Laser Cutting

Laser cutting is a low-distortion hot cutting process that most commonly uses a CO2 laser for the cutting of material, usually metal or sheet metal. Thus, a laser is sometimes also called a metal laser.

"Laser" is an acronym for Light Amplification by Stimulated Emission of Radiation; it emanates a light that contains a decent amount of electromagnetic radiation. This extremely focused radiation of a wavelength does not dissipate like conventional light beams. A laser beam is way stronger and denser than any other type of light that we have known so far. The beam emission device can be programmed and the intensity of the laser beam can be manipulated according to the requirements of the application.

Quick links to Laser Cutting Information

The History of Laser Cutting

As far as technology goes, lasers are a fairly recent invention; while their foundation stretches back to the theories of Einstein in the early 1900s, the first laser was built just a little over fifty years ago, in 1960, by Theodore H. Mainman. The first laser cut material on an industrial scale in 1965. Made at the Western Electric Engineering Research Center, it was used to drill holes into diamond dies. Two years later, in Great Britain, engineers developed the first laser-assisted oxygen jet cutting systems. They were used in sheet metal fabrication and cutting.

In the early 1970s, this metal laser cut technology was adapted for custom laser cut services, such as aerospace titanium cut services. Also, in the 70s, engineers used CO2 lasers to cut non-metal materials, like textiles. At that time, the CO2 cut laser was too weak to cut through metal.

Since then, laser cutting technology has grown by leaps and bounds. More recent improvements include: power efficiency increases, cost reductions, new wavelength bands, and more. Today, laser cutting can be used in surgery, weapons technology, and intricate machining. We predict that, as science and engineering continue to march forward, so will laser cutting services.

The Benefits of Laser Cutting

Using lasers to cut and machine metal has distinct advantages over conventional cutting processes like thermal machining, mechanical machining, arc welding, EDM and flame cutting. Let’s go over some of those advantages below.

- Laser Cutting Quality

- First, laser cutting systems have very high levels of beam control and motion stability; these allow them to produce products with an extreme edge quality. In addition, laser-cut parts have nearly zero edge deformation and zero roll-off or edge factor, leaving very little burring on part edges.

- Accuracy of Laser Cutting

- Laser cutting services offer neither quite as much cost efficiency as cold-water jet cutting, nor the completely burr-free finished edging of water jet cutting processes. Nevertheless, laser cutting is capable of creating tighter accuracies on a smaller scale than any other type of metal cutting process.

- Laser Cutting Turnaround Time

- Laser cutting is faster than conventional tool-making techniques and has a quicker parts turnaround time, regardless of complexity. This is because the service allows for easy accommodation of design changes.

- Laser Safety

- Although laser cutting systems release a potentially dangerous CO2-based laser beam, if protocol is properly followed, they do not pose any threat of damage or human injuries during operation. Furthermore, because they are controlled by CNC machining, laser cutters require few technicians on the floor.

- Of course, the machines do need to be handled with extra care, especially when you are working on materials that are prone to catch fire. Also, any operators that go near the laser need to wear proper protective eye gear.

- Cutting Versatility

- Many different kinds of laser cutting services are available, all of which make highly efficient use of materials, creating little waste.

- Ease of Maintenance

- Laser cutting and engraving systems require little maintenance. You can easily maintain your premises and materials by simply ensuring proper ventilation in the working area and making sure that no flammable gases or chemicals (droplets) are there in the atmosphere. For this, we recommend a robust and efficient air filtration system installed at your place.

- Energy Efficiency

- Laser cutter, laser cutter engraver, and laser drilling machines do not consume much energy. Instead, they are rather energy efficient, and save you money on your power bill.

Laser Cutting Design

When designing your custom laser cut product, manufacturers take a variety of factors into consideration. These include: required tolerances, required thicknesses, best material, best laser cut system, the sharpness and cleanliness of the laser cutter, and the position of the nozzle or head.

- Cutter Cleaning

- By checking that the lens, or cutter, is adequately cleaned, laser cutting services try to make certain that their process machine is ready to perform the material cutting task. Most importantly, they have to make sure that their lens or cutter is in good and working condition.

- Nozzle Position

- To test out whether the nozzle is in the center, the laser cutting service provider takes a thin tape and broadcasts a low-intensity laser beam on it. Then, they check if the hole created by the beam is at the desired place. This particular test helps them in determining that their laser drilling machine is ready to use.

- Manufacturers offer a wide range of custom laser cut services. To give you the tolerances and part thickness that you want, they can tweak elements of their laser system, including cut speed, assist gas, CNC laser cut programming inputs, the heat-affected zone, etc.

Laser Cutting Images, Diagrams and Visual Concepts

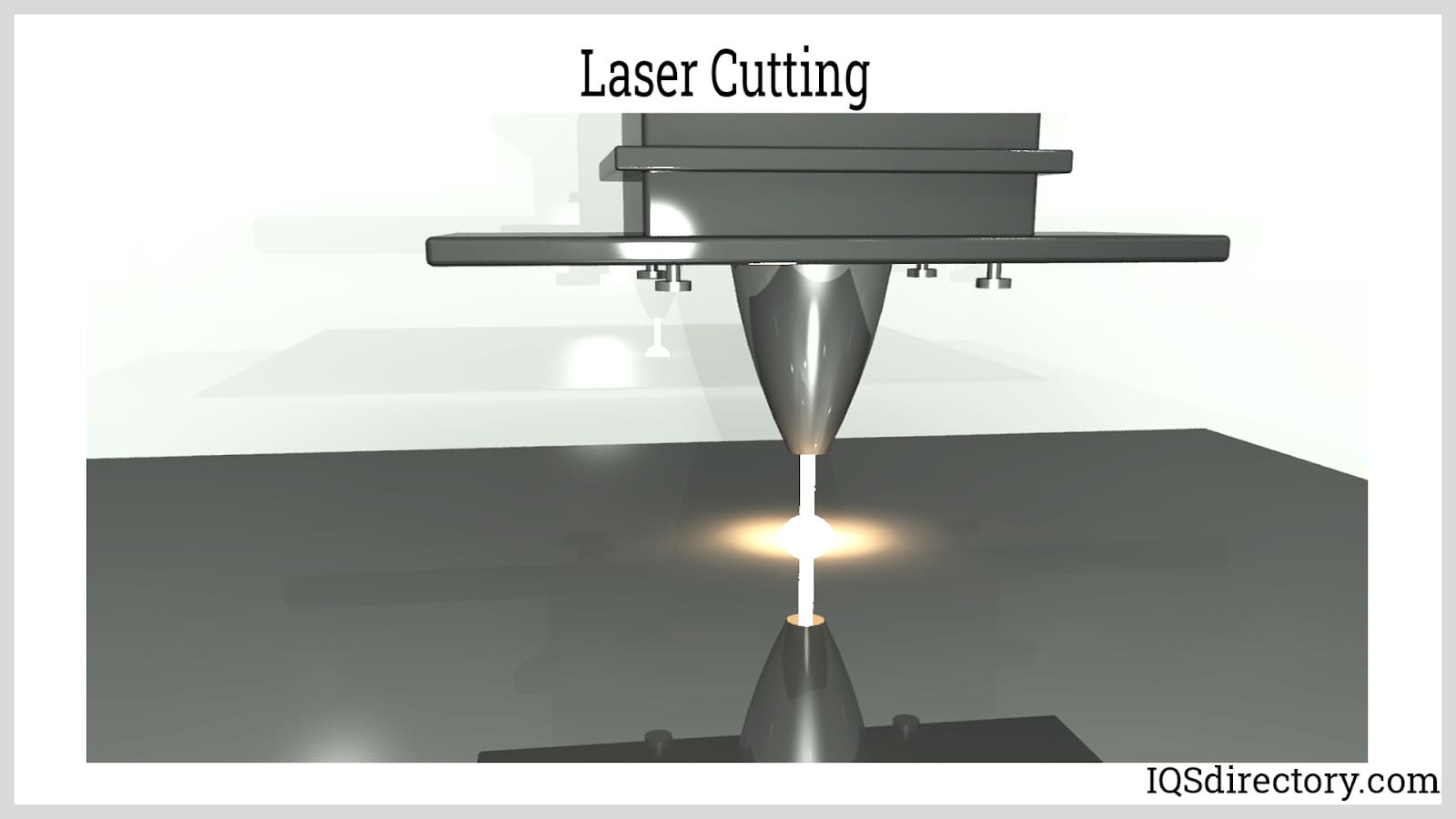

Laser cutting is material-cutting that uses an intensely focused laser to cut metals, paper, wood, and acrylics.

