Titanium Etching

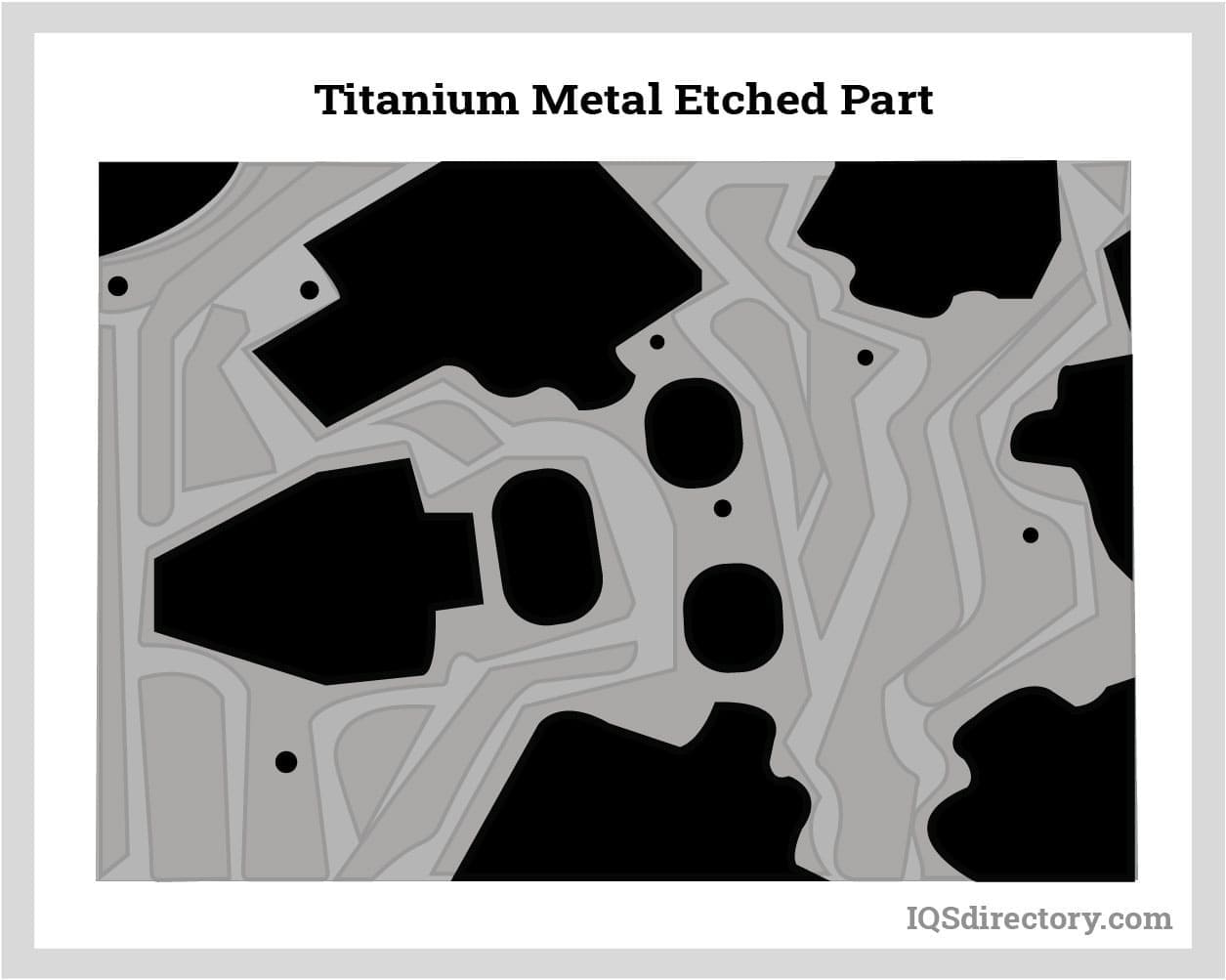

An acid is used in titanium etching to change a titanium part's surface

permanently. The acid acts as a corrosive, eating away at the metal's

surface and creating pitting and oxidation in some places. This process

produces a distinctive effect that can resemble tarnished metal or, when

done carefully, can produce a mirror-like sheen. In essence, this procedure

enables one to give titanium items' surfaces a distinctive finish. Jewelry,

medical equipment, and other products requiring a high level of durability

frequently use this method. When done properly, titanium etching can produce

a distinctive, aesthetically pleasing, and corrosion-resistant finish.

