Electric Switches

Electric switches are devices used to open or close an electrical circuit. Most electric switches are binary, meaning they have two states: (1) closed, which allows electrical current to pass through the circuit, or (2) open, which prevents the current from flowing. Some electric switches have multiple closed positions, allowing varying voltages to pass through, thereby altering the output of the device or equipment connected to the switch.

The term "circuit breaker" is sometimes used interchangeably with "electric switch." This usage originates from the "open" state of a switch, in which the electrical circuit is physically interrupted to "break" the circuit and stop current flow. However, a circuit breaker is more accurately described as a safety device designed to switch the circuit to an "open" state when excessive electrical current is detected, preventing damage to the system.

Electric Switches FAQ

What is an electric switch and how does it work?

An electric switch opens or closes an electrical circuit to control current flow. When closed, it allows current to pass through; when open, it stops the current, effectively turning a device on or off.

What is the difference between an electric switch and a circuit breaker?

While both interrupt current flow, a switch is manually operated, whereas a circuit breaker automatically opens when excessive current is detected to prevent system damage.

What are the most common types of electric switches used today?

Common types include toggle, rocker, push-button, rotary, and slide switches. These are used across homes, vehicles, and industrial systems to control circuits safely and efficiently.

How are poles and throws used to classify switches?

Poles indicate how many circuits a switch controls, while throws define the number of conductive positions. The main types are SPST, SPDT, DPST, and DPDT, each offering specific circuit control configurations.

What materials are used in electric switches?

Electric switches use conductive metals like copper, aluminum, or gold for contacts and terminals, enclosed within insulating materials such as rubber or plastic for safety and durability.

How should electric switches be maintained for safety?

Switches should be regularly tested with continuity testers, replaced if faulty, and used within their rated current limits. Proper maintenance helps prevent electrical hazards and extends component life.

What are electronically controlled switches?

Electronically controlled switches, such as transistors or relays, operate automatically in response to electrical signals. They are widely used in modern electronics, from lighting controls to computing devices.

The History of Electric Switches

Electric switches were created out of necessity. While the ability to have electrical current flow through a circuit is valuable, without a simple and safe way to control it, the possibilities are limited. The invention of switches revolutionized the use of electricity, and as a result, the history of electric switches is closely linked to the overall discovery and development of electricity. While wall light switches are not the only type of electric switch, examining their development provides a helpful overview of the progression of switch technology.

The origins of electric switches can be traced back to 1800, when Italian scientist Alessandro Volta created the first real battery, known as the voltaic pile, which enabled the continuous flow of electrical current and created the foundation for electric circuits. However, significant advancements in electric circuit refinement didn’t come until the late nineteenth century. Thomas Edison, a pioneer in electric lighting, was among the first to apply electric circuits for practical and commercial use. For a New Year’s lighting display at his laboratory in 1879-1880, Edison developed various electrical components, including switches.

In 1884, British engineer John Henry Holmes developed the quick break switch, which allowed for faster meeting of electric contacts and improved the durability of switches by preventing residue buildup. This technology led to the next major development: the toggle switch. Invented by New York’s William J. Newton and Morris Goldberg, the toggle switch replaced the popular push-button switches of the late nineteenth century. Today, the toggle switch remains the most common type of switch in North America.

Although electric switches have evolved, the core technology behind them has not drastically changed. Compared to other types of technology, electric switches are relatively simple. A notable twentieth-century development was the rocker switch, a version of the toggle switch designed for flat panels, which emerged in the 1980s. Despite these improvements, the basic design of the standard wall switch has remained largely the same for nearly a century.

Components of Electric Switches

Switches typically consist of conducting materials (such as wires), terminals, and actuators, all enclosed in an insulated, protective casing. While the specific quantity and arrangement of these components can vary, most switches function similarly by using these elements to complete a circuit and allow electrical current to flow through.

How Electric Switches Work

To properly understand electric switches, it's essential to consider them within the broader context of electric circuits. There are two primary types of electric circuits: power circuits and electronic circuits. Power circuits are the more visible types, harnessing electricity to power large systems or appliances, such as generators, power lines, and circuit breakers. In contrast, electronic circuits are smaller systems that transmit various types of information via electricity, as seen in devices like computers and radar systems.

Switching refers to the process of making or breaking electrical connections to complete or disrupt an electric circuit. An electric switch is any component in an electric circuit responsible for this function. While switches are often associated with mechanical parts in commercial lighting systems, electronic or hydraulic switches also perform the same function. Each electric switch contains conducting materials in the form of "contacts," and these contacts either connect or disconnect to complete or disrupt the circuit.

The terms "open" and "closed" in switches may seem counterintuitive. An open switch actually "breaks" the circuit by disconnecting the electric contacts, stopping the flow of current. This is typically referred to as the "off" position. Conversely, a closed switch completes the circuit by joining the contacts, allowing current to flow freely. A closed switch is often described as being in the "on" position.

