Automated Guided Vehicles

One of the essentials of manufacturing is the facilitation of the movement of raw materials, an important part of supply chain management. The processes of moving, shipping, and supplying are completed by a complex group of operations referred to as mobility, a necessary part of production. There is a wide assortment of devices that are designed to supply production lines, move finished products to shipping, and mechanisms to speed up storage. The types of equipment designed to accomplish this constant motion vary from the wheels on carts to automated guided vehicles (AGV) that function independently.

For production to be successful, its raw materials and supplies need to be immediately available. This applies to manufacturing, construction, and office management. A shortage of either of these factors causes unnecessary delays and loss of production. To prevent the negative effects of shortages, supply chain managers are constantly developing and perfecting mobility products that are efficient, reliable, and resilient.

The process of supply movement begins with the simplest of devices as part of a caster assembly, the common wheel. Regardless as to how ordinary wheels may be, they are the foundation of the design of all mobile devices and have been perfected with new materials and configurations to perform in the harshest of conditions. The most advanced method of supply movement, the automated guided vehicle (AGV), depends in precisely designed wheels that can hold the weight of the AGV as well as what it carries.

A dependable part of all warehouses, production line supplying, and other heavy operations is the forklift, which is capable of lifting extremely heavy materials. The initial design of forklifts was to assist in warehousing and shipping since they can move packages, boxes, and containers rapidly. That initial use has spread to a wide variety of industries that include construction, military operations, and others.

An important factor regarding the use of forklifts, in any industry, is the safety they provide for workers. In the past, when heavy loads had to be moved, workers used a variety of hand tools to carry or drag materials and supplies. Those types of procedures were unsafe and led to serious injuries. With the development of the forklift, the safety of workers improved, and production happened faster and more efficiently.

Another development that enhanced the safety of workers was the development of hydraulic lifts that can be on wheels or platforms. Hydraulic lifts come in a variety of sizes and shapes, from ones that are the size of a table for lifting packages from the floor to a workable height, to others that are able to rise several stories to assist in counting inventory and moving materials. As with the forklift, hydraulic lifts are another efficient, labor saving safety tool that protects workers.

A special form of hydraulic lift is the mechanized platform that can raise and lower packages, people, machinery, and goods. Platform lifts are found in all types of industries from warehouses to large production facilities. They are a convenient and reliable method for moving raw materials from difficult locations or offering a point of view for overseeing a complete operation or construction.

