Electric Coils

An electric coil or electromagnetic coil is an electrical conductor, usually wire, in the shape of a coil or similar shape. Most of these coils are wrapped around a core made of a ferrous material such as iron.

This simple component can be used in countless applications, due in large part to the unique interactions between magnetic fields and electrical current in such a configuration.

Electric coils are a common component of heating units. In heating applications, the device may be an electromagnetic coil generating heat through induction, or a simple resistance-based heating element in a coil shape.

Quick links to Electric Coils Information

The History of Electric Coils

The history of the electric coil is the history of electromagnetic science in general, as it was with a coil of wire and a magnet that Michael Faraday first determined that electric current could be generated with magnetic forces. In the years since, practical application of this knowledge has come in many forms, though the most direct early application was of course Gramme's electric generator in 1871.

As our understanding and use of electromagnetic forces has advanced, so too have electromagnetic coils; for every potential application, one or more highly customized coils has been invented, refined, and upgraded countless times. The nature of electric coils is such that innovation in coil design is inherent to almost any application.

Applications of Electric Coils

Electric coils are used in electrical engineering across countless industries and specific applications, due to the importance of the interaction between electric currents and magnetic fields in so many electrical devices. In order to fit a wide array of applications, there are many types of electric coils differentiating in terms of wire gauges, wire lengths, coil diameter and the materials around which the wire is wound. Electric coil varieties are all able to be customized to meet specific demands. Also, in addition to transmitting heat, sound or electricity, electric coils are required to perform several different functions. For instance, electronics, automotive, medical, computer, appliance and telecommunication industries rely heavily on electric coils in order to produce movement, regulate flow and/or transform electric currents. The force created by this phenomenon is harnessed by companies such as solenoid valve manufacturers, electric motor producers, and MRI machine suppliers, among others.

Accordingly, electric coils turn up in nearly every industry. Any industry which uses electricity probably has at least a few applications utilizing electric coils, though they may be built into off-the-shelf hardware and not a specific concern of companies within every industry. Industries with specific applications and a unique need for electric coil winding or coil assembly manufacturing include, but are not limited to:

- Power Generation

- A key component in manufacturing any electric generator or electric motor.

- Heavy Industry

- Used for various heavy-duty motors and control devices, and in special electromagnetic applications.

- Telecommunications

- Used as antennas, relays, etc.

- Medicine

- Used in various electromagnetic imaging devices, and for specific applications such as bio filters.

- Computers

- Used in magnetic storage devices.

- Home Appliances

- Many heating coils use the same principles of electromagnetic induction; where heat would be an unwanted side-effect in other applications, it's the core goal in various home devices, such as heat pumps or an induction electric range.

- Automotive

- Used for various motors, generators. Notably the coil assembly, i.e. ignition coils, the solenoid coil or starter relay.

- Power Control

- Used in circuit breakers, contactors, relay coil switches, and various other power control mechanisms.

Materials and Design for Coils

Despite the relative simplicity of an electric coil, design and engineering of a coil to match your application is a task usually best left to a qualified electrician or comparable professional; a layman lacks the knowledge necessary to determine the best secondary coil design to match an existing primary circuit design.

- Designing Electric Coils

- The basic construction of the electric coil can quickly become complicated with the addition of more windings. A winding is defined as a complete coil assembly with taps and all. While a single winding can be utilized in some applications, others require the addition of secondary and even tertiary windings. An electric transformer, for example, is an electromagnetic component that consists of a primary and secondary winding that enables it to transfer electrical energy from one electric circuit to another electric circuit by means of a magnetic coupling with no moving parts. When a tertiary electric coil is added to an electromagnetic component, it is usually referred to as a tickler coil. In addition to the number of windings altering the function of the electric coil, differences in terms of the coil taps are significant as well. Defined as points in the wire coil that consists of an exposed conductive patch, coil taps can differ mostly in terms of size much like the diameter of the coil itself. When a coil has a large diameter, the amount of self induction is much larger and the current tries to flow on the inside of the wire instead of on the outside, which can be a problem. In addition, multi-layered electric coils can have issues with interlayer capacitance, which refers to an electrical phenomenon whereby an electric charge is stored, so the shape of the coil must be altered. As a result, for multi-layered electric coils, a spiral shape is the most practical shape to be used.

- Conductor Materials

- The base of any electric coil, including simple resistance-based heating elements, is the conducting material shaped into a coil. Most commonly, this is copper wire, but any conducting material can be used for this role. Aluminum is a popular alternative.

- Core Materials

- Most electromagnetic coils will also need to take into account the material of the core. This is usually some ferromagnetic material, such as iron. The core can be a solid piece, a bundle of wire, or any number of other configurations.