However, it's crucial to remember that not all titanium alloys can be

etched. Generally speaking, the greatest candidates for etching are titanium

alloys with a modest amount of nickel.

Why Titanium Etching is Preferred

There are various reasons why one might want to etch titanium. One of

these—possibly the most typical—is that it can be a reasonably priced method

of giving titanium objects a distinctive finish. Etching titanium parts are

frequently substantially less expensive than machining or using other, more

conventional techniques. Additionally, titanium etching might increase the

robustness of items. A titanium item may be strengthened by the acid used in

the etching procedure by hardening its surface. Additionally, etching

titanium parts can aid in preventing corrosion. A titanium surface that has

not been etched may be more susceptible to rust than one that has undergone

the oxidizing process.

The adaptable metal titanium (Ti) is renowned for its biocompatibility, high

tensile strength-to-density ratio, and resistance to heat and corrosion. Due

to these properties, Ti is widely employed in the aerospace, medical, and

automotive industries. There are various ways to work with Ti for

manufacturing; however, chemical etching is the most effective manufacturing

technique when working with Ti sheets or engraving Ti items. Compared to

other techniques like laser cutting or stamping, chemical etching titanium

offers more potential for large-scale production and significant cost

savings.

Titanium Etching Process

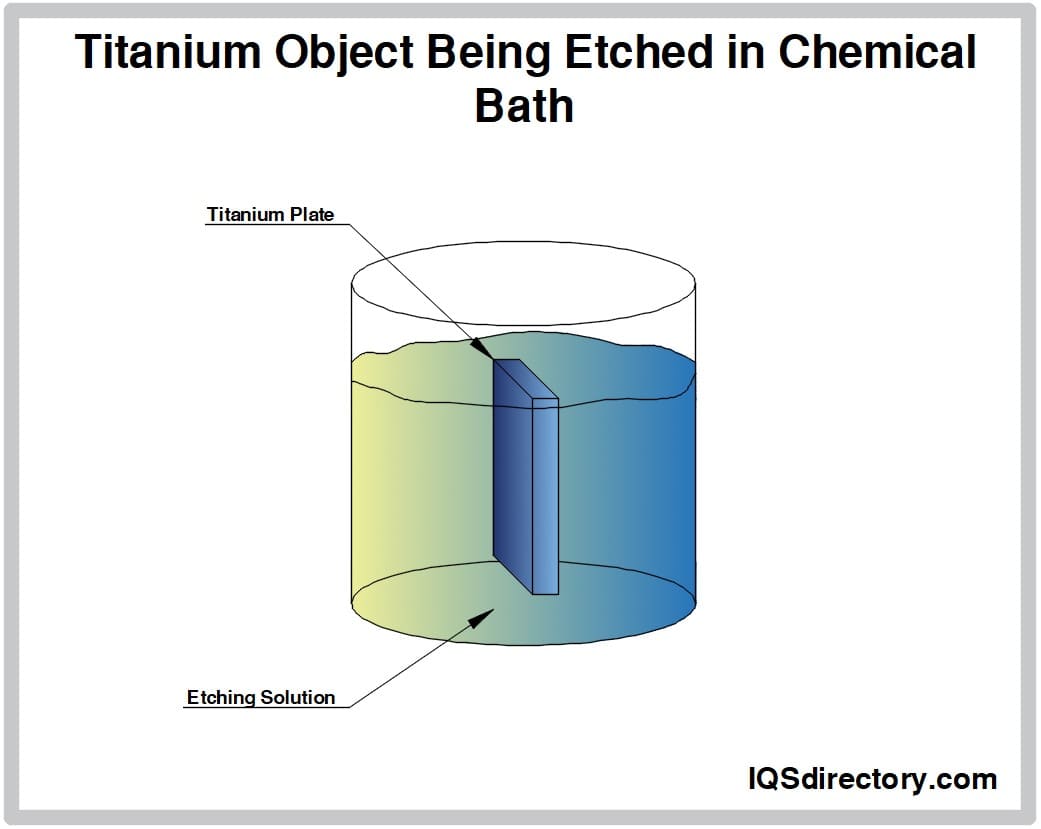

Cleaning and preparing the titanium part's surface is the initial stage in

the etching procedure. This step is frequently accomplished by using an

abrasive pad or machine to sand the surface. The cleaned component is then

placed in a chemical bath of water and sulfuric acid. The acid corrodes the

component by eating away at the surface. The thickness of the etched surface

determines the precise amount of time the item is left in the solution.

Typically, smaller components will etch faster than larger ones. Increasing

the temperature of the solution is another way to speed up the etching

procedure. The part's surface will have oxidized by the time etching is

finished. The part can then be cleaned out after being immersed in the

etching solution and dried.

Since titanium has great corrosion resistance, it may be the hardest metal

to etch. This quality means that high electron affinity etching solutions

are needed; hence, only hydrofluoric acid (HF) and ammonium bifluoride

(NH4HF2; hereinafter referred to as ABF) will etch titanium. Even though

both of these methods exist for etching titanium, HF is the most useful one.

