Locks

The word "lock" describes a broad variety of security devices designed to fasten and protect areas or objects from unauthorized access.

Frequently Asked Questions About Locks

What are the main types of locks used today?

The three main lock types are mechanical, electronic, and biometric. Mechanical locks rely on keys or combinations, electronic locks use keypads or cards, and biometric locks operate through fingerprint, voice, or retina recognition for maximum security.

How were the first locks developed?

The earliest locks date back to ancient Assyria and Egypt around 4000 BC. These early wooden pin locks used simple bolts and keys, evolving into metal warded locks and more complex mechanisms during the Roman and Industrial periods.

What materials are most locks made from?

Locks are commonly made from brass, zinc, titanium, steel, or stainless steel. Internal parts are often die-cast or machined for precision, while outer casings use durable alloys like nickel or chrome for strength and corrosion resistance.

How do electronic locks differ from mechanical ones?

Electronic locks use chips, actuators, and keypads or cards for access, offering programmable security and easy key replacement. Mechanical locks rely solely on physical keys or tumblers, providing durable, non-electric operation for general use.

What are the main standards for lock quality and safety?

Lock standards are set by Underwriters Laboratories (UL) and the American National Standards Institute (ANSI/BHMA). These organizations certify locks for safety, durability, and performance, ensuring products meet consistent grading benchmarks.

Where are biometric locks commonly used?

Biometric locks are typically used in government facilities, research labs, and high-security workplaces. They provide advanced protection by verifying identity through fingerprints, voice patterns, or retinal scans, eliminating risks of key or code theft.

What are some common applications for locks?

Locks secure homes, offices, vehicles, storage units, industrial facilities, and public buildings. They prevent theft, protect valuables, and enhance safety in both residential and commercial environments across the U.S. and beyond.

The History of Locks

- Early Locking Mechanisms

- Locks have existed for thousands of years. The oldest known lock and key artifacts were discovered in the ruins of Nineveh, ancient Assyria’s capital. These early locks featured a pin mechanism, which was later developed further in ancient Egypt around 4000 BC and also in Iraq. The earliest pin tumbler lock was found at the Palace of Khorsabad in Iraq. The Egyptian wooden pin lock had a post attached to the door, a sliding horizontal bolt, and a key. The bolt contained vertical holes for pins; inserting the correct key lifted the pins, allowing the bolt to move and unlock the door.

- Locks were highly valued by wealthy Romans, who secured their valuables in locked boxes at home. They often wore their keys as rings for both convenience and as a display of status.

- The warded lock, made entirely of metal, appeared around 870–900. Some claim English craftsmen invented it, while others attribute it to Theodorus of Samos in the 6th century BC. Regardless of its origins, the warded lock remains one of the most familiar lock and key types in the Western world.

- Modern Locks

- Modern lock designs emerged during the Industrial Revolution, as new manufacturing methods allowed for more precise and complex lock and key systems. This period saw the creation and standardization of many lock types. Innovations included the lever tumbler lock (improved by Robert Barron in 1778 and further by Jeremiah Chubb in 1818), the Chubb detector lock (1818), the first burglar-resistant safe (1835 by the Chubb brothers), the double acting pin tumbler lock (1805 by Abraham O. Stansbury), and the modern double acting pin tumbler lock (1848 by Linus Yale, Sr.), among others.

- Jeremiah Chubb, his brother Charles, and Joseph Bramah were among the most significant inventors of the 18th and 19th centuries. In 1818, Jeremiah Chubb created his lock for a British government contest to design a lock that only its own key could open and that indicated tampering. Chubb won the prize and later founded a lock company with his brother. Joseph Bramah, starting in the late 1700s, invented a lock with a notched cylindrical key, so precise that in 1790 he offered a challenge to anyone who could pick it at his London shop. His lock remained unpicked for 67 years, until Alfred Charles Hobbs succeeded at the Great Exhibition of 1851 after 51 hours spread over 16 days.

- Many locks invented during the Industrial Revolution are still used today, either unchanged or improved. Others have evolved with advances in electronic and biometric technology while still using the same fundamental locking principles.

Design of Locks

- Production Process

- Pin tumbler lock and key sets are manufactured through several steps. First, the key is made by cutting unique grooves into metal blanks, which can be replicated using grinding and milling machines or punch equipment. Next, the lock’s internal mechanisms, including small pins that must precisely match the key’s ridges, are produced using precision tools. Other parts, such as cams and guard plates, are typically shaped by die-casting and secondary machining processes.

