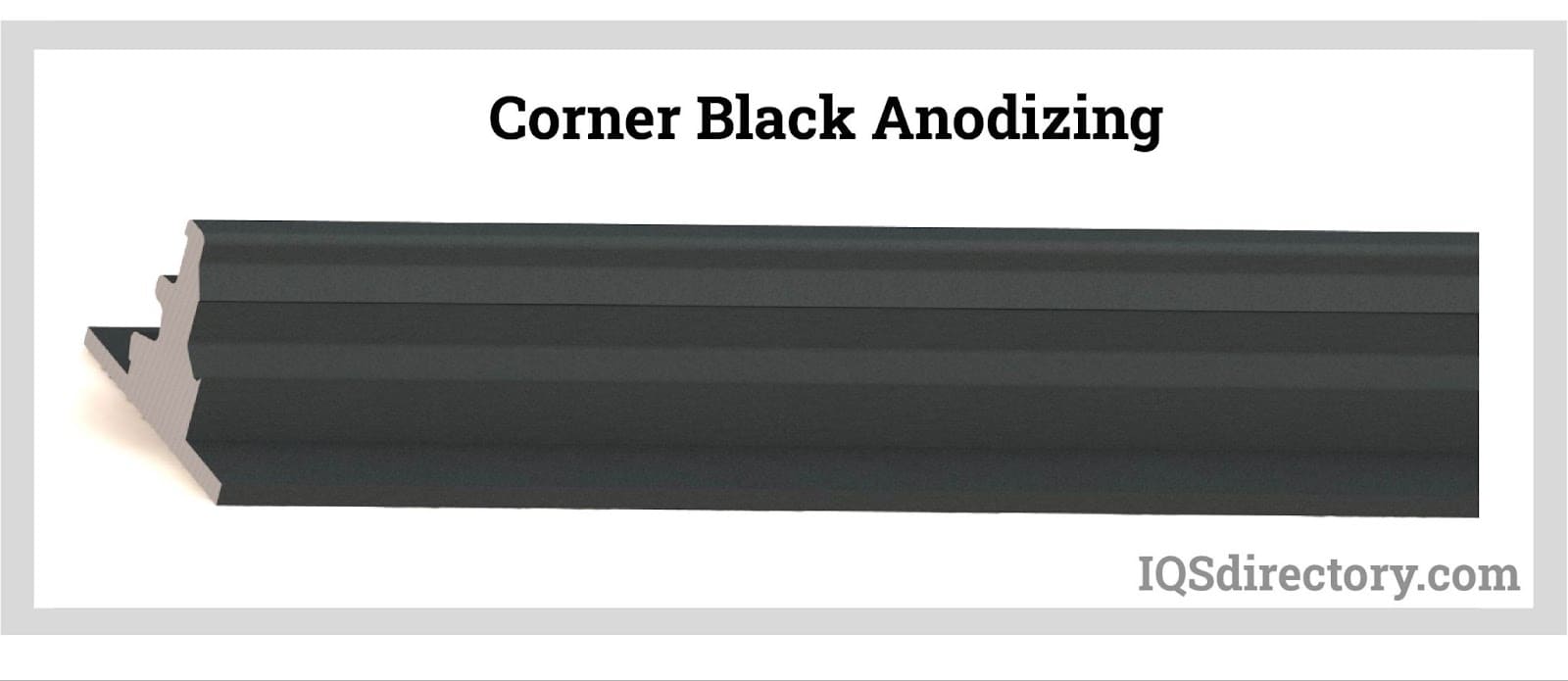

Black Anodizing

Black anodizing is a process used to color a metal's surface black. Prior to the sealing stage, a dye is added to a metal surface and absorbed into its pores during the anodizing process used to make the metal more durable.

Black Anodized Surface Finish for Aluminum

Metals can change their surface characteristics and appearance through the electrochemical process of anodizing. In aluminum, oxide forms a protective coating that becomes thicker and more durable through the anodizing process. In fact, its final finish is second only to diamond in terms of hardness. Aluminum's black anodizing process helps it to prevent corrosion, resist scratching, and enhance aesthetic qualities.

