Ball Valves

Ball valves provide a simple way to turn the flow of gases or liquids through a pipe on or off with the assistance of a secure seal. The handle of one of these valves moves in a 90-degree (or "quarter turn") range of motion. The valve itself in its most basic form consists of a sturdy metal joint housing containing a spherical ball with a hole bored through the center. A slot in the top of the ball connects with the stem of a handle extending to the exterior of the pipe.

Consumers sometimes confuse the ball valve with a specialized "ball check valve", a device intended to block backflow. The ball check valve differs because it employs only a solid interior sphere, not a bored one. This article discusses only conventional ball valves.

Quick links to Ball Valves Information

Ball Valve History

Sometimes known as a "spherical plug" valve, the ball valve originated only comparatively recently. Aviation experts working for the United States government engineered the first ball valves as components of Allied aircraft during the Second World War. A ball-type valve patented in 1871 by inventor John Warren possibly inspired the invention.

During the post-WWII period, the use of ball valves spread widely. Inventors have continued to improve the design of these valves. Today, manufacturing innovations permit this technology to assist multiple economic sectors.

The Benefits of Using a Ball Valve

- Reliable Tight Seal

- Ball valves offer many benefits. First, these devices supply a reliable way to obtain a tight seal to shut off the flow of gases. They can permit the flow of materials in multiple directions (through the use of a three-way ball valve, for instance). Ball valves display low pressure drop properties too, making them especially useful when someone needs to turn the flow of a gas off or on quickly.

- Cost Effectiveness

- Second, ball valves today remain a very cost-effective product. Manufacturers produce these valves using a variety of materials, including brass and steel. Companies can locate a wide selection of affordable ball valves to resolve many engineering problems. These products do not require technical expertise to operate. Additionally, the process of repairing a ball valve remains simple.

- Attractive Design

- Third, ball valves available for consumers sometimes display attractive design features. For example, one of these valves in a stainless steel, brass or copper faucet may supply stylish lever handle properties designed to promote a fashionable décor. Ball valves have achieved popularity for both industrial and residential use.

Common Ball Valve Applications

Ball valves occur frequently in factory and manufacturing settings. This industrial valve often serves as a component of machinery, for instance. In mechanical designs, engineers frequently specify the use of an actuator (usually electric or pneumatic) to move a ball valve into an open or closed position.

The valve and actuator may perform important roles within a mechanical assembly. A more sophisticated type of ball valve called a "globe valve" sometimes serves as a control valve in auto transmissions. It helps regulate flow control.

Additionally, you'll find ball valves serving in both commercial and residential infrastructure settings. They enable operators to turn the flow of water or gas on or off conveniently simply by turning a lever handle at right angles. These devices perform a useful role in the delivery of water, heating oil, and natural gas, much like solenoid valves do.

Engineers have developed a variety of different types of ball valves. This popular "quarter turn" style of valve enjoys a wide range of uses around the world today. You'll discover the ball valve manufacturers listed on the Industrial Quick Search Directory carry great selections of ball valves Ball Valve Manufacturers Suppliers, including some special purpose models. We furnish helpful contact information for a number of suppliers.

Numerous enterprises rely upon these reliable industrial valves. Some of the economic sectors that use ball valves extensively include the mining industry, agricultural producers, the oil and gas industry, the construction industry, the transportation industry, the consumer goods industry, and the chemical industry. Variations in ball valve designs have permitted the adaptation of this valve for use in diverse settings. Some examples of specialized types of ball valves include the float ball valves and the trunnion ball valve.

The Design and Engineering of Ball Valves

Ball valves have gained importance in so many applications because they provide a simple way to shut off the transmission of gases and liquids through distribution systems effectively. The fittings and housings for these products vary, allowing excellent customer selection. Currently you can find these useful products in a variety of dimensions, designs and constituent materials, including stainless steel, ductile iron, carbon steel, bronze and brass.

While these valves sometimes work with a valve body and gear operator, they generally perform limited "on/off" functions. A ball valve usually won't suffice for sophisticated flow regulation as well as a globe valve, for instance. Nevertheless, these industrial valves do provide a very cost-effective solution for many engineering problems.