Switches can be used individually or connected with others to offer more control options within a circuit. When a switch remains in a new state after being actuated, it is known as a maintained switch. However, a momentary switch returns to its original state shortly after being actuated. The normal state of a momentary switch is typically open or off, though there are exceptions.

Switches can be differentiated further by their actuation mechanism. For example, toggle switches are maintained, staying in the position they are switched to until actuated again. Push-button switches, on the other hand, typically revert to their original position after being pressed, such as in a doorbell.

While not always thought of as part of a switch, receptacles are crucial for completing the circuit. Receptacles, like wall outlets, are responsible for conducting power to the intended target, and they work in tandem with switches to ensure electricity is applied where needed.

Electric Switch Images, Diagrams and Visual Concepts

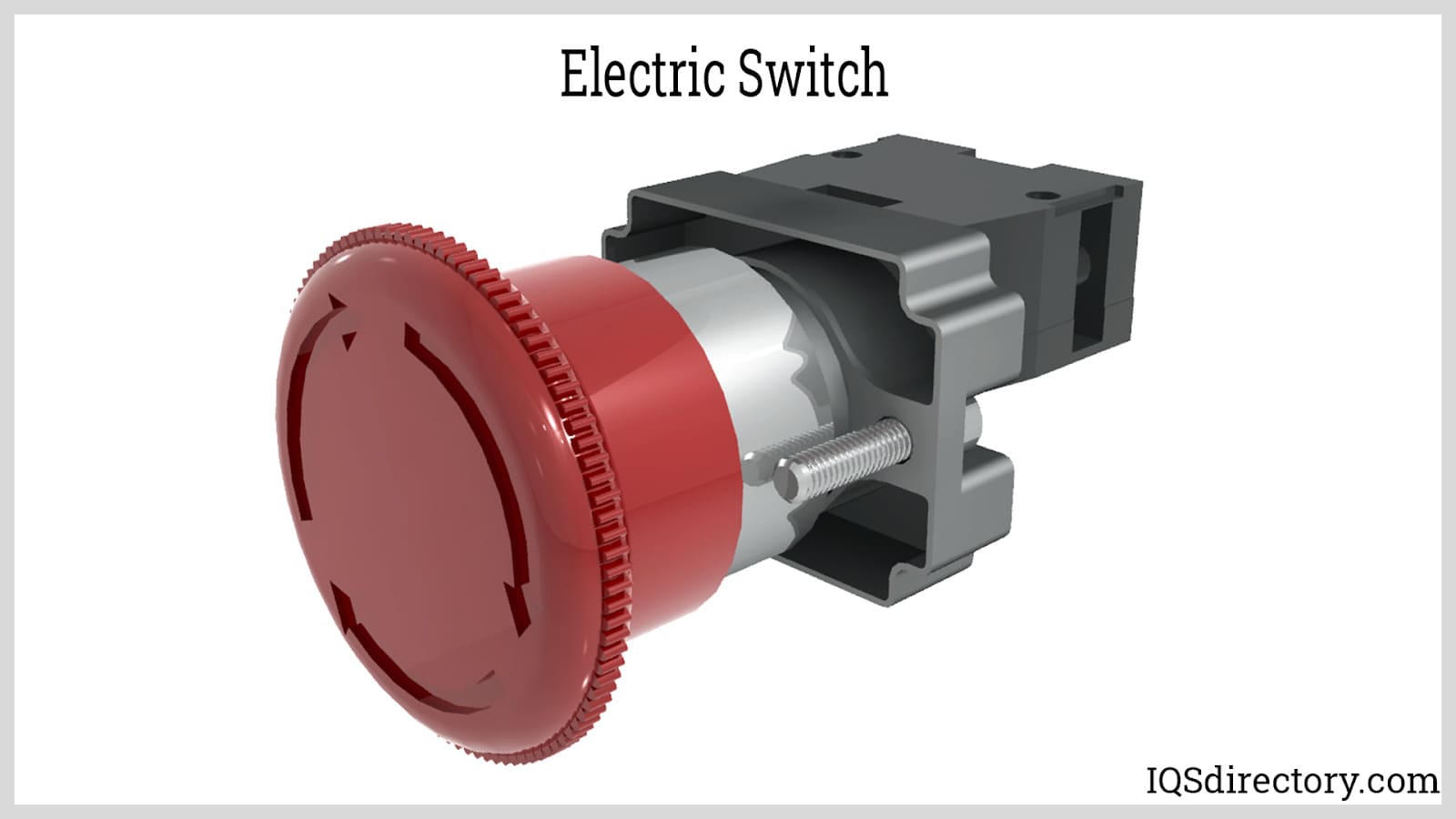

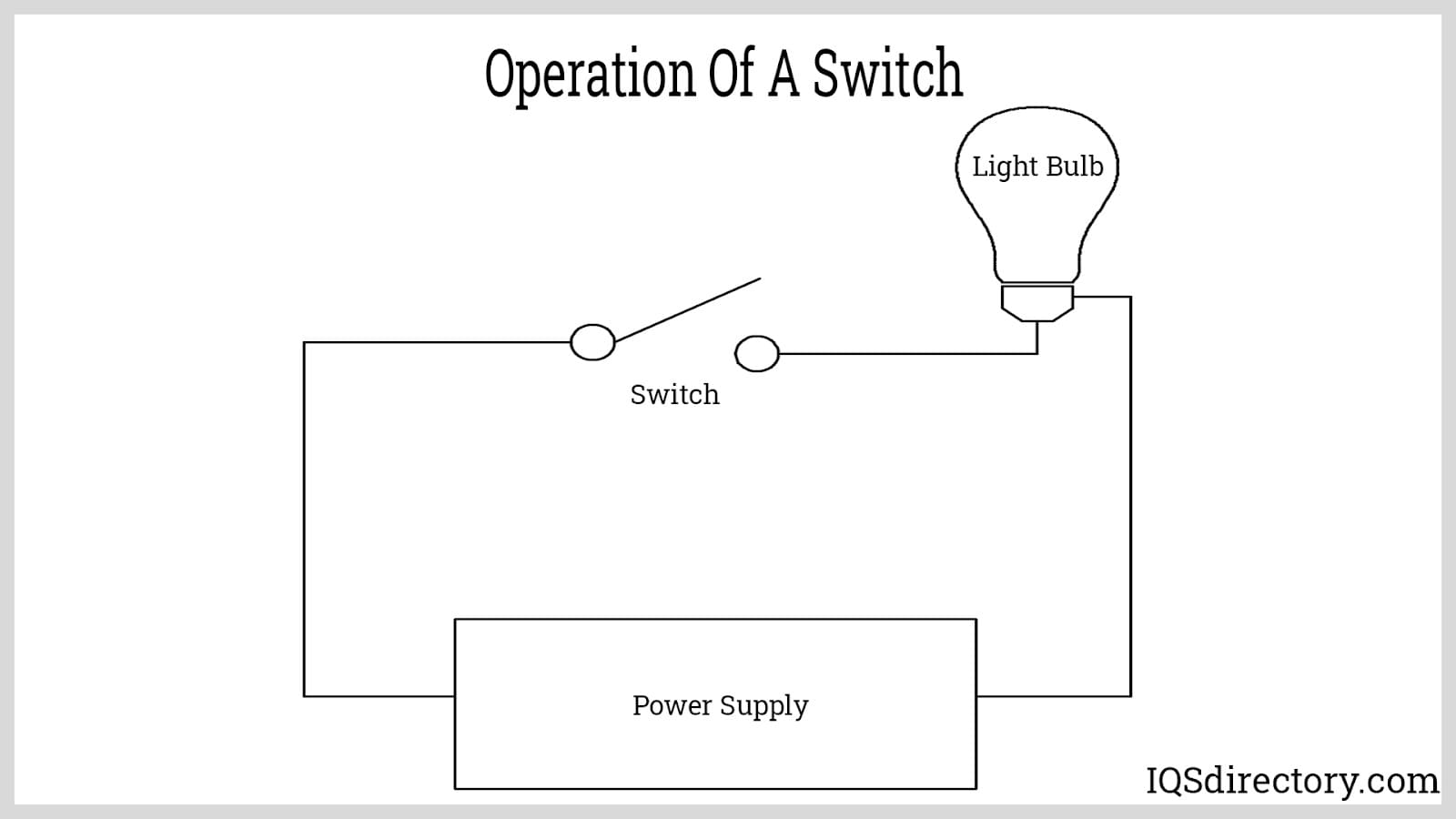

An electric switch opens or closes an electric circuit which disables and enables the flow of electric currents.

An electric switch opens or closes an electric circuit which disables and enables the flow of electric currents.