- Electronic locks incorporate traditional components like pins, tumblers, and bolts, but also include computer chips that automatically lock doors after closing. The bolt, which may be pivoted, rotated, or slid, is protected by a movable or fixed element. An internal actuator motor is connected to the bolt or cylinder, enabling remote or programmed operation. Keys for these locks are often produced using a CNC machine.

- For lever tumbler locks, manufacturers create the main locking bolt from a strong metal rod and machine it to the desired profile. All lock production processes may involve blanking, forming, drawing, pressing, cutting, and molding.

- Material Process

- Mechanical locks and key assemblies are constructed from robust metals. Internals are often made from die-cast zinc or brass, while deadbolts are typically crafted from titanium or strong steel. Cams are usually formed from steel or stainless steel. Lock outer casings can be made from durable metals or alloys, such as nickel, brass, steel, stainless steel, or chrome.

- Lock Customization

- Locks can be operated by key, keycard, combination, or keyless entry methods. When choosing a lock configuration, manufacturers consider factors like your security level, desired convenience, access speed, number of users, and frequency of use.

- For high-security applications, manufacturers recommend more durable locks, often including biometric systems requiring fingerprints or retinal scans. For less critical or portable uses, simpler locks may suffice. Electronic locks are ideal for shared access, since their keys are easier to manage and replace. By evaluating these needs, manufacturers can design a lock system tailored for your specific application.

Lock Images, Diagrams and Visual Concepts

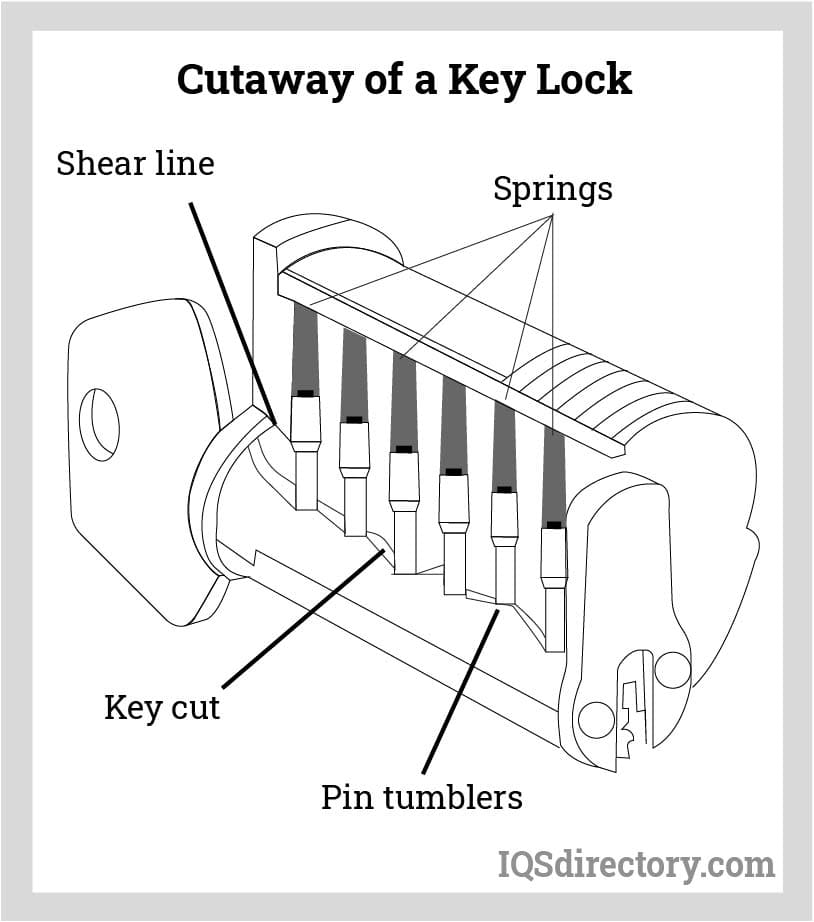

Standard tumbler key locks contain pins that align with the key's notches. When the correct key is inserted, the pins align, allowing the lock to turn and open.

Standard tumbler key locks contain pins that align with the key's notches. When the correct key is inserted, the pins align, allowing the lock to turn and open.

