Dynamometers

There are various categories of dynos and varied devices within those categories to suit the requirements of equipment being tested, from tiny nano-bots to huge ships turbines. Dynamometers are used in the medical field to test the accuracy of a vast array of equipment. They are used to measure flow and force of fluids and gases. Athletes and physical therapists use dynamometers to measure back, leg, arm, and grip strength. Dynamometer systems are probably best known for their use in mechanical applications with regard to measuring bolt tightness, engine torque, and increasing horsepower.

Quick Links to Dynamometers Information

The History of Dynamometers

Thomas Newcomen designed the atmospheric engine in 1712. It was the first commercially successful coal fired steam engine. Fifty years later, Scottish inventor and mechanical engineer, James Watt invented fuel economy. Watt noted that the atmospheric engine heated and cooled the cylinder with each power stroke, wasting about 75% of the thermal energy produced by burning coal. Watt designed a steam engine that burned less than half the amount of coal for the same amount of work being done. By adding a separate condenser, the steam was condensed without cooling the cylinder or piston. The power and efficiency of steam engines was radically increased. From a mechanized industrial standpoint this was an easy concept to grasp but many farmers and industrialists at the time were still using horses to draw and draft. Watt needed a formula to equate the amount of work his engine could produce by comparison so the farmers would understand the benefit and Watt could equate their savings to his sales. His steam engine could do the work of eight horses for the price of two. Anyone could readily grasp the economy in that! He came up with horsepower.

Most simply put, one horsepower equals the amount of power needed for one horse to lift 33,000 pounds one foot in one minute or 550 foot-pounds per second. Foot pounds are used in calculating torque, the rotational force around an axis or pivot. Torque, moment, or moment of force is measured as force x distance from the axis. A two-foot wrench with an applied force of one hundred pounds makes two hundred-pound feet (200 lb-ft) of torque. This means that it takes two hundred pounds of force on a one-foot wrench or lever to stop the rotation or one hundred pounds of force on a two-foot lever.

With a system of measurement came the need for measuring devices. These devices were named dynamometers, from the Latin dynamo-, meaning "force, energy, or power", and -meter, meaning "instrument used to measure or count". The invention of engine dynamometer testing provided standardized diagnostics for motors. The information gleaned from this testing was crucial in finding ways to improve engine efficiency and produce more power. Industries grew and flourished with the advent of more economical equipment and more efficient vehicles of nearly every trade. Since then, the dynamometer has been designed, developed, redesigned, and redeveloped to measure a wide variety of forces. It is an indispensable part of modern mechanical testing.

