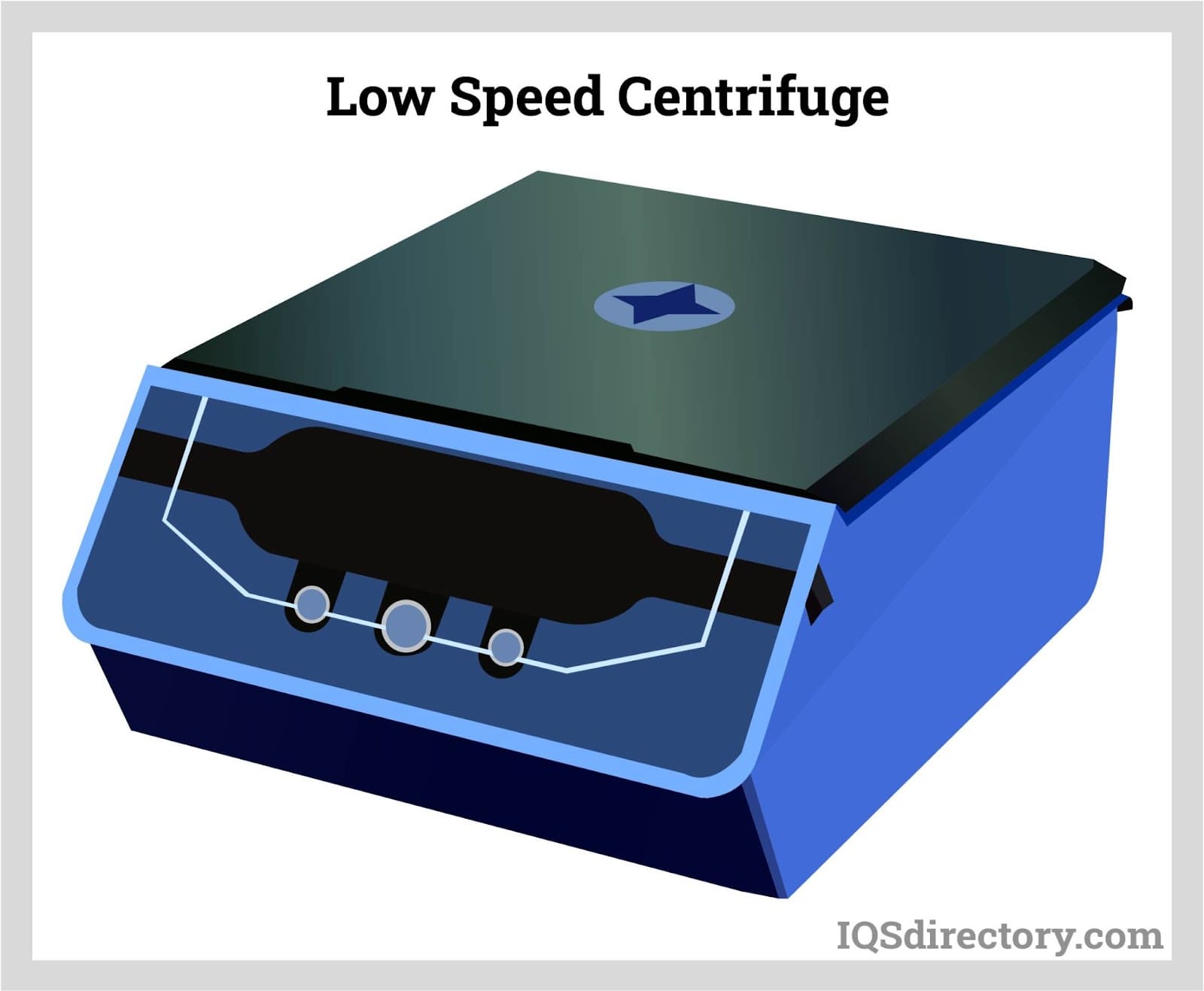

Low speed centrifuges routine sedimentation of heavy particles at speeds of 4,000 rpms to 5,000 rpms.

Low speed centrifuges routine sedimentation of heavy particles at speeds of 4,000 rpms to 5,000 rpms.

High speed centrifuges are used where higher temperatures and greater speeds for the sedimentation process at speeds of 15,000 rmps to 20,000 rpms.

High speed centrifuges are used where higher temperatures and greater speeds for the sedimentation process at speeds of 15,000 rmps to 20,000 rpms.

Basket centrifuge uses centrifugal force to separates a large amount of liquids or solids.

Basket centrifuge uses centrifugal force to separates a large amount of liquids or solids.