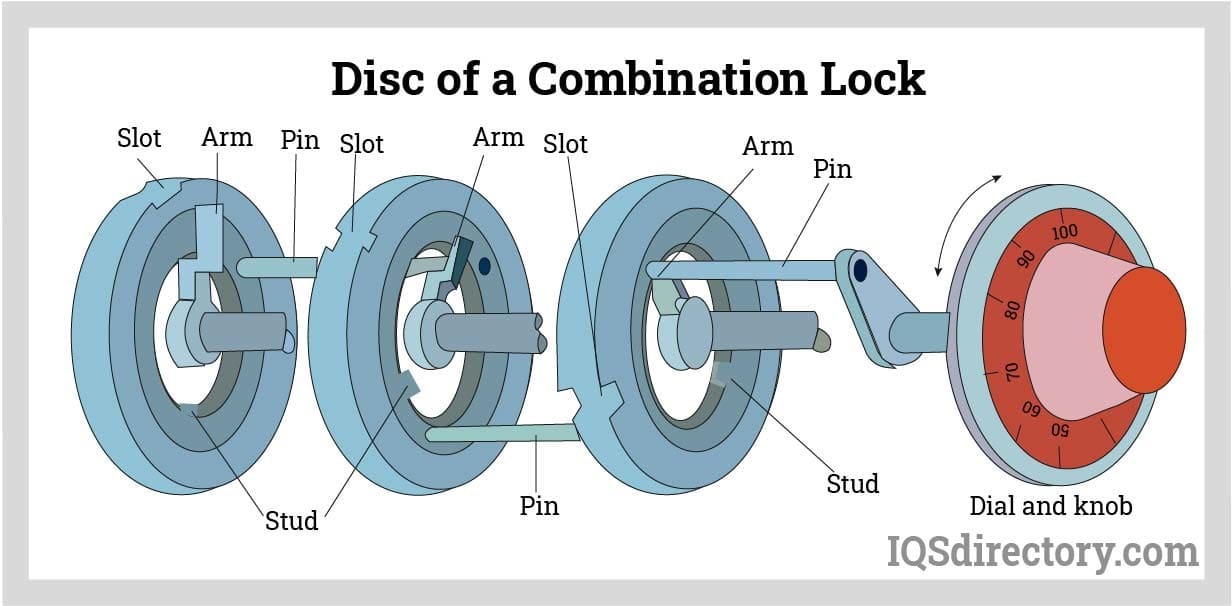

Combination locks operate by aligning a series of discs in a specific order to unlock the mechanism.

Combination locks operate by aligning a series of discs in a specific order to unlock the mechanism.

