Car Wash Equipment

Car washing is the process recommended by manufacturers for cleaning a vehicle. It can be done manually with basic equipment like a bucket and rag, though numerous products are available to help with hand washing, spraying, scrubbing, waxing, and drying. These tools include pressure washers, chemical or natural cleaners, waxes, sponges, brushes, nozzles, and both natural and synthetic cloths.

While hand washing is still practiced commercially, the advent of automated car wash technology has made manual washing, or at least most of its steps, nearly obsolete—except for those who prefer the traditional method.

Automated car washes can either be fully automatic or semi-automatic, where attendants handle certain tasks. These systems may operate with coin or credit card payments, with some staffed by attendants who oversee the machinery and equipment. In some cases, multiple attendants may be present to assist with tasks like interior detailing and drying.

Car Wash Equipment FAQ

What are the main types of automated car wash systems?

Automated car washes include in-bay automatic, tunnel, touch-free, steam, and waterless systems. Each uses different technologies to clean vehicles efficiently, with touch-free and waterless options designed for safer and more eco-friendly cleaning.

How does a self-service car wash work?

A self-service car wash provides a bay with high-pressure hoses, foaming brushes, and a control panel. Users insert coins or cards to activate the system, choosing functions like soap, rinse, wax, or tire cleaning, with time based on payment amount.

What is the difference between touchless and cloth friction car washes?

Touchless systems rely on high-pressure water and cleaning agents without physical contact, reducing the risk of scratches. Cloth friction systems use rotating soft cloth brushes with soap and water to scrub the vehicle’s surface more thoroughly.

Why are commercial car washes more environmentally friendly?

Commercial car washes recycle and filter water, minimizing waste and preventing contaminants from entering storm drains. They use less water than washing at home and employ biodegradable cleaning agents designed for vehicle surfaces.

What equipment is essential in a car wash system?

Key car wash equipment includes pressure washers, rinse arches, booms, mitter curtains, scrubbers, foam applicators, and digital control systems. These components work together to wash, rinse, and dry vehicles efficiently in commercial or self-service setups.

When did the first automatic car wash appear in the U.S.?

The first fully automatic car wash appeared in 1951 in Seattle, created by the Anderson brothers. It introduced automated soap and water nozzles, brushes, and dryers, setting the foundation for modern automated car wash systems.

What should be considered when purchasing car wash equipment?

When buying car wash equipment, consider the facility type, space, water and power requirements, and local demographics. Manufacturers can assist with system selection, setup, maintenance, and environmental compliance to ensure long-term success.

History of Car Washes

The concept of car washing has been a key part of urban life long before the popular 1970s movie brought it into the spotlight. In 1914, Frank McCormick and J.W. Hinkle launched the first known commercial car wash, the Automobile Laundry, in Detroit. Workers manually pushed cars through a tunnel, applying soap, washing, rinsing, and drying the vehicles. In the 1920s, the Auto Wash Bowl in Chicago featured cars driving in circles to clean off mud from the tires and undercarriages, before entering a stall for hand washing. The first automatic conveyor wash opened in Hollywood in 1940, where cars were still washed by hand, but were pulled through the tunnel by a conveyor.

In 1946, Thomas Simpson invented an overhead sprinkler that wet the car from above. That same year, Leo Rousseau founded Minit-Man, Inc., which created the first auto washing equipment. Rousseau's first customer, Paul Maranian, opened the world’s first automatic car wash in Detroit. Joe Dahm expanded the business to Indiana and beyond in 1948. The first fully automated car wash system was introduced in 1951 in Seattle, developed by the Anderson brothers, Archie, Dean, and Eldon. This system featured nozzles that applied soap and water, automated brushes, and a 50-horsepower dryer.

Dan Hanna, often called "The Father of the Modern Car Wash," founded Rub-a-Dub in Milwaukie, Oregon, in 1955. He continued to innovate and by the mid-1960s, his company had become the world’s largest manufacturer of car wash equipment. In 1962, Carlo Pecora of Appleton, Wisconsin, introduced the first express car wash, focusing on exterior-only cleaning.

