Metal Shelving

Metal shelving is a storage space that has compartments or partitions for safely keeping tools, equipment, books, files, and other items. These shelves are also used for placing chemicals in laboratories. In other words, they are a great invention for storage in a variety of industries.

Metal shelves are constructed by first designing the drawing according to the dimensions required. Suitable material is selected from the market, cut, and welded together to make a shelf. The final step is painting the shelf, smoothing it, and giving it a better finish.

Materials Used for Making Metal Shelves -

There are various materials that are used in making metal shelves. These are:

-

Stainless Steel Shelving

Stainless steel is the most common material used in constructing metal shelves because it is readily available, strong, easy to clean, can bear lots of weight, and has great tensile strength and high ductility. Stainless steel is also well known for its durability; it can withstand high temperatures and has a longer lifespan than any other material. Many industries use stainless steel material for making metal shelves such as the food and beverages industry.

-

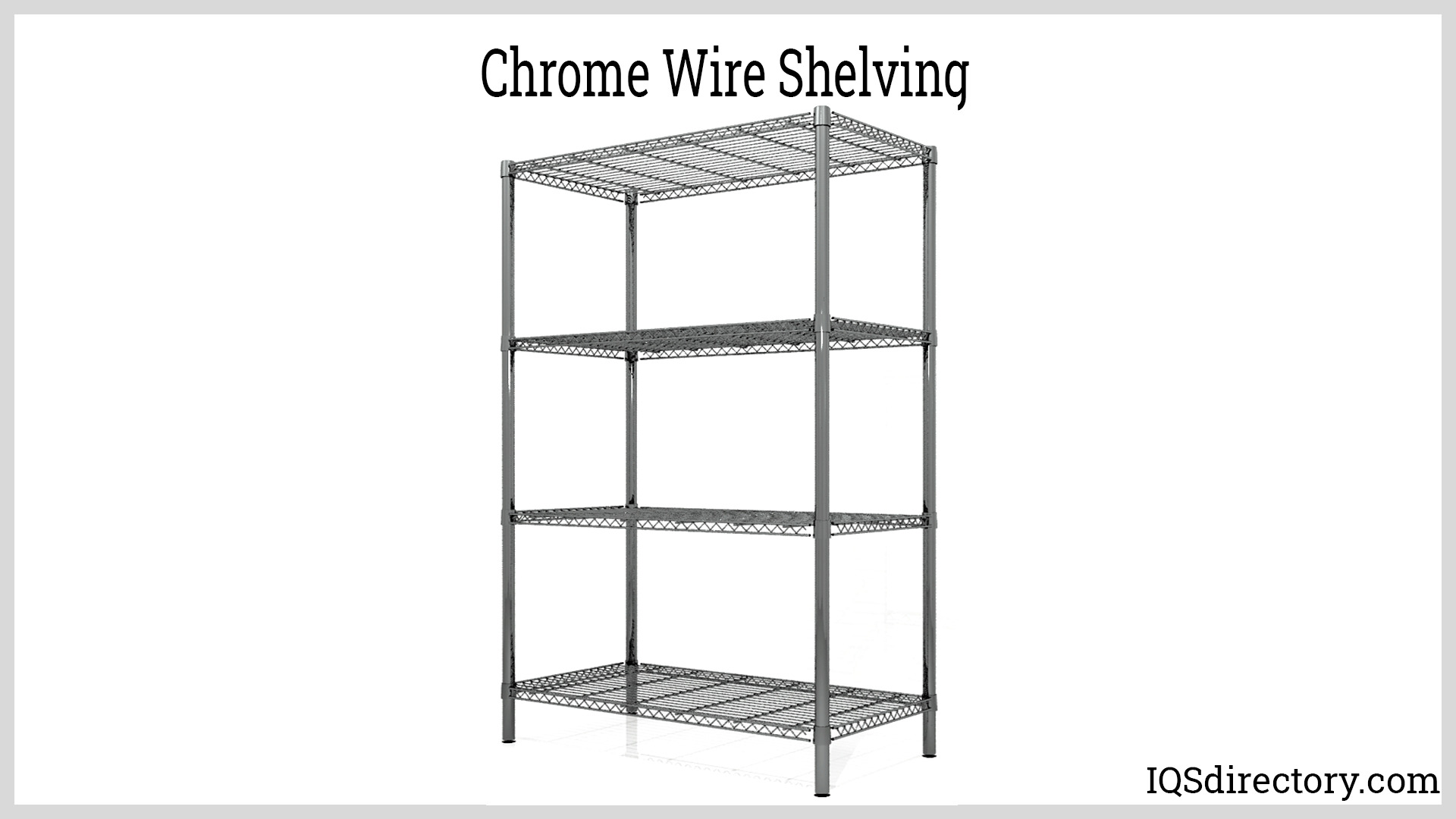

Chrome Wire Shelving

Chrome wire is also one of the metals that is used for making metal shelves. It is versatile and cheap, with great strength comparable to stainless steel. Chrome wire is also used in other facilities such as offices, dormitories, and store display units, but the shelves made from this material are best in kitchens or garages with limited space.

-

Wrought Iron Shelving

Wrought iron is also a metal used for making custom made shelving units. It is mostly used for making furniture, though this material is versatile. Wrought iron is less prone to damage, can bear lots of weight, and is water resistant.

-

Aluminum Shelving

Aluminum has the same properties as steel: ductility, durability, and thermal and electrical conductivity. Other ideal properties of aluminum are being corrosion resistant, lightweight, impermeable, odorless, and recyclable.

-

Copper Shelving

Copper is also a material used for making metal shelves. It is an attractive material; therefore, it is used in interior designing. Copper is highly resistant to corrosion with high conductive properties. The material also has non-magnetic properties, making it ideal for storing metals. Another unique property of this material is its antibacterial property; it slows down the spread of bacteria in areas where this material is used.

Types of Metal Shelving

Following are the types of metal shelving:

-

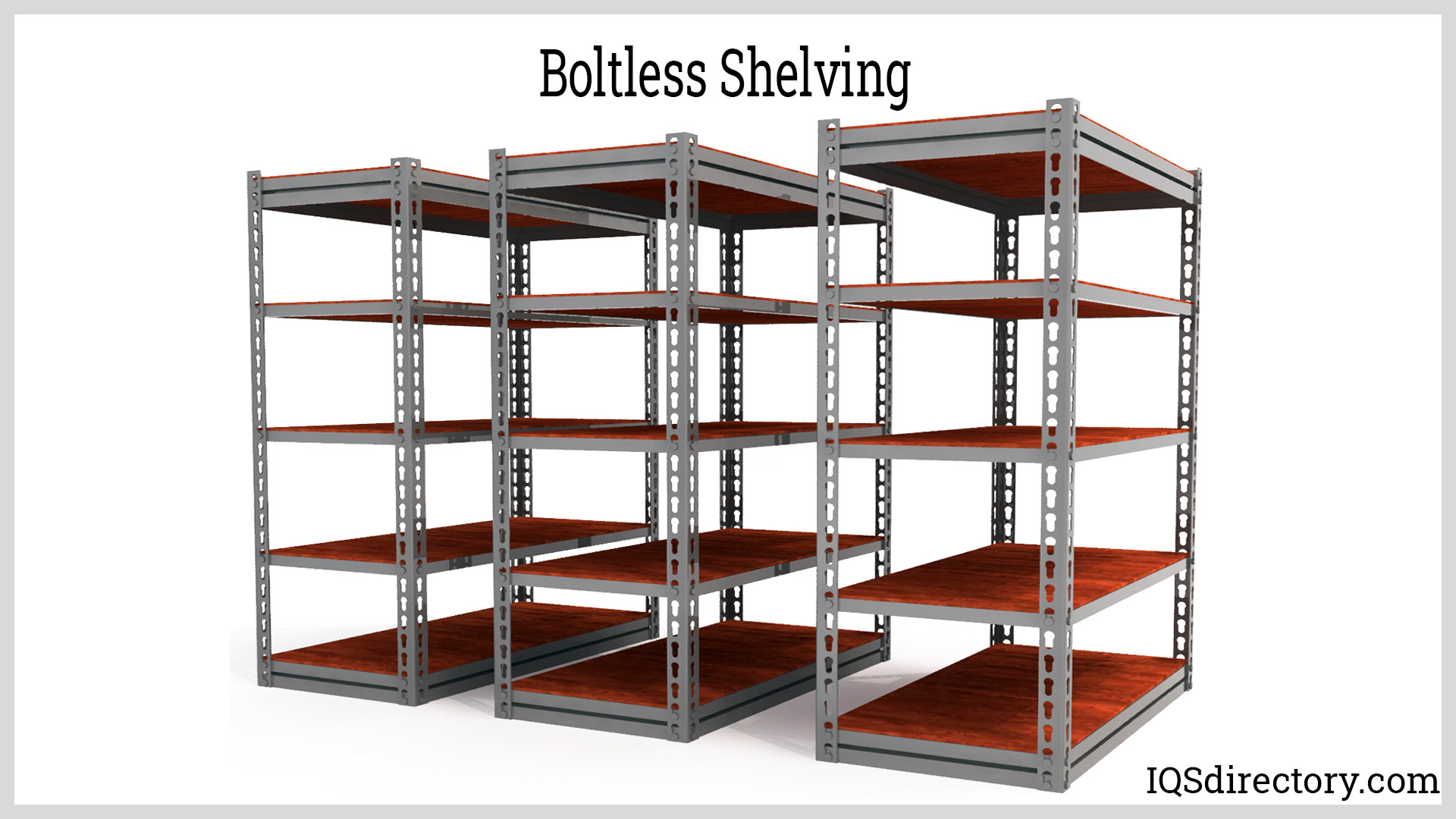

Boltless Shelving

Boltless shelving is ideal for storing heavy-duty equipment. It can be configured easily, with its boltless design making it highly versatile.

-

Clip-style Steel Shelving

Steel shelving is popular among other types of metals due to its durability and affordability. Clip style steel shelving contains all the properties of steel, and also has the addition of compression clips for easy configuration.

-

Bulk Rack Shelving -

Bulk rack shelving is used in retailers or distribution centers for holding bulky items in warehouses. It is also known as wide-span shelving. Bulk rack shelving is a boltless system with easy assembly and adjustment.