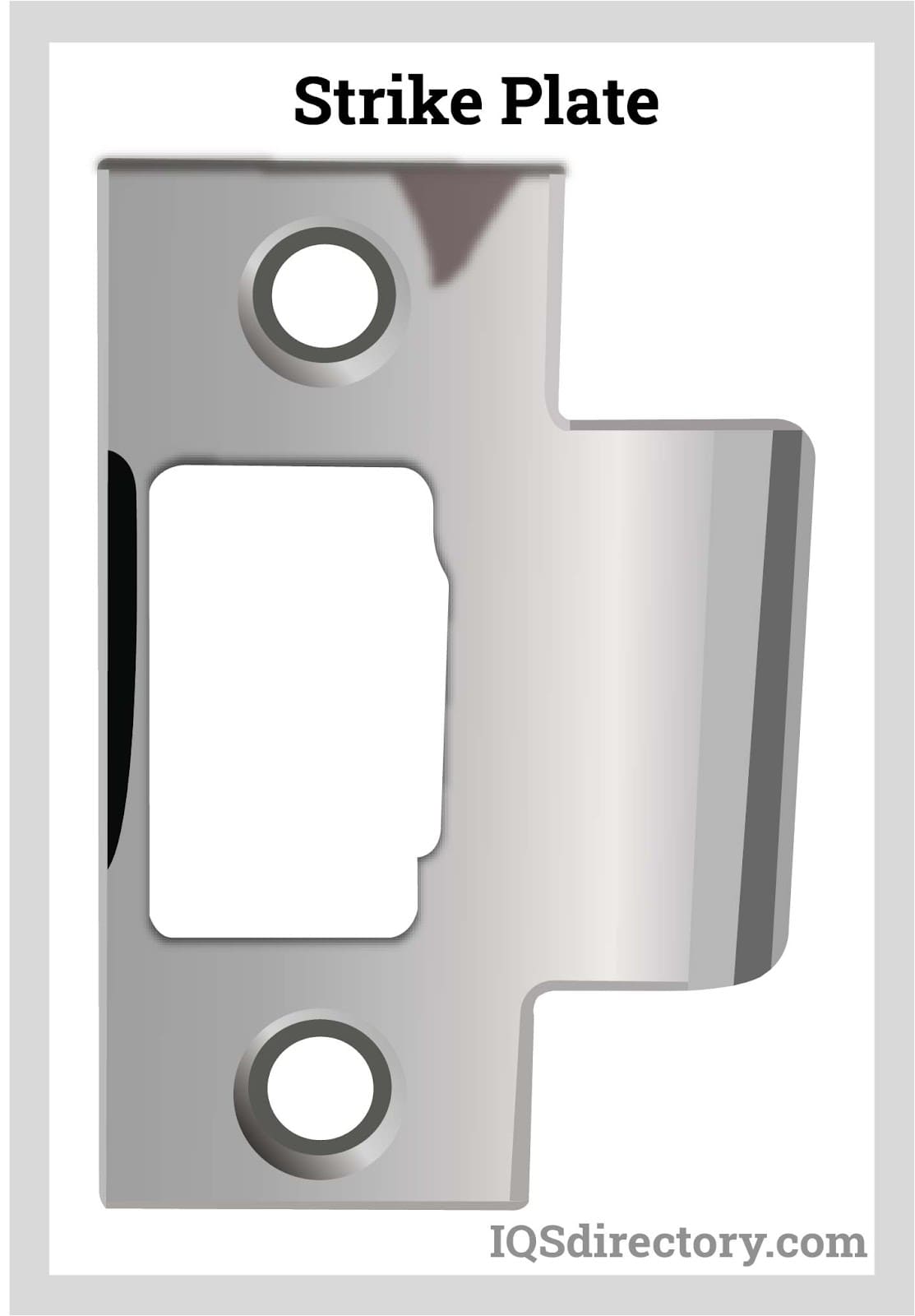

The strike plate is the metal plate where the plunger or bolt enters and secures into the door frame.

The strike plate is the metal plate where the plunger or bolt enters and secures into the door frame.

