Heat Treating Steel

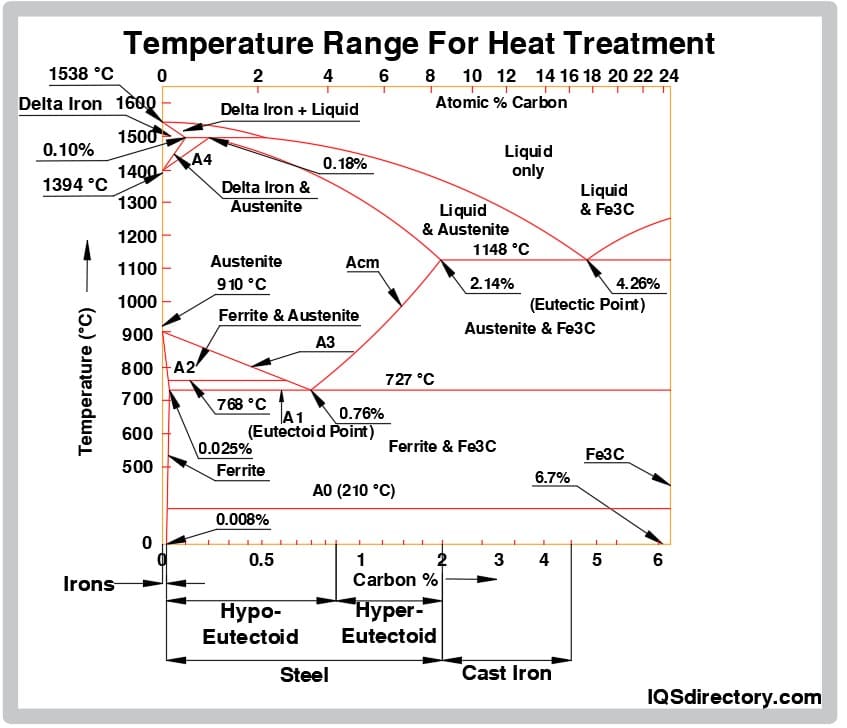

Heat treatment of steels can yield a wide variety of microstructures and characteristics. In most cases, heat treatment modifies the microstructure of a solid state by causing phase transformation during heating and cooling. Heat treatment typically involves thermal processing, which modifies only the steel's structural makeup. When steels are subjected to thermo-mechanical treatment, the shape and structure of the steel components are also altered. In addition, the surface chemistry and structure of steel are altered during the thermo-chemical process.

For heat-treating steel, the thermo-mechanical and thermo-chemical treatment processes are both effective processing methods that are being considered. Steel must be heated and cooled under strict control to complete the heat treatment procedure. The environment of the heating furnace has an impact on the state of the steel undergoing heat treatment.

