Plastic Dip Coating

In order to provide a plastic coating that can give protection and beauty to most metal items, the plastic dip coating technique submerges a heated component in liquid plastisol. The process might improve the part's aesthetics, offer a comfortable grip, or shield it from corrosives and abrasion.

The coating can be customized with special additives to offer particular properties like fungal resistance, dielectric strength, and flame retardance. It is available in a variety of colors and textures.

Plastic Dip Coating Methods

The various methods of plastic dip coating include:

Fluidized Bed Powder Coating

In fluidized bed powder coating, heated parts are either passed through an electrically charged powder cloud produced above a fluidized powder or directly dipped into a fluidized powder container.

When using fluid bed coating, the part must first be heated before being submerged in the coating and flowing out. Instead of dipping the item into the powder, electrostatically assisted fluidized bed coating creates a cloud of charged particles (much like a traditional electrostatic gun) through which a heated or unheated part passes.

Compared to fluidized bed coating, the coat it applies is often thin. The shortcomings are caused by the variations between the fluid bed and electrostatic coating.

Building up a film by heating and melting the powder to the part can solve many issues but also lead to new ones. For example, details on smaller parts like stamped or raised lettering will probably be masked. Additionally, if the part has details that are close to one another, the coating may cross over.

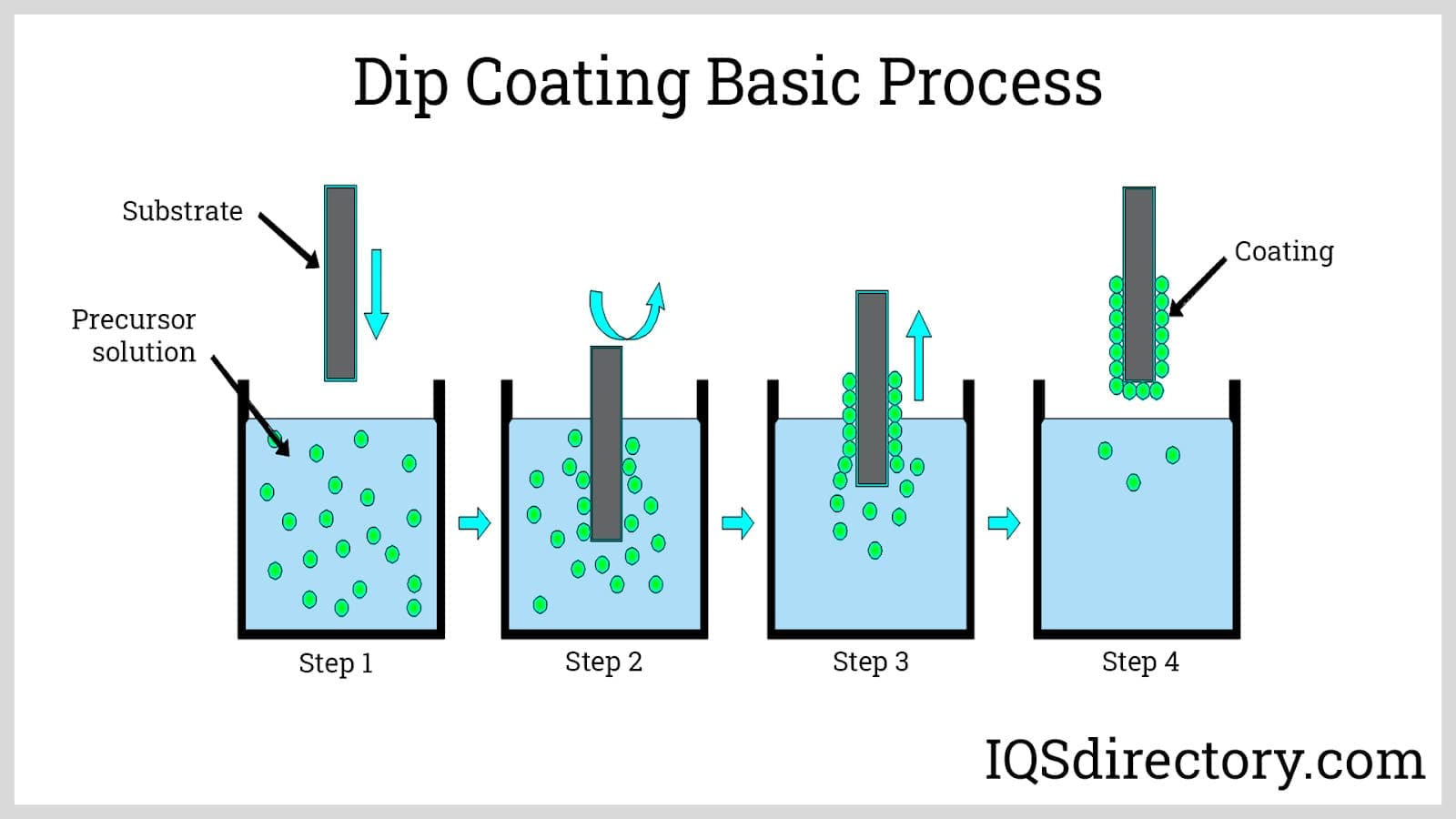

Hot Dipping of Parts in Vinyl Plastisols