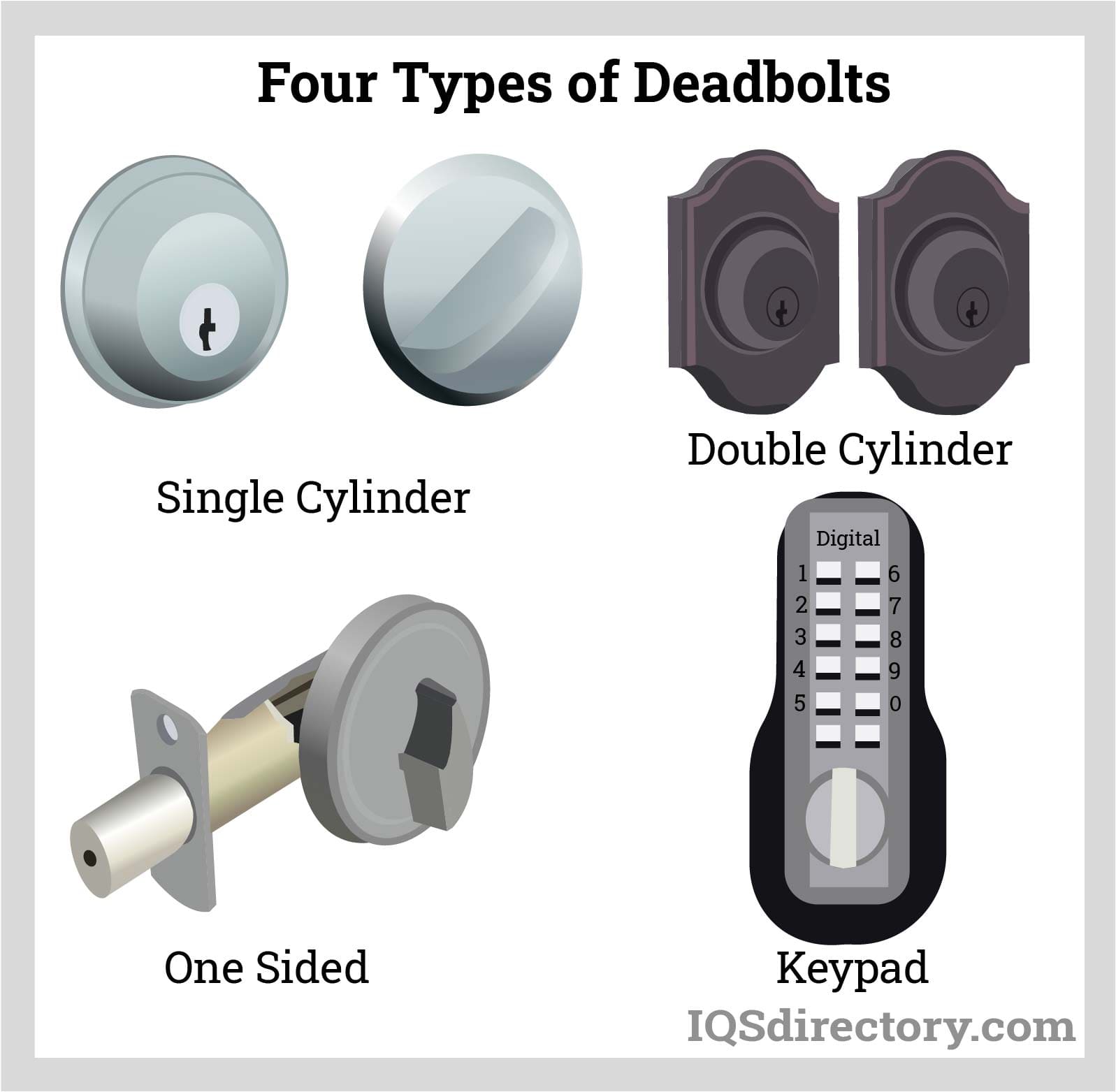

The four main types of deadbolts—single cylinder, double cylinder, one-sided, and keypad—offer enhanced durability and security compared to other locks.

The four main types of deadbolts—single cylinder, double cylinder, one-sided, and keypad—offer enhanced durability and security compared to other locks.

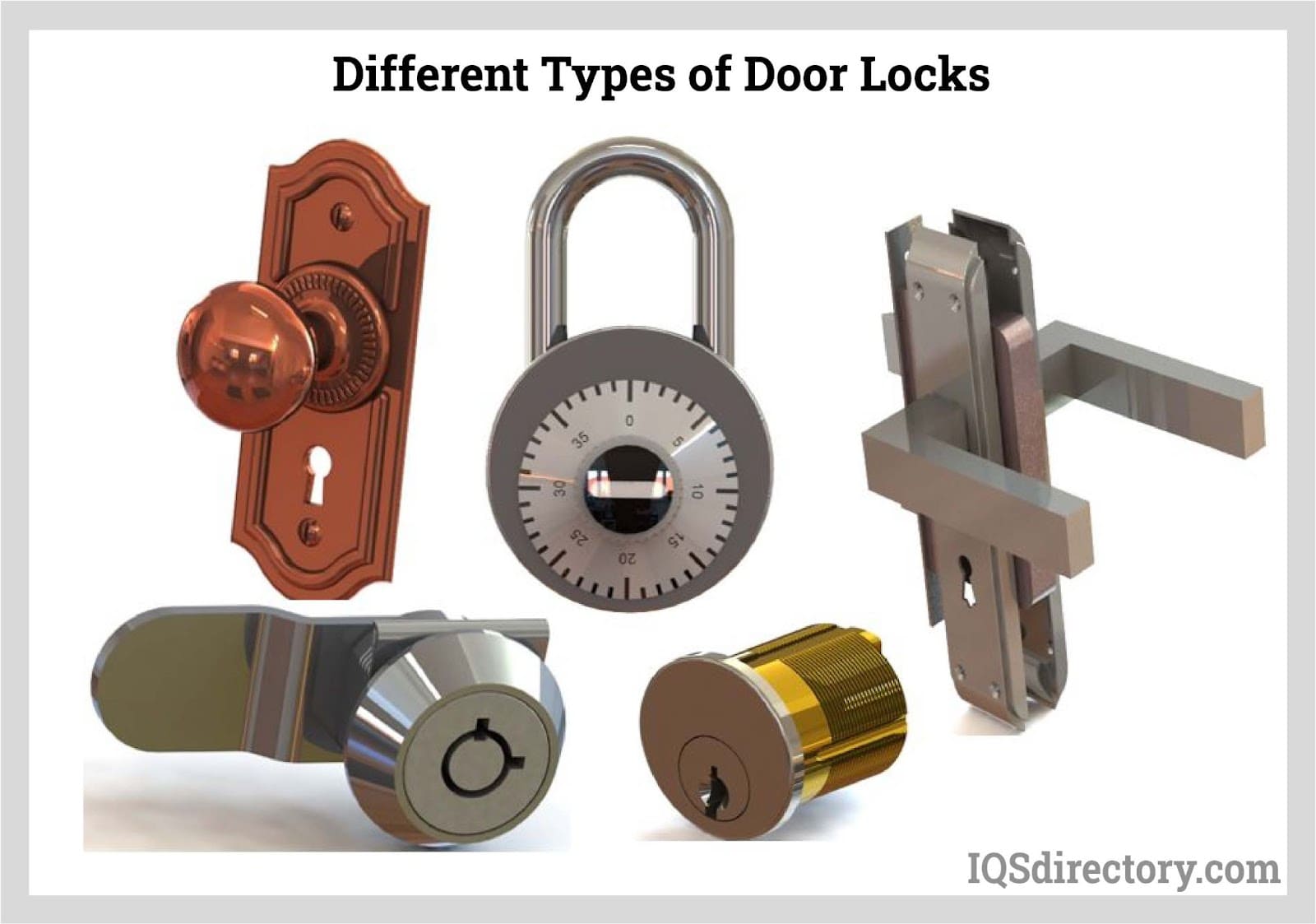

Door locks are devices or mechanisms designed to restrict or prevent unauthorized entry or access.

