Screw Conveyors

Screw conveyor systems are mechanisms responsible for rotating or moving a variety of fluid, solid, and granulated materials from one process to the next. In other words, they transfer materials.

Screw conveyors are also known as auger conveyors, helix conveyors, worm conveyors or flexible screw conveyors.

Quick links to Screw Conveyors Information

The History of Screw Conveyors

In the third century B.C., the ancient mathematician and scientist Archimedes theorized the screw principle and devised the first screw conveyor system; it was known as Archimedes' screw. It consisted of a hollow cylinder with a center shaft and a spiral fixed to the inner cylinder wall and the shaft. His contemporaries used his screw conveyor design for irrigating farmland and removing water from ships.

The modern screw conveyor system developed over time between the late 1800s and the mid-1900s. Initially, it was used in the United States to increase feed and grain production on farms. It was a major component of the first feed mills, as it still is today.

As materials of construction such as abrasion-resistant alloys and stainless steels have been developed over the years, the use of screw conveyors has increased to many more industries. Recent production technology improvements include automating specific manufacturing processes to improve quality and reduce costs. The best example of this is robotic welding in the screw-making process. One of the most recent developments has been the manufacture of a shaftless screw conveyor, which utilizes a screw without the center pipe. Suppliers who can help you implement this innovative equipment into your company's systems can be found on IQS Directory.

As time goes on, we can expect to see more and more innovations in the bulk material handling world.

Benefits of Screw Conveyors

- Low Cost

- Portable screw conveyors is probably the biggest reason behind the high adoption rate of these versatile products. In comparison to other types of conveyor systems, they are the least expensive choice. Mainly the cost of the machine depends on the type of tube; the length of the conveyor mechanism; the size of the motor; capacity; and other custom features. Owing to their small size and intelligent design, portable conveyors can suit numerous applications and low budget.

- Material Support

- As said earlier, these convenient machines are a product of intelligent product designing. They are designed to support and move thousands of materials efficiently. Using these devices, you can convey powders to mixtures and pallets to granules. IQS Directory lists companies who are able to design optimized conveyors for your company's applications.

- No Degradation

- Material degradation is not exactly an issue with the present-day flexible conveyors. Material degradation is less expected in these advances. However, it is only true when you use the suggested material for the process. That is the reason why you should get the machine that is suitable for your application and process.

- Device Speed

- The flow rate or speed of the device largely depends on its capacity and the amount and type of material being used. Portable SCs can be designed to support an adequate speed that is necessary for the process.

How Conveyors Work

Screw conveyors work based on the Archimedes’ screw principle. This principle maintains that: 1) a revolving screw or auger, correctly fitted into a cylinder or tube, can move water in a chosen direction, and 2) every rotation also allows new material to enter the tube.

Bearing this in mind, screw conveyors rotate bulk material through the conveyor from one area to another using a rotating, helical screw inside a tubular casing or a trough. Some can be powered by an electric motor; others have no conveyor drive, instead harnessing energy from nearby machinery, like a trailer's power take-off shaft. The material is conveyed at a precise flow rate that is measured in cubic feet per hour. In some bulk, industrial process machines, the capacity is measured in pounds per hour or tons per hour.

Screw Conveyors Images, Diagrams and Visual Concepts

Screw conveyors are industrial equipment used to transport bulk quantities of granular solids , semi-solids, liquids, and non-flowing materials.

Screw conveyors are industrial equipment used to transport bulk quantities of granular solids , semi-solids, liquids, and non-flowing materials.