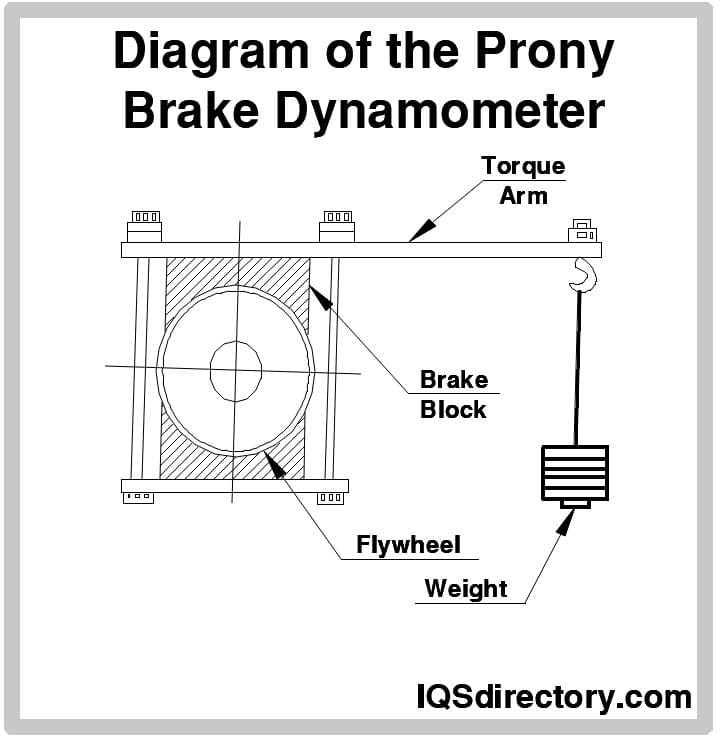

The Prony brake, invented in 1828 by Gaspard de Prony, was a simple machine made from a frame with a torque arm and a flywheel attached, a wooden block, a belt, and brake shoes. The belt was wrapped around the output shaft of an engine bolted to a test stand. Spring-loaded bolts were tightened, changing the center of gravity, and causing a weight at the end of the torque arm to increase friction. Tension on the belt was increased until rotation stopped. This was used to determine braking power by measuring the force required to stop the rotation of wheels. Because this process converted the dry friction to heat, the Prony brake had to be cooled.

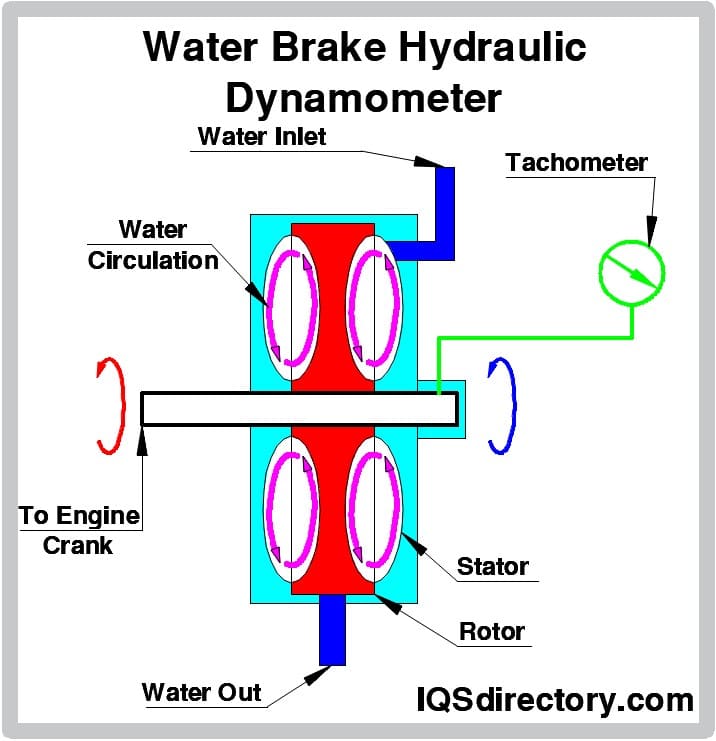

William Froude invented the water brake to measure naval engine power for the British Admiralty in 1877. Froude's water brake went into commercial production in 1881 and the company is still manufacturing them- with modern improvements. The water brake dynamometer, one of the oldest dynos still in use, utilizes a fluid coupling consisting of a stationary half called the stator, and a rotating half called the rotor. The stator is mounted inside an enclosure or absorption unit and the rotor is attached to the prime mover, usually the crankshaft of the motor being tested. The absorption unit is then filled with water or hydraulic fluid. As the prime mover turns the rotor, the fluid is pushed by curved vanes attached to the rotor toward similar vanes on the stator. Fluid flowing against the stator's vanes creates a measurable torque reaction. The power absorption unit (PAU) absorbs the power from the prime mover and converts it to heat which is then cooled with water or air, and dissipates.

Through the use of constant force control, the PAU provides a set torque load, the constant, while the prime mover operates at specified test levels. The prime mover accelerates the engine through the designated range of speed and RPM to create max torque or maximum rotational speed. Through use of constant speed control, where the dyno has a speed regulator, the PAU creates a variable braking force causing the prime mover to operate at a constant speed or RPM. The formula: rotational speed x torque x constant calculates the amount of power produced.

