Vibration Isolator

Vibration isolation is the process of protecting a piece of equipment from sources, typically mechanical sources, of vibration. Mechanical vibration is caused by the looseness of machine components, misalignment of parts, or by having equipment improperly imbalanced on the flooring below. Mechanical vibration is harmful to machinery and can be dangerous to those working with such equipment and the products being created. Vibration isolators are pieces of equipment used to protect machinery, people working with such equipment, and the products being created from the potentially harmful effects of mechanical vibration. Some vibration isolators absorb and dampen mechanical waves. Other vibration isolators feature sensors and actuators to actively produce disruptive interference to cancel out incoming vibration, also referred to as active vibration isolation.

Passive Isolation

In contrast to "active vibration isolation" or "electronic force cancellation," which uses electric power, sensors, actuators, and control systems to cancel vibrations, "passive vibration isolation" refers to vibration isolation or the abatement of vibrations through passive means such as rubber pads or mechanical springs. Typical applications include protecting factory equipment like pumps and motors, as well as your home’s HVAC system and washing machine. In rare instances, passive vibration isolators are employed to protect priceless pieces of artwork and statues and lab equipment from earthquakes.

Frequently-Used Passive Isolation Systems

Pneumatic Air Isolators

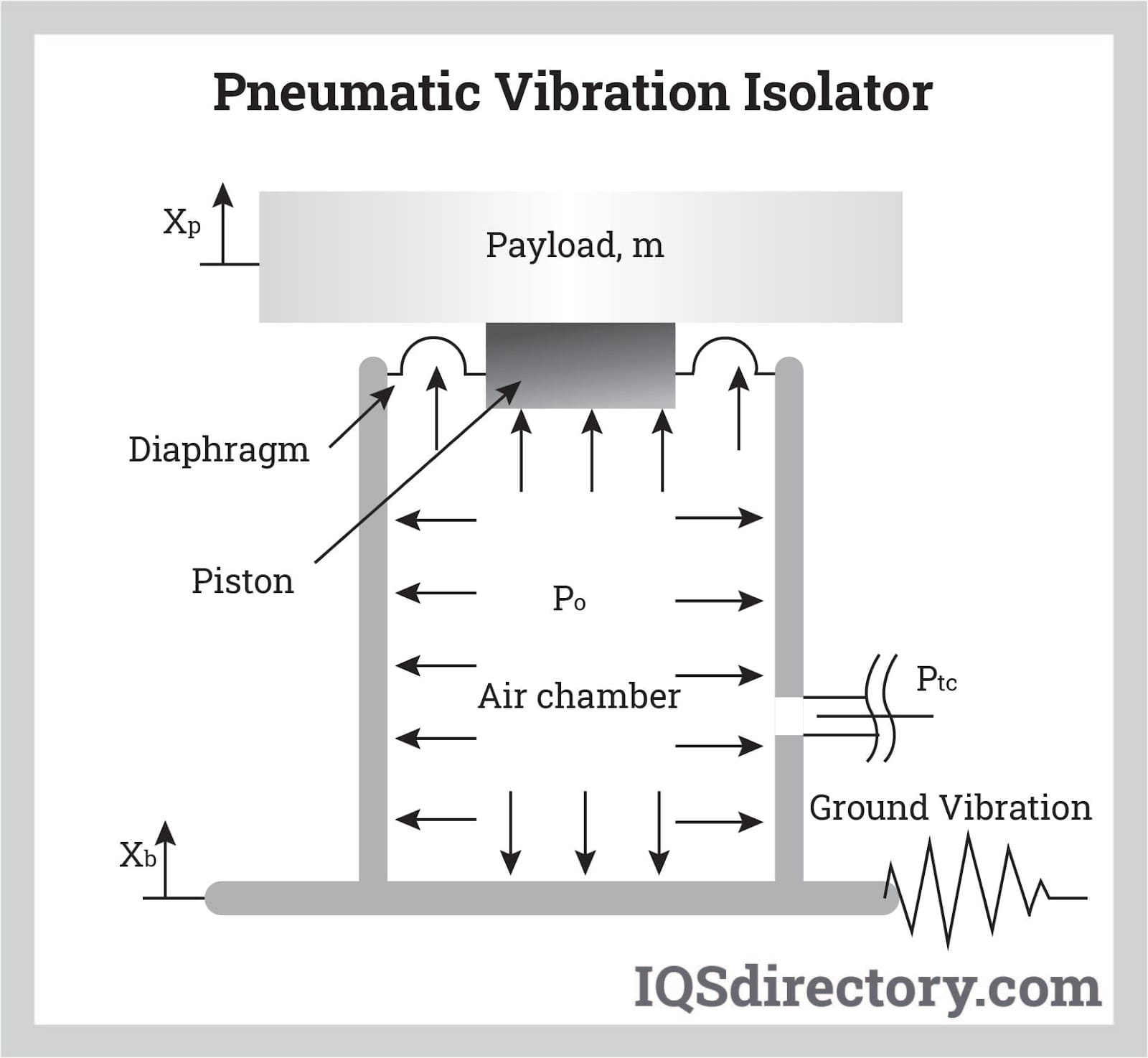

Pneumatic air isolators are essentially compressed air bladders or canisters and require compressed air to keep them running. Pneumatic air isolators feature a piston that moves between air chambers, which are connected by a small orifice. The piston produces a damping effect, or reduction in a vibration’s amplitude of oscillation and resulting energy, on a payload by its repeated up-and-down movement and forcing air through the orifice. Pneumatic air isolators are often used to provide massive industrial equipment with low-frequency isolation. However, these bladders can eventually succumb to air system leaks, preventing them from providing low-amplitude vibration isolation.