Laser cutting is material-cutting that uses an intensely focused laser to cut metals, paper, wood, and acrylics.

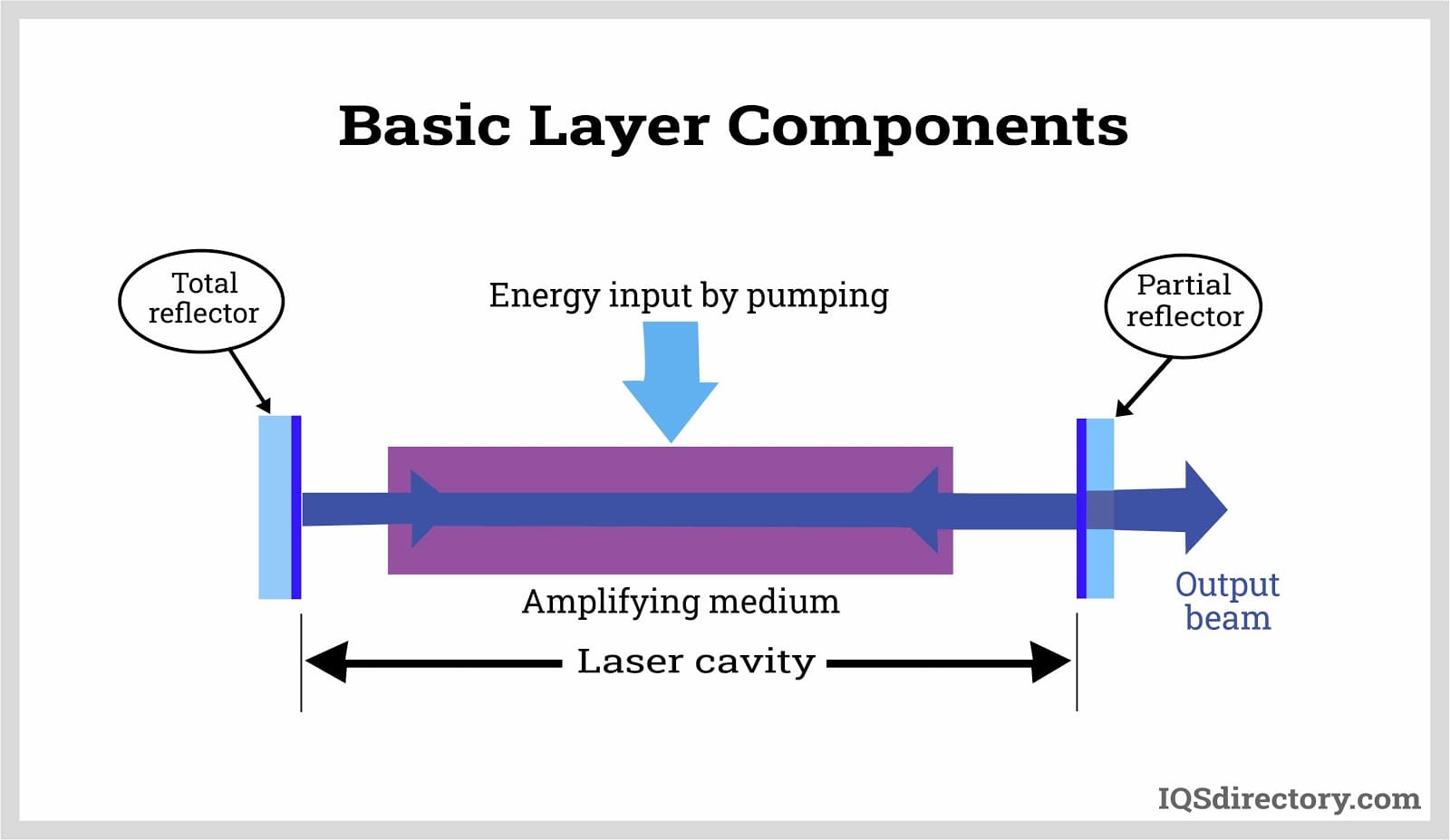

Lasers are generated by a high-intensity light source inside a reflective laser cavity, which contains a laser rod to generate radiation.

Lasers are generated by a high-intensity light source inside a reflective laser cavity, which contains a laser rod to generate radiation.