Steel Heat Treatment Methods

Annealing Heat Steel

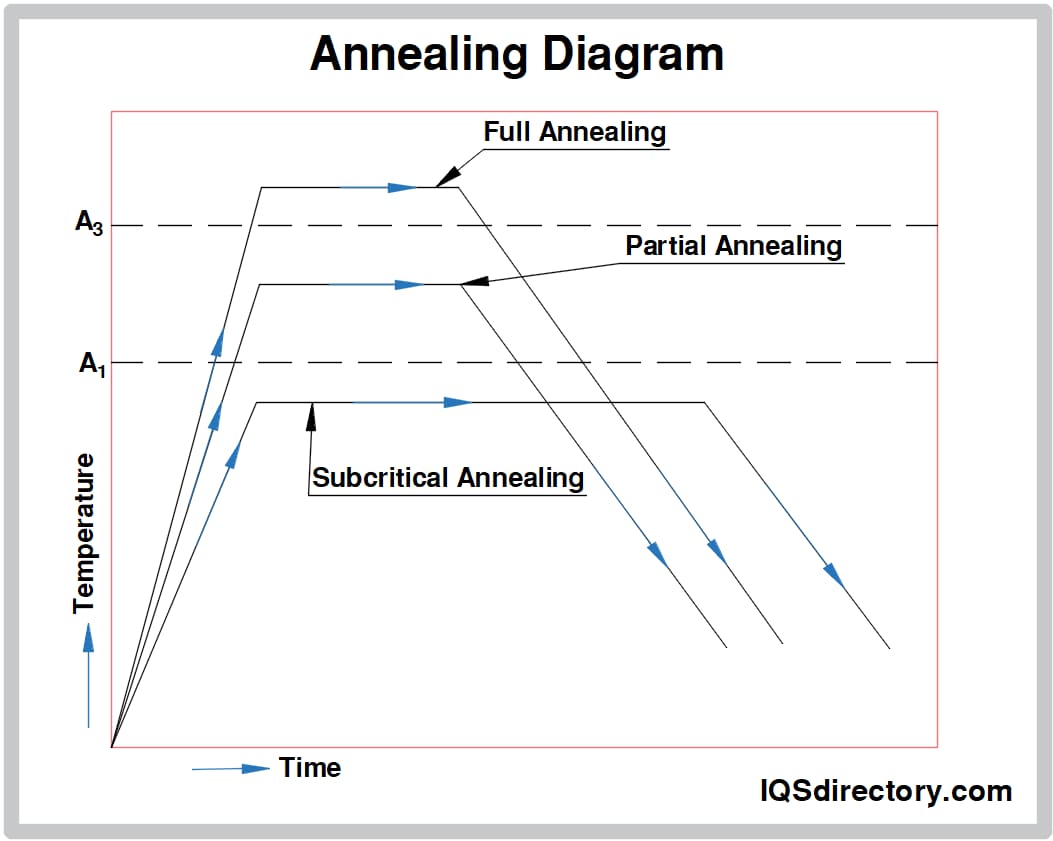

Heat treatment, called annealing, involves heating and cooling. The procedure is typically used to soften steel. The phrase also covers procedures designed to manufacture a specific microstructure, eliminate gasses, or modify mechanical or physical qualities. The type of steel being annealed, and the intended use of the treatment determines the temperature of the process and the rate of cooling. Below is a description of the various annealing process varieties.

Full annealing is a procedure for softening steel that involves heating it to a temperature over the austenitic transformation range, holding it there for a significant amount of time, and then gradually cooling it to a temperature below the transformation range. Although it can be withdrawn and cooled in another cooling medium, steel is often allowed to cool slowly in the furnace. Given that the steel's carbon content influences the transformation temperatures, high-carbon steels can be fully annealed at lower temperatures than low-carbon steels. Ferrite and pearlite make up the microstructure of the hypo-eutectoid steels produced after full annealing.

Spheroidization

Steel is heated and cooled during the spheroidization process, resulting in a spherical or globular form of carbide in a ferrite matrix. However, it can be aided by alternating periods of heating steel to temperatures just above the A1 temperature and then cooling steel to just below the A1 temperature. It is often carried out by sustained heating at temperatures just below A1. However, the last step involves keeping steel at a temperature below the critical A1. After cooling gradually to about 540° C, the remaining cooling rate is not significant. The initial structure has an impact on the rate of spheroidization. Spheroidization occurs more easily when the pearlite is finer. Spheroidization is extremely amenable to a martensitic structure. High-carbon steels with a carbon content of 0.60% or more typically receive this treatment. The goal of this treatment is to make steel more machinable. High-carbon steel is also prepared using this method before being cold-drawn into wire.

Tempering

Reheating hardened (martensitic) or normalized steels to a temperature below the A1 threshold is the process of tempering, also known as drawing. Except for some steels prone to temper brittleness, the cooling pace is insignificant. The hardened steel martensite goes through several phases of tempered martensite as the tempering temperature is raised. It eventually transforms into a structure made up of cementite spheroids embedded in a ferrite matrix. Decreased hardness and increased toughness go hand in hand with these changes. The desired qualities and the intended application of the steel determine the tempering temperature. If significant hardness is required, a low tempering temperature is required. On the other hand, a high tempering temperature is required if significant toughness is required. Hardened steel must be properly tempered, which takes time. Any chosen tempering temperature causes the hardness to decrease initially quickly before decreasing more slowly as time passes. In general, short-tempering times are undesirable and should be avoided. Good practice calls for at least 30 minutes (or ideally 1 to 2 hours) at a tempering temperature for any hardened steel.

Flame Hardening

It involves using a high-temperature flame to heat the steel's surface layers above the transformation temperature, followed by quenching. The gas flames directly hit the steel surface, which needs to be hardened during this procedure. Although not quite as quick as with induction heating, the pace of heating is still fairly quick. While alloy steels can be cooled at different rates, ranging from a rapid water quench to a leisurely air cool, depending on the composition, plain carbon steels are typically quenched by a water spray. Flame hardening can be done on any hardenable steel. The carbon concentration should be at least 0.35% for optimal outcomes, with a typical range of 0.40% to 0.50%.

Tools for Heat-Treating Steel

Steel's hardness and ductility can be increased by heat-treating the material. The metal's tensile, impact, and yield strengths may also be enhanced. Heat treatment involves the use of a wide variety of equipment. These tools include furniture, torches, salt baths, hot blankets, and lasers. No one right approach to heat treat metals exists because many goods are unique and specialty built. However, there is consistently a big demand for the goods.

A range of steel products used in the automotive, aviation, construction, manufacturing, and tool and die industries are produced via heat treatment. Knives, swords, gears, medical devices, valves, drive shafts, ventilation systems, and bearings are a few examples of items made using heat-treated steel.

Choosing the Proper Heat-Treating Steel Manufacturer

To ensure you have the most beneficial outcome when choosing a heat-treating steel manufacturer, it is important to compare several companies using our directory of heat-treating steel manufacturers. Each heat-treating steel manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each heat-treating steel company website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple heat-treating steel businesses with the same form.