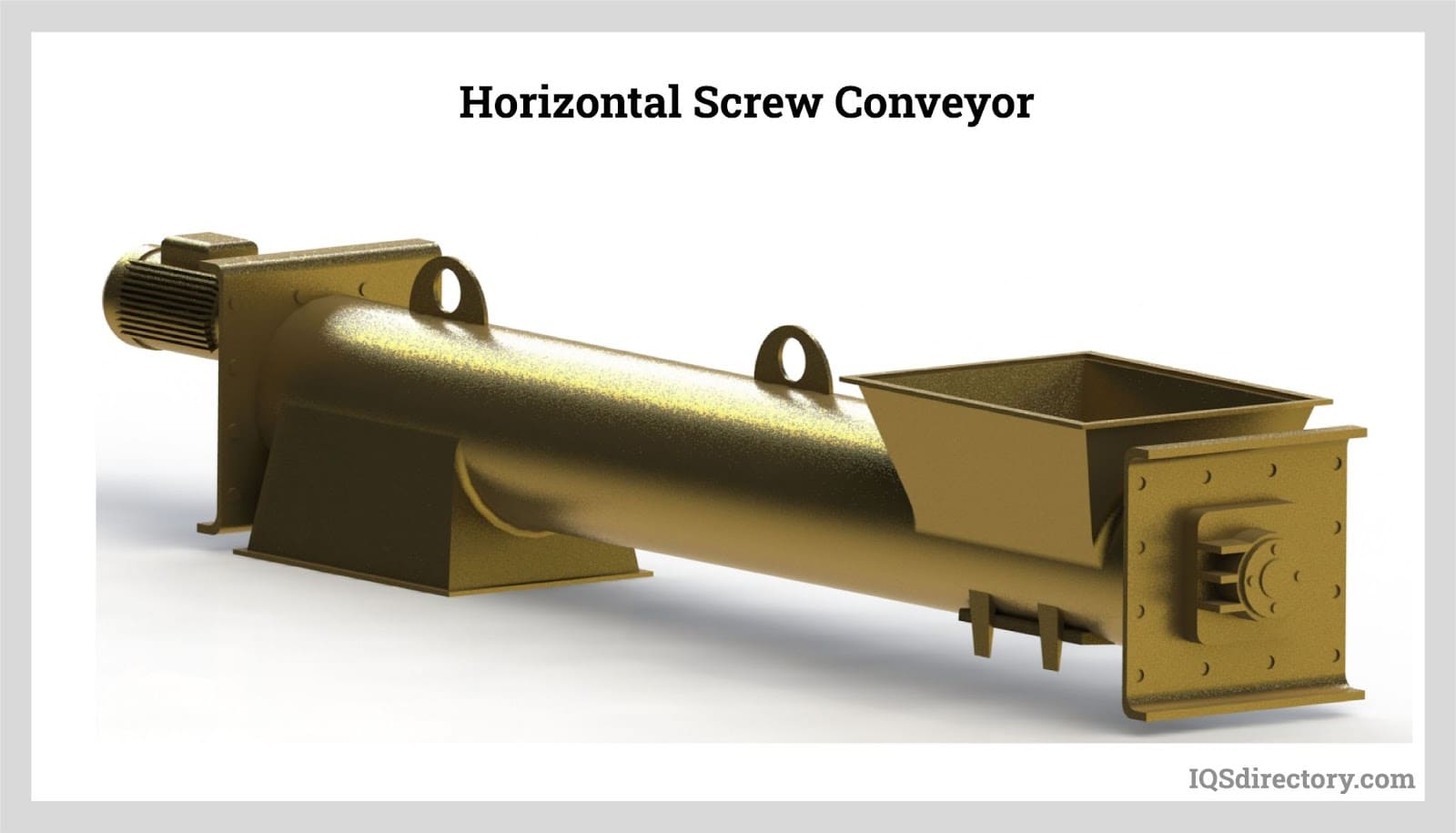

Horizontal screw conveyors are the simplest form of screw conveyors, which can handle a wide range of bulk material characteristics and effectively distributes bulk materials to multiple inlets and discharge points.

Horizontal screw conveyors are the simplest form of screw conveyors, which can handle a wide range of bulk material characteristics and effectively distributes bulk materials to multiple inlets and discharge points.

Inclined screw conveyors offer an inclined path that eliminates the need for additional equipment for transporting bulk materials to or from an elevated surface.

Inclined screw conveyors offer an inclined path that eliminates the need for additional equipment for transporting bulk materials to or from an elevated surface.