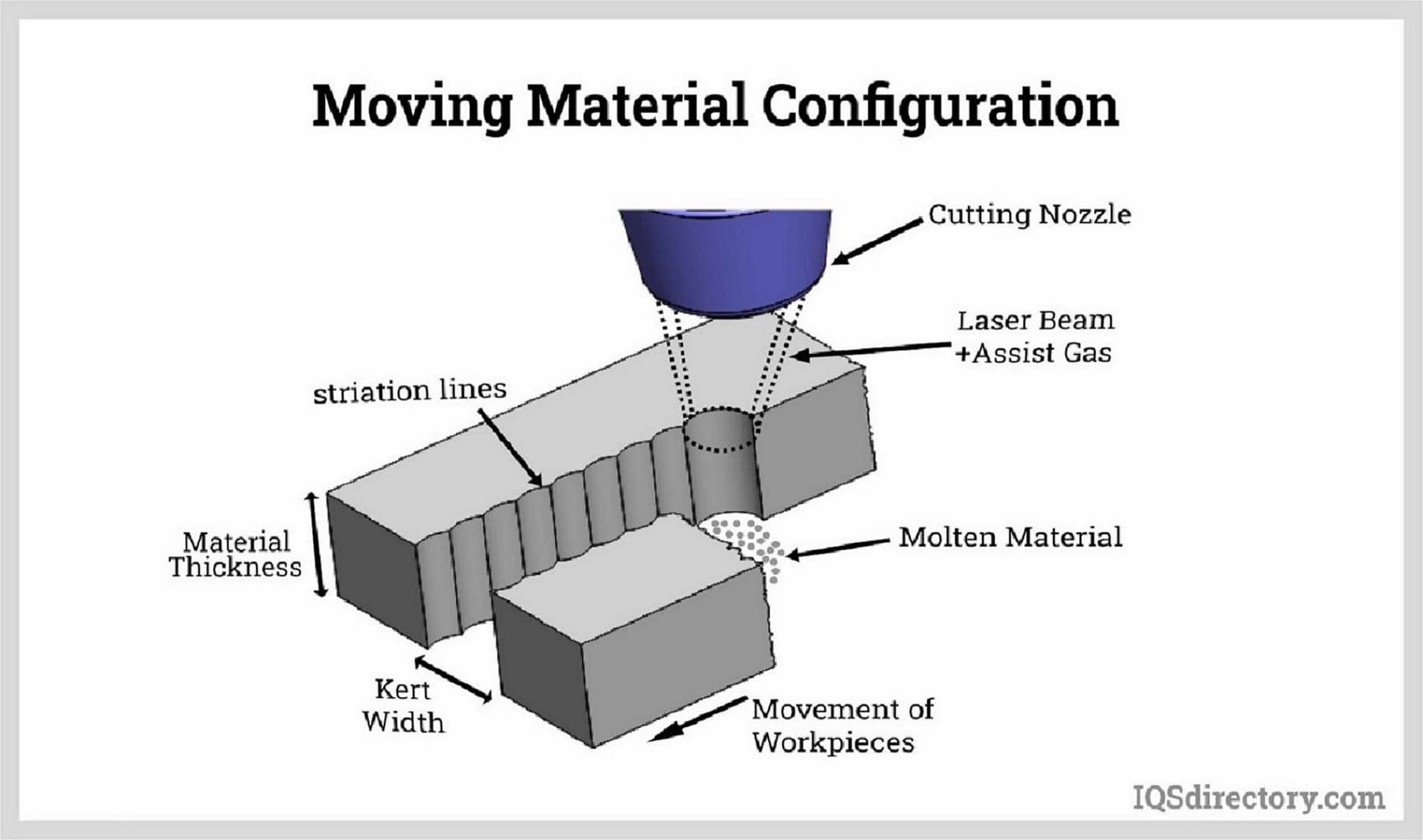

The laser cutter is stationary while the material surface moves.

The laser cutter is stationary while the material surface moves.

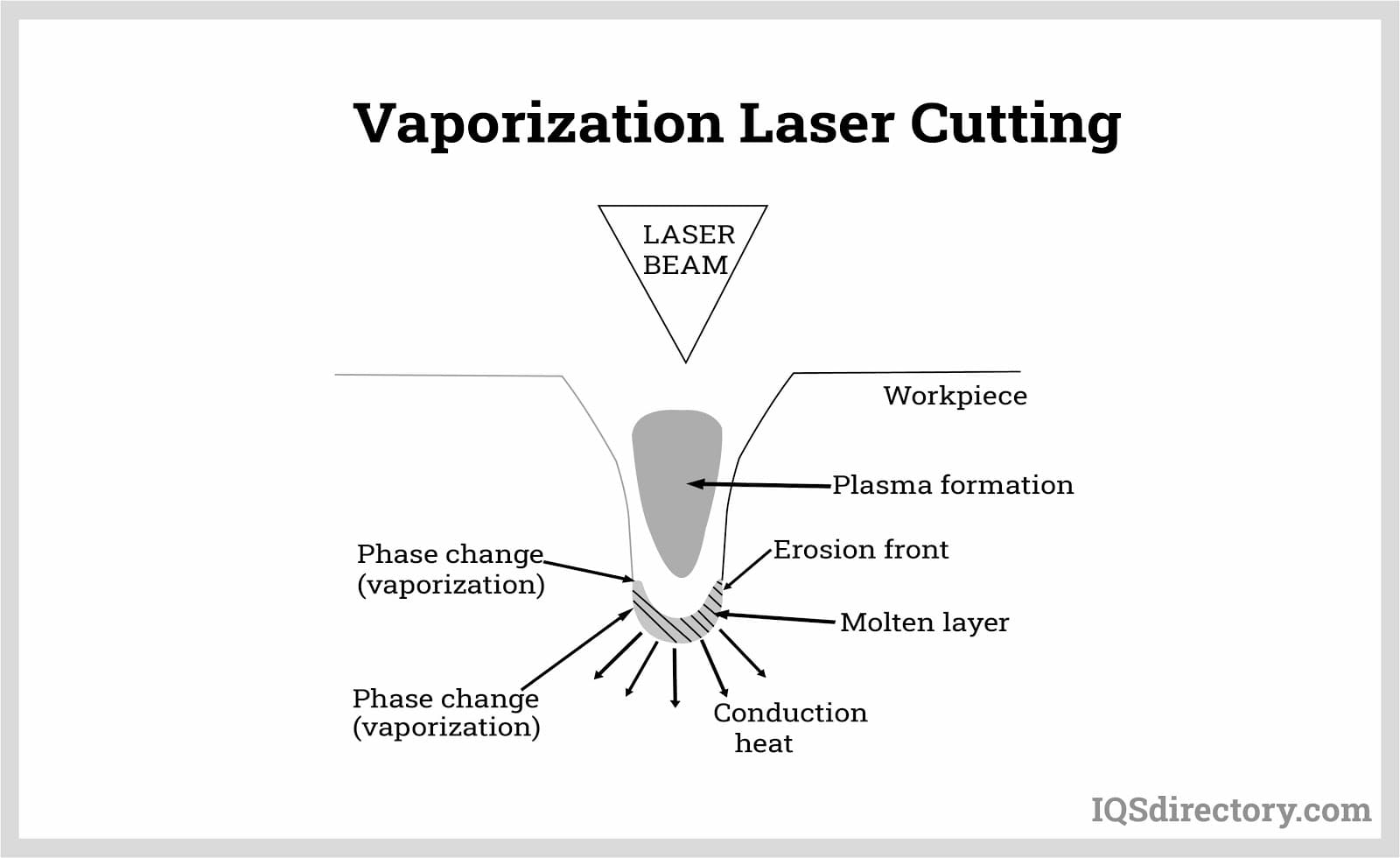

Vaporizing laser cutting changes the state of the material to a gaseous state.

Vaporizing laser cutting changes the state of the material to a gaseous state.

