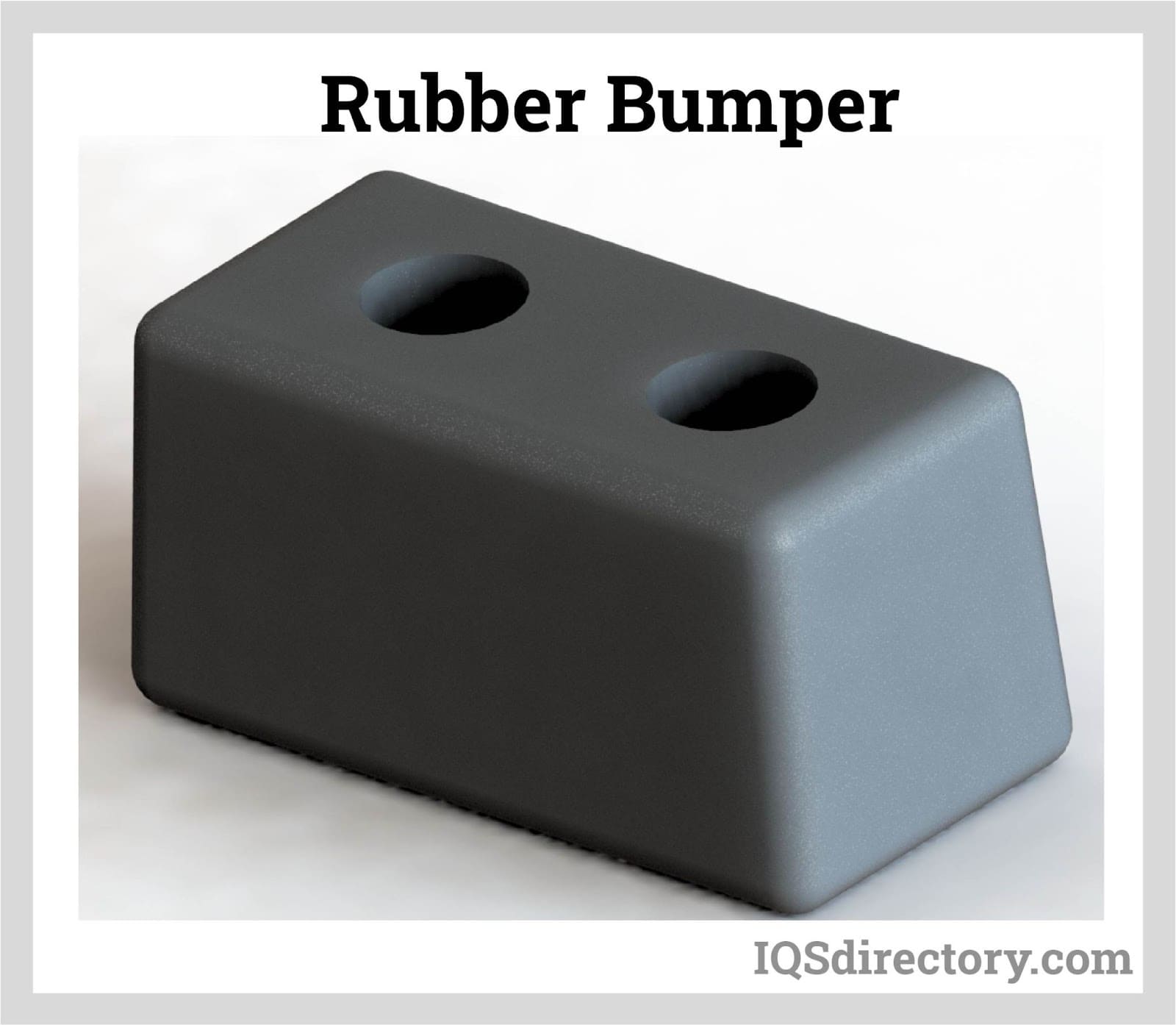

Rubber Bumpers

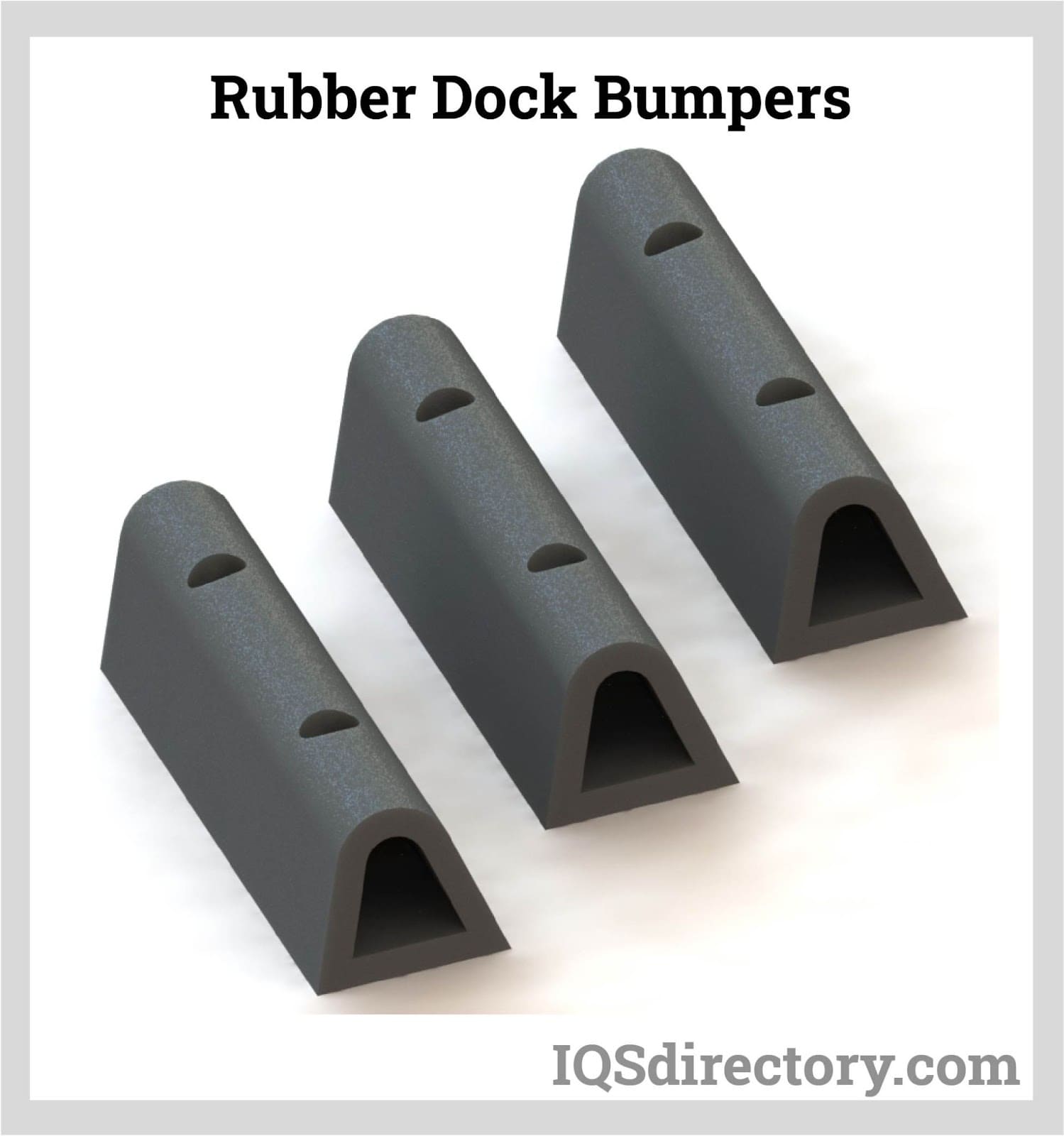

Rubber bumpers are solid rubber profiles which offer traction and shock absorption for industrial and commercial applications. Depending on an application's needs, rubber bumpers can be recessed or threaded and are composed of different rubber materials and compounds. Rubber bumpers come in various shapes and can withstand corrosion, moisture, and dust. Rubber bumpers may be used to attach to items like the feet of chairs, tables, and machinery to prevent these objects from slipping across floors. Rubber bumpers can also be inserted into walls to provide pathways for wires and cables and to separate them from one another. Rubber bumpers are typically produced through rubber molding. Under this process, rubber material is melted and poured into dies to create rubber bumpers and various other items. There are also extruded rubber bumpers (where rubber is pressed through dies to form these objects) available.