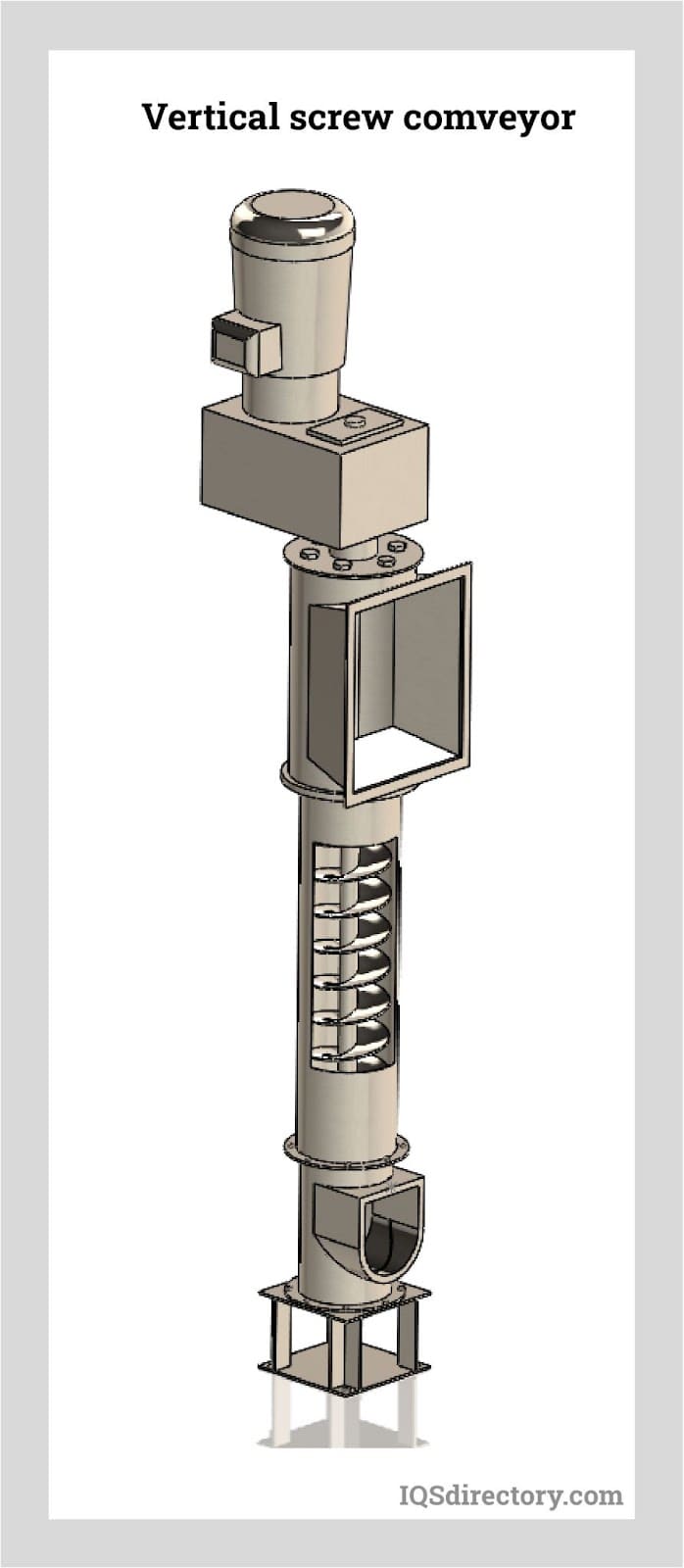

Vertical screw conveyors transport bulk materials on vertical paths with an angle of inclination greater than 45°.

Vertical screw conveyors transport bulk materials on vertical paths with an angle of inclination greater than 45°.