-

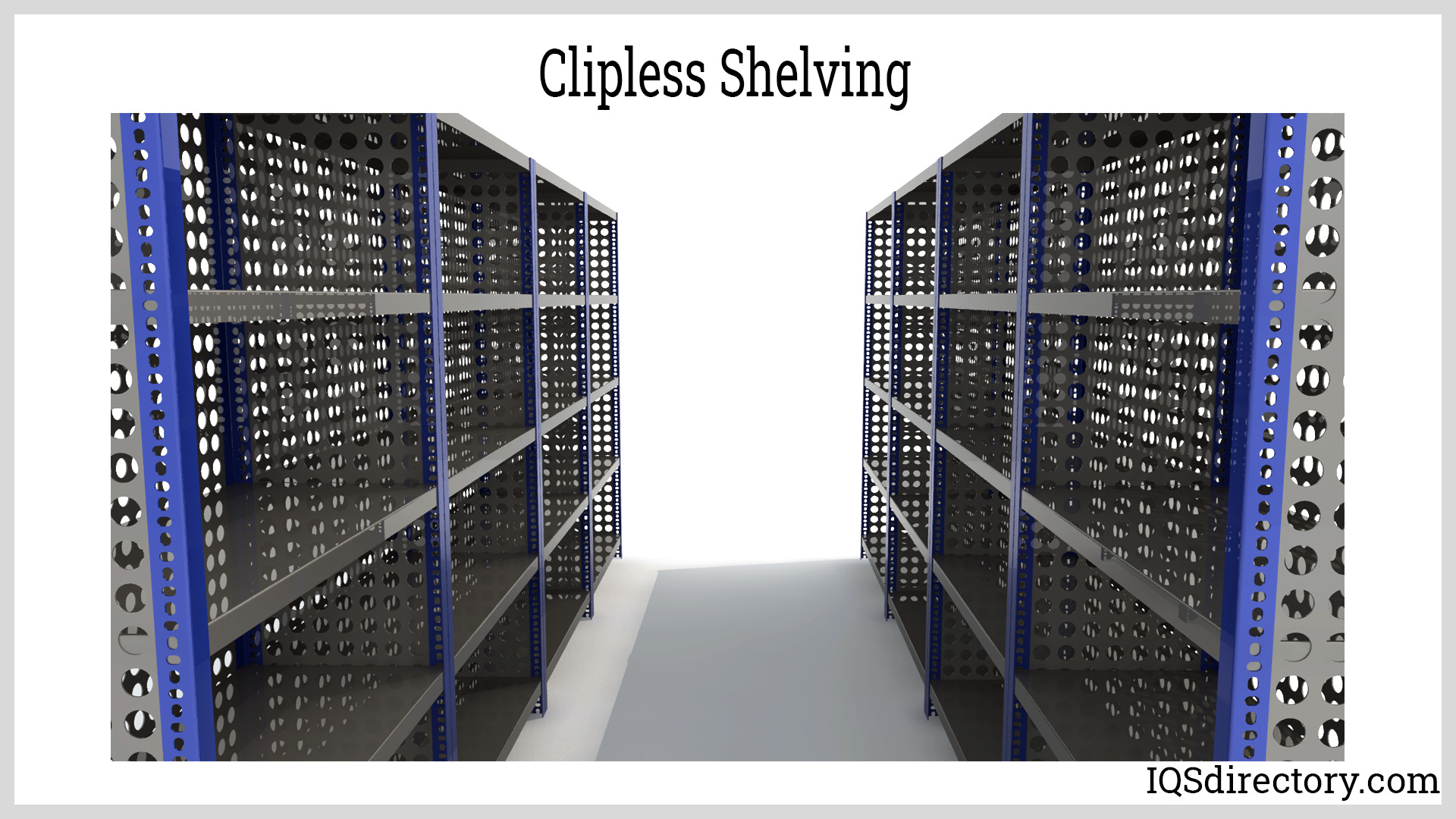

Clipless Shelving -

Clipless shelving is also referred to as backroom shelving. This system is easy to assemble and extremely versatile. This shelf can carry weight of more than 500 pounds (227 kg). Clipless shelving is widely used in store rooms or back rooms for stock storage. As they are made of steel, clipless shelves are great to hold cartons and other heavy objects.

-

Mobile Shelving

Mobile shelvings are ideal to use in areas where space is an issue. These shelves have a rail track system and individual aisles to open when needed. Mobile shelves are often used in offices or storerooms for storing small parts.

-

Rivet Shelving

Rivet shelving is the best choice for durability and convenience. This type of shelving does not require any clips or bolts and also has the ability to withstand heavy loads. Rivet shelving is easily adjustable, and its shelves can be fabricated according to custom requests. Particle board and metal wiring are the two materials used in its creation.

-

Wire Shelving

Wire shelving is not designed to bear heavy loads, but can give a better visibility of products with good air circulation. Thesy are mostly used in the food industry for storing baked items. The shelves of wire shelving can be customized according to individual needs.

Applications of Metal Shelving

- Metal shelving is used for storing heavy items in industries, thus providing space for other work.

- This shelving is also used in storing business documents in offices, warehouses, schools, colleges, etc.

- Metal shelves are also used in temperature controlled or cold storage units for storing different items.

- The food and beverage industry uses metal shelving for storage of products.

- The retail sector uses metal shelving for visual merchandising.

- Metal shelvings are also used in the chemical industry for storage, packing, and unpacking of different sorts of chemicals.

- Backroom organizations and hotel laundry rooms use these metal shelves for holding their products safely.

Choosing the Proper Metal Shelving Manufacturer

To make sure you have the most productive outcome when purchasing metal shelving from a metal shelving manufacturer, it is important to compare at least 4 to 5 companies using our list of metal shelving manufacturers. Each metal shelving manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each metal shelving business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple metal shelving companies with the same quote.