Although both require rigorous safety measures, handling HF is simpler than

ABF and has a production-ready etch rate.

One can effectively etch Ti using HF. Though not optimal, this process

results in hydrogen gas (H2) generation. Its manufacture poses greater

safety challenges because H2 is so explosive. Nitric acid (HNO3) is

introduced to the reaction to lessen the creation of hydrogen during this

process.

The Advantages of Titanium Etching

-

The component's surface will oxidize, increasing its corrosion resistance.

-

The component will have a distinctive finish that will set it apart.

- The portion will be stronger since the surface will be thicker.

- Parts that are too large or expensive to grind can be etched.

- smooth edge profile

- smooth surface etch profile

- no surface burrs

- tight tolerances possible

- ±10% of material thickness

- complex geometries at no extra cost

- 1:1 aperture aspect ratio possible

- thicknesses from 0.010 mm – 1.00 mm

- part size up to 280 mm x 480 mm

- fast turnaround

- serial production capacity

- no heat-affected zones

- safer chemistry reduces personal and environmental risks

Limitations of Titanium Etching

- The etching procedure can take some time.

- The precise level of corrosion might not be under control.

- There may be variations in the surface finish.

- Some titanium alloys are not appropriate for etching.

- The finish on the surface could be prone to scuffing or peeling.

Conclusion

An acid is used in titanium etching to change a titanium part's surface

permanently. The acid acts as a corrosive, eating away at the metal's

surface and creating pitting and oxidation in some places. This produces a

distinctive effect that can resemble tarnished metal or, when done

carefully, can produce a mirror-like sheen. The component's surface will

oxidize, increasing its corrosion resistance. The component will have a

distinctive finish that will set it apart. The etched portion will be

stronger since the surface will be thicker. Parts that are too large or

expensive to grind can be etched.

To ensure the most constructive outcome when selecting a titanium etching

company, it is important to compare several companies using our directory of

titanium etching businesses. Each titanium etching company has a business

profile page highlighting their areas of experience and capabilities, along

with a contact form to directly communicate with the company for more

information or request a quote. Review each titanium etching business

website using our proprietary website previewer to quickly learn what each

business specializes in. Then, use our simple RFQ form to contact multiple

titanium etching companies with the same form.