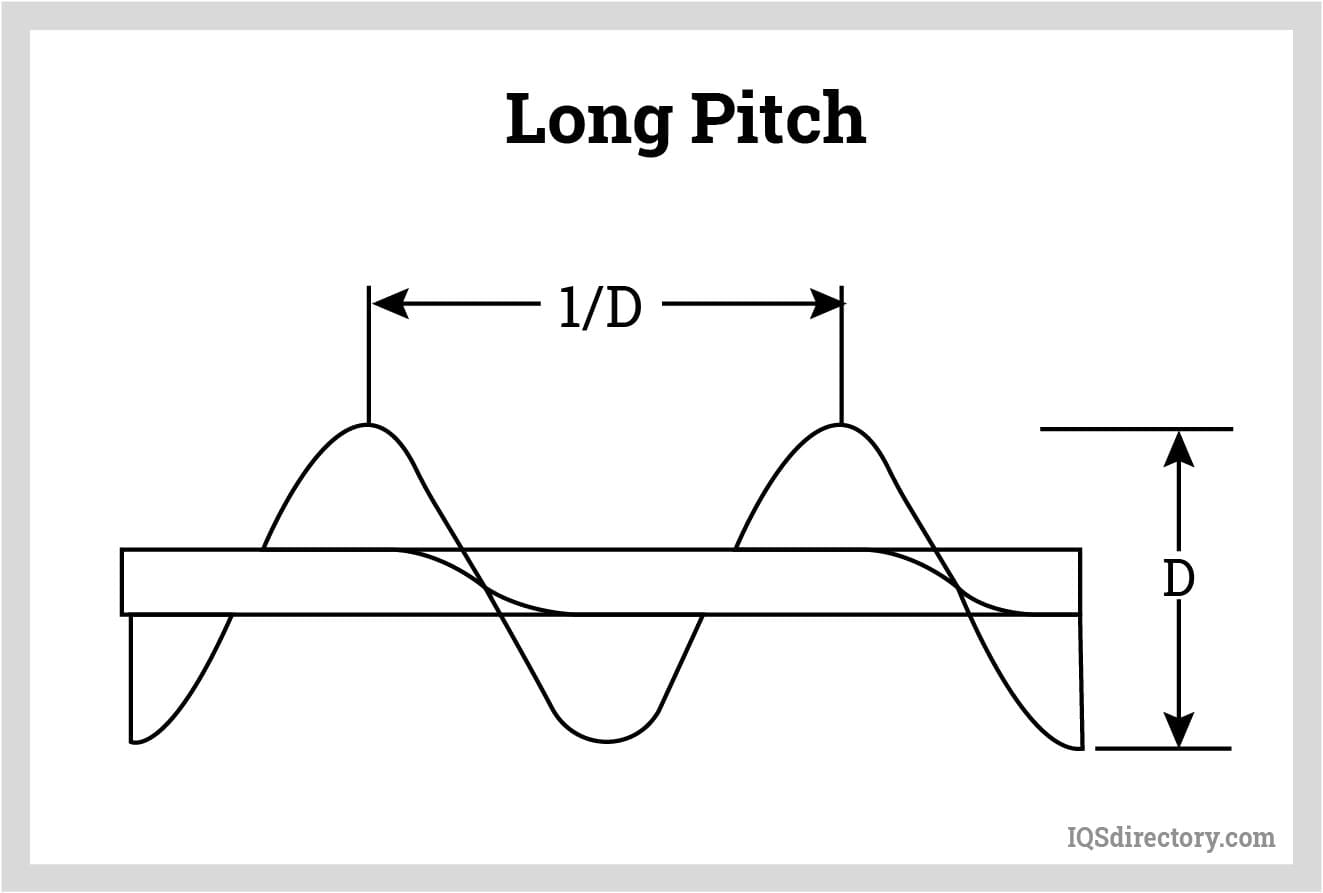

The pitch and the pattern of the conveyor screw affects the over all efficiency of the conveyor.

The pitch and the pattern of the conveyor screw affects the over all efficiency of the conveyor.

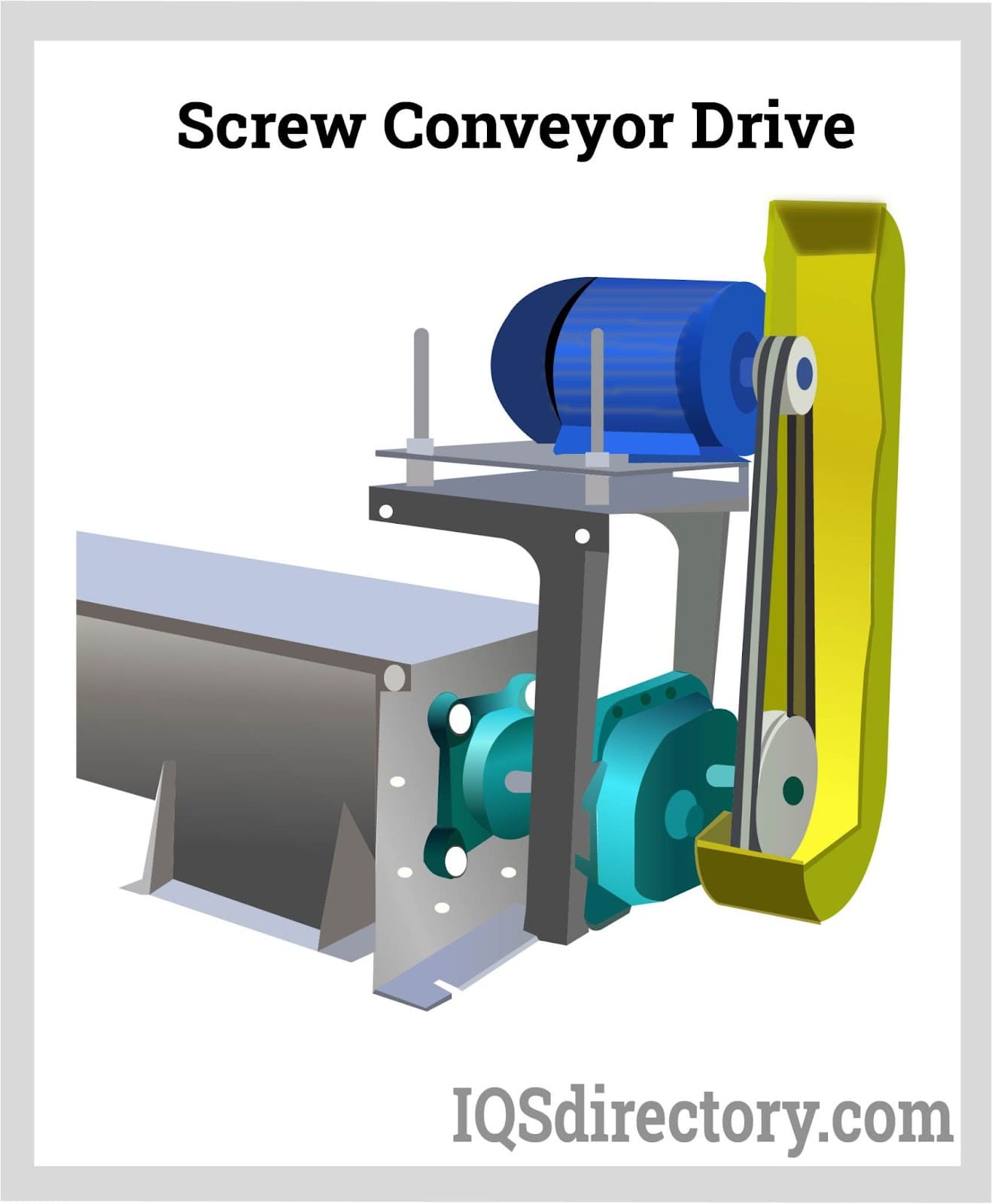

A motor that drives the assemblies for screw conveyors which can be powered by an electric motor.

A motor that drives the assemblies for screw conveyors which can be powered by an electric motor.