- Type or Shape

- Depending on the application at hand, you'll usually be fairly limited in the overall style of electric coil. A project which needs a DC-compatible stator doesn't need the coil for an AC electric motor; your options would thus be fairly limited. To make sure you're choosing the right type, familiarize yourself with the variety available and discuss the matter with your engineers. Alternatively, asking your winding company for a recommendation can get you a few specific options to consider.

- Other Design Aspects

- The specificity of design in electric coils means that every small aspect of configuration can greatly impact the final product's performance. For example, the inductive properties of a simple electromagnetic coil is directly impacted by these factors and many others:

- Number of Wraps

- Area of the Coil

- Length of the Coil

- Material of the Core

- Material of the Coil

- While there is a basic underlying similarity in the construction of electric coils, there are many ways in which each coil can be designed specifically to its application. For instance, some electric coils require protection from harsh environmental conditions such as moisture, salt, oil and vibration. In order to protect the fragile coils from the harsh elements, since with prolonged exposure conductivity can be easily lost, electric coils may be molded or encapsulated. While molded coils are encapsulated in plastic coverings that seal the entire coil unit, encapsulated coils are made from wire that has itself been encapsulated in a polymer epoxy. Other types of electric coils, such as toroid transformer coils, are wound around ferrite rings and wrapped in sealing tape for environmental protection. One of the more common types of electric coils, solenoid coils, is at times simply referred to as solenoids. Often used as a remote switch, solenoids are current-carrying coils of wire that become magnetic when a current passes through the coil, which is typically wound around an iron core. Other, lesser-known types of electric coils include Garrett coils, used in metal detectors, Rogowski coils, used to measure alternating current (AC), Oudin coils, which are disruptive charge coils, and Braunbeck coils, used in geomagnetic research.

Electric Coil Types

- Air Core Coils (Self-Supported Coils)

- Electromagnetic coils which are wound "around air" without any core, hence the terms "air coils" and "self-supported coils".

- Bobbin Wound Coils

- Electromagnetic wire which has been wound around a plastic core, or "bobbin". Plastic cores come in many sizes, and bobbin wound coils may be impregnated, molded or taped to meet various medical device, sensing, relay and automotive applications.

- Choke Coils

- Also known as choking coils, are low-resistance electric coils with high inductance that are used to block high-frequency alternating currents (AC) of electricity while allowing low-frequency direct currents (DC) to pass through.

- Custom Coils

- Provide either movement or electric current transformation.

- Electrical Coils

- An alternative name for electric coils, consisting of a series of loops manufactured from conductive metallic wire and wound around a ferromagnetic core.

- Encapsulated Coils

- Electric coils which have been enclosed in a silicone rubber, polyester, liquid or thermoformed epoxy casing.

- High Voltage Coils

- Electric coils that use a voltage higher than what is generally accepted as safe.

- Ignition Coils

- Electrical induction coils that are used to transform lower voltages of power to the higher voltages of power required in order to fire a system's spark plugs.

- Impregnated Coils

- Coils which have first been dipped or co-extruded into an epoxy before being wound; the laminating epoxy seals the conductive electromagnetic wire from the elements, creating a unit which is effectively protected from weather and dirt without the tooling costs of molded coils.

- Induction Coils

- A common synonym for electric coils, electromagnetic coils are used to create electromotive force by being activated to magnetism through electrical currents.

- Magnetic Coils

- Coils which can also be referred to as electromagnetic coils or simply just coils, including all types of electric coils that operate based on the principle of induction.

- Molded Coils

- Electromagnetic coils which have been encased and sealed in thermoformed or injection molded plastic enclosures, protecting the coil from weather, dirt and vibration.

- Solenoid Coils

- Also referred to as solenoids, are three-dimensional loops, or coils, of wire that have been wrapped around a metallic core, and function to provide a magnetic field when an electric current is passed through the coil.

- Tape Wrapped Coils

- Usually bobbin wound, which are encased in sealing tape to protect the electromagnetic coil from weather, dirt and vibration; tape wrapped coils are not as effective at blocking these harmful elements as impregnated or molded coils, but the costs of manufacturing tape wrapped coils are much lower.

- Tesla Coil

- An electrical device that generates extremely high voltages, usually for the purpose of creating dramatic electric arcs and lightning effects or for producing x-rays.

