Contract Manufacturing

Contract manufacturing is a service performed by a company that is hired to provide manufacturing services on behalf of another company, known as the original equipment manufacturer, or OEM. Typically, contract manufacturing involves both producing goods on behalf of an OEM and applying that company’s brand to the finished product. Many businesses across many industries take part in contract manufacturing to reduce production costs and maximize use of resources. Companies on both sides of the contract often benefit from this kind of agreement.

Multiple terms are sometimes used, interchangeably, to reference contract manufacturing. Some of these terms include private label manufacturing and outsource manufacturing. Technically speaking, each term refers to a specific type of contract manufacturing. While private label manufacturers create products for another company like regular contract manufacturers, they often apply their own designs or branding to the finished product. Furthermore, although outsource manufacturing is technically the same as contract manufacturing, it colloquially refers to international contract manufacturing operations and not simply any form of contract manufacturing.

Contract manufacturing is an important piece of virtually every major industry. These industries include the chemical, automotive, construction, food and beverage, marine, pharmaceutical, medical device, military, electronic and aerospace fields. The importance of contract manufacturing is especially pronounced in some industries such as the global electronics market.

Quick links to Contract Manufacturing Information

The History of Contract Manufacturing

The widespread usage of contract manufacturing today is made possible by improvements in technology (specifically communication and transportation) and the resulting phenomenon of globalization. It is important to note that before the Industrial Revolution, multiple skilled tradesmen (such as a carpenter, upholsterer, and blacksmith) would have been necessary to create certain products. In this sense, then, “contract manufacturing” has been used for many centuries. The modern version of contract manufacturing, however, only came into being with the advent of the Space Age.

The electronics sector of contract manufacturing (electronics manufacturing services, or EMS) can justifiably claim to be the origin of the field as a whole. When NASA funding withered away in the mid-1970s, an Alabama businessman and government subcontractor named Olin King switched from offering his services to NASA to offering them to OEMs such as IBM. Another Alabama-based company named Solectron followed a similar pattern. The first contract-manufactured IBM PCs appeared in 1981. Besides economic benefits, factors such as environmental concerns with certain aspects of in-house OEM manufacturing (such as printed circuit board manufacturing) played a role in increasing the popularity of these original contract manufacturing efforts. These humble beginnings in the Deep South laid the foundation for the global EMS industry and a parallel for many other types of contract manufacturing.

Despite the success of the original contract manufacturing efforts, it took another decade (early 1990s) for contract manufacturing to truly spread to other commercial sectors such as clothing, pharmaceuticals, and toys.

Due to the rise of technology and globalization, the modern industry of supply chain management is a complex, multi-faceted field. The defining mark of supply chain management today is the critical role of contract manufacturers. Former challenges like the difficulty of locating a quality local manufacturer have been replaced by new challenges like choosing the appropriate contract manufacturer out of multiple national and international options. Some US-based estimates put the overall annual growth of contract manufacturing at 10% A rate which is only expected to increase in the future. In the United States, factors such as federal initiatives to mimic national manufacturing strategies in other developed countries are expected to assist this increase. From a global perspective, important sectors of contract manufacturing continue to grow at high annual rates. Two recent examples include the contract pharmaceutical industry (7.5% annual growth) and the global electronics market (15% annual growth).

Advantages of Contract Manufacturing

As explained earlier, businesses involved in contract manufacturing enter into a contract for a predetermined (and usually significant) length of time or until a certain number of units are manufactured. Businesses are willing to enter agreements like this because there are many benefits connected to contract manufacturing agreements.

- Maximization of Time

- With manufacturing contracts, OEMs are free to focus on their core strengths such as research and development (R & D), product development and design, marketing, etc. Increasingly, OEM employees rarely or never come into direct contact with the actual product a contractor is making for them. Some OEMs, of course, control the manufacturing portion of the supply chain and some contract manufacturers (in the pharmaceutical industry, for example) do participate in certain aspects of design and/or development. However, when both businesses focus on their core capabilities, the overall supply chain process is expedited.