Types of Rubber Bumpers

Recessed Bumpers: Recessed rubber bumpers bumpers come with rubber feet that are mechanically attached to an item with a rivet or screw. These rubber bumpers are utilized because they provide a non-skid surface and a cushioning effect for a product.

Stem Bumpers: Stem bumpers fit into a hole that has already been drilled into the legs of furniture. They serve on the bottoms of cabinets and small boxes to avoid scratches and keep them from slipping. In addition, these plug-like bumpers can be used as a nipple or as a hole filler.

Screw-In Bumpers: Screw-in bumpers feature a hole in their core where the head of a screw is set inside. The screw is then fastened through an accompanying hole in a product.

Tack Bumpers: Tack bumpers feature a mushroom cap-design as their head which houses an outward-facing tack. They are used to dampen noise and shield surfaces from harm.

Grommet Bumpers: Grommet bumpers are round with a head featuring a wider diameter. They fit into pre-drilled holes in walls and are used to run wires and cables through. The rubber material protects wires from any rough edges that would otherwise be found inside a hole.

What to Consider When Buying Rubber Bumpers

Rubber bumpers may take a variety of hemispherical, hexagonal, oval, rectangular, and square shapes. They often work best when paired with rubber roll stock which further reduces their ability to slip. When selecting the appropriate type of rubber bumper, one should consider the following aspects.

Dimensions: The dimensional characteristics of bumpers are categorized by head height, head diameter, stem length, stem width, and overall thickness. Rubber bumpers are found in an array of dimensions which all reflect a specific application. As mentioned above, dimensions are also dependent on the specific type of bumper.

Construction Material: Rubber bumpers may require more hardness or more elastic qualities depending on their application. There are rubber bumpers which are hard, rigid, and pressure resistant, or, depending on the material used to construct them and their intended application, others which are softer and more flexible.

Compatibility Charts: Rubber bumper manufacturers should provide compatibility charts for their products listing what, if any, substances may damage the bumper when it comes into contact with its rubber material.

Rubber Bumper Features

Rubber has great traction. This traction allows rubber bumpers to be used in various applications as a non-slip material. Rubber bumpers are reasonably priced and prevent potentially expensive machinery repairs and replacements that can result from sliding on factory floors.

Rubber, like most materials, will eventually deteriorate and rubber bumpers will need to be replaced occasionally to provide equipment with the best protection. Some manufacturers will custom-color their bumpers to match particular goods or equipment. Bumpers are normally available in either black or dark gray but, along with size, shape, and pad configuration, color requests can also be accommodated. Rubber bumpers may include a metal washer or other component in their base to promote longer periods of use for heavy-duty industrial applications. Rubber bumper pieces designed for factory equipment are sufficient for most ordinary industrial uses and may also practically serve shock absorption needs. Many rubber bumpers come with a backing sheet and are self-adhesive. The strength of an applied adhesive can range from industrial-grade adhesive to a less permanent glue, depending on the intended application.

Application of Rubber Bumpers

- Rubber bumpers are used across various industries during their manufacturing processes to regulate vibrations of their equipment, including electronics, medicines, communications, consumer products, and more.

- Rubber bumpers are frequently used in automotive components, POP displays, circuit boards, and computers to protect furniture, work surfaces, and structures.

- Rubber bumpers are used to shield floors from nicks and scratches made by machinery, equipment, or pieces of furniture.

- One can protect an item through rubber bumpers while moving it directly across a floor.

- Rubber bumpers also prevent fraying in wires and cables. Rubber bumpers provide padding for wires and cables as they are run through holes in walls with potentially rough edges. Additionally, these wires can be run through the entire length of a rubber bumper for increased protection.

- Rubber bumpers are often used as spacers between a machine’s parts or between two separate pieces of equipment in order to prevent them from coming into contact with one another.

Advantages of Rubber Bumpers

- Rubber bumpers provide ventilation and space while protecting an items’ surfaces and the surface upon which they are set.

- An equipment's vibrations can be reduced by using a bumper.

- Additionally, a rubber bumper prevents equipment slippage.

- Rubber bumpers guard surfaces against scuffs and sliding.

- Rubber bumpers can be produced in any color that is needed.

Choosing the Correct Rubber Bumper Supplier

To make sure you have the most productive outcome when purchasing rubber bumpers from a rubber bumper supplier, it is important to compare at least 5 suppliers using our rubber bumper directory. Each rubber bumper supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each rubber bumper business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple rubber bumper businesses with the same form.