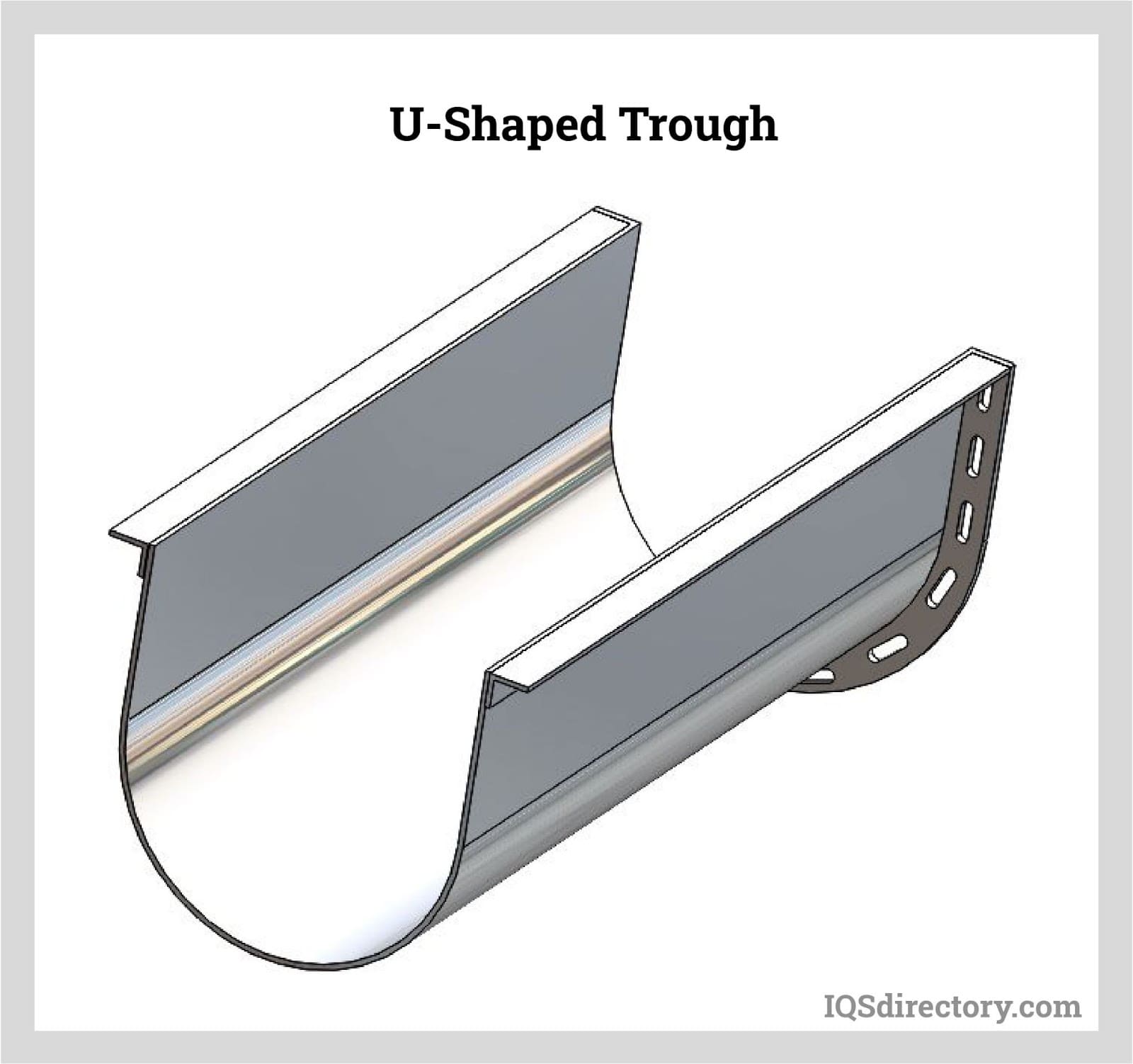

The trough supports the bulk material during transportation.

The trough supports the bulk material during transportation.