In the "open" position, the cavity running through the center of the ball aligns perfectly with the openings of the input and output pipes located on either side; it allows the contents of the input pipe to flow through the ball to reach the output pipe. However, turning the handle of the ball valve into the "closed" position will shut off the flow completely. This action turns the ball, placing its opening perpendicular to the flow of material in the pipes. A closed ball valve provides a secure way to shut off the flow of natural gas, oil, water, or other gases or liquids. It offers a more convenient type of handle than a cumbersome gate valve for most residential uses.

Ball valve manufacturers produce valves with two primary design options: floating ball and a trunnion. A floating ball valve uses a non-fixed ball to drift into place against the seat, providing a tight seal. A trunnion fixes the ball in a certain place and is used for more complicated applications and, therefore, is costlier. The handle, which can be motorized, actuated or manual rotates the ball a one-quarter turn. When the hole of the ball is facing away from the pipe opening, flow is restricted. When it is aligned with the opening, flow is restored. The position of the handle immediately indicates whether the valve is closed or open. Ball valves are manufactured from a variety of materials, the most common being stainless steel, brass, cast iron and plastic such as PVC. The size of ball valves can also vary. Mini ball valves are usually less than an inch in diameter and are therefore used in hard to reach areas or in confined spaces. 3-way and flanged ball valves are variations in ball valve manufacturing. Ball check valves allow liquids to flow in only one direction and high-pressure ball valves allow low and high flows of pressure and temperatures. Discover check valve manufacturers here on IQS Directory's company listings page.

Features of Ball Valves

The technical specifications for the interior ball in a ball valve may require the use of specific metal or metal and ceramic products, particularly when the valve functions in a high-pressure environment. Some manufacturers offer ball valves with interior plastic balls or metal balls. Customers will want to review requirements for this feature carefully when choosing any ball valve since it may impact the durability and usefulness of the valve for particular applications.

For example, a design specification may require the use of a stainless steel ball valve. Manufacturers have also developed specialized types of ball valves in which the interior metal ball receives nickel or chrome plating to increase the product's ability to withstand heavy use or to offer better protection against corrosion.

Currently, many types of fittings permit the connection of tubes and pipes, including the socket weld and the double ferrule. Today a design standard sometimes provides for the presence of a high-quality ball valve between two connecting pipes or tubes. The specifications for any given ball valve may vary widely, based upon the manufacturer standard, industry practices and the applicable testing standard employed by oversight bodies. Purchasers who obtain customized ball valves will want to confirm test inspection and quality control practices in some situations.

When customers evaluate suitable ball valves, considerations such as the constituent materials in the ball valve itself, the dimensions, the pressure, the lining material, the body material, the anticipated product lifespan, and the ultimate purpose of the valve (i.e. the types of gases or liquid flows it controls) may all become extremely important considerations. The majority of ball valves operate at room temperature, so design specifications may become exceedingly important for valves subjected to high or low temperature environments. Most manufacturers will offer customers detailed information about applicable product specifications and capabilities. They may furnish useful guidance about the anticipated lifespans of different ball valves.