There are two basic types of dynamometer, the power absorption dynamometer and the power transmission dynamometer. They are also respectively known as the engine dynamometer and the chassis dynamometer. The engine dyno provides a load on the prime mover, or source of the torque being measured. It measures power directly at the engine's crankshaft or flywheel by absorbing the force. The chassis dyno, or rolling road, transmits the load to simulate operation of a vehicle in a controlled environment. It can be used to measure emissions, vibration, electromagnetic compatibility, or performance through the use of a torque transducer, torque sensor, or torque meter.

During the 1920's, draft horses were still used extensively on farms. Professor E. V. Collins built a device to measure the pulling power of horse teams in different soil conditions. His draft horse dynamometer consisted of a set of vertical tracks with changeable weights called stone boats, designed to simulate variable plowing conditions. The teams would be harnessed to increasingly heavier stone boats and pull them down the track until only one team remained.

Advantages of Dynamometers

The importance of dynamometers cannot be overlooked in industrial and mechanical engineering. A dynamometer is a tool that engineers use to measure force, a moment of force (torque), and power, utilized or produced by an engine or motor. There are different types of dynamometers, working on a variety of principles and used for various applications in manufacturing operations. Some of the most common dynamometers are hydraulic dynamometers, chassis dynamometers, eddy current dynamometers, prony brake dynamometers, and rope brake dynamometers.

Some of these electric motor testers are used to determine the power required by an application to run smoothly and others measure the torque or tension applied by the brakes to stop the engine.

In a dynamometer, there is an absorption unit that typically includes a rotor motor. The engine or application to be tested is attached to this rotor. The rotor enables the machine's engine to rotate as per the programmed speed.

Basically, there are three types of dynamometers-motoring, absorbing, and universal. A motoring dyno helps assess and control the torque or power that a machine consumes. Absorbing dynamos absorb the power and their parts help measure the absorbed amount. They are also known as driven or active dynamometers. Universal dynamometers are a combined version of the other two types of dynamometers.

Dynamometers Images, Diagrams and Visual Concepts

Motor testing using a dynamometer to measure the torque of a motor.

Motor testing using a dynamometer to measure the torque of a motor.

A dynamometer used to measure torque, force, speed, and power required to operate the drive of a machine or motor.

A dynamometer used to measure torque, force, speed, and power required to operate the drive of a machine or motor.