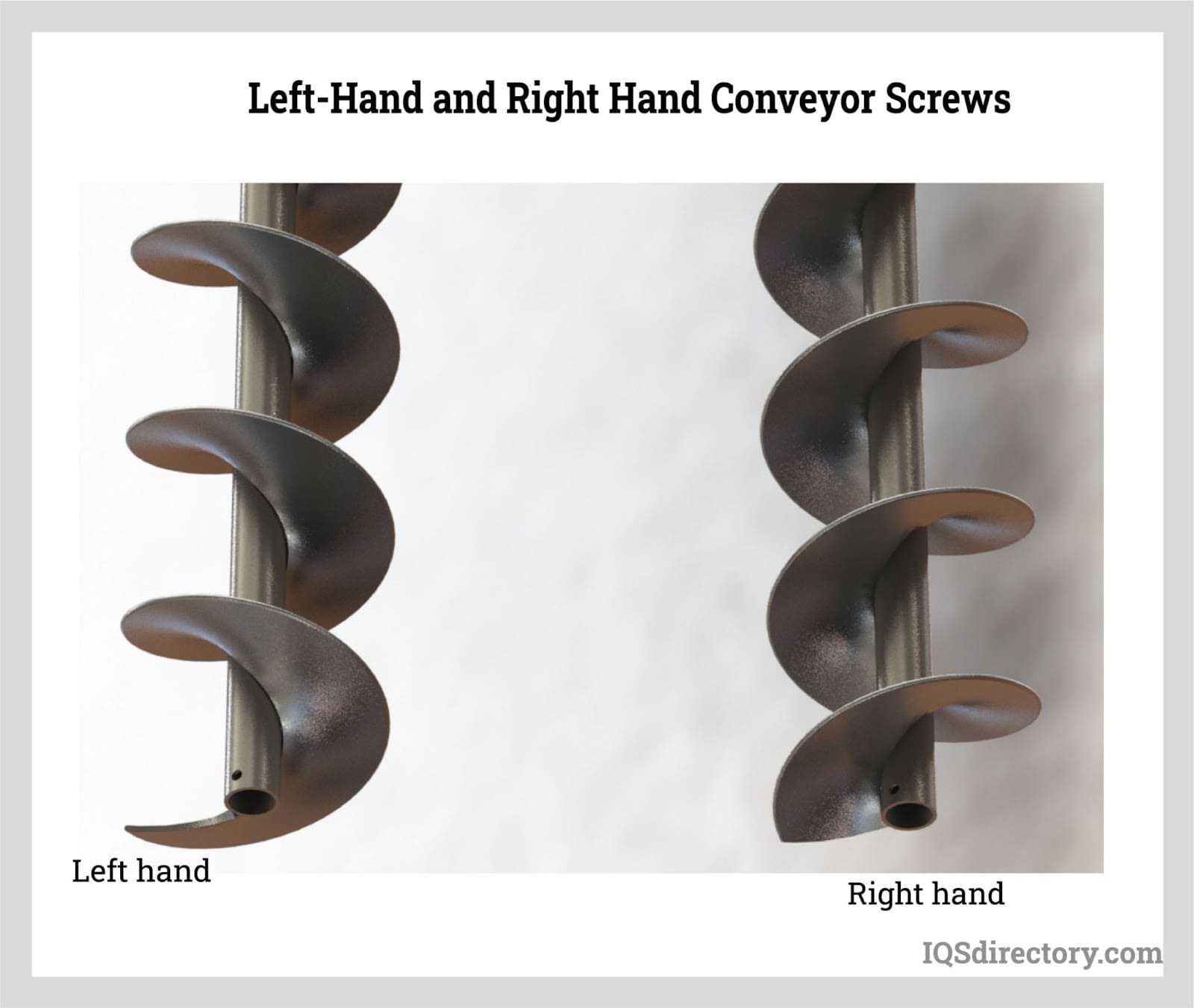

Screw conveyor handedness is determined by the end of the conveyor screw, turning clockwise are right-hand screw conveyors and counterclockwise are left-hand screw conveyors.

Screw conveyor handedness is determined by the end of the conveyor screw, turning clockwise are right-hand screw conveyors and counterclockwise are left-hand screw conveyors.

Types of Screw Conveyors

Based on the mechanism and placement in a tubing or cylinder, screw conveyors are available in a wide variety of types, which are outlined below.

- Tubular Screw Conveyor

- Refers simply to any screw conveyor that is contained within a tube. Many types of screw conveyors, regardless of their conveying style, can also be classified as a tubular screw conveyor.

- Vertical Screw Conveyor

- Typically, this industrial screw conveyor type is used for bulky material handling applications in the manufacturing and agriculture industries. Manufacturers of this equipment design their products specifically for space optimization, as moving things in a vertical direction requires much less square footage that your company needs to maintain. They are not weak, however. They can actually efficiently handle heavy duty and large size loads.

- Horizontal Screw Conveyor

- Quite similar to vertical conveyors, horizontal screw conveyors offer assistance to chemical plants in managing their fluids and gases. In addition, these mechanisms are used in heating, cooling, mixing, dewatering, drying, aeration, and compaction processes. They are very useful to manufacturing businesses looking to break down or compact uneven materials.

- Stainless Steel Screw Conveyor

- Use an inclined, spiraling plane to transport materials, usually liquids, granulated substances and semi-solid materials. They are very common in the agriculture industry, but are used in a wide range of fields. Conveyors such as this are perfect for handling jobs in food processing, pulp and paper, wastewater treatment, chemical, winery, brewing, and a number of other applications across various industries.

- Screw Feeder Conveyor

- A subtype of the horizontal screw conveyor. They are designed to perform at their full capacity, as opposed to common horizontal conveyors, which do only forty to fifty percent. These advancements are used for efficient and constant conveying of materials from one process to another.