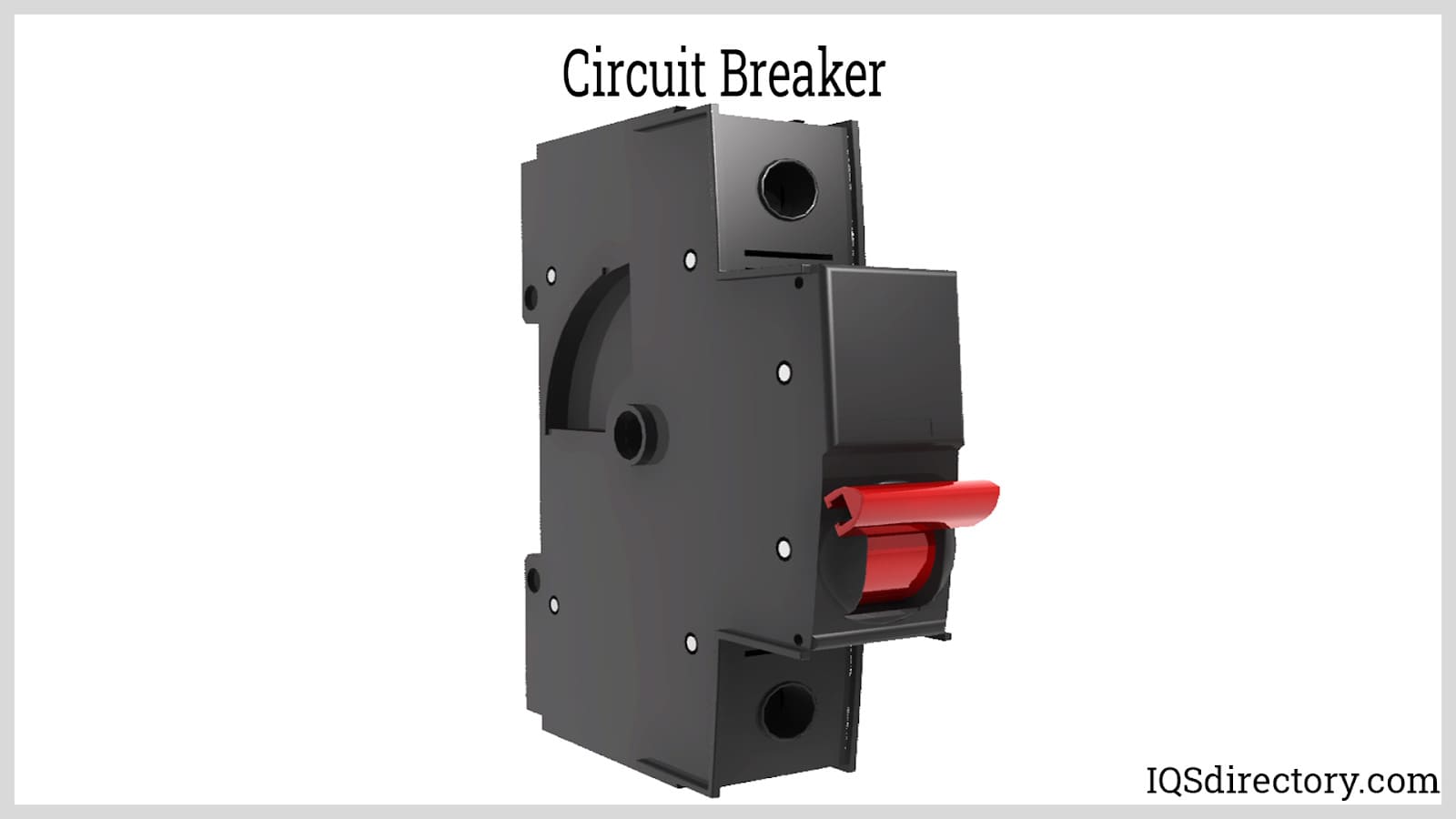

A circuit breaker, the rating is the current above which the breaker "trips" or breaks the circuit.

A circuit breaker, the rating is the current above which the breaker "trips" or breaks the circuit.