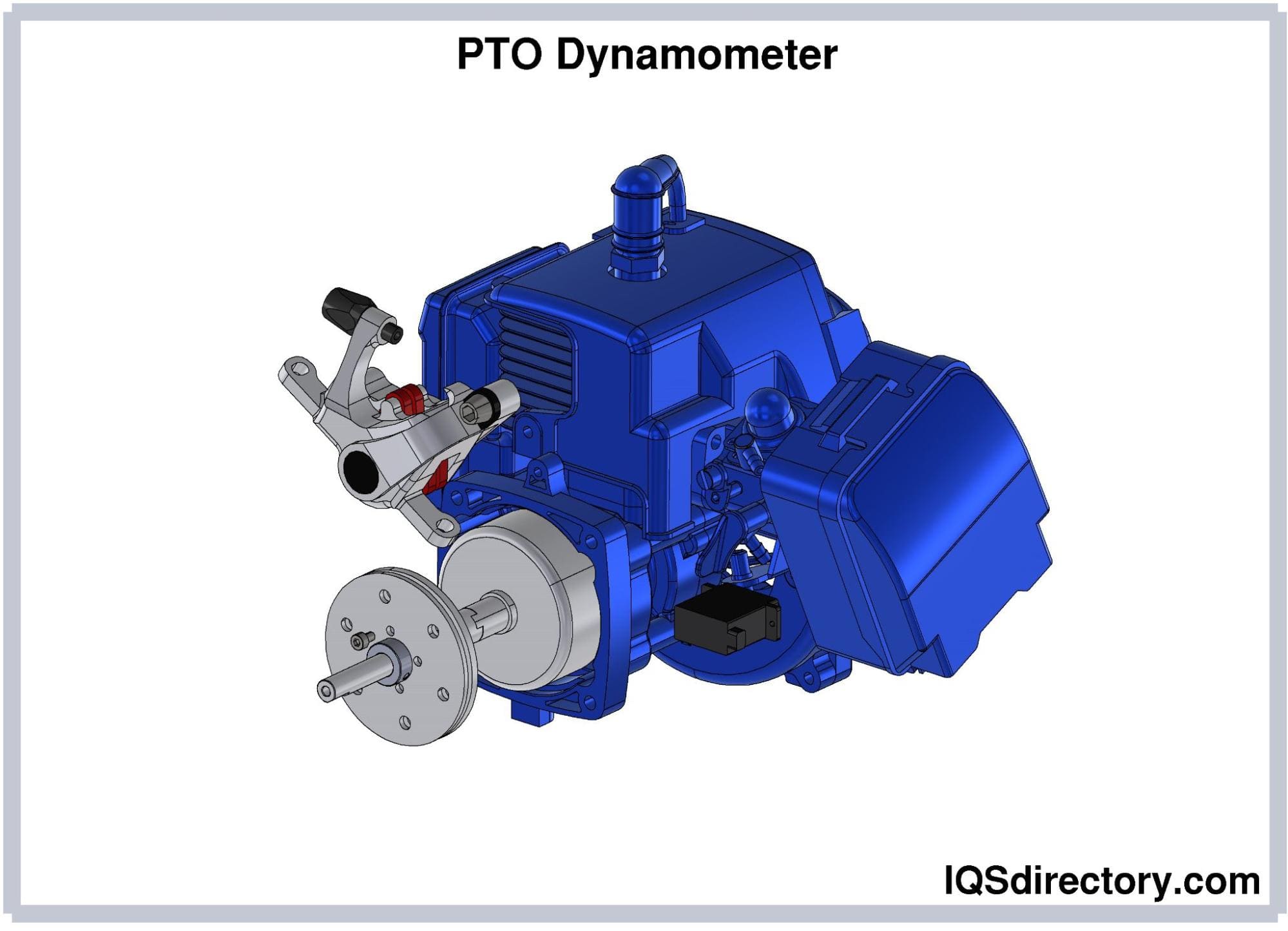

PTO testing is a series of tests performed by a dynamometer connected to an engine’s output shaft and tests speed, torque, power, and fuel consumption.

PTO testing is a series of tests performed by a dynamometer connected to an engine’s output shaft and tests speed, torque, power, and fuel consumption.