Springs and Dampers

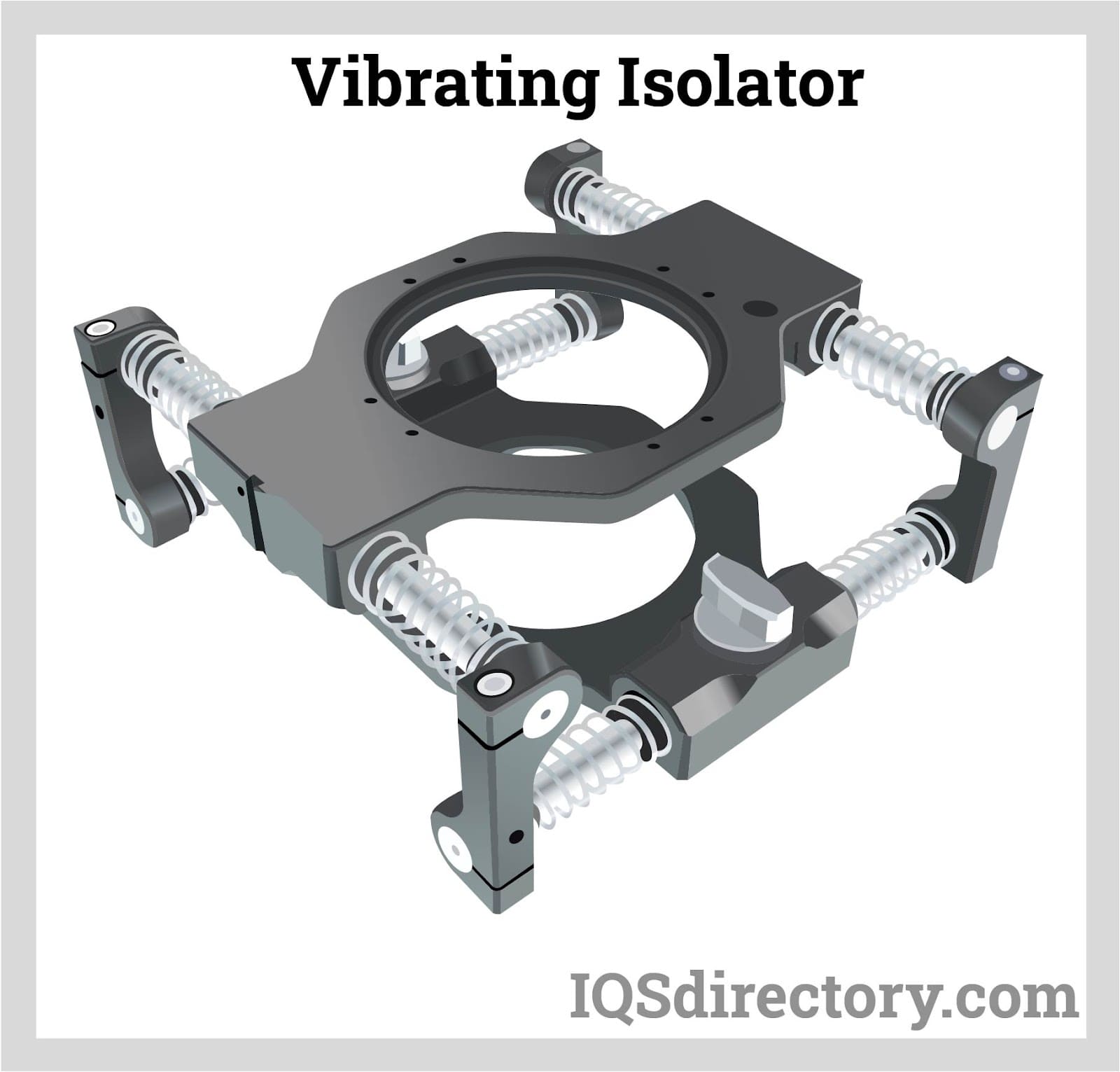

Dampers work in combination with springs to dampen hydraulic forces and reduce vibrations. Dampers are oil-filled tubes with a piston that is filled with nitrogen. The nitrogen keeps the piston moving by pressurizing the oil. When needed, the nitrogen also acts as an additional “spring” by smoothing out damping effects. Dampers are typically made from high-strength steel and feature elastomeric seals to prevent leakage.

Springs and dampers serve as heavy-duty isolators in industrial applications and in building systems to control floor vibration and building movements. Occasionally, the spring and damper combination serve as mounts to limit the movement of concrete blocks.

Negative Stiffness Isolators

Negative stiffness isolators are a purely mechanical passive isolator. Negative stiffness isolators use a combination of springs and columns to provide isolation from vertical and horizontal movements caused by vibrations. These isolators are often used in research applications such as gravity wave detection.

Elastomeric/Rubber Isolators

Elastomeric/rubber isolators are made from various metals and rubber components depending on their specific application. These isolators are designed to provide protection from seismic vibrations. They are used with panel boards and wall-mounted equipment like TVs and computers. Elastomeric and rubber isolators and mounts that have been molded and bonded

Factors Affecting Passive Vibration Isolators

The effectiveness of any vibration isolator is impacted by a variety of factors. We take a closer look at some of these better-known considerations below.

Size: The size of an item requiring isolation dictates both the type of device available and, potentially, the number of isolators required to perform the job. Smaller objects might need one isolator, but larger objects might need a system with numerous isolators.

Weight: Considering an object's weight is crucial when selecting the best passive isolation product for an application. Each passive isolator is designed for a certain range of intended loads.

Moving Parts: Isolation systems may be impacted by machines or instruments having moving parts. The moving parts' mass, speed, and distance traveled should all be examined since they can all have an impact on a machine’s vibrations.

Industrial Operating Environment: Dust, smoke, steam, and other items floating in an isolator’s operating environment can all affect its efficiency. Likewise, there are corrosive chemicals present in some situations that may cause isolator components to rust or deteriorate. Water and salty outside surroundings must also be taken into account when choosing a vibration isolator.

Vibrations: Vibrations caused by nearby machinery, foot activity, automobile traffic, or HVAC airflow might occasionally disturb the ability of a vibration isolator to function properly.