Ball Valves Images, Diagrams and Visual Concepts

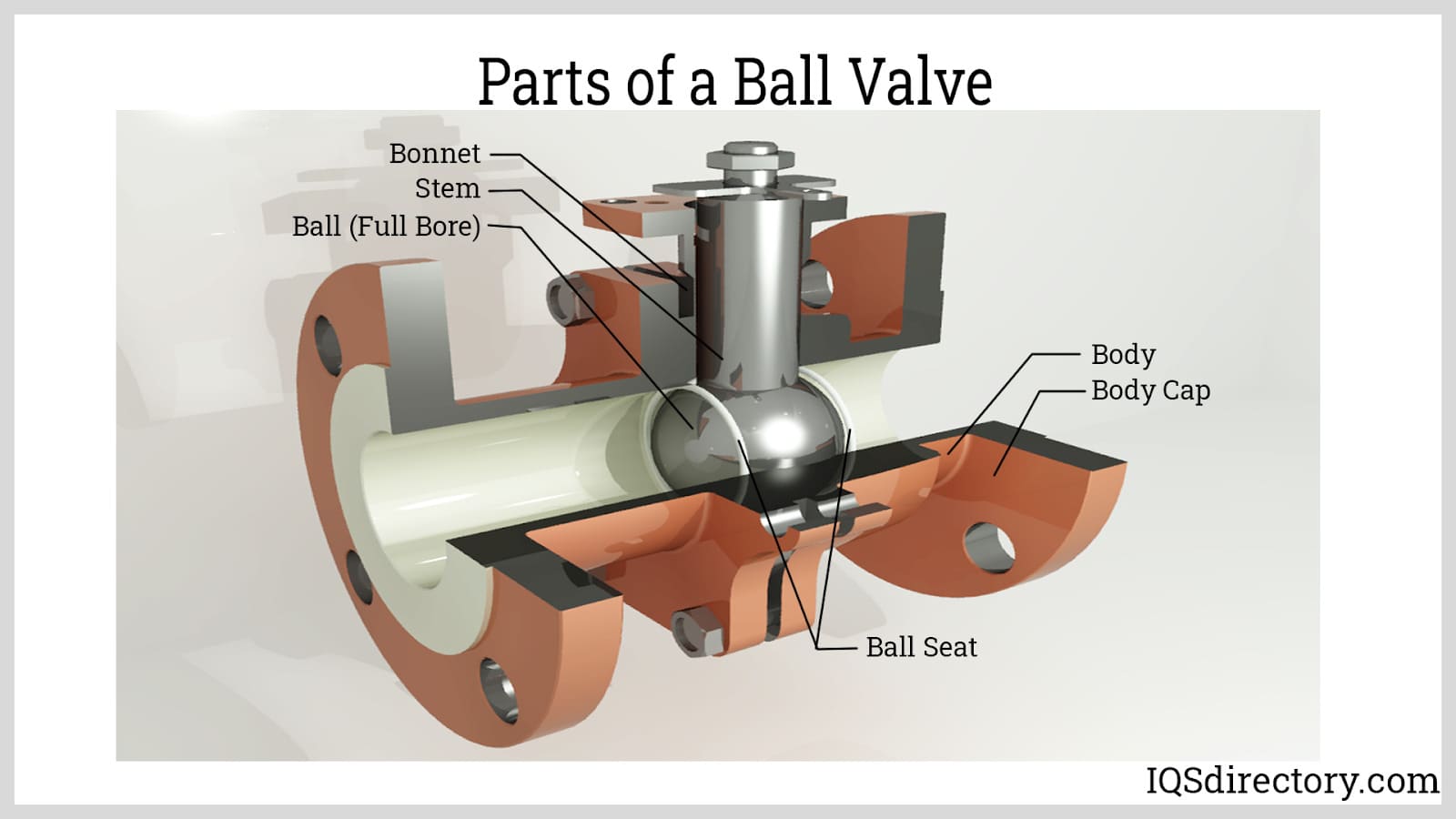

The internal components of a ball valve inside the valve housing.

The internal components of a ball valve inside the valve housing.

A one-piece ball valve has a single-piece cast body that houses the internal components and eliminates the risk of leakage.

A one-piece ball valve has a single-piece cast body that houses the internal components and eliminates the risk of leakage.