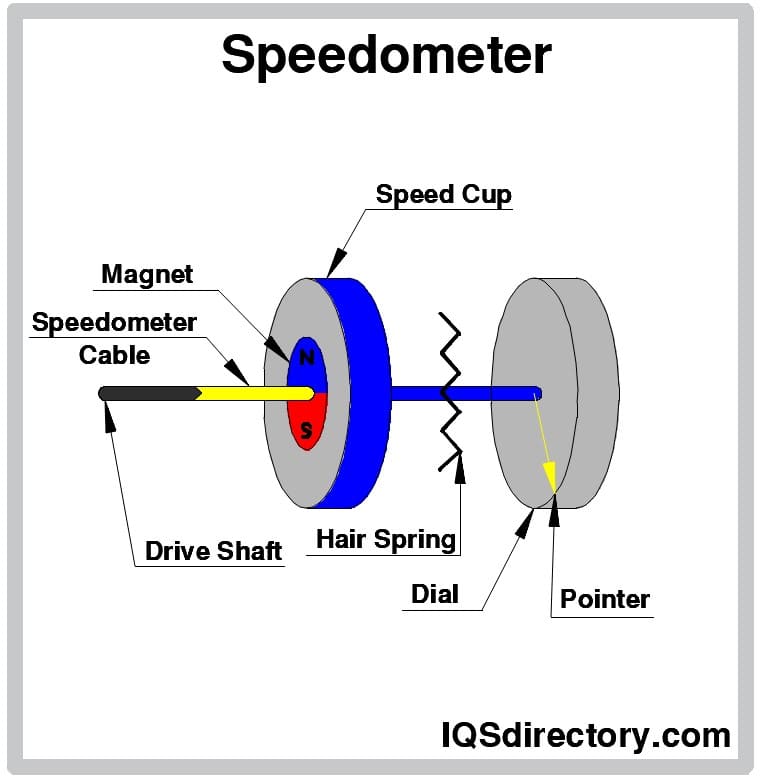

A speedometer, a form of dynamometer that uses electromagnetism which provides data.

A speedometer, a form of dynamometer that uses electromagnetism which provides data.

A Prony brake dynamometer is the simplest form of dynamometer that Prony developed, which is made up of brake blocks that press against a rotating wheel attached to the motor to measure braking power.

A Prony brake dynamometer is the simplest form of dynamometer that Prony developed, which is made up of brake blocks that press against a rotating wheel attached to the motor to measure braking power.

Water brake dynamometers are designed to work with high torque low speed diesel engines used in mining, marine, and naval applications.

Water brake dynamometers are designed to work with high torque low speed diesel engines used in mining, marine, and naval applications.

Types of Dynamometers

Transmission Dynos

- Towing Dynamometers

- Act on a similar principle by creating a constant load on the vehicle towing the dyno. This is used to calculate appropriate load levels for the vehicles in question.