Door locks are devices or mechanisms designed to restrict or prevent unauthorized entry or access.

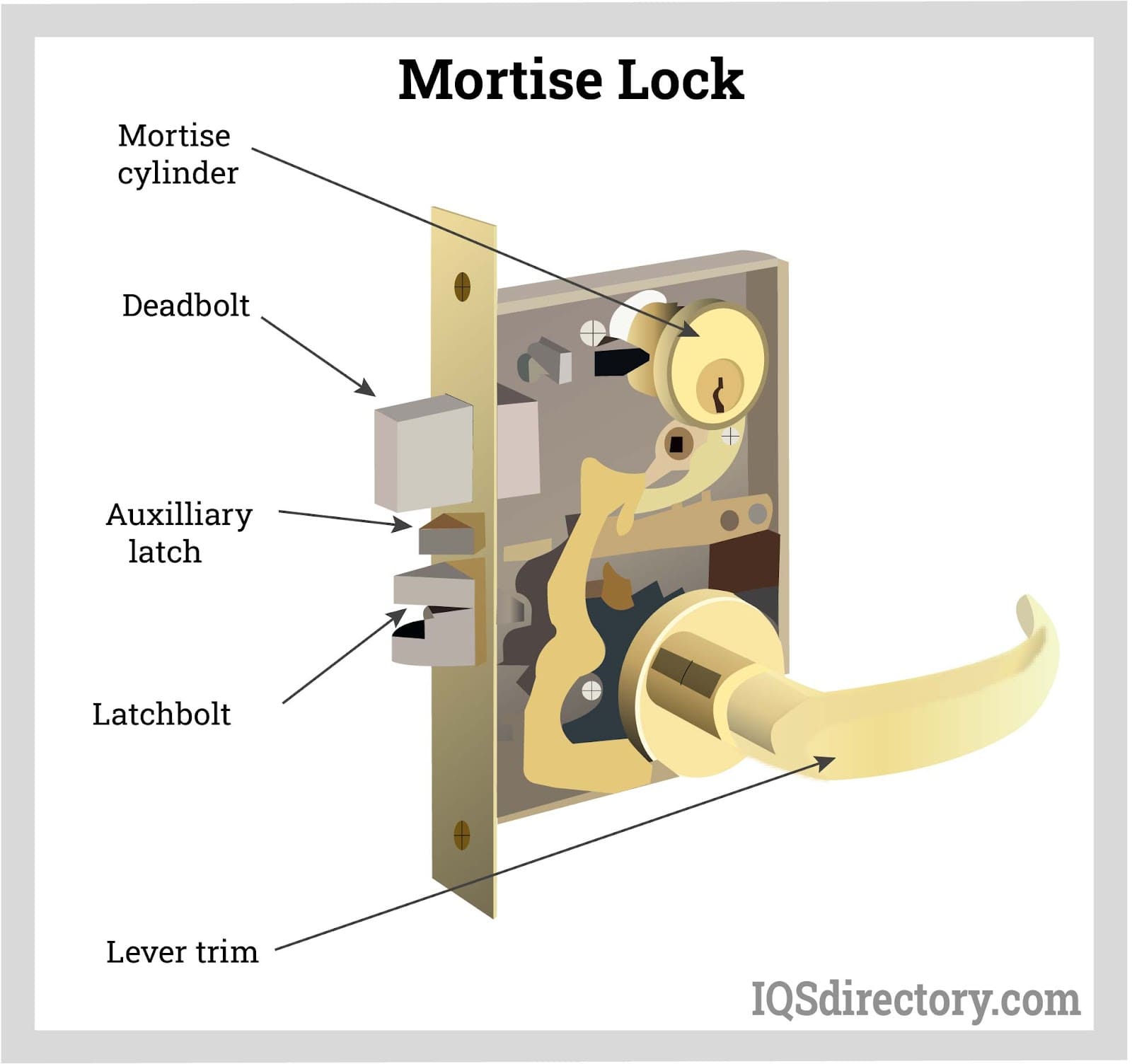

Mortise locks require cutting a pocket into the door, making them highly durable and suitable for frequent use.

Mortise locks require cutting a pocket into the door, making them highly durable and suitable for frequent use.