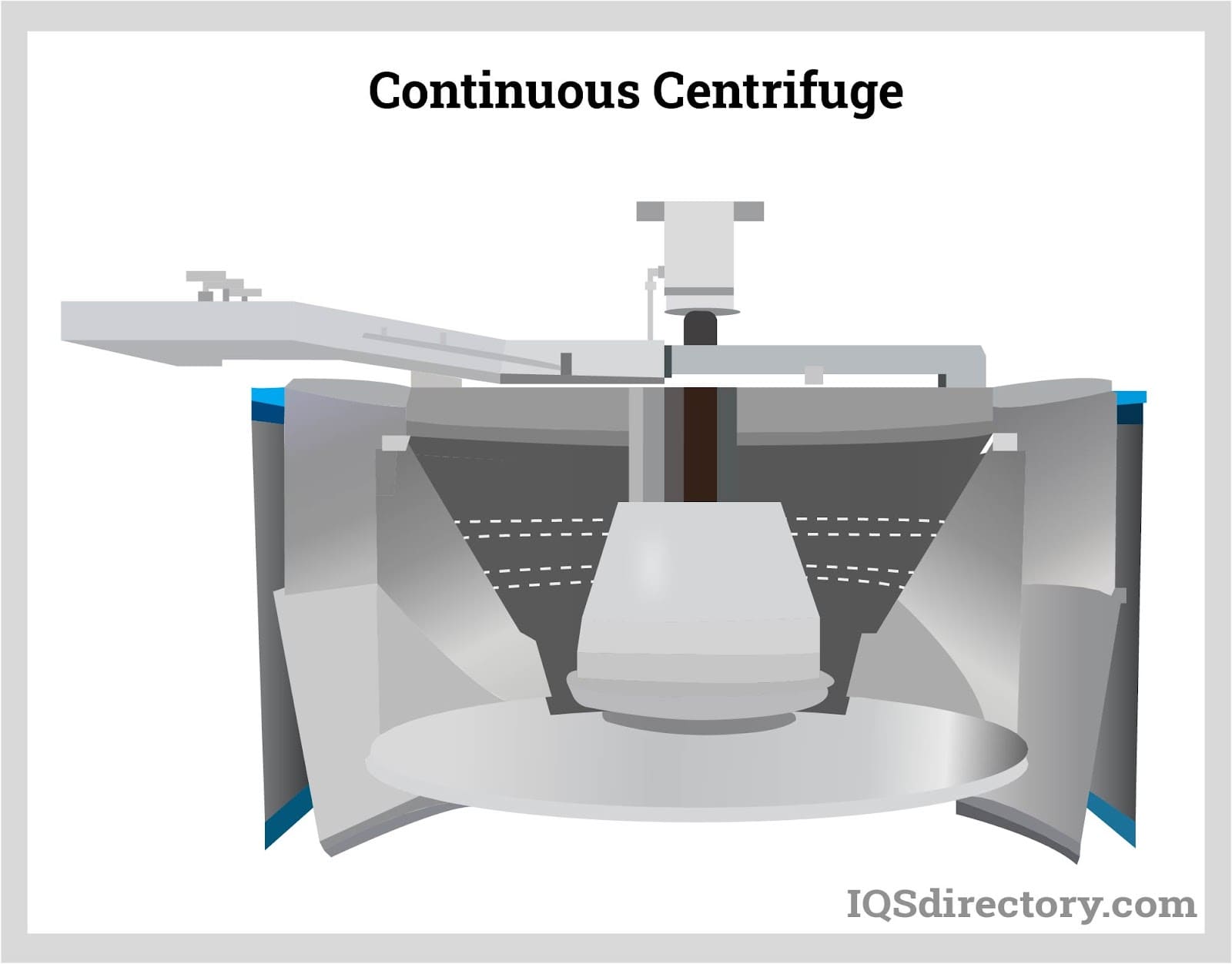

Continuous centrifuge uses large volumes of materials at high centrifugal forces without decanting centrifuge tubes or repeatedly starting and stopping the rotors.

Continuous centrifuge uses large volumes of materials at high centrifugal forces without decanting centrifuge tubes or repeatedly starting and stopping the rotors.

Types of Centrifuges

- Basket Centrifuges

- The basic types of filtering centrifuges and consist of a basket rotating around the vertical axis. You can find a list of them on IQS Directory.

- Centrifugal Separators

- Utilize centrifugal force to isolate particles and materials in heterogeneous slurries, suspensions and solutions. These devices not only separate elements from liquid, solid and gaseous mixtures; but may also be used to wash, extract and purify materials. You can find a list of manufacturers who make them on IQS Directory.

- Continuous Centrifuges

- Operate non-stop during a separation process, and generally contain intake and output channels to prevent buildup and ensure proper separation. Continuous centrifuges are often used in water treatment plants.