- The efficiency of contract manufacturing is directly related to its emphasis on specialization. By empowering both companies involved to focus on their core capabilities, contract manufacturing preempts them from poorly investing in time-intensive tasks they are not particularly skilled at.

- Economic Savings

- Contract manufacturing spreads significant cost savings to all aspects of the supply chain. By avoiding the time-intensive tasks of managing a production facility and managing a labor force, OEMs obtain significant financial savings in addition to benefiting time-wise. Contract manufacturers themselves typically do business through the mass ordering of material in order to meet the simultaneous needs of multiple clients. This has a net effect of lowering costs throughout the supply chain and illustrates the concept of “economies of scale.” Ultimately, this results in cheaper products for the end consumer and higher income for the original OEM. Furthermore, OEMs are sometimes able to enter markets that would otherwise be impenetrable by working with contract manufacturers (e.g., an American business getting a foothold in China through a contract manufacturing agreement).

- Once again, this particular benefit derived from contract manufacturing’s emphasis on specialization. Thus, it is clear that specialization via contract manufacturing drastically increases commercial cost-effectiveness as a whole. Specialization can be considered contract manufacturing’s main benefit because it leads to the supply chain world’s primary goals – specifically, the maximum use of time and financial resources.

- Product Quality

- Contract manufacturing tends to enhance the quality of a finished product as well as its price. Contracting companies are often narrowly focused on one product or field, and as a result they usually possess deep levels of expertise and technical capabilities in whatever their area of focus is. The OEM and consumer ultimately benefit from the expertise of the contracted company through that company’s own quality control and quality assurance processes.

- Commercial Stability

- Since contract manufacturing agreements have significant mutual benefits, they tend to develop over a period of time and strengthen ties between partnering companies. This results in a sense of commercial stability for both the OEM and the contracted company. OEMs value having a trusted partner to produce a prized product, which can be hard to do when dealing with full manufacturers rather than contract ones. On the other hand, contract manufacturers value securing steady work for a guaranteed period of time (3-5 years on average).

Disadvantages of Contract Manufacturing

Like virtually all aspects of commerce, contract manufacturing also comes with significant disadvantages. Proper risk evaluation is particularly crucial in the use of contract manufacturing, which is impossible to do without properly understanding the risks involved. It is very important for both parties in a contract manufacturing agreement to intentionally cultivate their relationship in order to mitigate these disadvantages and form the basis of a long-term, mutually beneficial partnership.

- Inefficient Use of Time

- A major benefit of contract manufacturing is its maximization of time through specialization. Ironically, this same process can also negatively affect time usage due to a number of factors. Since contracting companies are often servicing several OEMs simultaneously, they may be induced or forced to prioritize certain ones at various times, thus delaying production for other OEMs. Cross-cultural outsourcing, in particular, has the potential to disrupt efficient time usage due to geographic and cultural or linguistic distances and the communication barriers that these realities can create.

- Compromised Product Quality

- Contract manufacturing typically results in better quality of a finished product due to the contracting company’s expertise. At times, however, contract manufacturing can have the opposite effect. If a contract manufacturing internal quality control and processes somehow differ from the OEM’s preferences, the OEM may not be pleased with certain aspects of the finished product. This can become especially problematic in scenarios where the finished product is branded with the name of the OEM rather than the actual manufacturing company.

- Intellectual Property Loss

- A significant risk to contract manufacturing in the loss of intellectual property. By definition, contract manufacturing involves an OEM sharing internal formulas, information, etc. with a partnering contractor in order for the contractor to produce something on the OEM’s behalf. Unfortunately, contractors sometimes take advantage of this reality to conduct commercial theft. This risk is particularly concerning since the loss of intellectual property is often difficult to detect immediately. OEMs can handle this risk in several ways. Some of those ways include producing items through the silo method (i.e. using individual contractors to produce only pieces of the overall product), keeping internal control over final production and QA stages, and working with extremely detailed legal contracts.

- Physical Risks

- If international outsourcing operations are located in a low-wage or politically unstable country, physical risks potentially leading to political or economic consequences may occur. Fortunately, thorough preparation beforehand (e.g. targeted research and corresponding safety precautions) are usually sufficient to keep these types of risks at manageable levels.