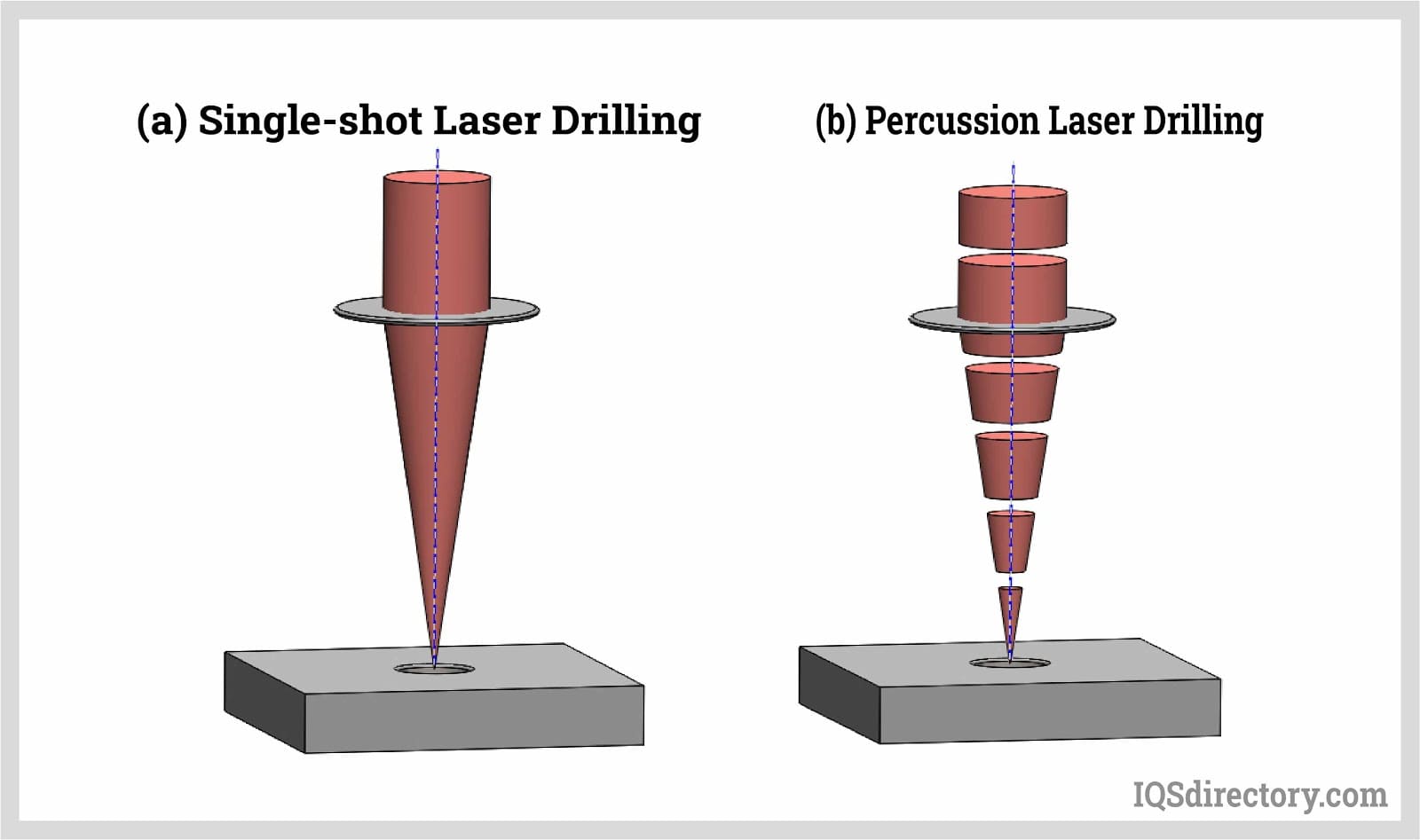

Percussion drilling allows the laser beam diameter to be the same as the hole diameter.

Percussion drilling allows the laser beam diameter to be the same as the hole diameter.

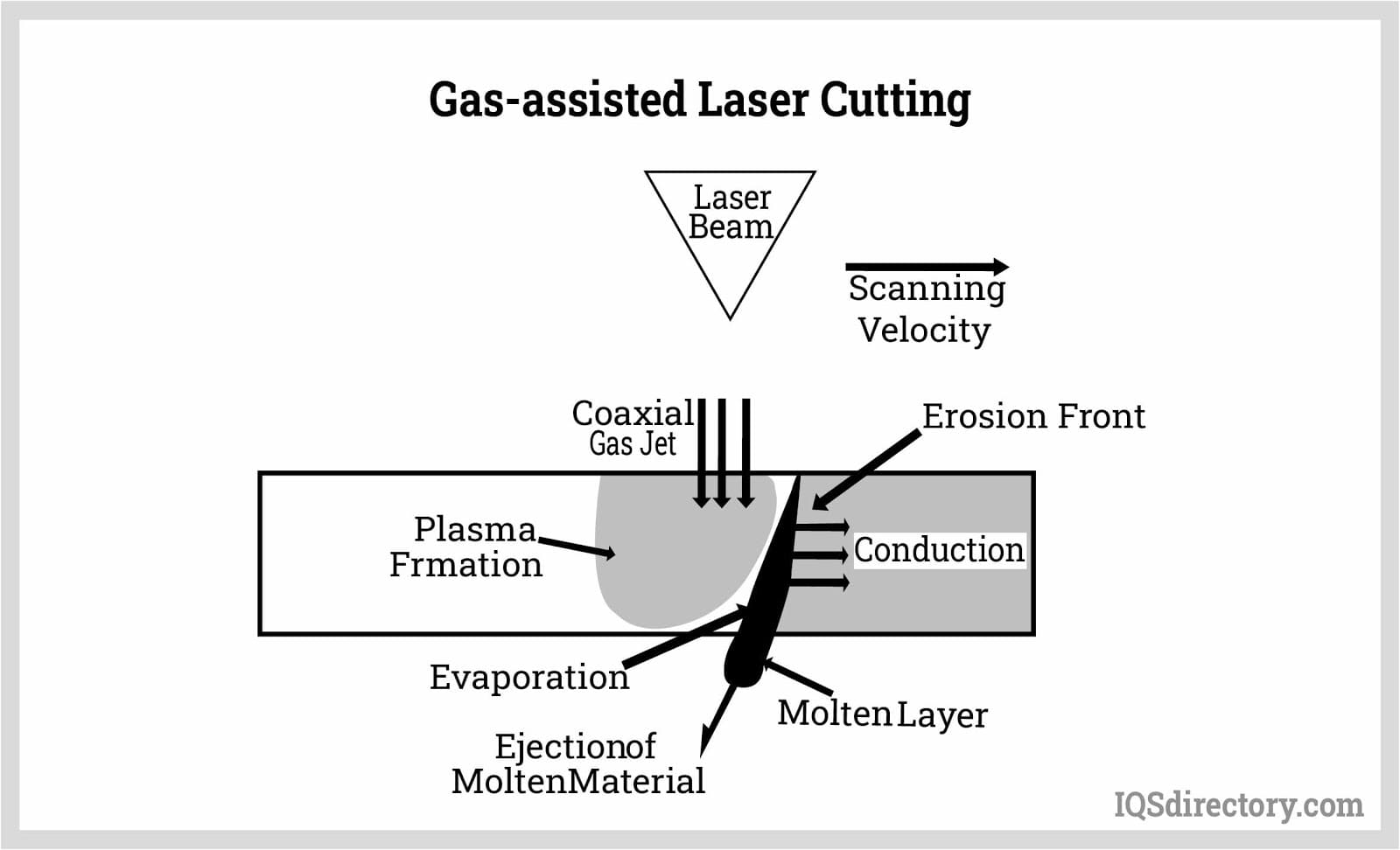

Using a jet of gas with the laser beam expels the material from the cut.

Using a jet of gas with the laser beam expels the material from the cut.