In the 1970s, Dan Hanna introduced the 3-in-1 system, combining a gas-up service, exterior wash, and interior cleaning. However, the system did not gain widespread popularity, partly due to the time it took and the large 14' x 28' setup, which was difficult for many businesses to accommodate. During the 1980s, Flex-serve car washes gained popularity, offering either full service or express detailing in separate sections of the wash bay. In 2001, Ben Alford introduced the first automated express wash with gates and a self-pay terminal.

As technology continues to advance, car wash systems are incorporating machines that use water and energy more efficiently, providing faster, safer, and more environmentally friendly cleaning solutions. The use of stainless steel and powder-coated materials in manufacturing ensures that the equipment is more durable and long-lasting.

How a Car Wash Works

For those who don’t have a driveway or a hose, a self-serve car wash is the perfect solution. These facilities provide a range of cleaning options, often starting with a coin-operated industrial-strength vacuum cleaner located next to a trash can, although in some cases, the vacuum station may be positioned at the end of the process.

Once the debris is cleared, with sand and gravel sucked from the carpets and crumbs brushed off the seats, the vehicle is driven into a bay where the washing process begins.

A control panel offers various cleaning choices, including rinsing, engine degreasing, tire cleaning, soaping, and brushing. The spray nozzle, typically connected to a swiveling overhead manifold that distributes water and cleaning solutions, has both low and high-velocity settings, which can be adjusted using a trigger on the spray wand.

A separate scrubbing brush, attached to another swiveling manifold that dispenses soap foam, can be selected from the control panel. The brush is typically used after an initial rinse and the application of cleaning solvents to scrub the surfaces.

Some self-serve wash stations offer a "truck wash" bay, which is either taller than the standard bays or open at the top. These bays are equipped with ladders to help wash the upper sides and roofs of trucks, buses, motorhomes, and trailers.

Once the vehicle is thoroughly cleaned, the system can be switched to the rinse cycle for the final wash. In some self-serve stations, a hot wax coating can also be applied using the high-pressure spray nozzle. After the final rinse, the car is driven out of the bay, where it can be hand-dried, air-dried, or detailed.

The amount of washing time available depends on how much money the driver is willing to spend. Most self-serve car washes require a minimum of two dollars to begin the wash, providing three to five minutes of cleaning. Additional coins can be added to extend the washing time, and some locations accept credit cards for payment.

In some areas, mobile car washes are available. A mobile washer comes to the vehicle to provide an environmentally safe, professional cleaning service upon request. This option is ideal for those with time or location constraints, or for businesses with fleets of vehicles that lack an on-site car wash facility.

Places to Get a Car Washed

-

Commercial Car Wash

A car wash equipment manufacturer provides the necessary tools and materials for various commercial and sometimes industrial car washes. When starting a car wash business, many opt to purchase used equipment. There are numerous types of car wash systems, some of which are entirely automated, while others require human involvement. Automated car washes have gained significant popularity, typically coming in two varieties: touchless and cloth friction.

Touchless car washes use high-powered water sprayers that move around a parked car or are stationary while the car passes through. Only water and cleaning agents come in contact with the vehicle, preventing scratches or damage to the finish. On the other hand, cloth friction car washes use large, rotating brushes made of soft cloth to clean the car, employing soap and water to scrub the exterior. Both types of automated car washes utilize sensors (also called "eyes") to trigger the digital control system, initiating the wash sequence and adjusting to the vehicle’s size. The process generally ends with a drying station, where high-pressure air compressors dry the car before it exits the wash. These systems are often housed in car wash tunnels, featuring car dryers.

Self-Service Car Wash

A self-service car wash is a do-it-yourself alternative to automated car washes, typically accepting either credit cards or coins. Inside, customers use a water gun with adjustable settings, with washing time being based on the amount paid. The more money a customer pays, the longer they have access to the wash. Most of these systems are coin-operated, though newer stations also accept credit or debit cards. The pressure sprayer and foaming brush are connected to a hose attached to a large central pump. The hose is mounted on a boom, allowing customers to move freely around their vehicles. As self-service and automated car washes often run without attendants, they are frequently open 24/7. Many stations also offer additional services like waxing and undercarriage cleaning.