Contract Manufacturing Images, Diagrams and Visual Concepts

The reasons for selecting contract manufacturing doing production.

The reasons for selecting contract manufacturing doing production.

Materials, items, and products produced by the contract manufacturer and sold under the hiring company or used for further processing.

Materials, items, and products produced by the contract manufacturer and sold under the hiring company or used for further processing.

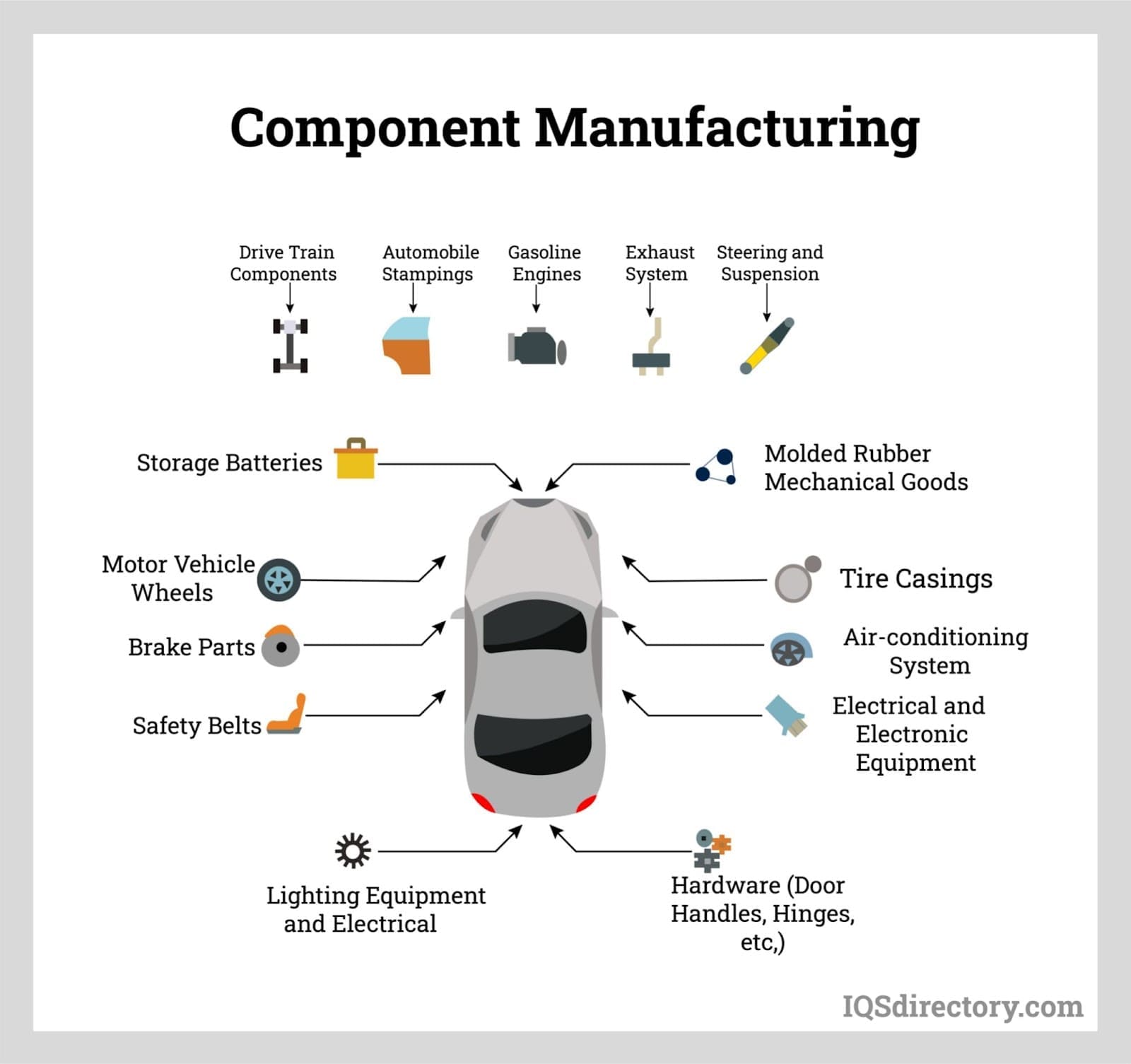

Component manufacturing helps produce components of products because a hiring company cannot afford to produce the components due to a lack of resources or expertise.