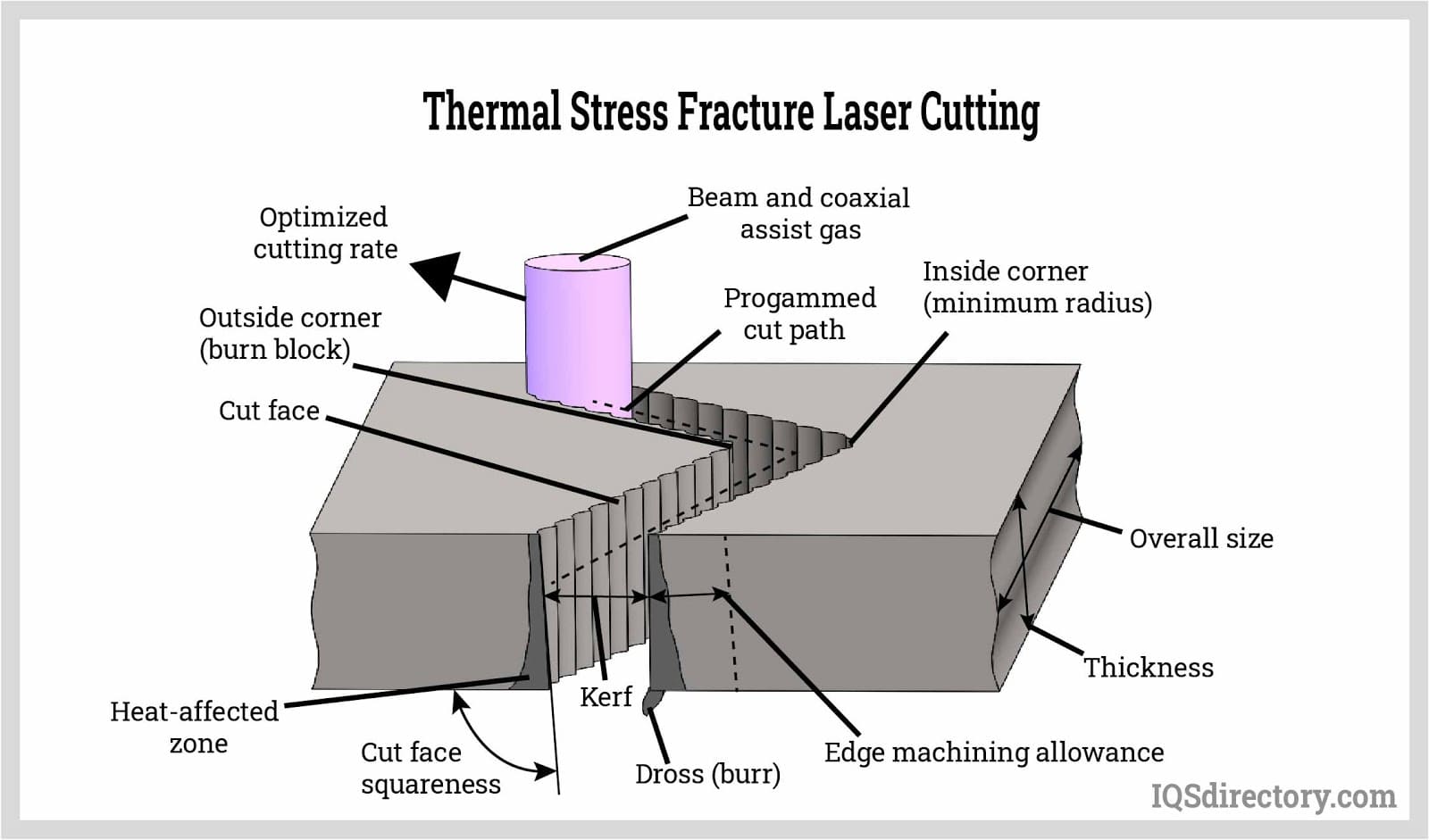

A process that involves introducing a small kerf at about one-third the thickness of the material using a laser.

A process that involves introducing a small kerf at about one-third the thickness of the material using a laser.

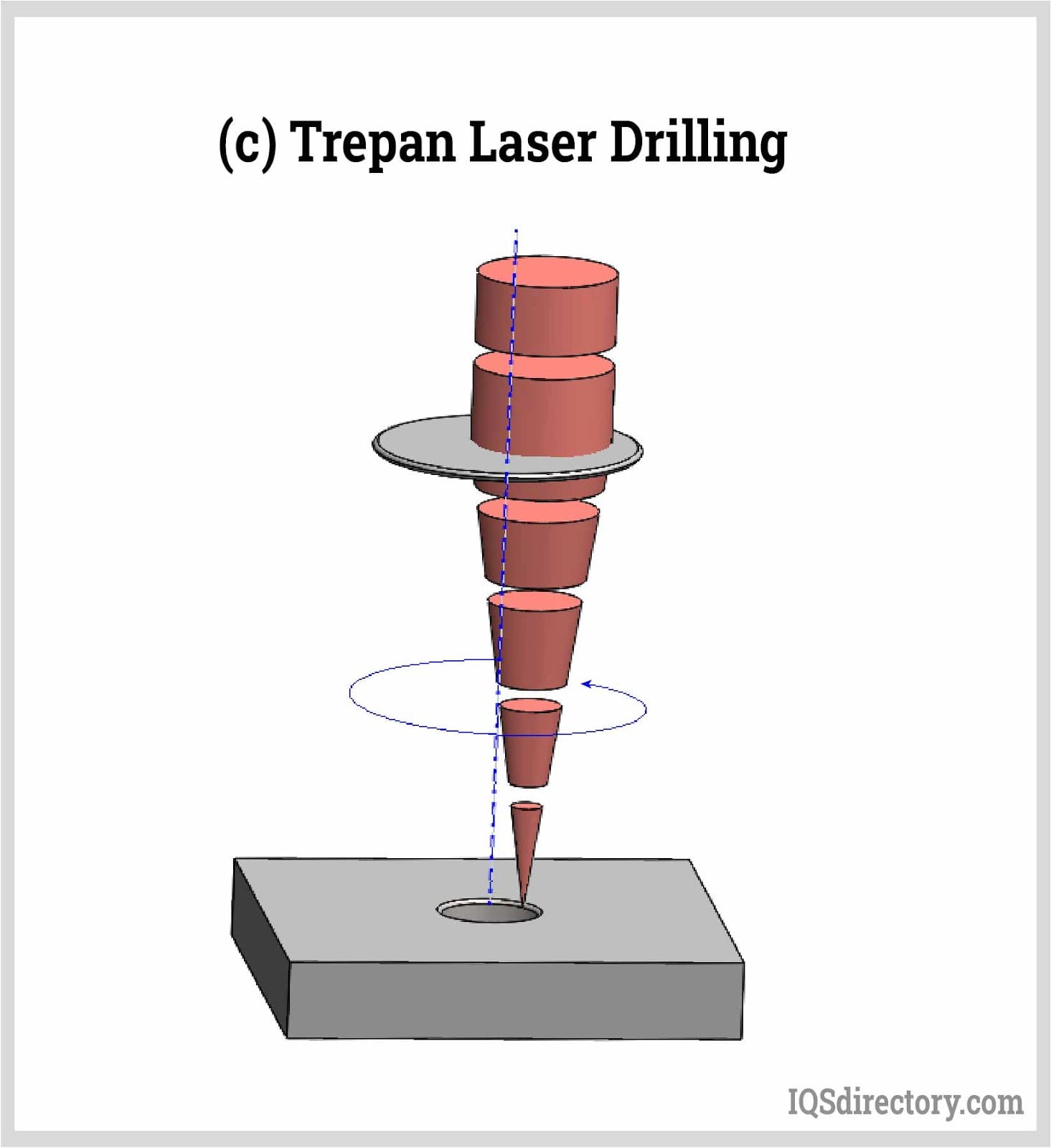

Trepan laser drilling, the laser spot size is significantly smaller than the hole size then traverses around the hole, expanding the drilled hole to the desired diameter.

Trepan laser drilling, the laser spot size is significantly smaller than the hole size then traverses around the hole, expanding the drilled hole to the desired diameter.