Hand Car Wash

A hand car wash is a more expensive option where workers clean and detail the car by hand. Some businesses also offer mobile car washes, where services are brought to the customer’s location. Hand car washes typically involve using wool towels or mitts for washing, and may include detailing and hand waxing in about 30 minutes. Some services also offer interior cleaning, carpet shampooing, and vacuuming , with prices reaching as high as $100 per visit. Mobile car washes provide the ultimate convenience, bringing exterior cleaning, waxing, and interior detailing directly to customers. While these services are often more expensive, they are ideal for those unable or unwilling to visit a car wash location. Customers pay for the use of equipment, labor, and sometimes transportation costs.

Benefits of Commercial Car Wash Systems

Commercial car wash systems offer many advantages compared to washing a car at home. They typically use far less water than a hose, and much of this water is recycled and filtered for future use. Washing a car at home can negatively impact the environment if the water is not properly collected and disposed of. Commercial systems are generally better equipped to handle water waste management. Additionally, using a commercial car wash is often more economical since less water is consumed per wash. Furthermore, the cleaning agents used at professional car washes are specially designed for car exteriors, unlike household cleaners, which can damage a car's finish over time. Despite some misconceptions, commercial car washes are a more environmentally friendly and cost-effective option.

Car Wash System Images, Diagrams and Visual Concepts

Car wash methods depend on the use of water, water reclaim systems, chemicals, various types of sprayers, brushes, and cleaning cloths.

Car wash methods depend on the use of water, water reclaim systems, chemicals, various types of sprayers, brushes, and cleaning cloths.

Brushes are essential components of a car wash and come in different varieties depending on the system.

Brushes are essential components of a car wash and come in different varieties depending on the system.