Component manufacturing helps produce components of products because a hiring company cannot afford to produce the components due to a lack of resources or expertise.

The electronics industry is a leading industry that utilizing contract manufacturing.

The electronics industry is a leading industry that utilizing contract manufacturing.

Metal fabrication services are contract manufacturers providing machining, casting, forging, grinding, drilling, spinning, bending, and broaching services for other companies.

Metal fabrication services are contract manufacturers providing machining, casting, forging, grinding, drilling, spinning, bending, and broaching services for other companies.

Contract manufacturers that produce finished or semi-finished plastic and rubber components are responsible for tooling design and fabrication.

Contract manufacturers that produce finished or semi-finished plastic and rubber components are responsible for tooling design and fabrication.

Most automotive companies contract out manufacturing of most of the automobile components, and assembly because automotive parts suppliers focuses on the quality and individual component accuracy.

Most automotive companies contract out manufacturing of most of the automobile components, and assembly because automotive parts suppliers focuses on the quality and individual component accuracy.

Overview of Contract Manufacturing

There are six major elements in any supply chain: the producer of raw materials, the supplier, the manufacturer, the distributor, the customer, and the consumer. The manufacturer’s role is to fashion raw materials prepared by the supplier into a product (complete or partial) that the distributor will ultimately give to both customers and consumers.

Contract manufacturing can be conceived of as a “division of labor” at the third link in the supply chain, since it is a service provided by a manufacturing company that is hired by an OEM. Contract manufacturers are simply companies that are hired to complete manufacturing for an OEM. This is usually their sole form of business. Contract manufacturers typically specialize in certain products in order to consolidate their expertise and value in a particular area. The contract manufacturing relationship consists of an agreement between the contracted company and the OEM to perform a certain job in a certain amount of time for a predetermined amount of money, which is sometimes paid up front. Companies are usually tied to deadlines that pertain not only to production dates but also to transportation timelines; if a contract manufacturer can produce a part but cannot ship it quickly and safely, then they will probably not secure a partnership with an OEM. Despite these realities, it is not uncommon for contract manufacturers to work for multiple OEM employers, including ones that compete with one another. Under normal circumstances, the OEM will merely provide the contract manufacturer with designs for production or improvement and handle all sales and marketing aspects pertaining to the finished product.

In some senses, supply chain management (the larger context for contract manufacturing) has not fundamentally changed over the centuries. Reducing production time and cost are still its top priorities, and the importance of special capabilities, advanced technology, communication, and transparency to achieve those goals remains constant. The most fundamental change to supply chain management has been the broadening of its context due to globalization. Today, a product might be shipped all over the world for various processes that make up the supply chain. A part might be designed in Germany but assembled in the Philippines from materials that were produced in China before it is finally sold in the United States.

Technological advancements in the twin fields of transportation and communication are largely responsible for this changed context. The degree of globalization described above would be impossible without fast and reliable methods of transportation. Improved communications have also contributed to the rise of globalization. As a result of advancing globalization, these developments have also advanced contract manufacturing. Now, companies and firms all over the world are able to effectively communicate, place bids, take orders and oversee production in the race to create the best possible end user products. Contract manufacturing is no longer limited by geographical borders; it is open to any firm who can meet the demands of interested companies.

Variations of Contract Manufacturing

As alluded to earlier, contract manufacturing can also be called outsource manufacturing. The term’s geographic connotation, however, can confuse clarity: the word outsourcing is often used to refer to manufacturing that takes place outside of North America. (This phenomenon was sometimes more crudely known as farming out.) Technically, however, the term outsourcing can refer to any type of manufacturing done outside of the OEM, regardless of geographic location. Nearshoring is a relatively new term associated with contract manufacturing which takes place in the same country as the hiring company, or a country that borders it. Nearshoring is sometimes used to cut down on project and product lead times and offset certain disadvantages to international operations (e.g. significant wage inflation in China).