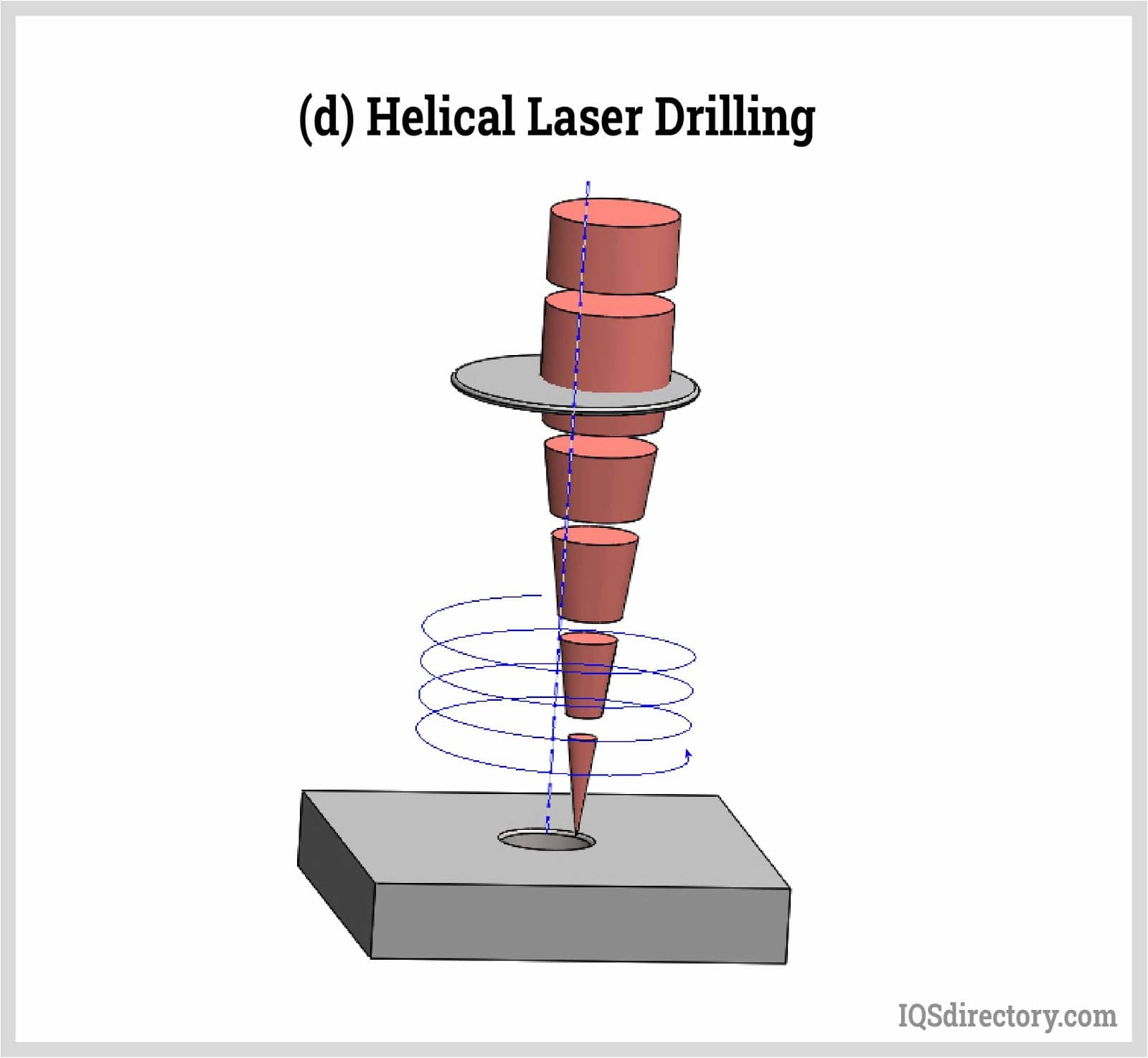

Helical laser uses a moving laser that rotates relative to the workpiece like a conventional drill bit.

Helical laser uses a moving laser that rotates relative to the workpiece like a conventional drill bit.

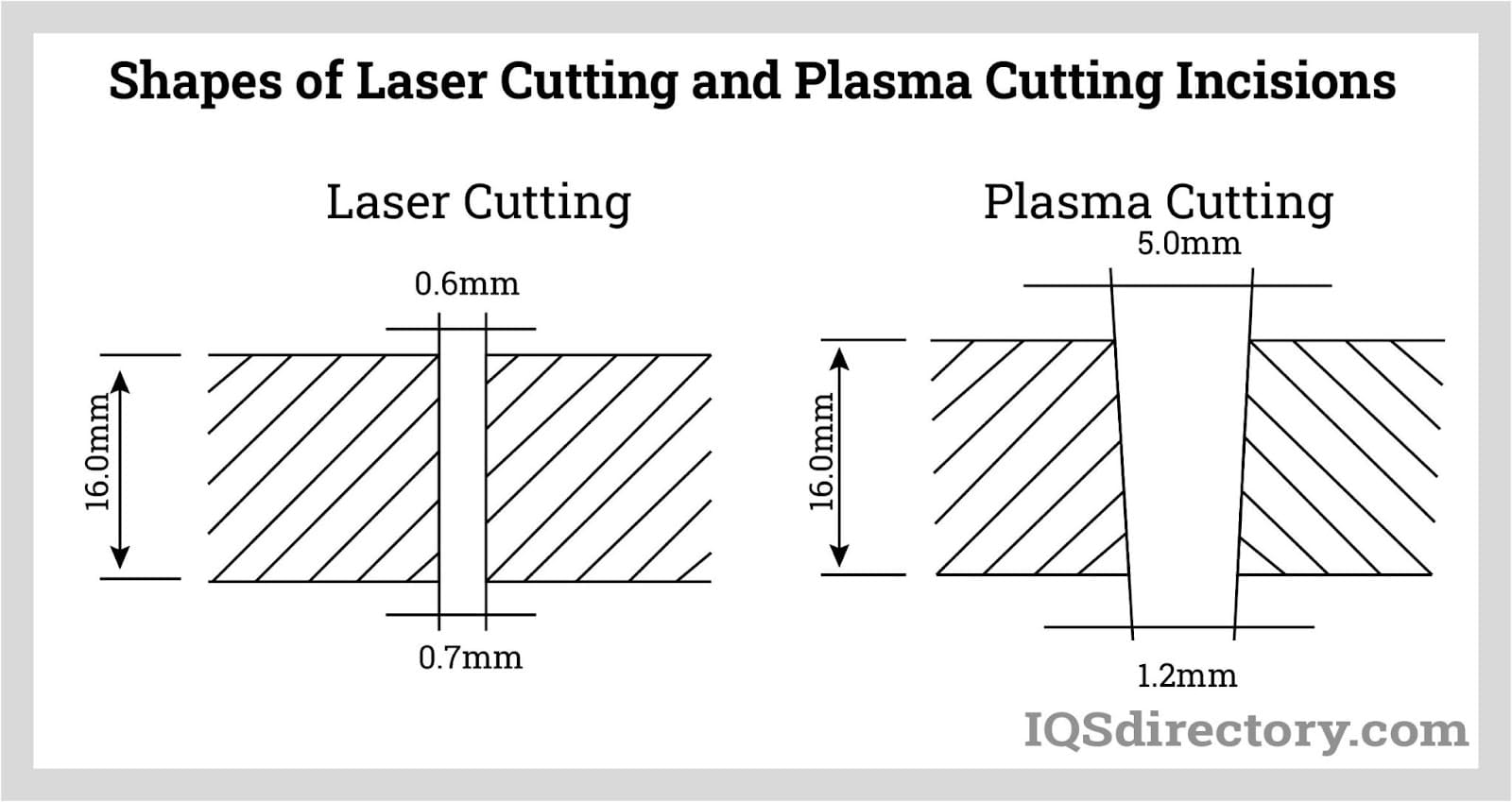

The difference between the two processes is the fuel to power the cutting process with plasma cutting using a plasma gas, while laser cutting involves a beam of light.