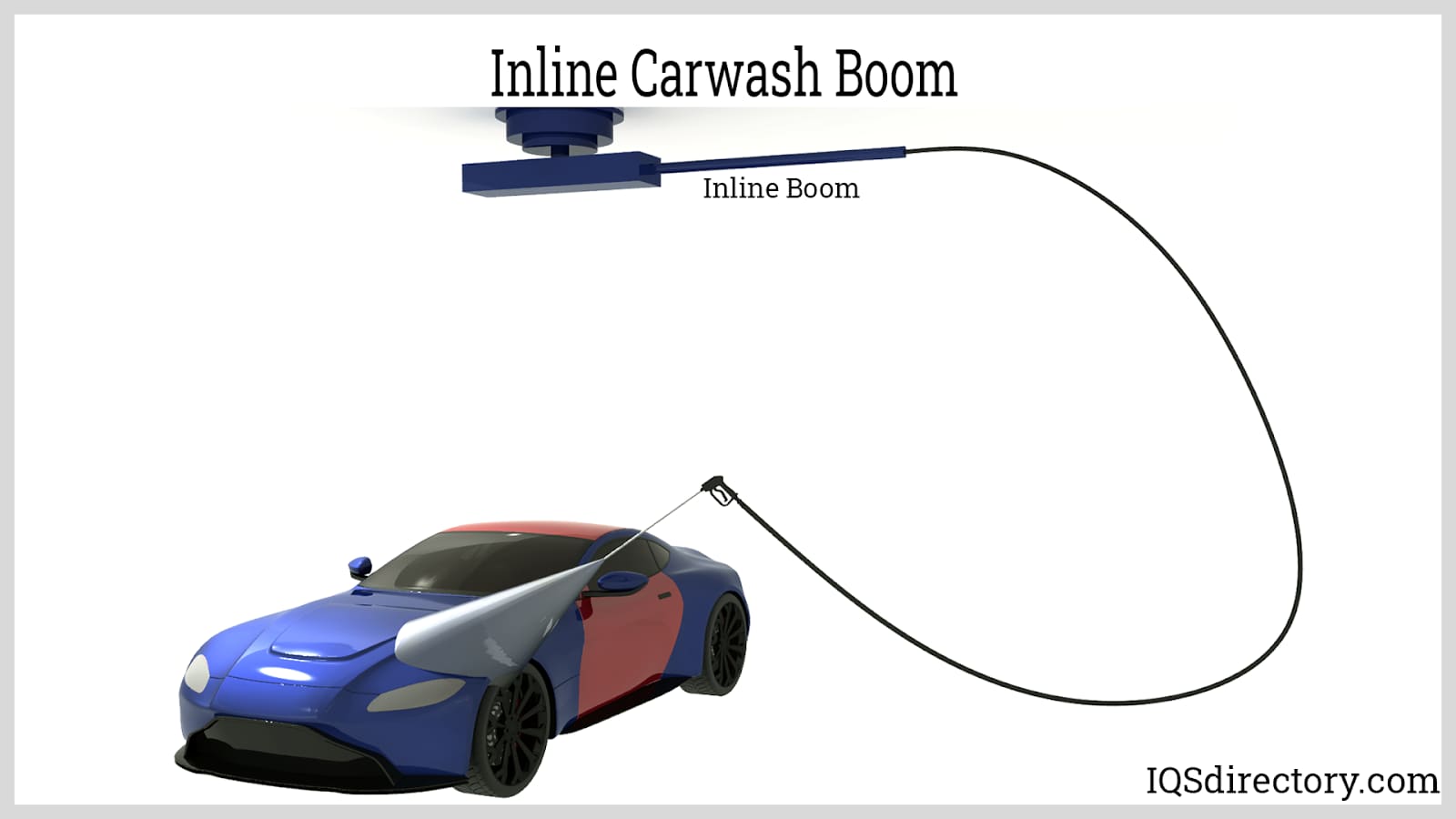

Booms are a part of self service car washes, which are rods that hold hoses from the ceiling or walls and have several varieties with inline and Z styles.

Booms are a part of self service car washes, which are rods that hold hoses from the ceiling or walls and have several varieties with inline and Z styles.