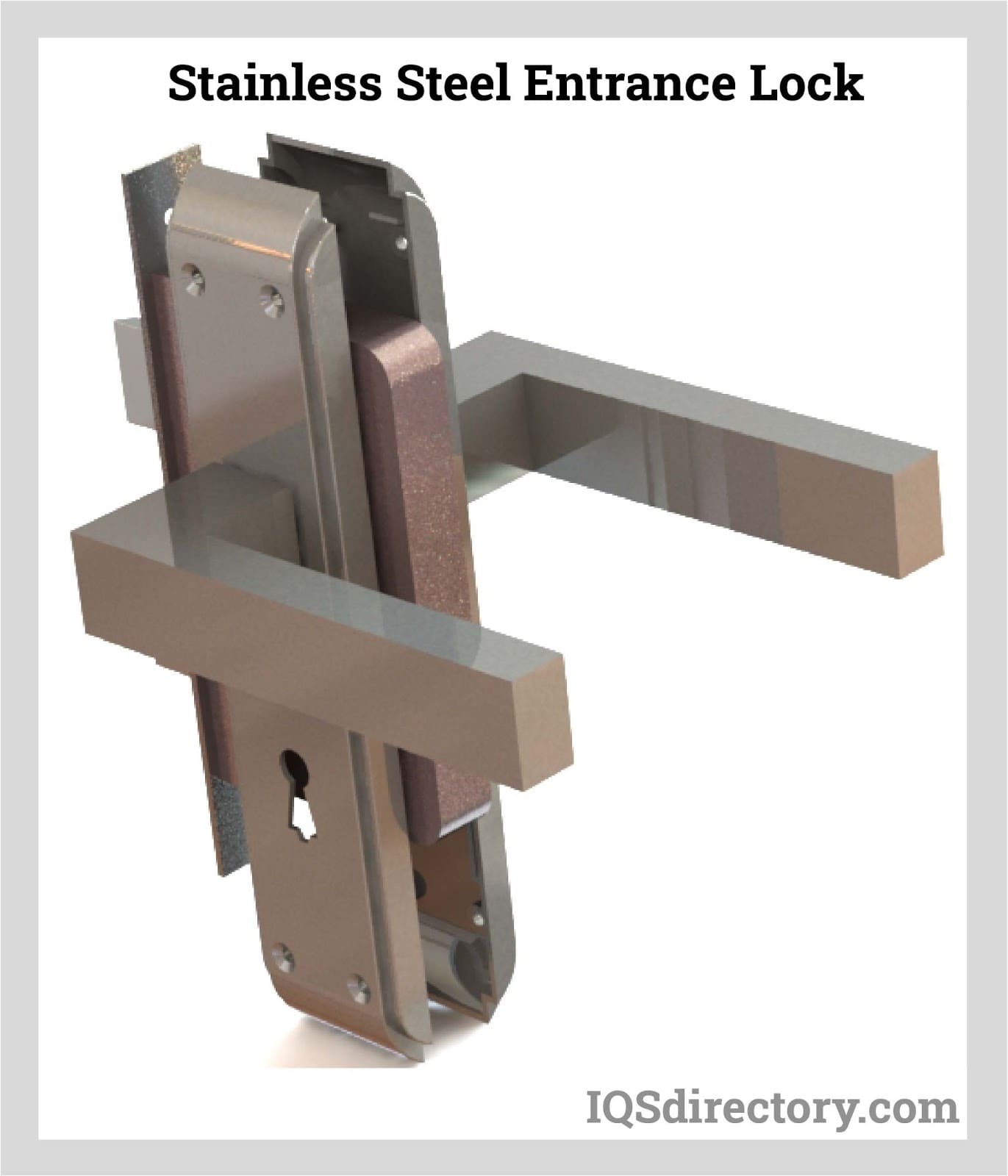

Locks made of steel or stainless steel are popular for their strength, reliability, and ability to withstand heavy and continuous usage.

Locks made of steel or stainless steel are popular for their strength, reliability, and ability to withstand heavy and continuous usage.

Types of Locks

The three main categories of locks are mechanical, electronic, and biometric locks.

- Mechanical Locks

- Mechanical locks are made of metal and are operated by a key or combination. They include padlocks, mortise locks, and cylinder locks, which are commonly installed on doors in homes, offices, and commercial buildings, as well as on interior doors and offices.

- Mortise Lock

- Mortise locks offer greater resistance to picking or forced entry but are generally more expensive and harder to install. These are typically used for exterior doors.

- Cylinder Lock

- Cylinder locks are easy to replace and cost-effective, but they provide only basic security.

- Combination Lock

- Combination locks, the first keyless locks, use disk tumblers that must be aligned to release the spindle. Most feature a dial that turns to specific numbers in both directions. Suitable for doors, vehicles, cabinets, padlocks, strong rooms, and safes, these locks require a correct combination to open.