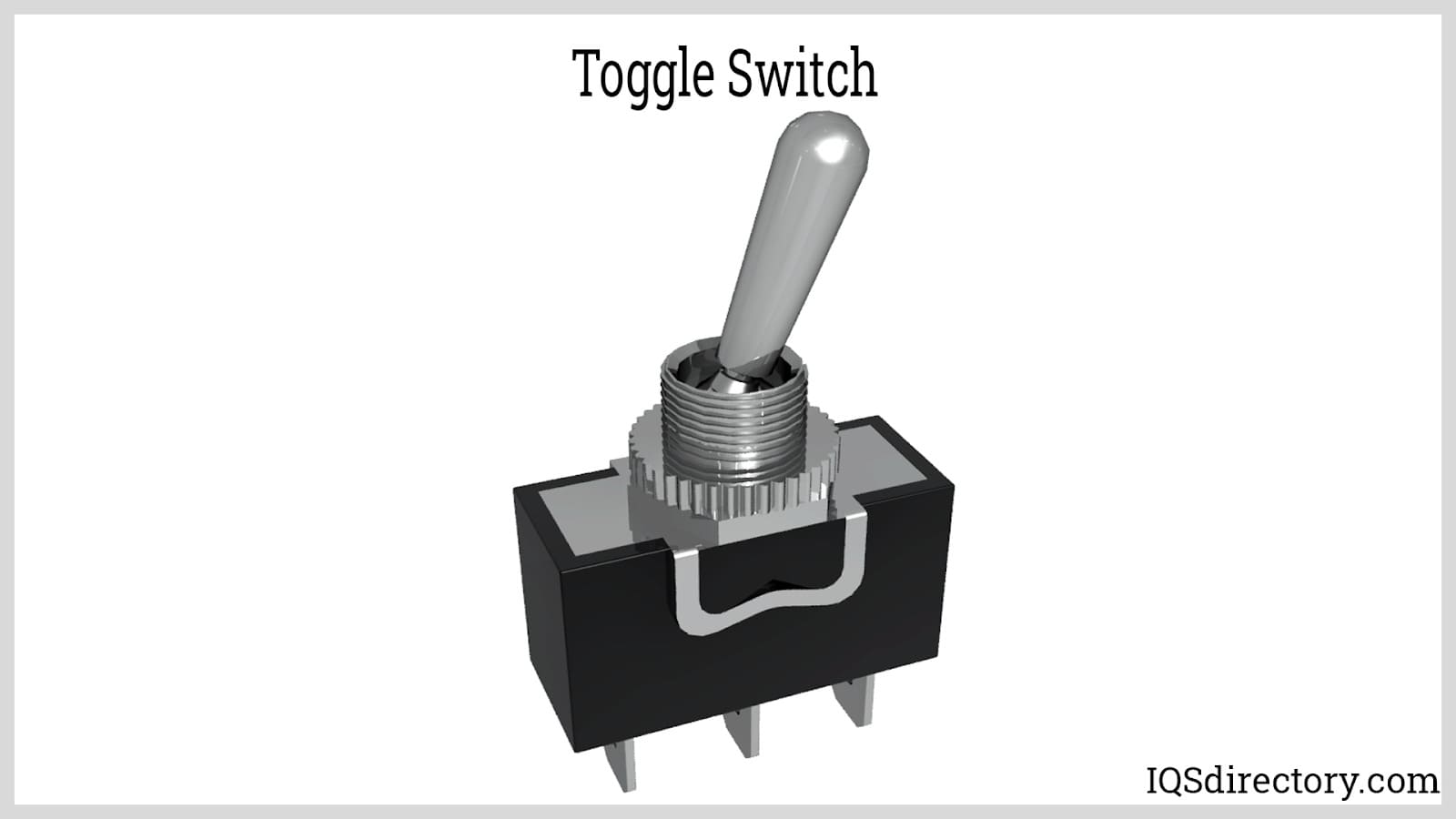

Toggle switches uses a lever to enable or disable the state of the connection.

Toggle switches uses a lever to enable or disable the state of the connection.

Push button, when pressed, either close or open the electrical circuits.

Push button, when pressed, either close or open the electrical circuits.

A set of switches and fuses associated with high voltage applications, power generation, and distribution.

A set of switches and fuses associated with high voltage applications, power generation, and distribution.

Switches provide a means to control the electrical current supply to electric loads.

Switches provide a means to control the electrical current supply to electric loads.