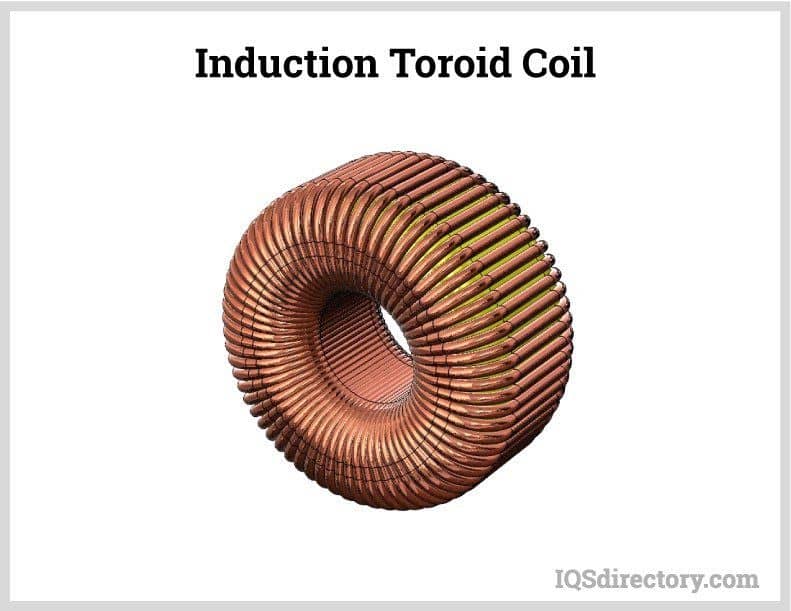

- Toroid Coils

- Copper wire which has been wound around a ferrite, or iron, donut-shaped ring. The ferrite core amplifies the coil’s inductance and may be used in transportation, audio & power supply applications.

- Transformer Coils

- Electromagnetic coils, usually impregnated or laminated, which are used to change the voltage of an incoming electric current, feeding the current back out at the same frequency, but with a different voltage.

- Voice Coils

- Consisting of a winding, a collar and a bobbin, a voice coil is a kind of electric coil. It attaches to the apex of a loudspeaker cone, where its purpose is to help it magnify sound.

Installing a Coil

Installation of any coil is highly dependent on the conditions of the system and application. The process and appropriate procedures can vary widely between two applications, even relatively similar ones, so a general comfort with electrical systems is necessary.

As an electrical component, installation of any electrical coil should in most cases be left to a properly certified professional using all appropriate safety equipment, in accordance with any national or local regulations.

Proper Care for Electric Coils

As with any electrical component, you'll want to make sure to perform regular checkups on your electromagnetic coils and all other components within your system. If you don't have monitoring built into your system, then regular testing should also be an aspect of your general care and upkeep.

Most electrical coils should experience minimal degradation in regular use, barring mistakes during installation or design. Components in high-stress systems, i.e. high currents, high ton heat, or external environmental factors, should be checked regularly for damage or corrosion.