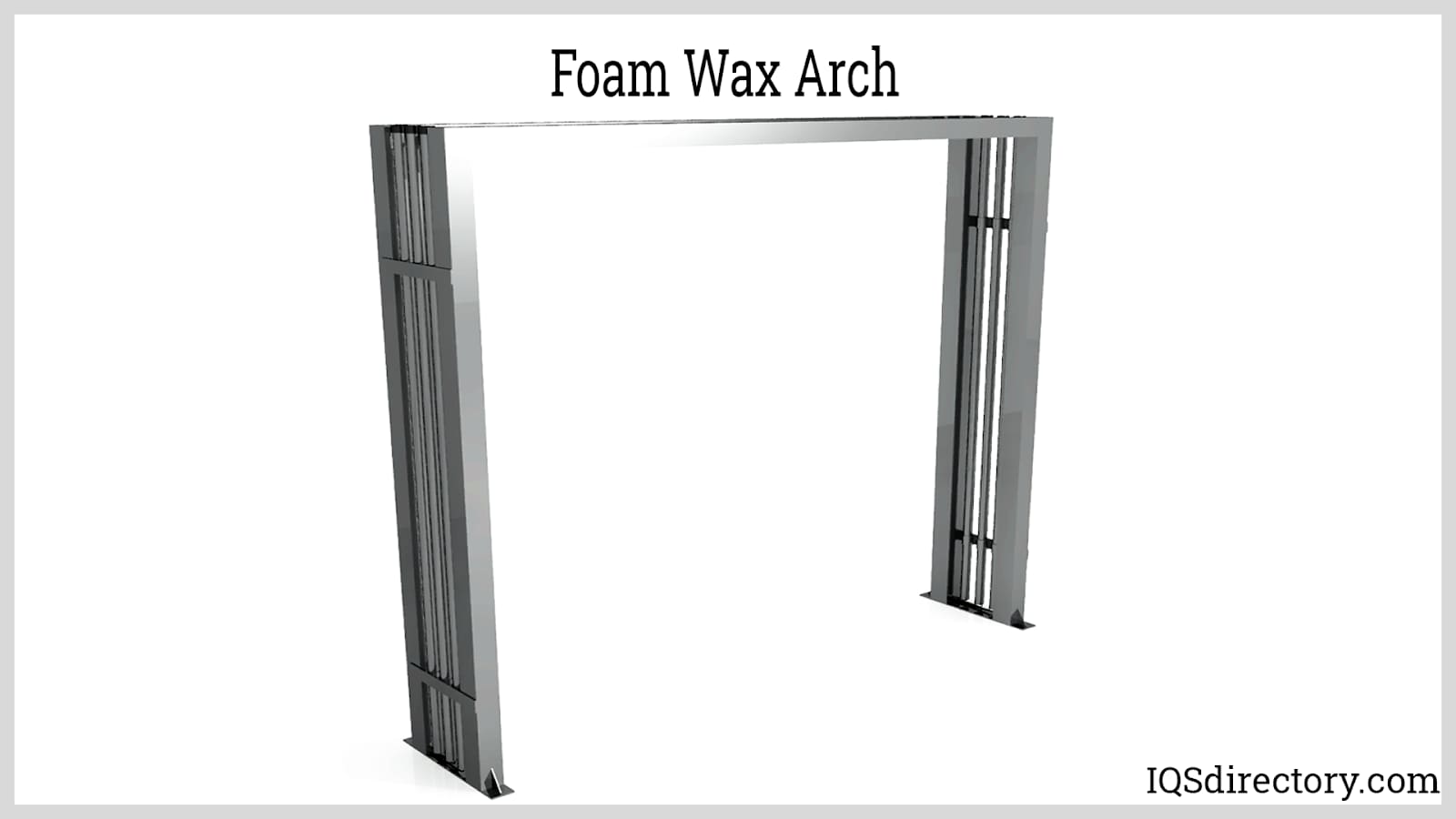

The wax arch applies a specially formulated wax designed for use on chrome, glass, and the surface of a car.

The wax arch applies a specially formulated wax designed for use on chrome, glass, and the surface of a car.