In accordance with procedures frequently used to prepare substrates for paint applications, parts to be plastisol coated should be chemically cleaned and phosphate or chromate treated. Substrates can also be vapor-degreased; however, this is typically not the preferred technique. Cleaning the substrate of impurities results in greater adherence to the powder.

Vinyl plastisol doesn't adhere to metal very well on its own and needs to be primed if adhesion is required. Primers can either be applied using standard air spray equipment or dipped into a tank. Then, the hot and freshly baked primed component is submerged in the liquid vinyl plastisol.

After being removed from the liquid plastisol, all hot substrate components will be covered with a layer of semi-fused vinyl plastisol. The quantity deposited will vary according to the part's immersion time, metal temperature, and vinyl plastisol formulation. Depending on the exact plastisol formula, the portion coated with the semi-fused vinyl plastisol is baked to a film temperature ranging from 300 °F (149 °C) to 350 °F (177 °C).

The correct temperature can be achieved by transporting the item back through the priming oven. However, a second separate oven for this activity is strongly recommended because of the increased processing versatility. The fused vinyl plastisol-coated portion is highly vulnerable to surface marring when it comes out of the oven.

Before handling, it is best to allow the piece to cool to a maximum temperature of 120 °F (49 °C). This is frequently accomplished via cold air circulation, water sprays, or a mix of the two. The components are often placed in a tank of constantly flowing, chilly water.