- Decanter Centrifuges

- Utilize centrifugal force to speed the dewatering or thickening of slurries and suspensions in many industrial and commercial applications.

- Disk Centrifuges

- Used primarily for separating two liquid phases, but are also suitable for clarifying if the solid material content in liquids is small.

- Gas Centrifuges

- Highly specialized devices used for the separation of isotopes in gaseous materials and mixtures. Uranium enrichment is one of the most notable and common applications for this specific type of centrifuge.

- High Speed Centrifuges

- Accelerate quickly and can be used for fast extraction, washing and separation purposes.As the name suggests, a high-speed centrifuge offers some of the fastest acceleration and overall speeds within the centrifuge family, and can be used for a number of different purposes, including traditional separation, large scale extraction, and product washing. Frequently, this centrifuge system employs a basket enclosure, and is typically used in operations such as waste water treatment.

- Industrial Centrifuges

- Wide ranging in styles and are used for the separation of larger volumes of liquid/solid from one another.

- Laboratory Centrifuges

- An apparatus used in the laboratory for separating substances of different density or particle size, when suspended in a fluid, by spinning them about an axis in a suitable container. A laboratory centrifuge is designed to handle much smaller amounts of a particular substance, and is traditionally used in biotechnology settings to separate fluid substances. Laboratory centrifuges often take the form of a benchtop centrifuge, which is compact enough to operate on a table or other relatively small workspace. They usually process between 0.2 to 2 milliliters of liquid. Because of their relatively small size and ability to separate very small particles, laboratory centrifuges must be carefully maintained. They should not be operated in an environment where dust and other random matter will pile up on them. They function best in a sterile or exceptionally clean environment free from heavy amounts of debris.

- Mini Centrifuges

- Used for the separation of small samples in a laboratory setting, which includes the separation of DNA, RNA and proteins that need isolation. Mini centrifuges are sometimes referred to as a bench top centrifuge.

- Oil Centrifuges

- Devices designed predominantly for the filtration and separation of contaminants suspended in oils. Some such centrifuges may be used in instances where oil is the contaminant, but more often industries rely on these devices to clarify industrial, edible and hydraulic oils which may carry undesirable solid, gaseous or liquid materials as a result of extraction or continued processing. In practical terms, oil centrifuges frequently purify hydraulic and industrial oils of unwanted solids or liquids. They are usually operated at speeds of 50,000 revolutions per minute, and can vary significantly in size. Some oil centrifuges are small enough to operate within a standard automotive engine, while others can hourly process thousands of gallons of oil.

- Pharmaceutical Centrifuges

- Used for the sterile processing of drugs and the separation of other fine chemicals in the pharmaceutical industry. This type of lab centrifuge deals with drugs only.

- Ultracentrifuges

- A high speed centrifuge used to determine the relative molecular masses of large molecules in high polymers and proteins. Ultracentrifuges are the fastest of the high speed centrifuges, and can become dangerous if they are not regularly cleaned and calibrated. This is because the components within the machine are moving so quickly that if they become dislodged or unbalanced, they can destroy the equipment and harm bystanders. Clients who need a high-speed centrifuge should also invest in a holding area or protected room where the machinery can operate safely. Operators of the equipment should be trained in safe operating procedures, including a thorough and regular schedule of maintenance.

- Used Centrifuges

- Refurbished devices designed for the separation of particles and isotopes, sedimentation and suspension isolation of materials and objects based on mass, specific gravity, size, shape or density.

Uses for Centrifuges

Because of their precision, speed, and varying formats, centrifuges are used in a number of different industries. In addition to the uses already mentioned, the aerospace industry, seismologists, and researchers studying viruses also use centrifuges to help them make breakthroughs in their work. Part of the appeal of the centrifuge is its ability to purify a substance based on density. This is especially useful in creating specific foods, drugs, and industrial products that must have a certain amount of a given substance in order to meet standards for certification. Because of this, the industrial applications for the equipment are virtually limitless. Chemical engineers, mixologists, and research scientists regularly use centrifuges. However, the exceptional power of the machines means that they are not always easy to procure, depending on their intended use. As an example, a centrifuge machine that is used in isotopic research, such as a gas centrifuge, is usually monitored by various government agencies to make sure it is not utilized for malicious or harmful purposes.

The only real drawbacks to using this machinery are the extensive hazards that can result from improper maintenance and calibration. Even the slowest centrifuge operates at a very high speed relative to how quickly a person can move. The higher the revolutions per minute, the greater chance there is for injury. Also, the byproducts of the process, such as industrial cakes of unwanted dense material, require safe handling and disposal. When separated, some substances can pose a lethal threat due to their concentration. Anyone operating a centrifuge should be aware of these risks, and make contingency plans to deal with an accident resulting from the operation of the machine.