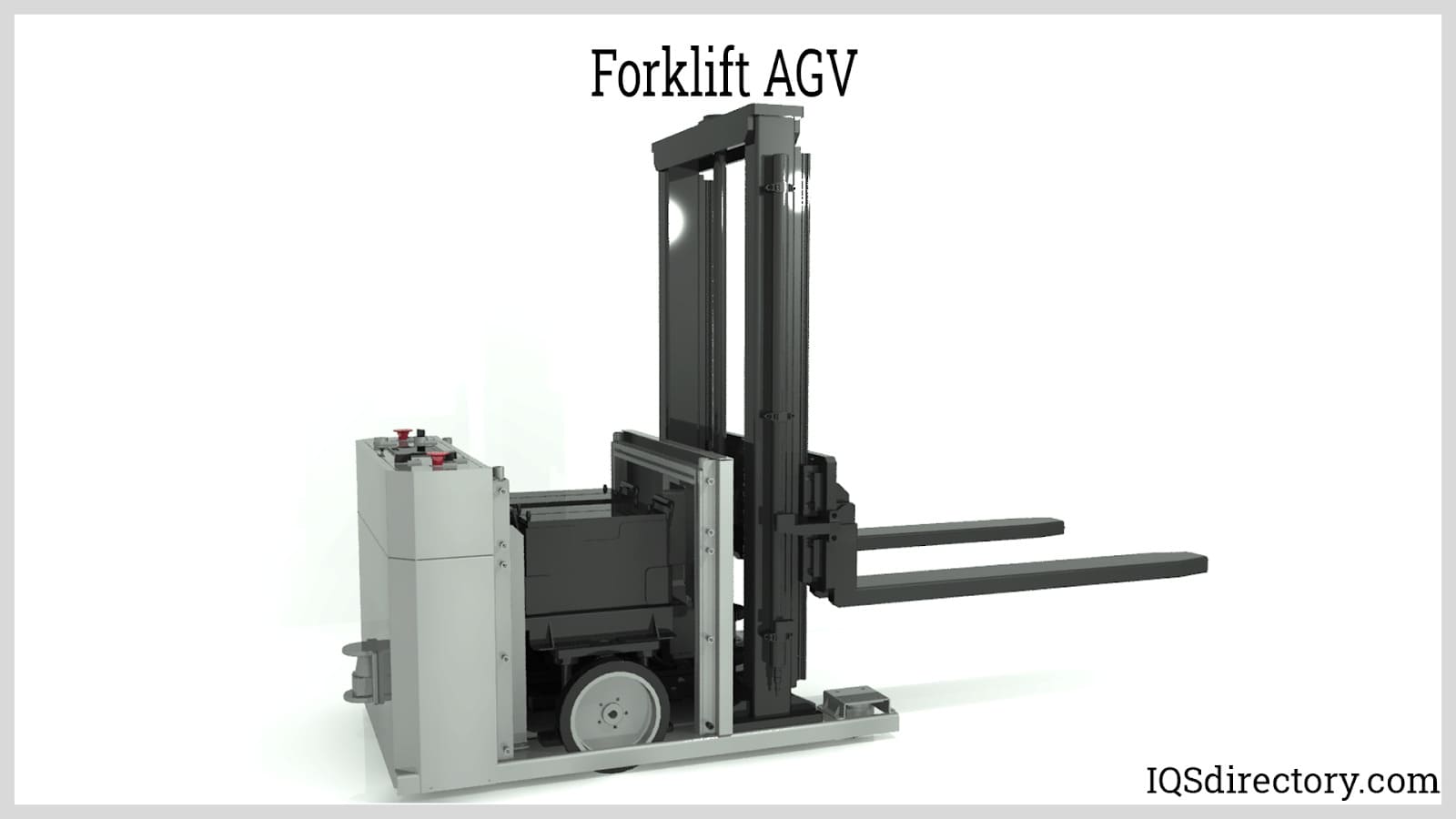

The most advanced of the mobility devices, and one that is growing very rapidly, is the automated guided vehicle (AGV), which eliminates the need for personnel to carry materials. These technically advanced machines are capable of carrying heavy loads along a predetermined path from one location to another and can be used to supply production lines, shipping docks, and warehouses. From their introduction in the middle of the 20th Century to the advanced models of today, these mobile equipment have proven to be the next step in the advancement of mobility products.

Engineers, manufacturers, supply chain managers, and designers are constantly looking for new and more efficient methods to assist in production and get products to market. Every year, they develop reliable and improved ways to move business forward.

Technology serves a multitude of functions; making the work people do easier and eliminating human error are the main goals of most technological advances.

AGVs, or automatic guided vehicles, are quickly becoming essential to manufacturers and other sectors of the heavy industry. With AGVs there is an increase in safety, less damage to materials and buildings, 24/7 operation, no labor expenses, and inventory/production control-- making AGVs the optimal solution.

Technology serves a multitude of functions; making the work people do easier and eliminating human error are the main goals of most technological advances.

AGVs, or automatic guided vehicles, are quickly becoming essential to manufacturers and other sectors of the heavy industry. With AGVs there is an increase in safety, less damage to materials and buildings, 24/7 operation, no labor expenses, and inventory/production control-- making AGVs the optimal solution.

AGVs are vehicles that are guided by a computer rather than a human. They are powered either by a battery or electric motor, and are able to complete many functions in manufacturing, warehousing, and even farming applications. These self-propelled machines have capabilities ranging from load transferring, pallet movement and stacking, assembly and even towing heavy loads. These functions have been traditionally performed by people, which increased the risks of injury and human error. With these self-propelled vehicles, these possibilities are eliminated. Learn more about AGVs.

Casters are the wheels of industry, although technically, the wheel is only part of the caster assembly.

The caster assembly is a wheeled device within a housing or framework used to provide mobility to an otherwise stationary object.

Casters are the wheels of industry, although technically, the wheel is only part of the caster assembly.

The caster assembly is a wheeled device within a housing or framework used to provide mobility to an otherwise stationary object.

Casters come in many sizes, to accommodate any load capacity. They may be manufactured from a wide variety of materials, may swivel, lock, run on tracks, or work in tandem with other casters. They may be configured as traditional wheels or as bearings that facilitate smooth and/ or multidirectional movement. Some casters are designed to absorb shock.