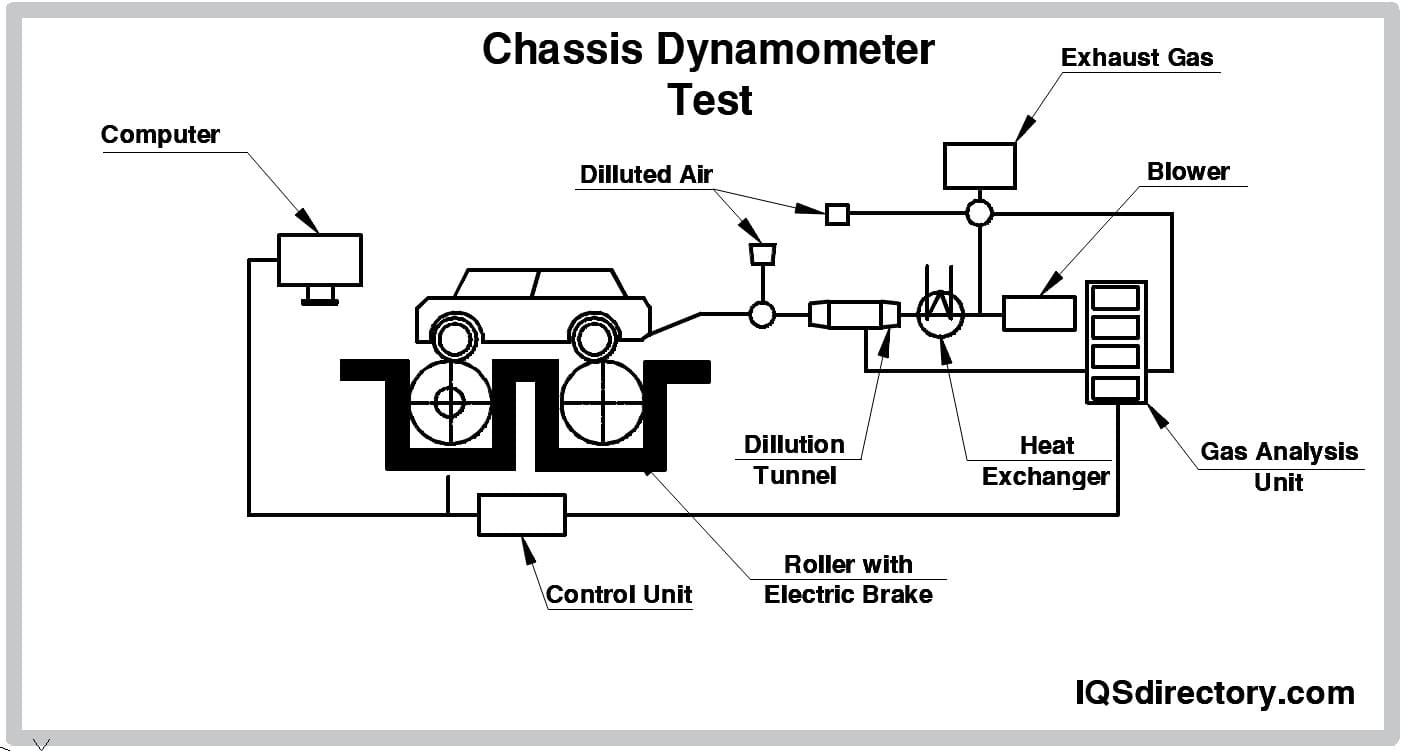

- Chassis Dynamometer

- Motor testing uses a test cell consisting of a one or two roller bed onto which the vehicle being tested is placed. The rollers provide the driving force to the wheels of the vehicle rather than using the torque of the motor as the prime mover. Computers are connected to the mechanical operations of both vehicle and test equipment. This allows for highly controlled, accurate dynamometer testing of a motor without removing it from the vehicle. Tractive forces between axles may be distributed evenly or not, depending on the information required through testing. Speed may be controlled by the varied application of force to the wheels. This measures static power at constant velocity.

- Chassis dynamometers measure an engine's torque output at the wheels of an automobile. The auto is placed on rollers, on which the tires turn, and the result is then measured. Some chassis dynamometers also work by attaching directly to the wheel hub and measuring its rotation. Chassis dynamometers may be fixed or portable units.

- Road Load Simulation Dynamometer

- Simulates road conditions, such as inertia and grade. Initial base readings, road parameters, are taken with the vehicle traveling on a simulated flat road without wind from any direction, and gear set in neutral. Braking times at varied intervals are taken. These parameters are entered into the workstation computer along with vehicle inertia. Specified alternate conditions are then applied. Because a simulated road cannot factor in aerodynamics, air drag must be calculated into the engine dyno and is facilitated through the use of increased brake force to the wheels of the test vehicle. Simulated changes in gradient are accomplished this way as well. As the computer reads the data from the tests, it can calculate the simulations into working results and recommendations for improving efficiency.

- Dynos can be configured to match the needs of the user. From small mechanic shops to houses of international industry, from torque specs to exhaust flow, dynamometer test equipment systems can be custom designed to fit a space or a space can be designed to fit the dyno. A good dynamometer company will take into consideration the purpose of the testing, the availability of shop space, and the economic advantage to the customer to help design a workplace and system that functions safely and efficiently. It will provide the proper machinery and equipment to correspond with the user's needs and capabilities and offer technical support to ensure the client's success.

Power Absorption Dynos

- Hydraulic Dynamometers

- Similar to water brake dynamometers in principle. They use an impeller enclosed inside a casing filled with hydraulic fluid and coupled to the prime mover. Centrifugal forces revolve with the impeller as friction is generated through resistance against a torque arm attached to a balance weight. The friction is measured by a spring balance. Flow through the impeller is controlled by the use of sluice gates. Heat created through the friction is dissipated in the continuous flow of the fluid.

- Eddy Current Dynamometers

- Determine the torque of an engine by creating eddy currents by moving a conductor through a changing magnetic field.