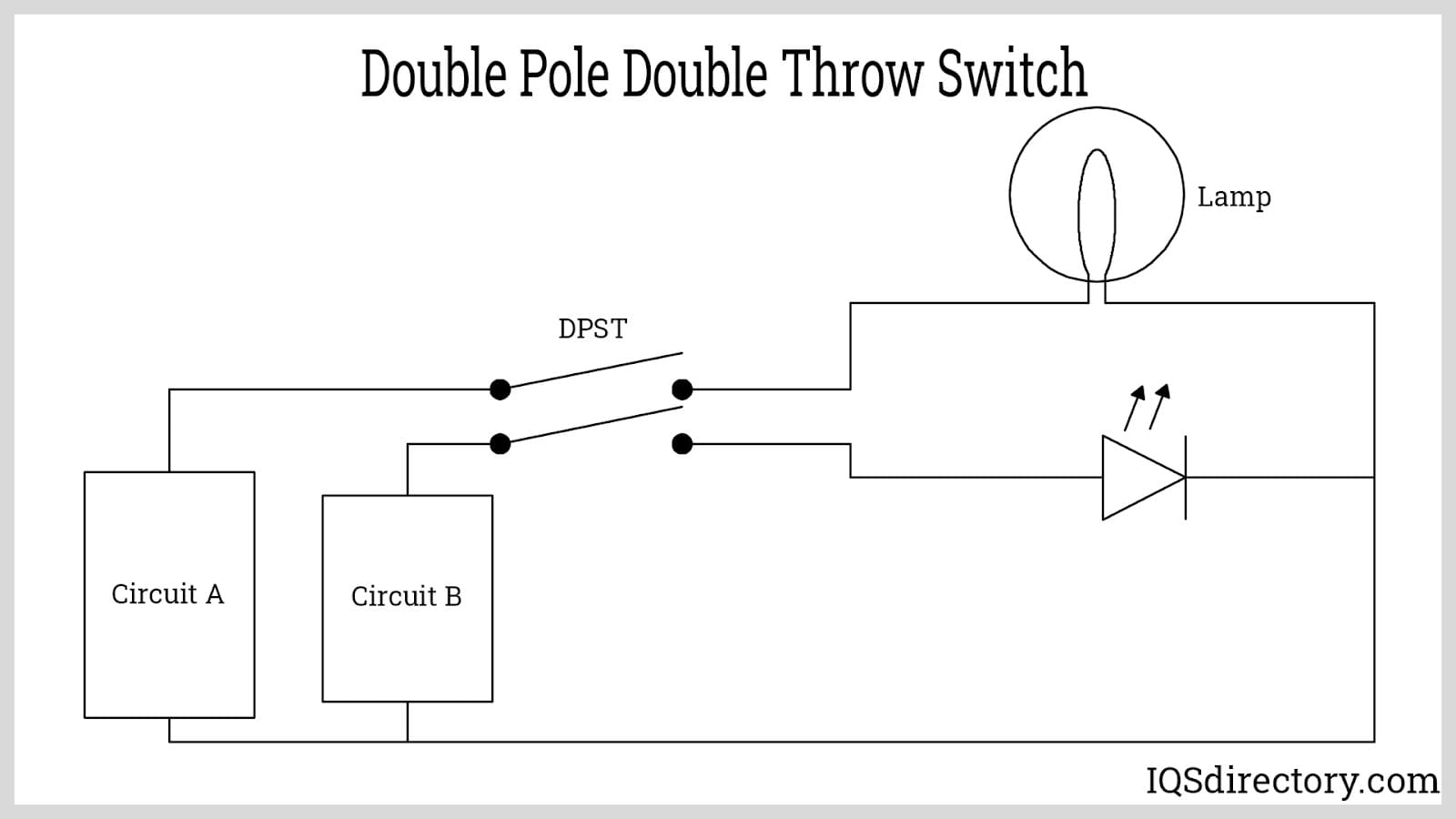

Double pole double throw switiches have two inputs and four outputs and operate the same as an actuator.

Double pole double throw switiches have two inputs and four outputs and operate the same as an actuator.

Types of Electric Switches

-

Cam Switches

These switches use a plastic disk (cam) over which a mechanical follower moves, controlling the contacts. The cam is attached to and rotated by a handle shaft.

DIP Switches

DIP (Dual In-Line Package) switches are small, manual binary switches found on circuit boards. These switches allow users to customize electronic devices, such as remote controls or garage door openers, by flipping the switches to the desired setting. They are inexpensive and commonly used for simple, manual control.

Double Pole Switches

These switches have two actuators that can either connect or disconnect two separate circuits. Double pole switches typically have at least four terminals and are used to control two circuits at once with a single actuator.

Double Pole Double Throw (DPDT)

These switches can open or close the connections between two conductors, allowing them to switch between two separate circuits. DPDT switches typically have six terminals and can be set to maintain contact, alternate contact, or momentary contact. These are useful for switching appliances with 240-volt circuits or devices with multiple mechanical components.

Double Pole Single Throw (DPST)

DPST switches control two conductors in a single circuit, often with four terminals. They open or close the connection between two conductors.

Electrical Switches

Used to change the flow of electricity in a circuit, these switches come in many forms, such as toggle, pushbutton, rocker, or dial switches, each designed to actuate the contacts and complete or disrupt the circuit.

Electronic Switches

These switches interrupt the flow of a circuit and are typically binary devices. They either allow current to pass through (closed) or break the flow (open).

Enabling Switches

Manually operated switches designed to protect workers in hazardous environments, enabling or disabling heavy machinery when necessary.

Key Lock Switches

Activated by turning a key, these switches control the power in a manner similar to starting a car, and they are used in various applications where security is required.

Lever Switches

These switches are operated by turning a lever connected to a pivot point. Lever switches typically feature three positions: on, off, and intermediate.

Limit Switches

Used in machinery and industrial equipment to monitor and control mechanical movement. Limit switches come in various sizes and configurations to suit different applications.

Maintained Switches

Switches that stay in their selected position after being actuated, maintaining the state until manually changed.

Miniature Switches

Compact switches used in applications requiring smaller mechanisms, such as in handheld devices.

Multiple Limit Switches

These switches are used for positioning and controlling machinery and equipment, ensuring precise movements in industrial settings.

Pressure Switches

Converts changes in pressure into electrical signals, often used in systems that need to monitor or regulate pressure levels.

Push Button Switches

Activated by pressing a plunger, these switches are commonly used in a variety of applications, including doorbells. They can be configured as single-pole, single-throw (SPST), double-throw (SPDT), or multiple other configurations, depending on the system.

Reed Switches

These switches contain two ferromagnetic reeds encapsulated in glass. The reeds close when exposed to a magnetic field, making them ideal for non-contact applications.

Rocker Switches

A type of switch activated by rocking a lever. They were developed as flat-panel alternatives to toggle switches and are common in devices like power strips and automobile locks.