- Flexible Screw Conveyor

- Have a flexible or bendable casing that is close-fitted in the cylinder. Flexible screw conveyors are able to adjust their angle and may bend in different directions, creating a wider range of uses within a single facility. These features are unique among conveyors, making flexible conveyors quite popular. They are much smaller than regular screw conveyors however.

- Portable Screw Conveyor

- Typically designed for moving granules of a wide range. They are also used for moving powdered materials. The reason why these devices are labelled as portable is their design; their radius allows you to set custom requirements between 45 degrees and 90 degrees angles.

- Inclined (Incline) Conveyor

- Many applications require the use of incline conveyors, which are set at an angle. They require ample space and an increased amount of power to lift the material, but their slant economically transports bulk material between facility floors. Some are portable and may be mounted and moved around on stands, carts or vehicles.

- Bucket Elevator

- A type of vertical or inclined conveyor that moves material with one or more buckets. It is used for conveying flowable bulk material up and down. These don't look exactly like a typical screw conveyor, but have a similar idea behind them.

- Coreless Screw Conveyor

- Also known as shaftless screw conveyors, do not have a core. Their main advantage is the fact that they are resistant to clogging. They also help catch and collect stringy materials.

- Sand Screw Conveyor

- Used primarily to dewater sand or granules. It can also be used for removing fine particles from the material.

- Grain Screw Conveyor

- A tool for the agriculture industry. Also known as an agricultural screw elevator, it is used for lifting and loading the material into a truck.

- Plastic Screw Conveyor

- A type of bulk material transportation system that uses a lightweight rotating helical screw inside a trough or tubular casing to elevate raw materials.

- Cement Screw Conveyor

- Use this specialized screw conveyor when you want to convey cement.

Applications of Screw Conveyors

The key reason industries use screw conveyors is to reduce maintenance and production costs. They do this by transporting materials down, across or up a linear space, as well as mixing, agitating or breaking them down.

Because the screw will cut through materials during operation, sticky substances like gels are not ideal for auger conveyor systems to process. Instead screw conveyors are used mostly to transport dry to semi-dry bulk materials, both free-flowing and non-free-flowing. Examples of these bulk material types include: powder, sludge, dust, flakes, granules, boiler ash and other loose products like seeds, food waste, wood chips, cereal, grain, fuels, process fluid, feed and cement. More specifically, they process products like carbon black, caffeine powder, gypsum, ferric sulfate, cocoa beans, flour, garlic powder, animal feed, epsom salts, vitamins, fiberglass, whey, and lead oxide.

Industries that rely on screw conveyors include: bulk handling, food and beverage, agriculture, production chemicals, pharmacy, construction, wood products, mining, minerals processing, oil and gas, pulp and paper production, rubber production, plastics production, stone cutting, glass manufacturing, concrete supply, environmental protection, and waste management.

Equipment Components

Screw conveyor systems are typically composed of: a spiral blade (also known as a helicoid flighting or flight), a tubular casing or trough and a shaft. The spiral is coiled around the shaft, and then stored inside the tube. The shaft and coil assembly, or shaft screw, is usually driven at one end and held at the other. If it’s a "shaftless spiral,” then it’s driven at one end and free at the other. Because of this spiral design, a screw conveyor is from time to time referred to as a spiral conveyor.

Rotating screws, which are sometimes known as augers, are usually made out of spring steel, carbon steel or stainless steel. Tubes likewise are usually made out of steel, though they can also be made out of something else, like plastic or thermoplastic resin.

Operating a Screw Conveyor

To use your screw conveyor, start by installing it in your system, whether that be an exhaust drain or a wood chip machine. Make sure to set up a feed system; auger conveyors must be control fed at the inlet. Often, operators feed their systems using another conveyor or meter device, like a screw feeder, tubular drag conveyor, chain conveyor, belt conveyor, rotary valve or another screw conveyor.

Screw feeders are designed specifically for use with screw conveyors. They’re especially useful because you can program them to volumetrically meter material at a controlled rate. You can control the material volume they process down to the amount per minute. In addition to flowrate, you can control and vary blade speed.

- Notes on Safe Operation

- Check the condition of the tube's discharge port before and during operation. It should not be blocked. If it is, use adequate measures, such as an interlocked switch, level detector, or safety coupling, to fix the blockade. In a blocked condition, the screw cannot push the material as desired. As a result, the performance of the device declines.

- Make sure that the casing is adequate in size. Sometimes the size or amassing of materials gets trapped before the exit. This condition makes the auger work harder while giving a subpar performance. Such conditions occur when processing wood chips, paper waste, foam granules, and flakes of hard materials. For smooth clearance of such materials, set the screw in the casing in a suitable way so that it can apply and move the material forcefully.

- Never load the casing cross section frequently and unnecessarily, especially if the system has hanger bearings installed. The supply feed can surge because of overloading. It results in the overfilling of the screw's cross sections, which eventually affects the performance of the device. The material should not pass an open and intermediate outlet. It can contaminate the quality. As a solution, you could use an expanded outlet port that has an intermittent flight arrangement for the outlet. If you observe frequent stoppage of flight, try making adjustments in the flight offset. The new setting will allow the material to fall from the blade of the screw into the preferred space.