Rolling chairs and grocery carts are perhaps the most familiar use of casters. They are found on heavier appliances, such as refrigerators and freezers, and on lighter furniture, such as tea carts or portable filing cabinets. Many pieces of luggage are fitted with casters, as are boxes and shipping crates used for transporting delicate items, such as musical instruments or electronic equipment. Smaller aircraft can be towed by caster dollies, allowing a single person to move an entire plane. Hospital gurneys and medical equipment are placed on casters that are antimicrobial, quiet, and capable of total or directional locking. Learn more about casters.

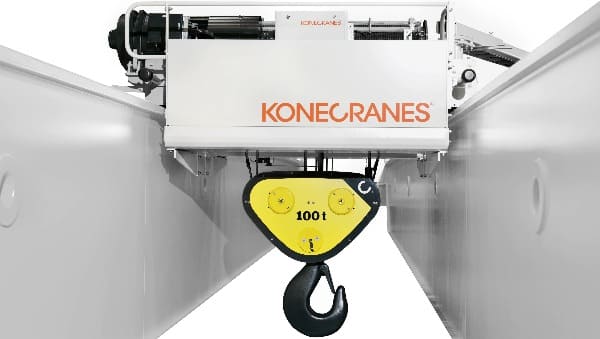

Crane manufacturers are operations that supply industries and commercial operations with materials suspension equipment.

Materials handling operations require a great diversity of equipment to accommodate all of the different kinds of loads that they are used to move. Cranes are often indispensable tools for such operations.

Crane manufacturers are operations that supply industries and commercial operations with materials suspension equipment.

Materials handling operations require a great diversity of equipment to accommodate all of the different kinds of loads that they are used to move. Cranes are often indispensable tools for such operations.

Crane manufacturers offer many different varieties of cranes. They are made for a wide range of lifting and positioning applications and vary in load capacity up to nearly 1,000 tons. Bridge cranes, which in some cases are known as track cranes, are stretched across building structural beams and used as permanent fixtures in manufacturing or distribution facilities, operating from a set of overhead rails. Gantry cranes are bridged between two movable supports, often on wheels, and are typically used outside in large industrial construction applications. Jib cranes, unlike other classes of overhead cranes, are only supported on one side by a vertical support or wall fixture; many workstation cranes are types of jib cranes. A beam extends from the support or wall on a pivot, while the trolley carries the hoist along the overhead beam. Stacker cranes are used in automated computer warehouse systems and move vertically or horizontally on tracks to reach items in large storage facilities. They are an alternative to forklift trucks and are popular in warehouses where conditions are inhospitable to workers. For crane applications that require more than linear movements or are in hard-to-reach places, mobile cranes are used as an alternative to overhead cranes. A large percentage of modern construction operations are accomplished with the help of some kind of crane. Bridges, monuments, cargo ships and other large vehicles and vessels are built using gantry cranes, and most industrial equipment manufacturing and large metalworking processes use built-in overhead traveling cranes to move objects around. Bridge cranes present a safe, easy-to-use alternative to ground transportation in many situations, particularly when handling extremely heavy or awkwardly shaped objects. Because all of a bridge crane's constituent parts are suspended above ground, they do not occupy any space on the ground. Small jib cranes can provide excellent relief from factory or assembly workers continually lifting and moving objects around a facility while taking up little or no valuable floor space. Cranes used for material and equipment handling within a facility, like monorail cranes that are mounted to the ceiling, are often referred to as workstation cranes.

Gantry cranes are one quite common crane variety. Gantries are sometimes supported on one side only and are usually counterbalanced on the side opposite the hoist; these are called half gantries, semi-gantries or cantilevered gantries. Jib cranes differ from semi-gantries or cantilevered gantries in that the overhead arm typically pans 180 degrees horizontally, as opposed to the half gantry's fixed arm. Jib cranes may have a portable one-sided support, or smaller workstation jib crane arms may be attached to the wall; these are often called wall cranes.