Contract manufacturers provide a wide range of manufacturing processes including turning, boring, drilling, milling, sawing, shaping, planning, tapping or grinding as well as new technologies like electrical discharge, electrochemical or ultrasonic machining among others. Contract manufacturing companies employ this broad range of processes in many different kinds of manufacturing services such as contract machining, subcontract machining and contract assembly. While contract/subcontract machining focuses on creating original parts, contract assembly occurs when one company assembles parts to create a finished product for another (normally with the use of an assembly line).

Contract manufacturing is dispersed across a wide variety of fields.

- Electronic Contract Manufacturing

- Electronic contract manufacturing (the historical foundation of the overall field today) produces sophisticated electronic parts and products. It is a leading sector of contract manufacturing today.

- Industrial Contract Manufacturing

- Has some overlap with the EMS field (e.g. the production of semiconductors, robotics, etc.). However, its range of products extends beyond just electronics. In addition to electronics, industrial manufacturers also rely on contractors for things such as heavy industrial equipment, commuter rail lines, plastic products (often made by injection molding), various rubber products, various textile products, etc.

- Medical Device Contract Manufacturing

- The system by which a manufacturing company makes medical devices or components that are later sold by another company.

- Pharmaceutical Contract Manufacturing

- Produces goods or services for a pharmaceutical company such as pills, capsules, lotions, liquids and other items in addition to containers or packaging. Pharma contract companies, in particular, are commonly known as contract manufacturing organizations (CMOs) or contract development and manufacturing organizations (CDMOs).

- Chemical Contract Manufacturing

- A company that performs chemical manufacturing and synthesis on behalf of another obtaining the necessary starting materials, compounds and equipment in order to fulfill their end of the contract.

- Military Contract Manufacturing

- Completed by a company that produces military products including aircrafts, weapons, shelters, body armor and other equipment. This type of manufacturing is only done by specially approved companies based in the United States. It is not uncommon for military contractors to undertake significant amounts of non-military contracting to offset the unpredictable nature of governmental military spending.

- Aerospace Contract Manufacturing

- Produces parts and products related to the aerospace field: airplanes, helicopters, unmanned aircraft and military jets.

Choosing a Contract Manufacturer

Several factors should be considered when choosing a custom manufacturer. First, an entire supply chain is dependent on strong performances from each of its individual links. Thus, choosing the right contract manufacturer (arguably the most important chain in the link) is crucial to your business’s overall well-being. Additionally, this age of digital marketing and direct consumer access to commercial sources has witnessed a trend of consumers prioritizing cheap prices over specific brands. Contract manufacturers are therefore crucial in keeping market prices reasonable and satisfying this pattern in consumer behavior. Ironically, as the importance of choosing a contract manufacturer has increased, the ease of doing so has not necessarily done the same; although globalization has increased the potential pool of accessible contractors, it also confronts businesses with a dizzying array of choices. It is important to remember, however, that contract manufacturers depend on OEMs as much, or even more, than the reverse. Since contract manufacturers often exclusively perform contract manufacturing, they require a steady stream of commercial partnerships for their own stability.

Many of the things to look for in a contract manufacturer fall into the sometimes nebulous -- but important -- category of “soft traits.” Since contract manufacturing agreements are usually fairly long partnerships, it is imperative to look for signs that indicate the likely long-term success of such agreements. Consider a potential contractor’s reputation through reputable sources and/or referrals. When meeting with potential partners, look for qualities that will establish and enhance any future partnership: a shared passion for your product, willingness to meet your specific needs through customization and creative methods, etc. Consider a potential contractor’s level of transparency or accountability; it is a very positive sign if a potential partner actively encourages activities such as a trial partnership period or regular status reports.

Some more objective characteristics to look for in a contract manufacturer are:

- Technological Capabilities

- Including things like their level of investment in the latest technologies.

- Adherence to Industry-Specific Certifications and Standards

- E.g. GS1 standards for contractors in the healthcare industry.