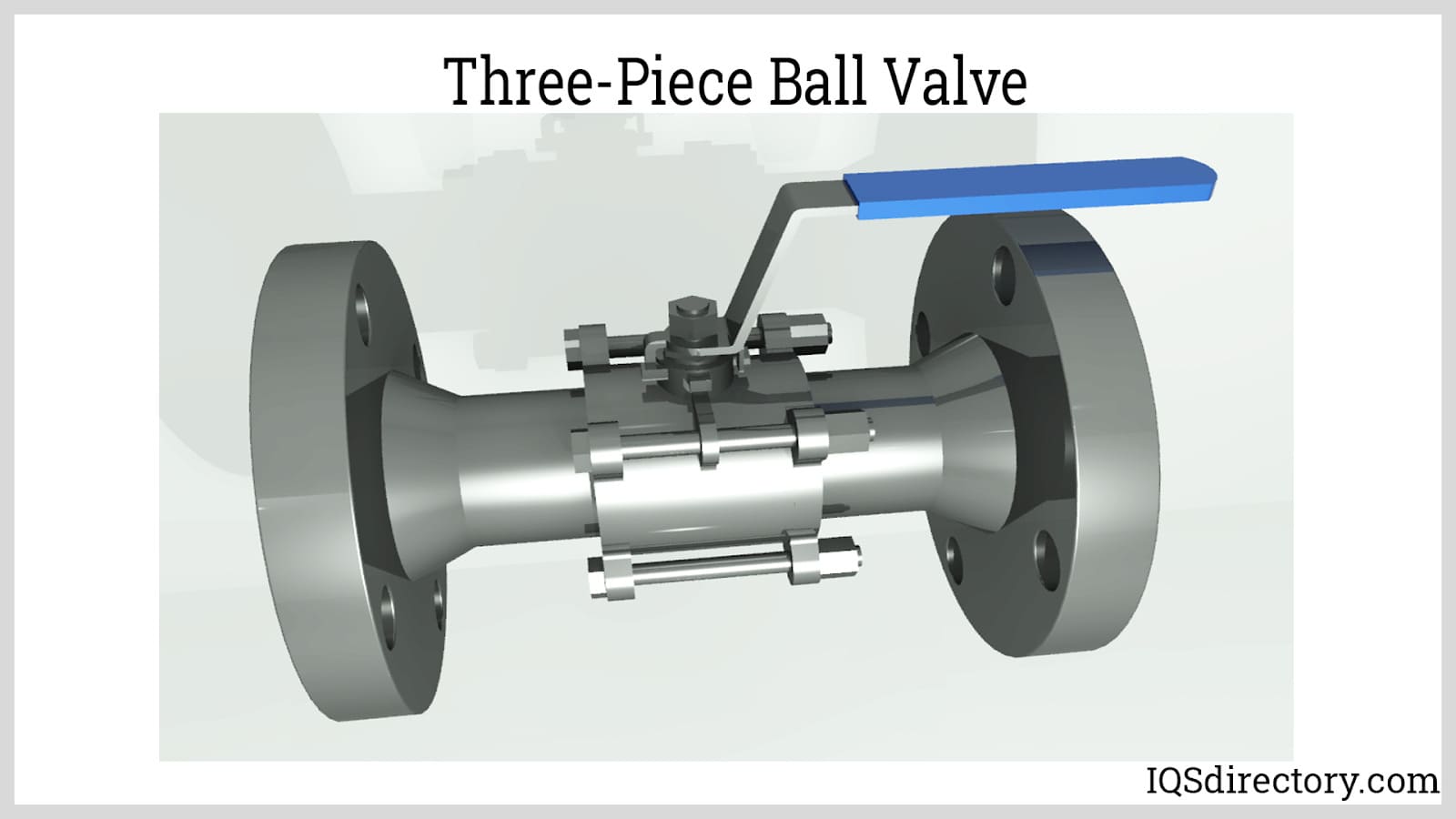

A three-piece ball valve, the internal components are fitted and held together by bolt connections.

A three-piece ball valve, the internal components are fitted and held together by bolt connections.