- Eddy current dynamometers, developed in the 1930's, are a type of absorption dyno that consist of an electrically conductive, rotating core inside a magnetic field. They use electromagnets attached to the stator and a copper or steel rotor attached to the output shaft to place a load on an engine through the conduction of electricity. Rotation of the rotor creates eddy currents, due to magnetic flux in the stator, which can be measured by a moment arm. The developing eddy currents are smooth and can be controlled to match the torque of driving force. Eddy current dynos provide smooth operation with good control and accurate readings without limitations on the size of the engine being tested. Because of heat created by the friction, eddy current dynamometers must be externally cooled.

- Power Take Off Dynamometers

- Are used in industrial and agricultural sectors. They use an external drive, usually located in a truck or a tractor, to provide power to the attached machine. The PTO dynamometer uses an eddy current to measure torque. PTO dynamometers are measurement and diagnostic equipment used to test the performance of power take off components in engines.

- Power Dynamometers

- Similar to an eddy current dyno, uses a fine magnetic powder in the air gap between the rotor and the electromagnets on the stator to create metal particulate chains which provide torque.

- Inertia Dyno

- Uses an electric motor to turn a flywheel mass approximately equal to one fourth the weight of the test vehicle. Once the flywheel achieves RPM equivalent to specified vehicular speed, braking forces are applied and measured. Inertia dynamometers are becoming the most widely used type of dynamometer in the torque-testing sectors of both the commercial and racing automobile industries, because they provide real-world results. The inertia of the roller drums is measured to calculate torque, revealing the rate at which an engine can accelerate a known rotational inertia from one RPM to another.

- AC Dynamometer

- Driven by an electric motor using alternating current, as opposed to direct current. The AC control unit uses a transducer called a load cell to provide an electrical signal to variable frequency drive at a magnitude proportional to the force being tested. The drive can be configured into a universal dynamometer which absorbs the power of the engine, but can also drive the engine for measuring friction and pumping losses. They are typically more complex than other types of dynamometers, therefore more expensive, but their regenerative control units may be harnessed to collect and sell electricity back to the utility provider.

- Rope Brake Dynamometer

- Also measures braking power. Turns of rope are wound around a cylinder or rotating drum attached to the prime mover. One end of the rope is attached to a spring balance and the other end is attached to a loading device, which can be as simple as a hanging weight. Rope brake dynamometers are inexpensive but are not very accurate due to the coefficient of friction in the rope which changes with the buildup of heat when tension is applied.

Other Dynamometer Types

- Brake Dynamometers

- Measure horsepower at the engine's output shaft by applying variable load on the engine and evaluating its ability to maintain its speed as the braking force is applied.

- Brake Testers

- Used to test the effectiveness of a vehicle's braking system. As pressure is applied to the brakes, the force produced is measured, recorded, and displayed by the testing system.

- Dynos

- Machines that measure the torque of an engine.

- Engine Dynamometers

- Another sub-type of torque testing machines, which are hooked to the engine directly as opposed to the wheel chassis. Research and development departments at workshops and auto manufacturing plants use this style of testing, as the engine can be tested without being inside a vehicle.

- Hydraulic Dynamometers

- Machines that measure the power of an engine by using a cell filled with liquid to increase its load.

- Motor Testers

- Measure the performance of motors to ensure that they are efficient and safe. The equipment is automatic, performing a sequence of steps to determine whether the demonstrated capabilities of the motor are acceptable.

- Portable Dynamometers

- Used to measure the force, torque, or power. They are also used to determine how much torque or power can be used to operate a driven machine like a pump.

- Repair Grade Dynamometers

- Chassis devices used to simulate actual road driving conditions on a motor vehicle. Repair grade dynamometers consist of rollers, power absorbers and inertia simulation, either mechanical or electrical.

- Torque Testers

- Function basically the same way as dynamometers do, but are designed to test the torque of smaller mechanical devices other than engines. Devices, such as precision screwdrivers and wrenches, need to have their torque tested to ensure quality function.