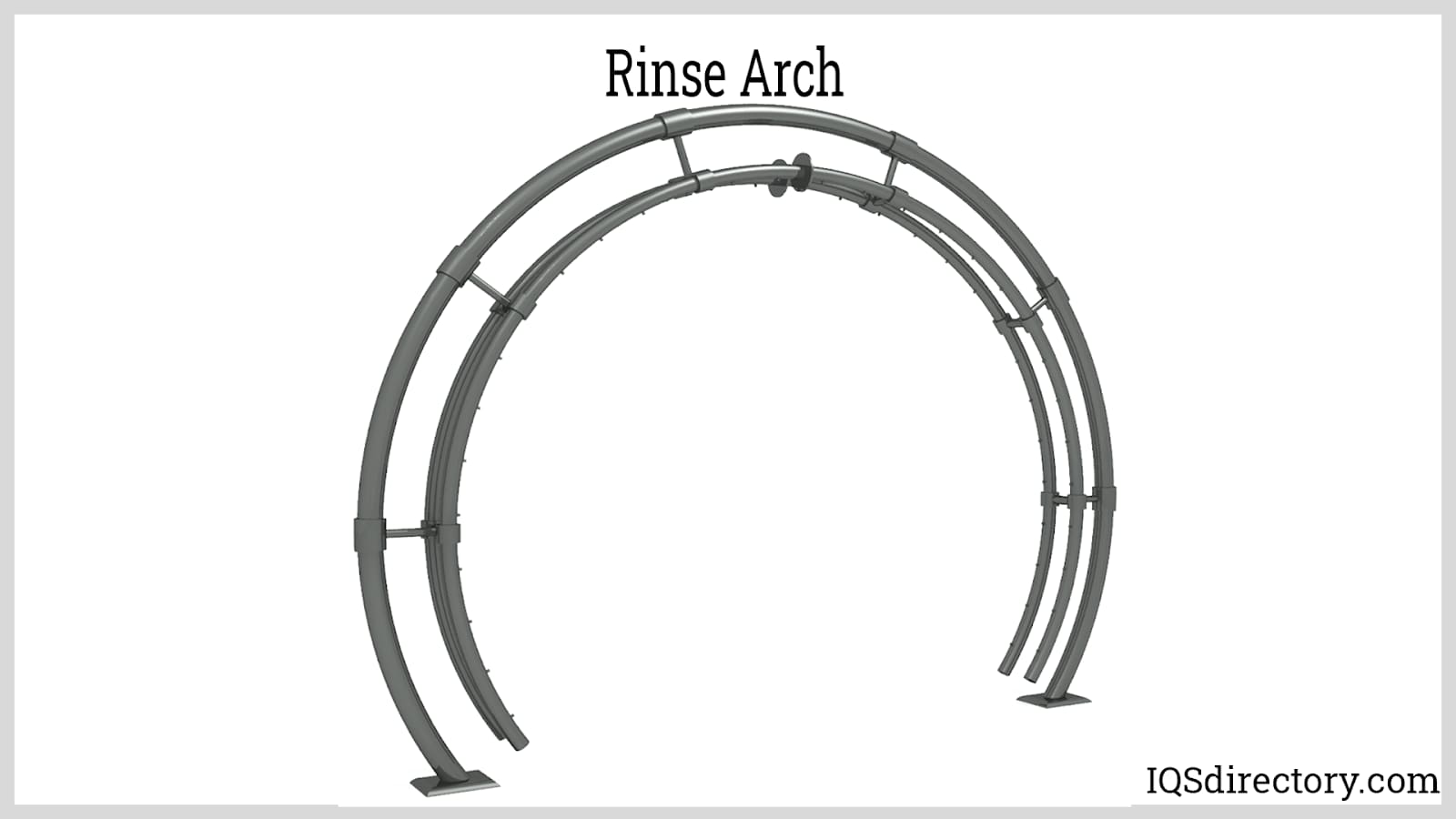

The rinse arch has a series of nozzles which sprays water to remove residue from the cleaning process.

The rinse arch has a series of nozzles which sprays water to remove residue from the cleaning process.