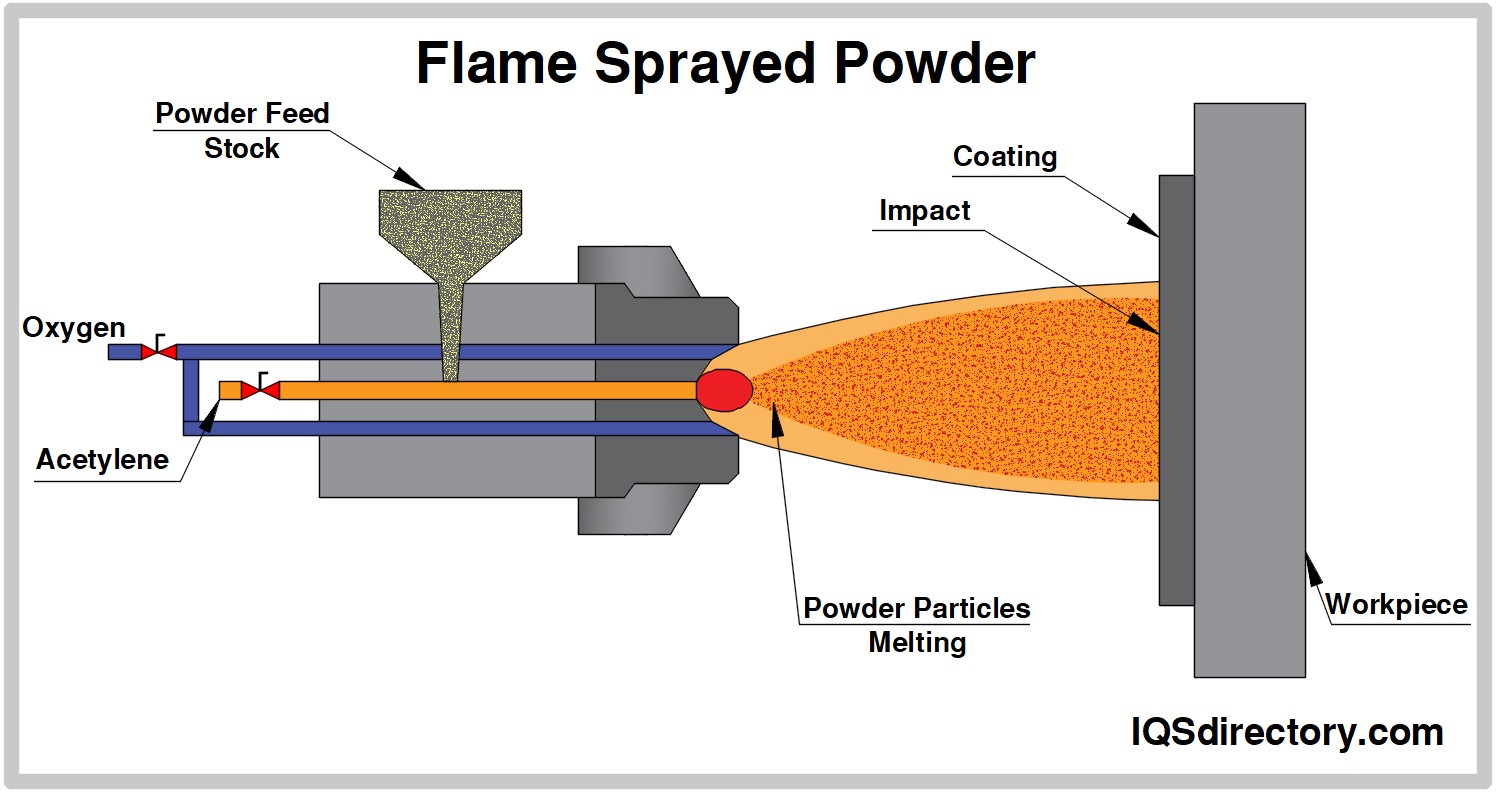

Flame Spray Coating

Spraying polymer powder over a heated product is the third way of plastic dip coating. Another name for this is flock spraying. Because it is more usable, a spray is used to coat some objects because they are too big to be coated by dipping them.

The spray melts and sticks to the part when it comes into contact with the still-hot part. If any partially melted spray remains at the end of the procedure, the product must be warmed. The procedure can be repeated numerous times to give the metal additional layers of protection.

Advantages of Plastic Spray Coating

- The coating creates a barrier that is resistant to corrosion.

- It is sound-dampening and insulates the surface from heat, cold, stress, and electrical currents.

- Products can be delivered quickly and in large quantities.

- The product gains UV protection and exceptional durability.

- Plastic dip coating varies widely in thickness, color, texture, and hardness.

Choosing the Right Plastic Dip Coating Company

To ensure the most beneficial outcome when selecting a plastic dip coating business, it is important to compare several companies using our directory of plastic dip coating businesses Each plastic dip coating company has a business profile page illustrating their areas of experience and capabilities, and a contact form to directly communicate with the business for more information or request a quote. Review each plastic dip coating company website using our proprietary website previewer for a better idea of what each company specializes in. Then use our simple RFQ form to contact multiple plastic dip coating companies with the same form.