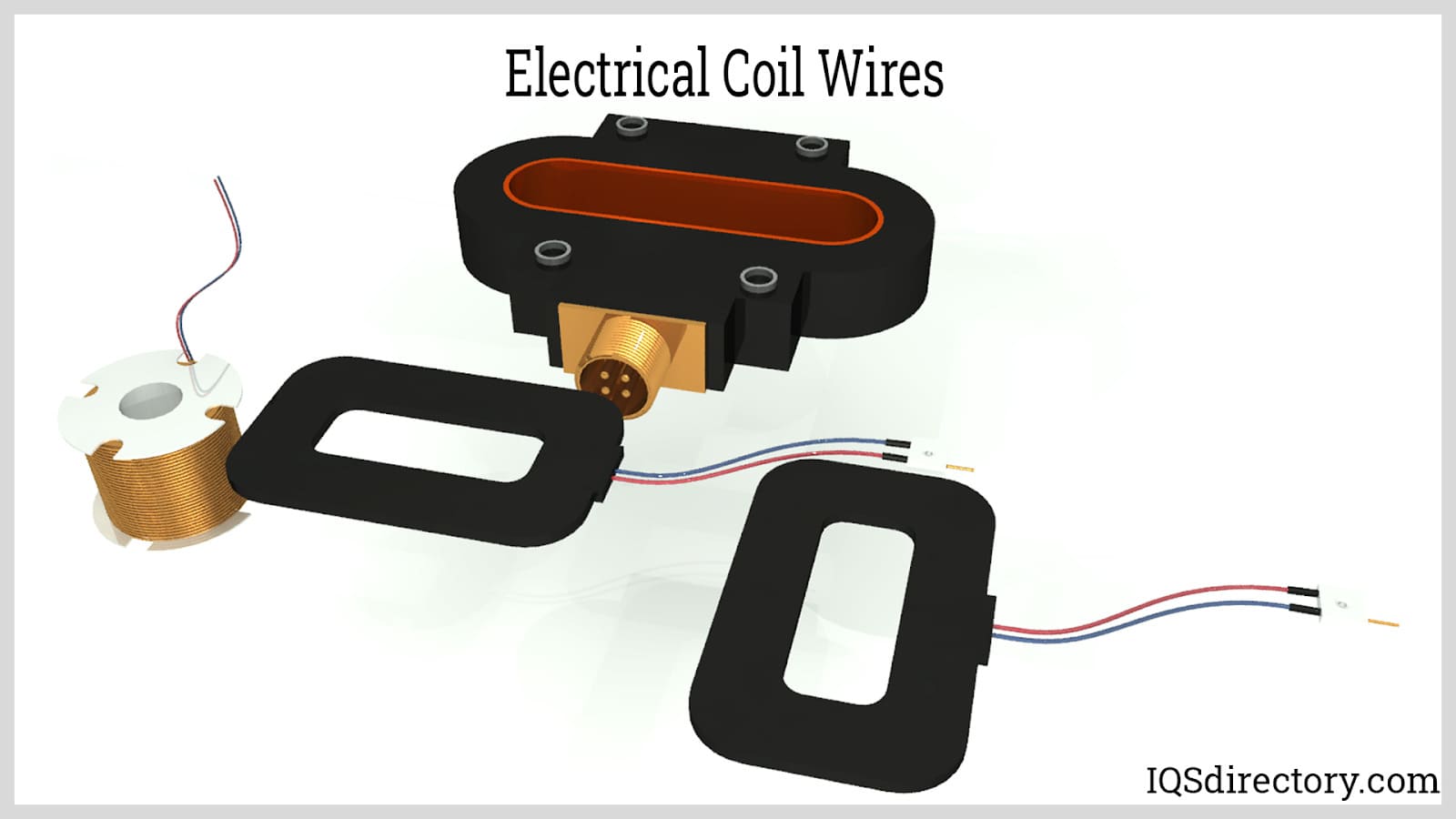

Electric Coil Images, Diagrams and Visual Concepts

An electric coil, is an electrical conductor that contains a series of conductive wires wrapped around a ferromagnetic core that is cylindrical, toroidal, or disk-like.

An electric coil, is an electrical conductor that contains a series of conductive wires wrapped around a ferromagnetic core that is cylindrical, toroidal, or disk-like.

The shape and dimensions of the wire used in a coil are chosen to perform particular functions.

The shape and dimensions of the wire used in a coil are chosen to perform particular functions.

Toroidal winding involves winding a conducting wire around a circular ring evenly distributing the wire over the circumference. Toroid coils are used for low frequency electricity applications.

Toroidal winding involves winding a conducting wire around a circular ring evenly distributing the wire over the circumference. Toroid coils are used for low frequency electricity applications.

This form of coil is used when space is limited with no room for a bobbin or core. Since the coils can be placed closer to the metal in the circuit, this allows for greater magnetic capability.

This form of coil is used when space is limited with no room for a bobbin or core. Since the coils can be placed closer to the metal in the circuit, this allows for greater magnetic capability.

Things to Consider When Choosing an Electric Coil

There are a few other factors in deciding on a design for your electric coil which you may want to consider before talking to a winding company. If you're unsure about any of these, feel free to ask any winding company you're speaking with for advice—or ask your electrical engineer.

- Environmental Factors

- There are countless environmental factors which may shape your choice of materials, design, etc. Many industrial applications place your coil in high-stress environments, which may result in sub-par performance, extra wear-and-tear, or sudden failure. Take the time to consider temperature, the presence of caustic substances, the potential for friction, and anything else that may be relevant.

- Personnel Needed

- Another factor to keep in mind when deciding what your electric coil needs is the people around it during operation and maintenance. Does it need to be insulated a certain way for safety due to high voltage? Does it need to be designed for easy upkeep, or will you have experienced people at hand? Think about who will be interacting with your coil most frequently; it might be important.

- Electric Coil Upkeep

- Do you need a design that can last a long time without anyone thinking about it, or will it be a component in a system that gets checked and maintained on a regular basis? While most electromagnetic coils are simple enough to be resilient in normal applications, it may shape your decision nonetheless.

- Coil Improvement

- Do you want a design you can forget about until it wears down and requires a replacement, or do you want something you can remove and replace with a superior component if you need to make adjustments later? Maximizing efficiency often involves a lot of tinkering with every component in the system, so think carefully about how much you want to invest in a particular electrical coil if you're not already confident in your target product.