Temperature: Isolators are typically designed to function in a temperature range that people consider comfortable. An isolator’s design might need to be altered if a wider temperature range is required.

Advantages of Vibration Isolation

Vibration isolation is a crucial component of many manufacturing processes since uncontrolled motion causes unnecessary wear and tear on machine components and can result in various issues, including equipment malfunction, dangerous working conditions, and inaccurate product creation. As a result, using vibration control parts has benefits such as lower maintenance costs, greater worker safety due to the equipment being less prone to wear and tear, and higher production because machinery can often run at faster rates if vibration and deceleration are controlled. Likewise, vibration isolators can extend the life of equipment used at home, such as washers and dryers, and limit the potential damage to walls and floors where these appliances are housed.

Conclusion

Vibration is a series of oscillations that move at a cyclic speed at various frequencies, and it can originate from internal and external causes. An unbalanced relationship between equipment's parts frequently results in internal vibration. A machine or gadget can be equipped with vibration isolation devices to maintain stability. By isolating the equipment to which they are attached, vibration isolators stop vibrations from spreading to other parts of the equipment and beyond. Elastomeric materials, such as rubber mounts or pads, are frequently employed as vibration isolators because they are inherently non-slip. This material prevents vibrations from causing a machine to move. Instead, the rubber between the machine and the floor absorbs the energy. Vibration isolators are popular because they are affordable, simple to install, and have a long lifespan. Furthermore, they expand the lives of machinery, promote worker safety, and reduce production errors. The size, weight, and kind of elastomer most appropriate for a specific application must all be considered when selecting a vibration-isolating system. Other relevant aspects to consider when selecting a vibration isolator include the substances, such as chemicals and oils, that the isolator may be exposed to and other stimuli such as shock and noise that may impact the equipment.

Choosing the Proper Vibration Isolator Manufacturer

To make sure you have the most positive outcome when purchasing vibration isolators from a vibration isolator manufacturer, it is important to compare at least 4 companies using our list of vibration isolator manufacturers. Each vibration isolator manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each vibration isolator company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple vibration isolator companies with the same message.