Dynamometer Accuracy

When it comes to precision in torque measurement, there is no match for dynamos. Whether you want to measure force, torque, or power output/input, dynamometers will provide the most accurate data. You can install these systems with any application, depending on your requirements. However, to attain the most accurate assessment, you will need to make sure that the devices have been installed correctly.

Testing with Dynamometers

To test the performance of an engine, test engineers need to thoroughly understand the dynamometer's operating instructions. A dynamometer controller is an electronic unit that enables engineers to control the load pressure on an engine. By gaining control over the control panel, you can measure the speed of and load on the engine. You can set the control panel to work for either Speed Control or Load Control.

For engine testing, various tests can be carried out using a good quality dynamometer or torque tester. When testing engine performance, make sure to perform the test with a wide-open throttle. You should also ensure that the test is being performed in Speed Control mode. During the initial stage of the test, the speed should be set at a low level to measure the engine speed and torque. Then, the speed level can be increased. After the increase, the performance measurement should be noted. This process should be repeated until the desired speed has been achieved or set.

During power or force measurement testing, it is important to provide adequate cooling to the engine. This practice helps to mitigate the problems caused by overheating. Cool air can be provided by fans and other cooling mechanisms. Some large industrial processes may need a cool air flow, flowing at 25 mph. To avoid hazards or inaccuracy in testing assessments, you should consider testing the temperature during the run of the machine.

Selecting the Proper Dynamometer

As said earlier, there are different types of dynamometers for different applications and motors. The design and function of these devices change with the application or process they are being used for. A number of devices are designed to be used by hand, while some are larger in size and suitable for industrial purposes. Smaller models are used by engineers, medical professionals, and construction professionals, and the largest models are suitable for industrial use. No matter what today, today's dynamometers include a digital interface that gives accurate information about the force or torque measure.

Dynamometer Terms

- Ambient

- Temperature Temperature of the surrounding medium.

- Base Line

- A vibration reading of a piece of equipment in good operating condition. The baseline becomes a reference point for testing and monitoring.

- Breakdown Torque

- Also known as maximum torque or pull-out torque, the highest torque that an AC motor will produce with the application of rated voltage and frequency and no abrupt drop in speed.

- Chassis

- The part of a motor vehicle that includes the engine, the frame, the suspension system, the wheels and the steering mechanism, but not the body.

- Code Letter

- The letter on AC motor nameplates that signifies the locked rotor kilovolt amperes per horsepower at rated frequency and voltage.

- Dynamometer

- A machine that measures the power by absorption derived from an internal combustion engine.

- Dynometer

- Is another term for dynamometers.

- Full Load Speed

- The RPM for an engine or generator, which is available at torque capacity.

- Full Load Torque

- For an engine or generator, it refers to the torque necessary to produce its rated horsepower at full load speed.

- Horsepower (HP)

- Unit of rate of doing work. One horsepower equals about 550 foot-pounds per second or 746 watts.

- Inertia

- Any motion or movement that is not in a straight line but remains constant in velocity.

- Locked Rotor Torque

- The lowest torque that an engine will produce from a standstill position, as measured from all angular positions of the rotor with rated voltage applied at rated frequency.

- Output

- The product of the torque available to do work times the rated RPM

- Rotor

- The rotating part of a motor or engine.

- R.P.M. (Revolutions Per Minute)

- Unit of measurement to determine power and torque.

- Throttle

- The act of acceleration.

- Torque

- The measure of the force applied to produce rotational motion, usually measured in foot-pounds.

- Transmission

- The gears that transmit power from an automobile engine via the driveshaft to the live axle.

- Trending

- A reading of the variation in the measurement of data over no less than three data measurement intervals.

- Velocity

- The rate of change of position in relation to time.

- Wide Open Throttle (WOT)

- The position of the pedal that allows the maximum amount of air to pass into the intake manifold.