The difference between the two processes is the fuel to power the cutting process with plasma cutting using a plasma gas, while laser cutting involves a beam of light.

Laser Cutting Types

- CNC Laser Cutting

- A process that uses an intense laser beam to cut part shapes out of sheet material. The parts remain flat because the heat distortion is minimal.

- CO2 Laser Cutting

- A process that uses carbon dioxide as the main lasing medium. CO2 lasers use a mixture of gases—such as helium and nitrogen, with CO2 being the most predominant—to create a cut quality similar to that of milled edges of mild steels and can operate in continuous wave (CW) or pulses.

- Custom Laser Cutting

- Always done with CNC machining programs that are custom programmed to design unique designs exactly like the buyer desires.

- Evaporative Laser Cutting

- The process of ablating target materials, typically low vaporization temperature and low thermal conduction materials, through direct vaporization.

- Excimer Laser Cutting

- A process that uses the noble gas compounds for lasing. Excimer lasers generate light in ultraviolet to near-ultraviolet spectra.

- Gas Laser Cutting

- A process in which gas is used as the activating agent.

- Nitrogen Cutting

- Or inert gas cutting provides cut edges covered with melted and resolidified metal composed of the same metal mixture of the material. Thus it has the same resistance to corrosion and is useful for food processing facilities, chemical plants and sign production.

- Laser Cutters

- Perform all the services and all of the processes that cut metal or other materials with lasers to create precision products.

- Laser Drilling

- The process of creating a hole in material with a laser beam.

- Laser Engraving

- Uses lasers to etch into a surface.

- Laser Etching

- The process of marking the material without cutting all the way through using reduced power.

- Laser Machining

- The removal of material brought about by laser material interaction. Laser machining is a term that includes laser drilling, laser cutting, laser grooving, laser marking or laser scribing.

- Laser Marking

- A process in which material is indelibly marked at very fast speeds (milliseconds per character). Laser marking is flexible, programmable and environmentally clean.

- Laser Metal Cutting

- Involves lasers cutting the most common material used to produce machining products: metal.

- Laser Micromachining

- A process used to create extreme detail and to cut very precise components that require close tolerances.

- Laser Welding

- The process of using a laser beam to connect two or more pieces of metal together by melting the areas to be joined and allowing them to resolidify.

- Liquid Laser Cutting

- The process in which large organic dye molecules are used as the active lasing medium.

- Melt Shearing

- Also known as "fusion," is the laser cutting process that creates a melt, which a gas jet blows out of the melt zone, typically with air. The resultant cut edge is of high quality but is covered with microscopic ripples.

- Moving Optics Laser Cutting

- A process in which mirrors are used to reflect the laser beam to the cutting head while the workpiece material remains fixed.

- Multi-Axis Laser Cutting

- A kind of laser cutting utilizing multiple axes instead of one. The advantage of multi-axis laser cutting is the capability of cutting three-dimensional shapes, while the disadvantages are the higher expense over flatbed cutting, longer set up times and increased safety hazards.

- Oxygen Assist Cutting

- A process in which the oxygen does the actual cutting, and the laser beam maintains the reaction.

- Pulsed Laser Cutting

- A cutting process that uses single or train pulses, as opposed to continuous wave lasers. These pulses supply greater power at shorter intervals.

- SemiConductor Laser Cutting

- A process utilizing semiconductor materials as the active medium.

- Solid State Laser Cutting

- A process in which the active medium of the laser (typically not semiconductor lasers) is in a solid state.

Laser Cutting Process

To control a laser cutter process, engineers and technicians use laser optics and a computerized or computer-controlled device to cast a programmed and well-controlled laser beam onto the material which has to be cut. CNC laser systems use CAD designs to input all the necessary machining details into a computer program that then fully directs the laser cutting process, requiring a minimal staff to simply oversee the production and make sure the machines are well maintained.

To cut the programmed pattern, either the beam or the workpiece can move. As one or the other does this, the focused beam melts material in a localized area. To direct the light of the laser, manufacturers use mirrors or fiber optics to point the beam to the lens, through which it focuses. They program the laser cutter to stimulate a laser material via electrical discharges or lamps within a closed container. As it is stimulated, the beam is reflected internally against a partial mirror. This continues until it has enough energy to escape as a monochromatic, coherent stream of light.

Assist gas such as nitrogen or carbon dioxide is used in conjunction with laser cutting to prepare newly cut surfaces for painting or corrosion resistance. When done with a tube laser, the gas is placed inside the laser tube. An example of the gas assist laser technique is CO2 laser cutting, which is considered the most powerful wave laser technique. In addition, for large and critical applications, manufacturers will couple a speed control system with the emission device. This way, the laser is controlled and considered safe for various industrial applications.

Laser Cutting Applications

In general terms, laser cutting is a value-added service that helps you to cut, slice or chip, melt, and vaporize a wide variety of materials. Various industrial processes would remain incomplete without this technology.

Many manufacturing industries depend on laser cutting's microscopic tolerances and precision accuracy to fabricate small, intricate parts. Such industries include: microtechnology, electronics, medical devices, automotive manufacturing, aerospace, military and defense, communications, plumbing and HVAC.

Products Produced Through Laser Cutting

Laser cutting is used for products and parts including: catheters, hypo-tubes, gas flow orifices, filtering devices, nozzles, solar cells, gaskets and circuit boards for aerospace, cell phone parts, computer microchips, transducers, water piping systems, refrigeration systems, and many types of military and communication devices.

Machinery Used in Laser Cutting

To create the high-quality results for which precision laser cutters are known, manufacturers rely on a variety of different machinery, particularly laser types. Some frequently used laser cut machine varieties include: fiber lasers, high-power lasers and metal lasers.

- Fiber Laser

- A laser that uses an optical fiber treated with rare earth elements like thulium, holmium, erbium, or ytterbium. Fiber lasers are great because they do not have moving parts, meaning that their maintenance requirements and operating costs are quite low.

- High-Power Laser

- Machinery used to cut stronger materials, such as mild steel, carbon steel, stainless steel or titanium. The high laser power label can be attached to many different laser types, including fiber laser and solid-state laser varieties.

- Metal Laser

- The name assigned to any laser machine that is designed for the cutting of metal materials specifically. Most often, these are metals like: mild steel, stainless steel, titanium, and/or scribing metals.

Things to Consider When Choosing Laser Cutting

Laser cutting does have a few disadvantages, most of which involve the drawbacks of hot cutting. The material being cut gets very hot, so in narrow areas thermal expansion and warping may be a problem. Distortion and oxidation can be caused by oxygen, which is sometimes used as an assist gas, because it puts stress into the cut edge of some materials; this is typically a problem in dense hole patterns. Lasers also require large amounts of energy, making them costlier to run. Lasers are not very effective on metals such as aluminum and copper alloys due to their ability to reflect light as well as absorb and conduct heat, nor can laser cutting be used on crystal, glass or any other non-metals.

Despite these drawbacks, laser cutting is an excellent service to consider. To learn about the possibilities for your application, contact a reputable laser cut service provider. Not all laser cut service providers are equal, so to help you narrow down the search, we’ve provided you with a list of manufacturers; find it near the top of this page. Browse their respective websites, pick out a few that have the capabilities you require, and then reach out to them. Talk over your specifications with them; make sure to voice all questions and concerns. Make your final decision based on who you believe will provide you with the best possible customer service and products.

Laser Cutting Variations and Similar Processes

Other common laser marking processes include laser engraving, laser drilling and waterjet cutting. Many manufacturers of laser cut products are able to offer custom laser cutting, which is used when the design is too complex or intricate to cut by hand.