- Industry Expertise

- E.g. years of experience in a certain industry, tendency to stay on top of regulations.

- Geographic Proximity

- Important for facilitating communications for the duration of the partnership.

- Flexibility with Payment Plans

- Indicative of a transparent contractor.

- Production Turnaround Policies and History

- E.g. policies for prioritizing different customers, measurable track records of on-time deliveries, etc.

Contract Manufacturing Terms

- Bill of Materials (BOM)

- A list which includes all subassemblies and components that go into a certain product. The BOM also shows quantities of each material used.

- Box-Built

- Refers to any assembly work that does not involve printed circuit board production.

- Contract Assembly

- Refers to a process that involves one company sending loose or modifiable components to a contract assembler. The business that receives the separate parts uses their machinery to assemble the product components and make a profit once the final products are sold back to the business.

- Contract Machining

- Is a service offered by many contract manufacturers that includes such processes as milling, wire eroding, punch press and laser cutting. You can find companies doing CNC machining work on IQS Directory.

- Contract Manufacturers

- Produce products for another company. The contract manufacturer's name does not appear on the finished product when it is sold, only the name of the hiring company appears on the finished product.

- Contract Manufacturing Services

- Involve any procedural actions performed by a contract manufacturer to meet the needs of a buying company. These services include but are not limited to product design and validation, rapid prototyping, assembly, testing, and sustained engineering.

- Core Competencies

- Procedures or actions that are essential to a company’s long -term growth and success. Core competencies tend to be skills and knowledge rather than company functions or products.

- Corrective Action Request (CAR)

- An action request usually filed by an OEM that asks the responsible business to conduct a cause analysis regarding the error and to resolve the issue at hand.

- Engineering Change Order (ECO)

- An alteration to a bill of materials (BOM) such as the replacement of a specified component by a substitute for it. ECOs commonly contain a reason and description for the change, and the date for implementation of the change.

- High-Mix, Low-Volume

- A production where low quantity products assembled vary in design and process.

- Intellectual Property (IP)

- Any unique product developed by human intellect. IPs include inventions, ideas and business methods.

- Joint Service Agreement (JSA)

- A contract and document used to define processes, performance estimations, and expectations for the contract manufacturer and the OEM. It also serves to reduce misunderstandings which sometimes occur.

- Low-Mix, High-Volume

- A production that includes one or few variations of a high quantity good.

- Manufacturing and Supply Agreement (MSA)

- A contract designed to outline responsibilities between a contract manufacturer and the OEM which purchases the product(s). MSAs describe what the manufacturer is to provide for the OEM and at what cost.

- New Product Introduction (NPI)

- A set of procedures used to turn a product design into a product ready for manufacturing. The product must also meet quality, cost, and time-to-market requirements.

- Non Recurring Expense (NRE)

- One or more activities/items required by a contract manufacturer that are specific to a single OEM’s product program. Some NREs include special tooling, programming and setup.

- Original Design Manufacturer (ODM)

- Any company that manufactures its own unique product. From the ODM, the product is commonly sold to an OEM. ODM designs are based on their own intellectual property.

- Original Equipment Manufacturer (OEM)

- A business that specifies and designs products under its own name. With outsourcing, many OEMs obtain “their” products from another source.

- Outsourcing

- The procedure used to subcontract a process. Product designs and manufacturing techniques are commonly outsourced by a third -party company such as a contract manufacturer.

- Prototype

- An original model or mock-up of a technological process or device. They are used to generate criticisms and other information that will help the final design before production takes place.

- Request for Quote (RFQ)

- A document prepared by an OEM and submitted to a contract manufacturer. The RFQ contains product quantities and specifications, as well as a BOM.

- Subcontract Machining

- Is another name for contract machining and is any one of many mechanical processes involving a cutting tool.

- Time to Market

- The time required to bring a quality product into the market.

- Time to Volume

- Length of time necessary to turn a prototype into a high-volume production good.

- Volume Price Agreement (VPA)

- A contract service agreement that contains deliverables, pricing, and cost reductions based on volume production.