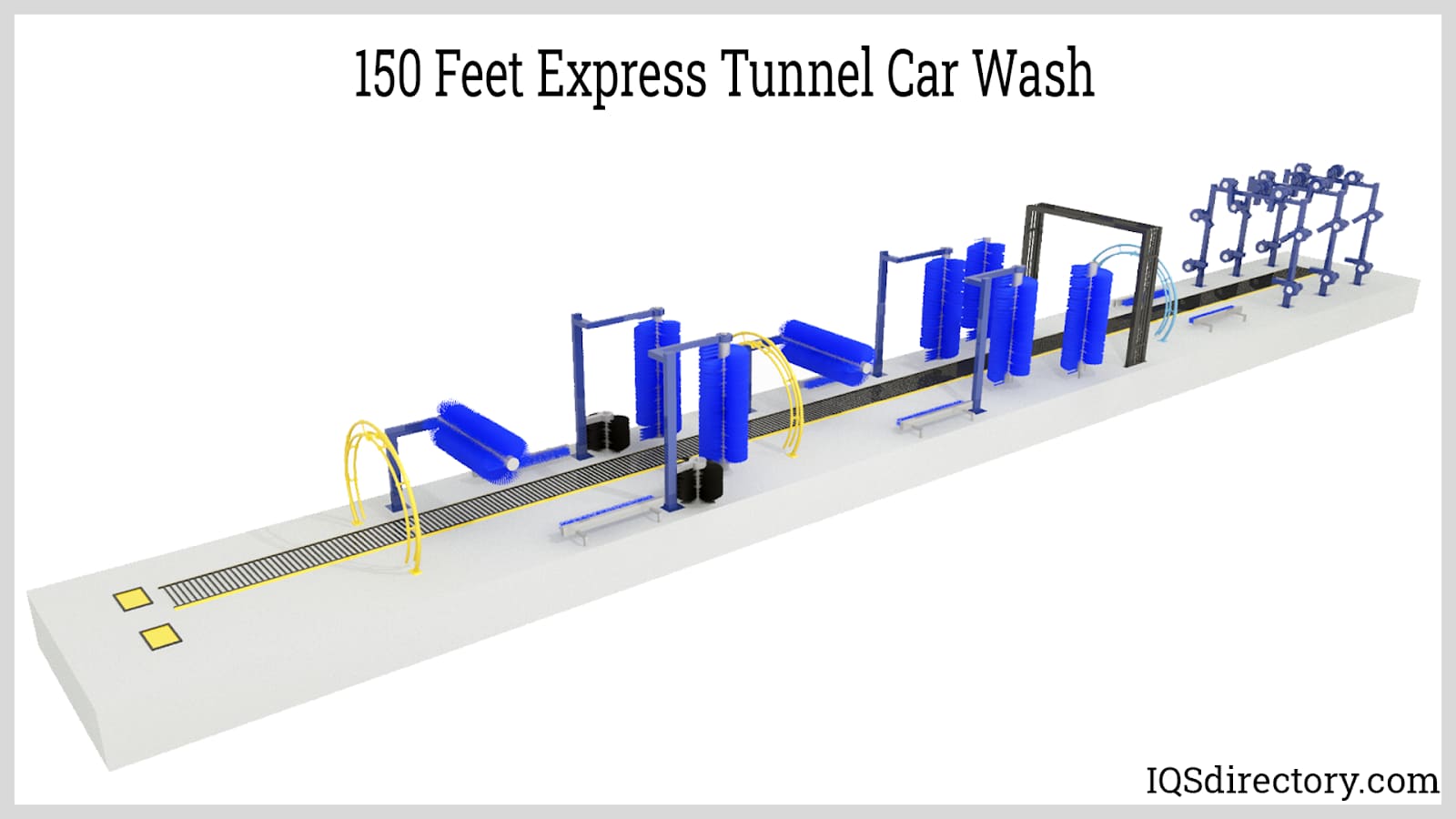

Express tunnel system can be touchless, friction, soft touch, or any combination.

Express tunnel system can be touchless, friction, soft touch, or any combination.

Types of Car Wash Systems

The automatic car wash has significantly evolved over the years. In the past, many car owners were concerned about the damage older systems could cause. Issues like scratches from hard or contaminated brushes, misbehaving arms that dented doors or tore off side mirrors, and rollers that damaged windshields or caved in roofs were common. Today, these problems have been eliminated, and modern car wash systems provide a thorough yet gentle cleaning that can help extend the lifespan of a car's paint job. There are now various types of automated car wash systems, including in-bay automatic washes, tunnel washers, steam washers, waterless systems, and touch-free options.

In-bay Automatic Car Washes

This is a single-station system, often unmanned, where the driver selects and pays for a wash level via an automated control box. After selecting, the driver enters the queue and moves into the bay when it’s their turn. Lighted signs and arrows guide the driver on where to stop. Once the car is in position, the entrance door closes, a sensor detects the vehicle’s dimensions, and the wash begins. A spray arm applies high-pressure water and cleaning solution to the car as it passes through. The system then rinses the car, removing dirt and cleaning agents. A second high-pressure air arm dries the vehicle. Afterward, the exit door opens, and the driver can leave. Some systems include multiple arms for a more thorough cleaning and an undercarriage spraying device to clean the car’s underside.

Tunnel Car Washes

These systems usually use a conveyor to move vehicles through the wash process. The car is parked on the conveyor and automatically moves through different stations where it is washed, scrubbed, rinsed, and dried.

Touch-Free Car Washes

Touch-free systems use high-pressure water and cleaning solutions rather than brushes to minimize the potential for surface damage. The efficiency of a touch-free wash depends on the water’s quality, pressure, temperature, the chemistry of the cleaning solution, and the time the solution is allowed to work. With the right combination, the vehicle will be thoroughly cleaned without scratches or streaks.

Waterless Car Washing

This process uses chemicals or wax to clean a car without water, developed in Australia due to common water restrictions. It’s ideal for regions experiencing drought or where water consumption is limited. The cleaning solution is sprayed directly onto the vehicle and wiped off using a soft cloth. Microfiber towels are ideal for this task. Initially, silicone or petroleum-based solutions were used, but now greener products like Carnauba wax or coconut oil are popular. These eco-friendly options provide a shiny, clean finish that is non-toxic, biodegradable, and affordable.

Car Washing and Environmental Factors

Car washes pose a unique environmental challenge, as water conservation and environmental cleanliness don't always align with the industry's practices. As a result, measures must be taken to manage runoff and overspray, which are inevitable in the process.