Still more innovations have been offered by crane manufacturers even within the context of individual crane configurations. The bridge crane, for example, is available in single and double girder configurations. A bridge crane is a complex of vertical girders to which one (in the case of single girder cranes) or two (in the case of double girder cranes) girders are attached. Attached to the girder or girders is a winch system that is used for lifting and lowering objects. Single girders are sometimes mistakenly considered to be diminished in their capacity for lifting loads compared to double girder varieties. In reality, the only significant difference between single girder and double girder varieties is the maximum height that the bottom of the winch hardware can achieve. Crane manufacturers can advise their customers about the best configuration for a given use. Especially in the construction industry, the applications for cranes can vary widely from project to project. In many cases, such as in the construction or repair of a bridge, mobile cranes, the dimensions and capacities of which can be specially suited for the task, are designed with that specific project in mind. This can be true in many other specialized applications as well. Learn more about crane manufacturers.

Conveyors are a type of material handling equipment which assists in moving products, packages, foods or equipment from one place inside a facility to another, or through various stages of automated manufacturing or finishing.

Because conveyors move such a broad range of items, different conveyor configurations are available to meet the material handling needs of manufacturers and distributors everywhere. Belt conveyors are the most common, followed by chain conveyors, roller conveyors, spiral conveyors, overhead conveyors, vertical conveyors and conveyor systems, which may use combinations of many different conveyor types.

Conveyors are a type of material handling equipment which assists in moving products, packages, foods or equipment from one place inside a facility to another, or through various stages of automated manufacturing or finishing.

Because conveyors move such a broad range of items, different conveyor configurations are available to meet the material handling needs of manufacturers and distributors everywhere. Belt conveyors are the most common, followed by chain conveyors, roller conveyors, spiral conveyors, overhead conveyors, vertical conveyors and conveyor systems, which may use combinations of many different conveyor types.

Conveyors are usually motorized, but some conveyor types, such as ball transfer and chute, are gravity conveyors. Pneumatic conveyors also assist in transporting materials, but these tubular air-powered conveyors specialize in bulk powder solid transportation, a different type of conveying. Manufacturers and package handlers in almost every industry make use of various types of conveyors or conveyor systems, especially food conveyors and industrial conveyors, to transport parts, products and packages through various processing systems. In a setting, such as a manufacturing business, conveyors may be set up between work stations.

The most typical conveyor is the belt conveyor, which consists of a wide polymer or rubber belt wrapped around rollers which turn in the same direction, giving the belt and all objects on the belt linear movement. This same construction is used with chain conveyors, except that chains are wrapped around the wheels instead of a belt; chain conveyors may move products along one chain or multiple parallel chains. These are the most common conveyor types, being used for general product movement in food processing, packaging and parts manufacturing industries to transport items or to move unfinished products through various stages of processing. Chain conveyors utilizes parallel horizontal chains to move materials through a conveyor system and from one place inside a facility to another, or through various stages of automated manufacturing or finishing. Chain conveyors are commonly used to move parts such as powdered metal parts through ovens for sintering or drying, or to move unfinished metal parts through parts washing processes.

Roller conveyors are commonly used in these industries as well, using individual rollers placed parallel to one another to provide movement. Vertical conveyors are configured with platforms, buckets, grippers or magnets around moving belts or chains, which lift items from one level to another; although not as common, vertical conveyors can be crucial in facilities where it is necessary to safely transport food items or parts vertically. Parts manufacturers frequently use overhead conveyors to transport parts and products across a facility and/or through processing systems such as spray paint booths, dryers or ovens. Conveyor systems combine many or all of these conveyor types to transport products across a facility or to move unfinished products through automated assembly lines or finishing processes. While most conveyors are powered by electric or pneumatic motors and drive systems, some conveyors are propelled by gravity; roller conveyors are often moved by the inertia of products or packages rolling over them, a design typically used in downward spiral conveyors.

Conveyor and conveyor system manufacturers are creating innovative solutions to new manufacturing challenges every day. All conveyors may twist, turn and travel vertically up and down floors to transfer items. As a result, modern conveyor systems are equipped not only to move parts across horizontal and vertical distances, but also to curve, divert, lift and sort products and packages as part of complete automated systems. These types of advanced conveying processes are done by brushes, magnets, automated levers, rails and even simple gravity. Packaging industries have designed conveyor systems pre-programmed to sort specific boxes into separate chutes, and automated food processing conveyors can handle and sort the most delicate fruits and vegetables using sensors and robotic handlers. When integrated with robotic processing, conveyors and conveyor systems become powerful processing tools. Learn more about conveyors.

Hoists are used to facilitate the raising, lowering, and transport of goods and materials in industrial settings where conveyor systems or cranes are not feasible or functional.