Things to Consider When Purchasing a Centrifuge

- Understanding Centrifuge Components

- Choosing the best centrifuge for a particular task is a matter of first understanding the substance or components that will be inserted into the machine. A medically oriented centrifuge will have a completely different set of specifications than a centrifuge used for processing scrap metal, for example. The specific substance will first determine the best type of enclosure for the centrifuge. A basket, tube, decanter, or arm apparatus may be used to hold the material that will be subjected to the centrifugal force. Secondly, the density and refinement of the substance will determine the speed of the machine. A high speed centrifuge may not be necessary for a bulkier material. However, manufacturers should be able to provide an interested party with an estimated operating speed, such as 5,000 pounds per hour, or specify the maximum amount of material that can be reasonably processed with the machine, such as 1 milliliter. In most cases, the operating speed is measured in terms of gravitational force or revolutions per minute. These markings, respectively shortened to “G” and “RPM,” commonly are paired with figures that specify the maximum viscosity and density of the substance that will be sorted within the machine.

- Centrifuge Specialization

- The wide range of centrifuges means that the companies that create them will likely have industries in which they specialize. A manufacturer who specializes in laboratory centrifuges will likely have different capabilities than a company who frequently creates decanter centrifuges. An industrial centrifuge will likely require sludge dewatering and self-cleaning capabilities. In some cases, a manual cleaning capability may be desired. Again, the centrifuge’s design and corresponding amenities will heavily depend on the specific substance it will be processing. Those who are seeking a company to produce the equipment should familiarize themselves with the types of centrifuges most commonly used in their industry and prepare a list of specific questions.

- Luckily, centrifuge manufacturing is highly amenable to custom needs and designs. From its earliest incarnation as a way to separate fat from milk, centrifuges have essentially been designed to respond to very specific uses and situations. In fact, a company’s ability to customize is often an indicator of how successful they will be in maintaining their business over the long-term. With this in mind, clients should be aware of the basic differences in size and speed before contacting a centrifuge producer. A construction contractor, for example, may need centrifuges to separate different kinds of paint, which would require an entirely different scale and level of sophistication from the equipment than a biologist hoping to study the platelets in blood. The best company or producer will understand not only the scope of the field the client is working in, but also the best types of equipment to use to provide a solution. However, clients should be open to a process of feedback and idea exchange. In some cases, the best centrifuge will require several iterations in the manufacturing process before it is ready for use.

Centrifuges Terms

- Beach

- In a bowl centrifuge, the dewatering part of the bowl. It is conical in shape.

- Bowl

- The area of a bowl centrifuge which rotates and separates solids to collect.

- Bowl Strips

- Small, thin strips of metal or other material attached to the inside diameter of the bowl used to help the settled solids convey out of the machine and to protect the inside diameter of the bowl from wear by locking in a layer of settled solids.

- Cake Slides

- The dryness or wetness of the discharged solids (solids phase). Usually measured as percent (%) by weight.

- Centrate

- The liquid (light phase) which is separated from the heavy solids (heavy phase) during the classification/clarification process, then exits through the effluent head. Centrate is also referred to as "mother liquor," "effluent" and "overflow."

- Centrifugal Force

- An outward force on a body rotating about an axis, assumed equal and opposite to the centripetal force and postulated to account for the phenomena seen by an observer in the rotating body.

- Chatter Torque

- This type of torque is generated by settled solids, resisting conveyance.

- Clarification

- Clearing action that occurs during wastewater treatment when solids settle out. This is often aided by centrifugal action and chemically induced coagulation in wastewater.

- Conveyance Speed

- Speed at which the settled solids are moved along the bowl walls and removed from the bowl.

- Density

- Measured in grams per cubic centimeter (or kilograms per liter); for example, the density of water is 1.0, iron is 7.9 and lead is 11.3.

- Dry Beach Area

- This area dewaters the solids and allows liquid to drain back into the pool and not be discharged with the cake solids.

- Gradient Centrifugation

- Separates particles on the basis of their buoyant densities. A gradient range is selected to encompass the densities of all particles to be banded.

- Heel

- Layer of compacted solids on the inside diameter of the bowl. This layer is not conveyed out and settled solids removed by the conveyor are conveyed over this heel.

- Main Bearing

- The frictionless central bearing on which the bowl is supported and rotates upon.

- Pillow Block

- Term used to describe the central housing holding the main bearing.

- Sedimentation

- The process where solids suspended in water settle to the bottom of a basin.

- Separation

- This process divides or separates a mixture of particles or liquids into separate components.

- Slurry

- Pourable mixture of solid and liquid.

- Supernatant

- The liquid in a centrifuge tube above a pellet or sediment, after centrifugation.

- Tube Size

- The length of a centrifuge tube, often given in both inches and millimeters.