Rope Pull Switches

Activated by tension in a safety cable, these switches are used in industries like printing, food processing, and pharmaceuticals to provide safety and monitoring capabilities.

Rotary Switches

A switch with contacts arranged in a full or partial circle. These are used in applications such as automotive ignition switches and are ideal for controlling multiple output options.

Safety Switches

These switches include integrated actuators to monitor movable components, protecting both equipment and personnel from accidents.

Single Pole Switches

These simple switches connect or disconnect one circuit, and are used as basic "on/off" controls in a wide variety of applications.

Single Pole Double Throw (SPDT)

Also known as a "three-way switch," SPDT switches control the connection between one conductor and two other conductors. These switches have three terminals and can be used to select between multiple circuit options.

Single Pole Single Throw (SPST)

The simplest type of switch, SPST switches have two terminals and are used for basic on/off control.

Slide Switches

These switches break an electrical circuit by moving a slider from one position to another, typically offering at least two positions such as on and off. They are commonly found in devices like flashlights.

Snap Action Switches

These switches quickly move their contacts from one position to another, often used in applications like mouse buttons or appliance settings.

Switch Panels

These panels provide easy access to multiple electric switches, often housed in an enclosure, for controlling several devices or systems.

Toggle Switches

A type of switch with two positions, commonly used for simple on/off control. Toggle switches are one of the most common and earliest forms of switches. They are ideal for quick switching and are often found on light switches and computer keyboard caps.

Waterproof Switches

Designed to operate in wet environments, these switches can either open or close a circuit while maintaining resistance to water damage, making them suitable for outdoor or industrial applications.

Usage of Electric Switches

Although switches may seem simple and basic to users today, they are essential components in the electric circuits and devices that power much of the modern world. For electricity to be practically applied, it must be continuous and controllable, and switches provide the control necessary to achieve this. They enable two major applications: binary "on/off" control (e.g., a remote control) and user input (e.g., computer keys).

Moreover, electric switches help conserve energy by allowing circuits to be turned off when not in use. Instead of leaving a device or appliance running continuously, switches allow them to be powered only when needed, promoting energy efficiency.

Conducting Material

An electric circuit is defined as a closed path that allows the flow of electric current. To function, an electric circuit must be made of materials that allow electricity to flow through them. Most electric circuits are constructed using conductive metals, with copper and aluminum being the most common choices. Gold, however, is preferred in applications involving delicate electronic components (such as electronic chips) due to its superior corrosion resistance.

Terminals of an Electric Circuit

The terminals, or pins, of an electric circuit are the points where current can enter or exit. A circuit typically requires at least two terminals, though most circuits contain more for various connections and purposes.

Actuators on Switches

When a switch is "actuated," it is changed from one state to another (e.g., from closed to open) through physical action. The actuators in a switch are the components responsible for carrying out this action by applying force to the switch's contacts.

Insulators and Housing for Switches

Insulators are materials that surround or encase switches and circuits. Unlike conductors, which transmit electricity, insulators are designed to prevent the flow of electricity. Common insulator materials include rubber and plastic, and they act as safety mechanisms to isolate conducting materials and prevent electrical hazards.

Powering an Electric Switch

Though all electric switches are used to open or close electrical circuits, there are many different types, each varying in size, design, and application. For example, some switches are tiny and require a miniature tool for operation, while others can be flipped with a finger or need a firm hand to operate. Electric switches are typically identified by factors such as the number of connections they can establish and their ability to handle varying amounts of voltage or current. Power switches and signal switches distinguish between switches used in power circuits and those used in electronic circuits. Load-break switches, which are typically used in high-voltage systems, often work with interrupters that convert direct current (DC) to alternating current (AC). The combination of a load-break switch and an interrupter is sometimes referred to as an interrupter switch.

The most practical way to categorize switches, however, is by how they are controlled or actuated. In general, switches are either mechanically controlled, physically controlled, or electronically controlled. Electric switches vary greatly in the complexity of their control mechanisms; some advanced switches can detect light or magnetic fields and respond accordingly, while simpler ones require physical contact between conductors and actuators. Common forms of switch control include manual methods, pneumatic or hydraulic methods, and remote controls.

Mechanically Controlled Switches

Mechanically controlled switches are highly practical and come in a wide range of types. For example, pull-chain switches, often found in ceiling fans, require pulling a cord to activate them. Some manually controlled switches are not categorized based on their control method; for example, waterproof switches are housed in watertight casings that resist corrosion, salt, shock, vibrations, and other harmful forces.

Electrically Controlled Switches

In electronic circuits, switches function at the level of tiny electrical components and are often invisible. These switches, known as signal switches, adjust the circuit based on external conditions detected electronically. The contacts within the switch open or close in response to applied electrical voltages, without the need for external physical intervention. A switch relay refers to any switch that is electronically controlled.