- Padlock

- Padlocks have a U-shaped design and are often used with combination locks. They consist of a bar, hinge, and chain; to lock, the bar passes through a chain link and secures into place.

- Tumbler Lock

- Tumbler locks have metal pieces that fall into place to block the bolt. The serrated key raises these tumblers to the correct height, enabling the bolt to move and the lock to open.

- Warded Lock

- Warded locks are among the oldest lock designs. They use a notched key that slides the bolt, and the notches must match the wards inside to open the lock properly.

- Cable Lock

- Cable locks are designed for visible security of large outdoor items like bicycles and trailers.

- Electronic Locks

- Electronic locks are keyless and provide medium to high security. Common in hotels and high-security workplaces, they allow access codes to be changed easily. Main types include magnetic key locks and keypad locks.

- Magnetic Key Lock

- Magnetic key locks are modern systems often used on dorm rooms, hotel doors, and secure workspaces. A plastic magnetized card is inserted into a slot, where magnets repel spring-loaded pins, unlocking the door temporarily in a way similar to tumbler locks.

- Keypad Lock

- Keypad locks require users to enter a code or password on a keypad to unlock the door.

- Biometric Lock

- Biometric locks are advanced, high-security solutions used by government agencies and facilities requiring maximum protection. These locks open via fingerprint, voice, or retina scans, eliminating risks of key or code theft and ensuring only authorized personnel gain access.

- OEM Locks

- OEM locks include products such as cam locks, vending machine locks, padlocks, cabinet locks, electronic locks, parking meter locks, and more, specifically designed for original equipment manufacturing purposes.

- Door Lock

- Door locks are the most widely used lock type and are primarily mechanical, though other mechanisms are also used. Their main purpose is to prevent unauthorized entry into buildings, rooms, or other structures.

- Vending Machine Lock

- Vending machine locks are specialized to prevent unauthorized access to products and cash inside vending machines, allowing only technicians and service staff entry.

Lock Applications

Locks are used to control access and secure a wide range of environments and items, including homes, commercial properties, vehicles, furniture, cabinets, gates, storage units, industrial sites, windows, drawers, jewelry boxes, and luggage.

Customers rely on locks to prevent theft, deter vandalism, enhance public or staff safety, and protect against unauthorized entry or tampering.

Lock Installation

The installation process for a lock depends on the specific lock type and the surface where it will be mounted. For detailed instructions, consult your lock supplier or manufacturer.

Standards & Specifications for Locks

The two most prominent organizations for lock standards are Underwriters Laboratories (UL) and the American National Standards Institute (ANSI). UL is an independent safety certification organization that helps manufacturers ensure products are safe and reliable through services like inspection, training, marketing claim verification, auditing, and certification. ANSI/BHMA (Builders Hardware Manufacturers Association) is a non-profit group that sets hardware grading standards, allowing products to be classified by grade based on quality, durability, and performance benchmarks.

Choose the Right Lock Manufacturer

The lock industry serves almost every sector worldwide, making the selection process challenging. To choose the best provider, seek a reputable lock manufacturer. Start by reviewing the list at the top of this page, then visit their websites to explore products and services. Narrow your options to three or four, and contact each with your questions and specifications. Compare their products, services, prices, lead times, and customer support. Select the manufacturer most dedicated to delivering a high-quality product at a fair price.

Accessories for Locks

Common lock accessories include chain door guards, plated knobs, security bars, latch strikes, FOBs, internet control components, Wi-Fi adapters, and latch shields. For details or specialized needs, consult your lock or door lock manufacturer.

Lock Terms

- Automatic Deadlocking

- Enables a door or gate to automatically deadlock after closing.

- Deadbolt

- The component of a lock that moves from the locked to the unlocked position when the key is turned.

- Detainer

- A mechanism used instead of a lever to allow for more key variations.

- Differs

- The total number of unique key combinations possible for a particular lock.

- Dual Control

- A lock that provides both electronic and mechanical methods for unlocking.

- Escutcheon

- The protective or decorative plate surrounding a keyhole.

- Lever

- A part inside the lock that moves out of the way for the correct key but blocks incorrect keys from unlocking the mechanism.

- Snib

- A knob or button used to hold a deadbolt in a locked or unlocked position.

- Throw

- The length or distance a bolt moves between locked and unlocked positions.

- Tumbler

- An internal lock component that, when properly moved by a key, releases the bolt and allows unlocking.

- Ward

- The ridge inside a lock that prevents a key from turning unless it matches; also refers to the part of a key cut to fit the ridge.