Key environmental concerns for the car wash industry include water restrictions, water reclamation, and soil contamination. The main pollutants produced during car washing are grease, oil, lead, and phosphates. To address this, commercial car washes use interceptor drains to remove these contaminants from the water before it is sent to storm drains or natural water sources.

In some states, there are regulations discouraging home car washing due to its environmental impact. These states have introduced incentive programs encouraging consumers to use commercial car washes and have even promoted charity car washes, often hosted by schools, churches, or local parking lots, to be held at commercial facilities instead.

Things to Consider When Purchasing Car Wash Equipment

Industrial car wash systems come in a range of configurations and offer various options. Your car wash equipment manufacturer can guide you in selecting the system that best fits your needs.

Facility Setting

The type of setting your car wash will operate in plays a crucial role in the decision-making process. Whether you're setting up a single bay unit or multiple bays at a gas station, vehicle maintenance facility, car dealership, or a standalone location, the required space, water, and power usage will vary. Your car wash manufacturing company will provide high-quality equipment and cleaning products to optimize the specific process you've chosen.

Demographics of the Facility

The demographics of the area are vital to the success of your business. A poorly located car wash is likely to struggle, and inadequate facilities can hinder growth. Finding the right balance between location and customer base is key. Your car wash manufacturer can assist in demographic studies and evaluating environmental impacts, or they can refer you to specialists who can help. They will guide you through the setup, offer suggestions, provide maintenance, service your equipment, and support your business growth as it expands.

Car Wash Equipment Terms

-

Acid

An essential chemical additive that reacts with alkalis or bases in water to create salts.

Boom

An extension arm that holds the hose and nozzle assembly for washing vehicles in a self-service car wash bay. It can be mounted to a bay wall for 180° or to the bay ceiling for 360° mobility.

Centrifugal Separator

A device used to remove large particles of dirt from the flow of reclaim water.

Cloth Friction Wash

A method of using cloth material to scrub the vehicle's surface to remove dirt.

Correlator

Located at the beginning of the conveyor in an automatic car wash, this system of rollers aligns the vehicle wheels with the conveyor.

Detergency

The ability of a cleaning agent to remove or clean soil, typically associated with detergents, soap, or other cleaning mediums.

Dissolved Solids

Tiny particles of dirt or debris in water that are too small to be visible.

Digital Control System (DCS)

A system that uses sensors to gather data and activates the necessary wash stations and phases based on the vehicle’s size and needs.

Exterior Wash

A car wash service that cleans only the outside of the vehicle, usually without any detailing services and often with no attendants.

Eyes

Infrared sensors with beams that activate the car-washing system when a vehicle enters, measuring its length and width.

Foam

A cleansing foam created by mixing chemical cleaners with water and air, often used for deep cleaning or as a main wash.

Foam Applicator

A device that applies foam detergent to the car, typically equipped with adjustable nozzles.

High-Pressure Washers

Rotating water jets arranged like a pinwheel that spray concentrated streams of water to clean the car, especially effective for removing mud, dirt, and salt from the lower portion.

Mitter Curtain

Long strips of cloth that hang from the top of the tunnel, typically motorized to move up and down the vehicle to clean the hood, roof, and trunk.

Motor Control Center

An enclosed area that houses the electrical switching, starters, and overload protection for operating the motors of various car wash machines.

Pre-Soak

A solution sprayed over the car in the initial wash stage to wet the vehicle and loosen dirt and oil before applying detergents.

Rinse Arch

A structure with nozzles that spray clean water to remove residue left from the wash process.

Scrubbers

Large cylinders that rotate rapidly (from 100 to 500 rpm), spinning cloth strips attached to them to clean the vehicle.

Tire Applicators

Low-positioned nozzles that spray the tires with a solution designed to remove brake dust and brighten the rubber.

Undercarriage Wash Applicator

A device that delivers high-pressure water to clean the underside of vehicles, removing mud and salt and sometimes applying a rust inhibitor.

Wax

A protective, water-resistant coating applied to vehicles for shine and protection, sometimes applied in foam or liquid form.

Wrap-Around Washers

A type of scrubber mounted on short booms that move around to clean the front and rear of the vehicle.