Process for Black Anodizing Aluminum

Dyes used in black anodizing tend to be more lightfast because the basic black dye is derived from an inorganic material, a chemical compound called ferric ammonium oxalate. The same substance can also be used to make gold dye. Being lightfast refers to the colors' propensity not to deteriorate as rapidly when exposed to light. There are a few alternate techniques, but the fundamental method for producing black anodizing is the same as the method for producing all other colors. The majority of anodizing procedures, like sulfuric acid, make a metal's surface more porous and enable it to absorb and keep the color of dyes. So a dye can be used right away following the significant chemical change in the metal's crystal structure.

Anodizing in Continuous Coils

This procedure entails unwinding pre-rolled aluminum coils after they have undergone cleaning, etching, and anodizing processes. This technique is appropriate for high-volume foil, sheet, and items like space bars, reflectors, and roofing systems.

Batch Aluminum

In this procedure, aluminum components are submerged in a row of treatment tanks. Extrusions, sheets, castings, and cookware are a few examples of things that can be batch anodized.

The quality and look of the finished product can be enhanced through the black anodizing process. After the anodizing process is complete, then the black dye is added to coat the metal. As a result, pewter, polished brass, and stainless steel can all be mimicked on black anodized aluminum. Numerous electrical applications are made possible by the anodized finish's dielectric characteristics.

According to estimates, the covering is 30% thicker than the aluminum metal it is replacing. This is due to the fact that more oxide is formed during the process than aluminum metal is replaced. The porous nature of the black anodic coating makes sealing and coloring simple.

Aluminum metal that has been anodized is submerged in a bath during electrolytic coloring which is the black dye.

Black Anodized Aluminum's Advantages

There are noticeable advantages when black anodized aluminum is contrasted with regular aluminum.

Simple Maintenance

Handling, installation, manufacture, and surface cleaning wear and scars disappear. The only thing needed to return black anodized aluminum to its original appearance is a simple rinse or cleaning with water and mild soap. Use mild abrasive cleaners if there are stubborn residues.

Corrosion Protection

It should be noted that the corrosion resistance of black anodized metal is higher than that of ordinary aluminum. Aluminum does not rust, although it can corrode when exposed to air, salt, moisture, and other compounds that prevent corrosion. The advantage of anodized aluminum is that the heavy oxide layer makes it unlikely to rust.

Lubrication

Although one advantage of typical anodized aluminum is that it is simple to lubricate with the deeper pores that are produced when aluminum is anodized, they can obviously get filled with black dye during the black anodizing process. As a result, a coating of dry-film lubrication may be required if needed.

Aesthetics

Obviously, black anodized aluminum can be quite aesthetically pleasing. Combine that simple fact with its UV resistance and corrosion-fighting properties and, again, you’ll you’ll understand why it utilized in various consumer, commercial, and industrial applications

Applications of Black Anodized Aluminum

Aluminum oxide is created during anodizing from the common aluminum metal. As a result, a new product with a more resilient and weatherproof finish is produced. It also gives a variety of workable options with the addition of a beautiful appearance. Applications for black anodized aluminum can be found in commercial, consumer, and industrial settings.

Keep in mind that black anodized aluminum will not corrode or wear under UV or saltwater exposure. It also won't fade, peel off, or chip. Anodized aluminum is used to make a variety of products, including tools and medical equipment. Manufacturing of dentistry and medical equipment, oxygen equipment, regulators, emergency room tools, and lab apparatus all employ these parts and goods.

Examples of Products Made of Black Anodized Aluminum

- Appliances, including coffee makers, microwaves, and dryers

- Pans, grills, refrigerators, and display cabinets for the food industry

- Storage beds, tables, desks, picture frames, clocks, and bathroom items for the home and office

- Equipment for boats, golf carts, fishing, camping, sports and recreation

- Automotive parts, including nameplates, control panels, wheel covers, and trim pieces

- Construction materials, including patio covers, curtain walls, roofing materials, vents, and exteriors of buildings

Choosing the Proper Black Anodizing Company

To make sure you have the most productive outcome when purchasing Black Anodizing from a Black Anodizing Company, it is important to compare at least 4 Companies using our Black Anodizing directory. Each Black Anodizing Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Black Anodizing company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Black Anodizing businesses with the same form.