- Optimizing Performance

- Because the operation of an electric coil is ultimately very simple, optimizing performance usually comes down to perfectly matching the coil design to the application. That means making sure everything matches, fits effectively, and flows cleanly without wasted heat, motion, etc. Depending on the specific application, improving performance may mean changing out the coil for a better design or it may mean changing out components to better match your coil. You'll have to decide based on what you're trying to do.

- Of course, to do any of this requires insight into how your system is performing, which makes analytical tools and software ideal for anyone trying to eke out every bit of performance. You may be able to spot a few surface-level problems without proper equipment, but for anything approaching peak performance you'll need modern equipment.

Choosing a Coil Manufacturer

There are a few things any company should keep in mind when choosing an electric coil manufacturer. These aren't points to help you identify a good manufacturer, necessarily, though they'll do that; they're to help you identify the right manufacturer for your needs. Keep these points in mind and you'll be able to avoid a lot of waste and inefficiency in the future.

- Product Versatility

- If you're looking for a manufacturer to provide you with electric coils over time, for different applications, consistent endeavors, or for adjustments down the line, you're going to want to work with a manufacturer that can keep up with the changes you need—it's highly disruptive and inefficient to change to a different manufacturer suddenly down the line because your current one is no longer sufficient for your needs. Also be aware of the potential for growth in necessary volume, or even a shrinking of necessary volume; if your electric coil needs become bigger or smaller in the future, will you still be satisfied with the services of this manufacturer?

- Manufacturer Communication

- You should never have to call a dozen times hoping to maybe get someone on the line at a manufacturer. If after a few calls during normal business hours you haven't heard a peep from a human being, it's time to move on to another option. Lack of communication will cost you money in inefficiency, potential downtime, and other headaches. Along similar lines, if you're going to be operating with a manufacturer's assistance long-term, make sure your logistics and theirs will be compatible; in many cases, it's simply not worth the investment of time or money to get your systems playing nicely with theirs, if they aren't already compatible.

- Transparency About Services

- Try to choose a winding company that gives clear, honest answers to any question with a fixed answer—and be very leery of those that hedge, obfuscate, or stonewall your inquiries. Good communication isn't worth much if you're not getting any useful information from each discussion. If there's a delay or a problem, you should hear about it. Charges shouldn't show up for the first time on your final invoice.

- Familiarity With Electric Coils

- If possible, choose a winding company familiar with your specific application and industry. The fine details that determine the overall efficiency and efficacy of the product and service you receive will be largely shaped by these factors, so it will give you a head start on a smooth relationship if the manufacturer already knows what you're after and what you'll expect.

- Manufacturer Support

- When choosing a manufacturer or supplier, the quality of service surrounding the product matters as much as anything. After all, designing a custom coil and going through the coil wind process is only a small part of the overall experience; what determines the quality of your experience as a customer is, instead, everything about ordering, scheduling, receiving, maintaining, etc. If getting someone on the phone for your initial consultation or a follow-up question is a struggle, the manufacturer isn't a good choice.

Electric Coil Accessories

The nature of electric coils makes it difficult to put together a comprehensive list of potential accessories. Any given wound coil might be matched with hundreds or even thousands of additional components in a given system.

Outside of the many industry and application-specific accessories you'll need to consider on your own, the accessories you might want for electromagnetic coils are the same accessories you would want for any other electrical equipment: storage bins, safety equipment, measuring devices, etc.

Electric Coil Terms

- Bobbin

- Plastic core around which electric coils are often wound.

- Coil Winding

- The process of coiling electromagnetic wire around a core or in a self-supporting "air" coil; coils may be single-layer or consisting of many multiple layers. Precise technical coils often require "precision winding".

- Conductor

- A material, often metal (such as copper), which passes along electric currents through the movement of free electrons.

- Electric Current

- The flow of electrically charged electrons or ions towards a positive pole, caused by the introduction of an electric energy field.

- Electromagnetism

- Magnetism which is created by and conditional upon an electric current.

- Field Coils

- A field coil is an electromagnet used to generate a magnetic field in an electro-magnetic machine, typically a rotating electrical machine such as a motor or a generator. It consists of a coil wire through which a current flows.

- Henries

- The SI unit used to measure the inductance of an electromagnetic coil; inductance of single-layer coils can be found using the formula: µH = (R² x N²) / (9R + 10L), where µH = microhenries, R = the coil radius, N = the number of times the coil is wound and L = the length of the coil.

- Inductance

- The electromotive force, or strength, of an electromagnetic coil (or circuit) created by the coil’s exposure to an electric current.

- Transducer

- An electrical device which converts energy from one form to another.

- Turns

- The number of times an electromagnetic coil is wound, either around its core or, in the case of air coils, the number of times the coil is fully looped.