Design and Customization for Conveyors

When designing screw conveyors, manufacturers consider aspects like safety requirements, the type of material to be conveyed (size, flowability, density, flammability, roughness and corrosiveness), application load volume, frequency of use, and other application specifications.

Using these considerations, they decide between various materials, orientations and add-ons. For example, for food processing, they will likely make the trough and screw out of food grade rubber (UHMWPE). Likewise, for moving explosive materials, they often select anti-static UHMWPE trough and screw materials. For generic use, manufacturers usually make screw conveyor machines from steel products. Screw conveyor suppliers choose between three basic orientation designs: horizontal, vertical and inclined. The one they select depends on whether the system must transport materials linearly, up and down or on an angle.

Screw conveyors are also customizable. For example, while they are almost always stationary, manufacturers can also make them portable. They can also add features like a flexible discharge hose, wash down section, mobile base unit, right angle gear reducer, integral bag dump hopper, and/or control panel variations. In addition to these, you can also add access and inspection ports near the outlet. These access points will allow you to ensure reliable performance of your conveyor.

Safety and Compliance Standards for Conveyor Equipment

The most important safety and compliance standard certification should have is a CEMA certification.

- Conveyor Equipment Manufacturers Association (CEMA)

- There are certain parameters for sizing a screw conveyor. The capacity calculation takes into account the outside diameter of the screw, the outside diameter of the pipe, the pitch of the screw and the trough loading. The calculation determines the capacity in cubic feet per hour that will be conveyed with each revolution per minute of screw rotation. It is not necessary to memorize this calculation. Most CEMA approved screw conveyor manufacturers have the capacity calculation and the CEMA guidelines as part of their screw conveyor design software.

Things to Consider When Purchasing a Conveyor

Because there are so many types of screw conveyors out there, looking for one can be a daunting task. The best way to get what you need is by working with a reputable screw conveyor supplier, but how do you find one of those? Simple: use a directory. Of course, we can assume that, since you’re here, you already knew that. Instead, you’re looking for the next step.

Our advice is to peruse the list of high quality providers that we’ve listed near the top of this page. After checking out their capabilities and services, pick a top three or four. Then, with all of your specifications and requirements gathered, reach out to all of them. Convey your exact requirements to them separately, paying attention not only to whether or not they can do the job, but whether or not they can do it within your timeframe and budget. Also, make sure they can deliver to your area. Ultimately, the right manufacturer for you will be one that can deliver you the quality product you need without breaking the bank.

Screw Conveyors Terms

- Conveyor Screw

- The driving force of a screw conveyor, consisting of a spiral flight fused to a metal pipe that rotates within the conveyor trough.

- Discharge End

- The point of exit for conveyed materials.

- Double Pitch Screw

- Conveyor screw containing two flights.

- Flight

- The metal spiral ridges or threads on a screw.

- Flow

- A product’s direction of travel on a conveyor.

- Frame

- The structure that supports the various components of the conveyor.

- Hanger

- Screw conveyor mechanism that aids in the correct alignment of the conveyor screws.

- Helicoid Flighting

- Screw conveyor flight that consists of a continuous metal strip configured in a spiral shape.

- Horsepower

- A measure of the time rate of doing work.

- Inlet Opening

- The point of entry for conveyed materials.

- Liner

- A barrier placed between a conveyor screw and a screw conveyor component, such as a trough, to reduce friction between the screw and trough.

- Long Pitch Screw

- Conveyor screw in which the pitch is greater than the diameter of the screw.

- Motor

- The machine on the conveyor that converts electrical energy into mechanical energy.

- Multiple Ribbon Screw

- Conveyor screw containing more than one ribbon flight along the length of the screw.

- Paddle Screw

- Conveyor screw containing blades attached at different angles, depending on the industrial application, used for mixing, blending or similar applications.

- Pitch

- Distance between conveyor screw flights.

- Ribbon Screws

- Conveyor screws that contain sectional flighting and are used to prevent sticky conveyor materials from accumulating inside screw conveyor pipes.

- Sectional Flighting

- A screw conveyor flight consisting of individual bends or sections, fused together into spiral form. Sectional flighting is created by inserting a ring in a hydraulic press. It is a durable yet sometimes expensive type of fighting that is useful in tough applications, such as those in the construction and mining industries.

- Shaft

- The portion of the screw that provides support onto the flight to which it is fused.

- Short Pitch Screw

- Conveyor screw in which the diameter is greater than the pitch. Short pitches are used on inclined screw conveyors with slopes measuring 20° or greater.

- Total Load

- The total amount of material being conveyed at any particular moment in time.

- Trough

- A duct inside of which the screw is inserted and through which the materials are conveyed.

- Variable Pitch Screws

- Conveyor screws in which the pitch increases along the length of the screw.