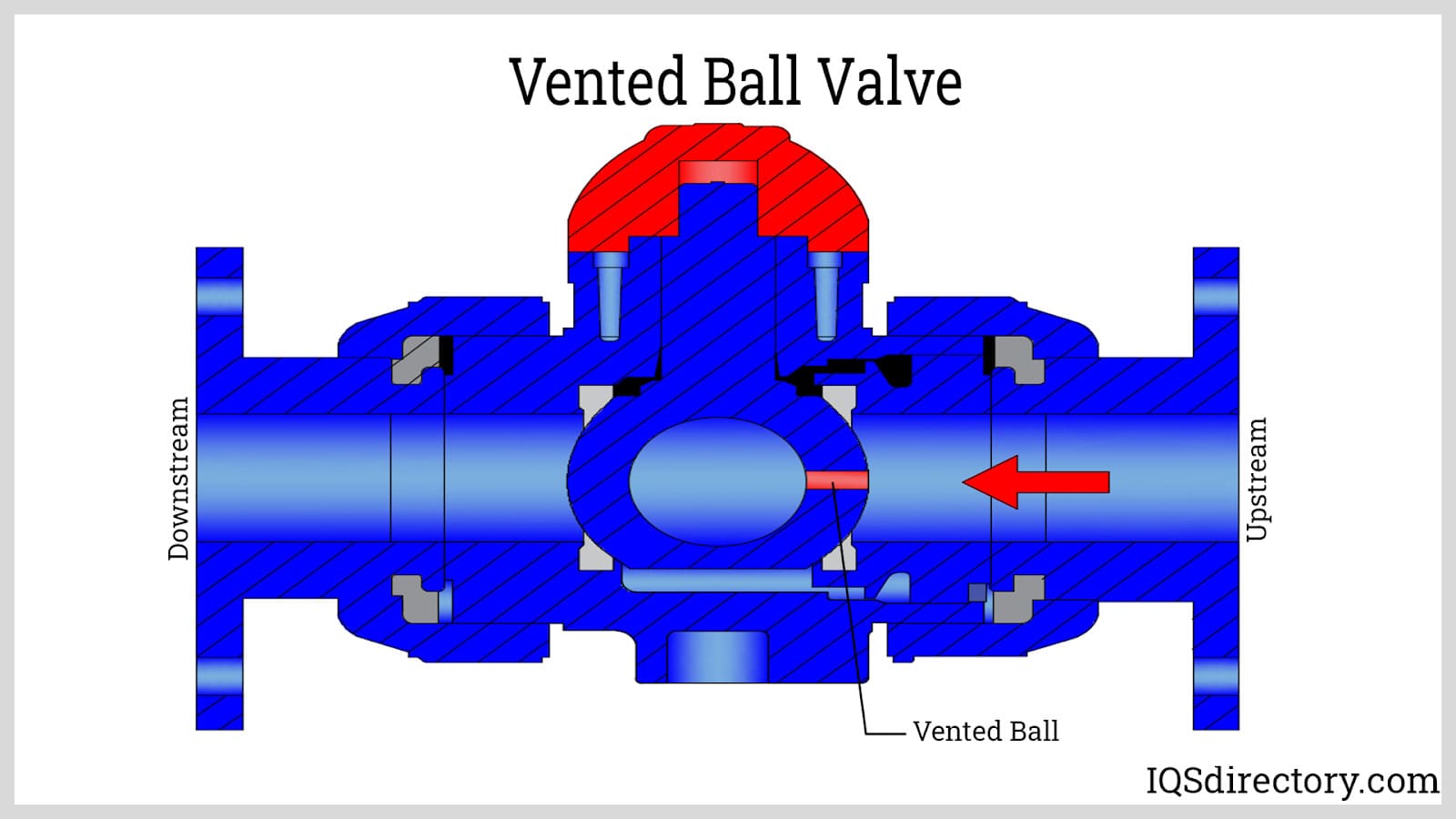

Vented ball valves are constructed and operates the same as a standard ball valve, except that the vented ball has small orifices drilled into its side.

Vented ball valves are constructed and operates the same as a standard ball valve, except that the vented ball has small orifices drilled into its side.

Types of Ball Valves

Manufacturers usually categorize different types of ball valves using two main criteria: the movement of the interior ball and the depth of the bore (full bore, reduced bore or specialized bore). For instance, the ball inside the valve may receive additional anchoring, or it may remain attached only to the stem. In some cases, specialized ball valves rely upon moveable stems. Engineers have developed some popular varieties of ball valves for use in some settings:

- 3-Way Ball Valves

- Have three different ports. Some three-way valves have all ports open while others may all be closed or only have one open.

- Actuated Ball Valves

- Not operated manually, but rather automatic power actuators.

- Ball Check Valves

- Valves where liquids can flow only one way. The pressure from the liquid forces the ball to move, when the pressure from the fluid stops the ball also stops and the valve closes.

- Brass Ball Valves

- Valves made from brass, one of the most common materials for ball valves.

- Flanged Ball Valve

- Many industrial ball valves provide a body which joins along a central rib, or flange. This flanged ball valve design may offer ease of access, but sometimes also increases the risk of leakages.

- Floating Ball Valve

- In some cases flows in a pipeline will cause an interior ball attached only to the stem to float slightly. The seal will remain tight, although some wear may occur against the stem.

- Full Port Ball Valve

- This special type of ball valve has gained wide use in refineries and chemical plants. It employs an identical diameter for the pipeline and the bore of the interior ball in order to maximize flow. A full port ball valve may assist pipeline operators in controlling the impacts of friction and pressure.

- High Pressure Ball Valves

- Can handle small and large flows with high pressure ratings.

- Mini Ball Valves

- Very small valves that use a rotating ball to create a seal.

- Motorized Ball Valves

- Engaged by an electric motor instead of being manually operated.

- Multiport Ball Valves

- Will connect multiple pipes to the valve. They sometimes play an important role in mixing gases or other products used for manufacturing.

- Plug Valves

- Quarter-turn valves which utilize a cylindrical or tapered plug with a hole in the middle to control flow.

- PVC Ball Valves

- Made of a polymer of vinyl chloride.