The hoist incorporates the use of a cable, rope, or chain with a pulley or system of pulleys to provide the lifting capabilities. They may be manually operated or powered by pneumatic air, hydraulics, or electricity.

Hoists are used to facilitate the raising, lowering, and transport of goods and materials in industrial settings where conveyor systems or cranes are not feasible or functional.

The hoist incorporates the use of a cable, rope, or chain with a pulley or system of pulleys to provide the lifting capabilities. They may be manually operated or powered by pneumatic air, hydraulics, or electricity.

The most widely recognized hoist systems are found in elevators, although there are thousands of other applications throughout many industries, including automotive, paper, mining, forestry, gas, petroleum, shipyards, energy, and nuclear.

Hoists used in pharmaceutical applications may be required to lift very heavy loads in a clean room environment. Food service hoists must meet sanitary standards for safe food handling. Those used in production facilities may have to withstand extreme temperatures, harsh or toxic environments, or continuous heavy operation. Hoists may even be explosion proof for use in areas where flammable materials are handled. Learn more about electric hoists.

Forklifts are industrial vehicles used in applications such as warehouse storing and distribution for the lifting, moving and loading of heavy products, materials and packaged pallets.

Forklifts typically have a power-operated, moving forked platform attached to the front of the vehicle. This is designed to be inserted under loads and raised in order to move the load to a desired location.

Forklifts are industrial vehicles used in applications such as warehouse storing and distribution for the lifting, moving and loading of heavy products, materials and packaged pallets.

Forklifts typically have a power-operated, moving forked platform attached to the front of the vehicle. This is designed to be inserted under loads and raised in order to move the load to a desired location.

Forklifts are sometimes referred to as forklift trucks or simply lift trucks. Practically speaking, these terms are all interchangeable. In a technical sense, lift truck is more accurate since not every type of this machine possesses actual forks for lifting. Since the vast majority of lift trucks do possess forks, the term forklift is sufficient and will be used for the purposes of this article.

Almost every industry which handles heavy items and large quantities of materials or goods utilizes industrial trucks or pallet trucks. Using a forklift in most industrial or commercial situations improves storage potential, reduces risk of injury and cuts stocking time. Forklifts are used in both indoor and outdoor applications and can be designed to meet a number of specific requirements. They are particularly useful in storerooms, construction sites and loading docks where efficiency is improved by the addition of mechanical power. Forklifts also enable a facility owner to maximize vertical storage space by enabling loads to be stacked as high as the lift trucks can reach. Learn more about forklifts.

Hydraulic lift systems are tools used to lower or raise work platforms and other surfaces that could not be moved by manual labor.

They are powered by liquid mechanics, via a combination of a hydraulic cylinder and hydraulic fluid.

Learn more about hydraulic lifts.

Hydraulic lift systems are tools used to lower or raise work platforms and other surfaces that could not be moved by manual labor.

They are powered by liquid mechanics, via a combination of a hydraulic cylinder and hydraulic fluid.

Learn more about hydraulic lifts.

Platform lifts are highly versatile lift machines, available in a variety of configurations, shapes and sizes.

In general, the purpose of lifts is to lower and raise goods and people. Platform lifts are designed to, as their name suggests, lower and raise platforms. They have applications in industrial settings, commercial settings and consumer settings alike.

Platform lifts are highly versatile lift machines, available in a variety of configurations, shapes and sizes.

In general, the purpose of lifts is to lower and raise goods and people. Platform lifts are designed to, as their name suggests, lower and raise platforms. They have applications in industrial settings, commercial settings and consumer settings alike.

Available in custom designs that serve specific tasks, some of the most common uses of platform lifts involve construction, automotive repair procedures, accessibility, transportation and building maintenance. For example, quite a few large commercial institutions and facilities buy a small set of platform lifts so that they can independently perform tasks, rather than having to rely on outside contractors for work. Also, many businesses purchase and install permanent platform lifts that serve to fulfill the requirements of wheelchair accessibility regulations like those outlined in the Americans with Disabilities Act. Similarly, private residents with wheelchairs sometimes have platform lifts installed in their homes to make it easier for them to get from one floor to another. Platform lifts may also function as industrial or small, privately-owned elevators. The latter are generally low-power and low-capacity in comparison to their industrial counterparts. Likely, they are powered by electricity and able to bear the weight of only one or two average weight people at a time. Learn more about platform lifts.