- Laser Engraving

- Also known as laser etching, is an engraving process that uses laser technology in order to etch marks into a surface. The best way to laser engrave something is using a laser engraver. This type of engrave machine is usually CNC-controlled, using inputs from a CAD computer program and a human operator to determine the speed, spread and intensity of the laser beam. The big difference between a laser cutter and engraver is the that the laser engrave machine, instead of melting surfaces, either fractures or vaporizes them.

- Laser Drilling

- To create precise holes with tight tolerances, manufacturers go with laser drilling. As its name suggests, this process uses a laser beam to make holes.

- Waterjet Cutting

- This cut service creates and machines shapes using highly pressurized streams of water. When manufacturers waterjet cut materials instead of using laser cut technology, they save energy and resources. However, this method can only be used on some materials; it cannot be used on super hard materials like diamonds, nor can it be used on breakage-prone materials like some glass compositions.

Laser Cutting Terms

- Ablation

- The elimination of material with an industrial laser by evaporation, vaporization or melting.

- Alloy Steels

- A steel alloy containing a primary iron component minus any other metals necessary to make stainless steel.

- Articulated Arm

- A device consisting of a series of hollow tubes and mirrors that supplies the beam in a CO2 laser.

- Assist Gas

- A gas used to facilitate the cutting process and to blow melted material through the cut area. Oxygen is usually utilized for cutting ferrous metals, and any inert gas produces oxide-free cut edges.

- Attenuation

- The decrease in radiation power or energy as the beam is passing through a scattering or absorbing medium.

- Beam

- A group of rays that may be convergent, divergent or parallel.

- Beam Diameter

- The diameter of a circular beam at a particular point in which the intensity lowers to a fraction of its maximum value.

- Beam Divergence

- The spread of the beam angle, expressed in milliradians. One radian equals 3.4 minutes of arc or nearly 1 mil.

- Computer Numerical Control (CNC)

- A computer that controls the machine's movement. CNC controls motion tables or position the work piece beneath the focused laser beam.

- Coated Steels

- Carbon or mild steel made with coatings like zinc plating, mill scale, paint, rust or identification marks. Reduced cutting speeds and more dross on the bottom of the cutting edge are the result.

- Collimation

- The capability of a laser beam not to spread significantly (low divergence) with distance.

- Collimator

- An optical device consisting of two lenses separated by the sum of their focal length that is used to provide a desired beam diameter to meet beam delivery specifications.

- Continuous Wave (CW)

- The continuous-emission mode of a laser, as opposed to the pulsed operation mode.

- Copper/Copper Alloys

- Metals that exhibit an extreme reflectivity to laser light and have high thermal conductivities. These two characteristics lower the cutting speeds and the highest thickness of material that can be cut.

- Crystal

- A solid crystalline material with a regular array of atoms utilized as laser sources.

- Cut Initiation

- Also called "piercing," it is the use of the laser in the pulsed mode for hole drilling with air or oxygen as the assist gas.

- Cutting Bed Size

- A characteristic that determines the size of the material to be cut. Bed sizes are commonly 4' X 8' and some are as big as 5' X 10'.

- Cut Width

- A measurement that is dependent on the properties of the material cut, the lens focal length and the type of gas in the laser. The width of a cut from a laser will usually be between 0.1 and 0.4 mm.

- Cycle Time

- The amount of time required for the completion of the laser process.

- Depth Of Field (DOF)

- The operating span of the focused laser beam calculated as a function of the focal length of the lens, the wavelength and the diameter of the unfocused beam. A shorter focal length gives a smaller depth of field.

- Drift

- Undesirable variations of either amplitude or frequency of laser output.

- Dross

- Solidified melt on the lower edge of the laser cut. Higher amounts of dross result from surface rust, poor quality steel and incorrect process parameters but can be reduced by increasing the oxygen pressure and pulsed laser cutting.

- Duty Cycle

- The actual length of time that the laser beam is cutting, drilling, welding or heat-treating, as compared to the cycle time.

- Enclosed Laser Device

- A laser or laser system closed off to prevent hazardous optical radiation from escaping the enclosure.

- Feed Rate

- The rate at which the cutting head moves.

- Focal Point

- The position of maximum energy concentration of a focused laser beam. Focal point is determined by measuring where the laser beam has the least diameter and the refracted light rays of a lens conjoin.

- Gas Jet Assist

- A coaxial assist gas utilized to attain extreme power levels required for cutting particular metals, usually nitrogen, oxygen and argon.

- Gas Jet

- A device that blows gas into the cutting zone to clear away molten metals or other materials. At times, the gas reacts chemically with the work piece to create heat and increase the cutting speed.

- Heat Affected Zone (HAZ)

- A small area next to the cut zone that undergoes changes in material properties as a result of heat conducted into the work piece as it is cut.

- Hologram

- An interference phenomena captured on a plate or film that can contain large amounts of information and from which 3D images can be constructed.

- Kerf

- The slit, notch or groove produced by a laser cutter or the width of such a cut. The kerf is reliant on the work piece thickness, the properties of the material, the lens focal length and the kind of cutting gas in the laser.

- Laser Cutting Grade Steels

- Kinds of steels particularly manufactured for laser cutting applications. These steels maintain the strength of standard materials, but with reduced amounts of impurities like sulphur and silicon, and can be cut to a greater highest thickness at faster speeds.

- Laser Resonator

- Also called "laser cavity," it consists of the optical mirrors, pumping system and active medium. Laser resonators can be stable or unstable based on whether the oscillating beam converges into the cavity or spreads out from the cavity.

- Laser Product

- A legal phrase indicating a laser or laser system or any other product that integrates or is intended to integrate a laser or laser system.

- Lens

- An optic that is either refractive or reflective and affects the convergence of rays of light at a point. The depth of focus and power density of a lens can change with differences in laser beam diameters.

- Melting Point

- The temperature at which a material melts. Materials having high melting points must be cut more slowly with a laser, since more energy is needed to melt them.

- Mode Locking

- A method that creates very short laser pulses by making the phase differences of many modes or frequencies in the laser cavity fixed (locked).

- Neodymium Solid-State Glass (Nd:Glass) Lasers

- Lasers that provide high-power, short pulses for particular industrial applications.

- Neodymium:Yttrium-Aluminum Garnet Solid-State Lasers (Nd:YAG Lasers)

- Lasers that are like Nd:glass lasers in that they are both pumped by flashlamp and beam transmissions through fiber optics, but the ND:YAG laser light can achieve finer detail work. It is also better than the CO2 laser on highly reflective material.

- Nozzle

- A component of the gas jet in laser cutting that constricts the assist gas and directs it to a columnar flow.

- Power Density

- Laser output per unit area, expressed in watts per square centimeter (W/cm2).

- Pulse

- A single, irregular burst of a laser, in contrast to a continuous beam. True pulses attain greater peak powers than what a continuous wave output can do.

- Pulse Frequency

- The speed at which pulses are produced, expressed in pulses per second.

- Reflectivity

- The degree to which a material reflects laser light. Extremely reflective material such as aluminum and copper alloys are harder to cut, necessitating lowered work speeds.

- Substrate

- A sheet of base material that may or may not have an interconnection pattern.

- Ultrashort Pulsed Laser

- Laser whose pulse duration time is below one nanosecond.

- Vaporization

- The conversion of a solid or liquid into a vapor. Lasers vaporize the metal or material they are cutting.