- Stainless Steel Ball Valves

- Made of stainless steel.

- Swing Check Valves

- Use outside levers to slow down the flow of materials through a pipe. The lever pulls the ball into the flow which causes the flow to stop more quickly.

- Trunnion Ball Valve

- Ball valves with extra support for the ball on both the top and bottom contribute to high pressure pipelines.

- Two Way Valves

- Have an inlet pipe connection and an outlet pipe connection.

- V-Port Ball Valve

- Manufacturers sometimes create the bore or the ball inside a ball valve in a "V" shape in order to gain greater control over flow speeds.

Installing a Ball Valve

Always follow manufacturer guidelines to ensure the correct installation of ball valves. Specific industry protocols also may apply during some installations. People working in unique work settings sometimes must adhere to specific safety practices to avoid job hazards.

Ball valves tend to work dependably; they supply an easy learning curve for manual operation. Even extended periods of disuse generally won't impact their performance. These simple valves have achieved popularity today in part because of their relative ease of installation and use.

Ball Valve Standards and Specifications

Ball valve manufacturers and customers need to pay close attention to standards promulgated for use by different industries with respect to pipes and valve products. These regulations sometimes establish specific testing requirements. For example, 49 CFR 195.116 sets forth federal requirements for transporting hazardous liquids by pipeline. It specifies minimal standards for valves (including ball valves) used for this purpose.

Industry associations sometimes offer assistance to companies seeking to learn about specific compliance and testing requirements. Piping codes, such as ASME B31.3, have established standards for specific categories of ball valves in many situations. It makes sense to explore these regulations carefully when you manufacture or purchase ball valves for specific purposes.

Ball Valve Care and Maintenance

In some situations, technicians may need to periodically verify the condition of the interior ball inside the ball valve to ensure it has not become plugged or corroded. Since the valve requires the maintenance of contact between the ball and the stem of the valve handle in order to function correctly, a broken or heavily worn stem may require valve repair or replacement.

How to Select a Ball Valve Manufacturer

Businesses sometimes inquire about the best process for selecting a ball valve manufacturer. We have listed above many excellent companies. Ultimately, the best manufacturer will address your company's unique product needs. You will find our web pages offer a wealth of helpful information about ball valves and ball valve suppliers!

Ball Valve Accessories

Some vendors offer ball valve accessories, such as stem extension devices. Since many ball valves function in highly regulated capacities, it makes sense to consult industry safety and legal code requirements before using any accessories. Additionally, some manufacturers today supply original equipment manufacturer products designed to work solely with specific customized brands of spare parts. Using unauthorized or non-OEM products may void manufacturer warranties in some situations.

Ball Valve Terms

- Actuator

- Used to operate the ball valve. The actuator is often used to control the flow of materials.

- Ball

- The closure portion of the valve that restricts or controls the liquid or gas flow.

- Butterfly Valve

- A valve that utilizes a circular disc or vane in order to control flow by turning the valve’s pivot axis at 901/4 angles to the pipe’s flow direction.

- Flange

- A projecting rim or edge used to strengthen or attach one object to another.

- Full Bore Value

- The diameter of the ball inside the valve equals the diameter of the pipe. This is also called full port.

- Globe Valve

- A globular shaped valve whose internal moving parts consist of the disk, the valve stem and the hand wheel.

- Poppet Valve

- A valve that moves up to or from its seat perpendicularly. This valve generally provides more flow than a ball valve.

- Port

- Flow path.

- Pressure Control Valve

- A valve that controls the amount of pressure. Typically the valve will shut when a predetermined pressure is reached.

- Pressure Relief Valve

- A valve that releases pressure if needed. This valve is self-operating.

- PSI (Pounds Per Square Inch)

- A unit of pressure; equivalent to the metric unit of Kilonewtons per square centimeter.

- Reduced Bore Value

- The ball inside the valve has a hole smaller than the opening in the pipe, allowing for better control. This is also called standard bore or port.

- Relief Valve

- A valve that when open allows for the release of excess pressure or temperature.

- Slurry

- A mixture of liquid, typically water, and solid materials to create a material similar in consistency to mud or plaster of Paris.

- Trunnion

- Upper and lower supports used to keep the ball under pressure.

- Valve Seat

- A stationary part of the valve which restricts liquid or gas flow when it comes in contact with the movable portion of the valve.