While mechanical switches are common, semiconductor transistors now dominate the majority of electrical switching applications. Transistors control electrical circuits by being controlled themselves by a smaller electric current, and are crucial in the computing industry. A more visible form of an electronically controlled switch is the remote electrical switch, which is used for functions like controlling lighting systems. Common products utilizing electric signal switches include driving lights, thermostats (which react to temperature), and security lights (which respond to changes in light levels). Other devices such as food processing and medical equipment also typically use electronic switches. Looking forward, the electric switch industry is increasingly focused on electronically controlled switches, with innovations such as touch and waving switches becoming more prevalent.

Poles and Throws Switches

Switches can also be categorized based on the arrangement of their internal components, specifically the poles and throws. A pole refers to an area of the switch that can accept electrical input, determining how many circuits the switch can control. A throw refers to the number of conducting positions the switch can adopt, or the number of terminals that complete the circuit. Switches are commonly categorized as single-pole or double-pole, and single-throw or double-throw, resulting in four standard combinations: SPST (single pole, single throw), SPDT (single pole, double throw), DPST (double pole, single throw), and DPDT (double pole, double throw). While switches can have any number of poles and throws, the single- and double-throw varieties are by far the most common.

Customizing Switches

Switches can be customized in a variety of ways beyond just their control method or internal arrangement.

When multiple switches are installed in a single device, the device is typically referred to as a switch panel. Manufacturers of switch panels design them to incorporate a mix of single-pole, double-pole, and other types of switches, enabling them to control multiple electronic circuits. The wires, terminals, and other components are concealed within the panel’s housing, which can be made from plastic, metal, or wood, while the switches are mounted on the front of the panel for easy access.

Regarding size, smaller components enable switches to be compacted, allowing them to fit in tighter spaces. This smaller form factor means that entire electronic devices using the switch can also be made more compact.

Advancements in materials and precision machining have enhanced the quality of switch components, resulting in parts that are more durable and capable of withstanding hundreds, if not thousands, of uses over their lifetime. These improvements allow switches to function effectively even in demanding environments where reliable performance is crucial.

Choosing and Maintaining Electric Switches

A common theme with electric switches is their critical role in the operation of an electrical circuit, despite their relatively simple design and function. This makes it essential to avoid carelessness when choosing electrical switchgear or related products. Switches come in a wide range of qualities, designs, and specific functions. As a general rule, it's advisable to invest in higher-quality, durable switches and accessories (such as receptacles), which will prove to be more reliable in the long run. Selecting a reputable manufacturer or supplier who can offer a switch that fits your specific needs is crucial.

Since electric switches are the most vital components of any electrical circuit, they should be handled and maintained with utmost care. Switches can fail, often more frequently than expected, due to internal damage from heavy use or unforeseen shocks. It is recommended to regularly test switches, using tools like a battery-operated continuity tester, and replace any faulty switches immediately. Always adhere to safety guidelines and never exceed a switch’s rated current capacity (e.g., using an SPDT slide switch in a high-power circuit). Also, avoid using receptacles with different amperages or voltages than what is intended for the circuit controlled by the switch.

Electric Switches Terms

-

Actuator

A mechanism that triggers automatic action. In the context of electrical switches, actuators include plungers, levers, roller levers, and many other variants.

Alternating Current (AC)

An electrical current that periodically reverses its direction of flow.

Ampere-Turns (AT)

A unit of measurement used to define the sensitivity of a switch. It is calculated by multiplying the number of coil turns by the current (measured in amps) passing through the coil.

Break

The act of opening a circuit, which stops the flow of current.

Circuit

A closed loop or path through which electrical current flows.

Detent

A mechanism, usually consisting of a spring and starwheel, that holds a switch in a designated position.

Direct Current (DC)

An electric current that flows in one consistent direction.

Drop-Out (DO)

The point at which the switch contacts release, measured in ampere-turns.

Ground

The part of an electrical circuit connected to the earth, providing a zero potential. Most electrical switches have a ground connection.

Latching

A function of a relay that keeps the contacts open or closed until a new command is given.

Make

The act of closing a contact, allowing current to flow through the circuit.

Maximum Switching Current

The highest load (measured in amperes) that an electric switch can safely handle.

Normally Closed (NC)

Refers to a switch that is closed and connected in its default position.

Normally Open (NO)

Refers to a switch that is open and disconnected in its default position.

Plain Lever

A small rigid bar attached to a pivot point, activated by being pushed in one direction. Lever switches typically have two or three positions.

Plunger

An actuator type that is activated by a push or thrust.

Pole

An independent electrical circuit within a switch.

Set Point

The specific point at which an electrical switch functions, measured in psi, psia, or inches of mercury.

Terminal

The location in a circuit where a connection is typically established or interrupted.

Thermoplastic

A plastic material that can be softened by heating and hardened by cooling, without undergoing significant chemical change. Thermoplastics are commonly used for the housing of some switches.

Rating

The specified performance limits for switches, typically expressed in volts (V) and amperes (amps).