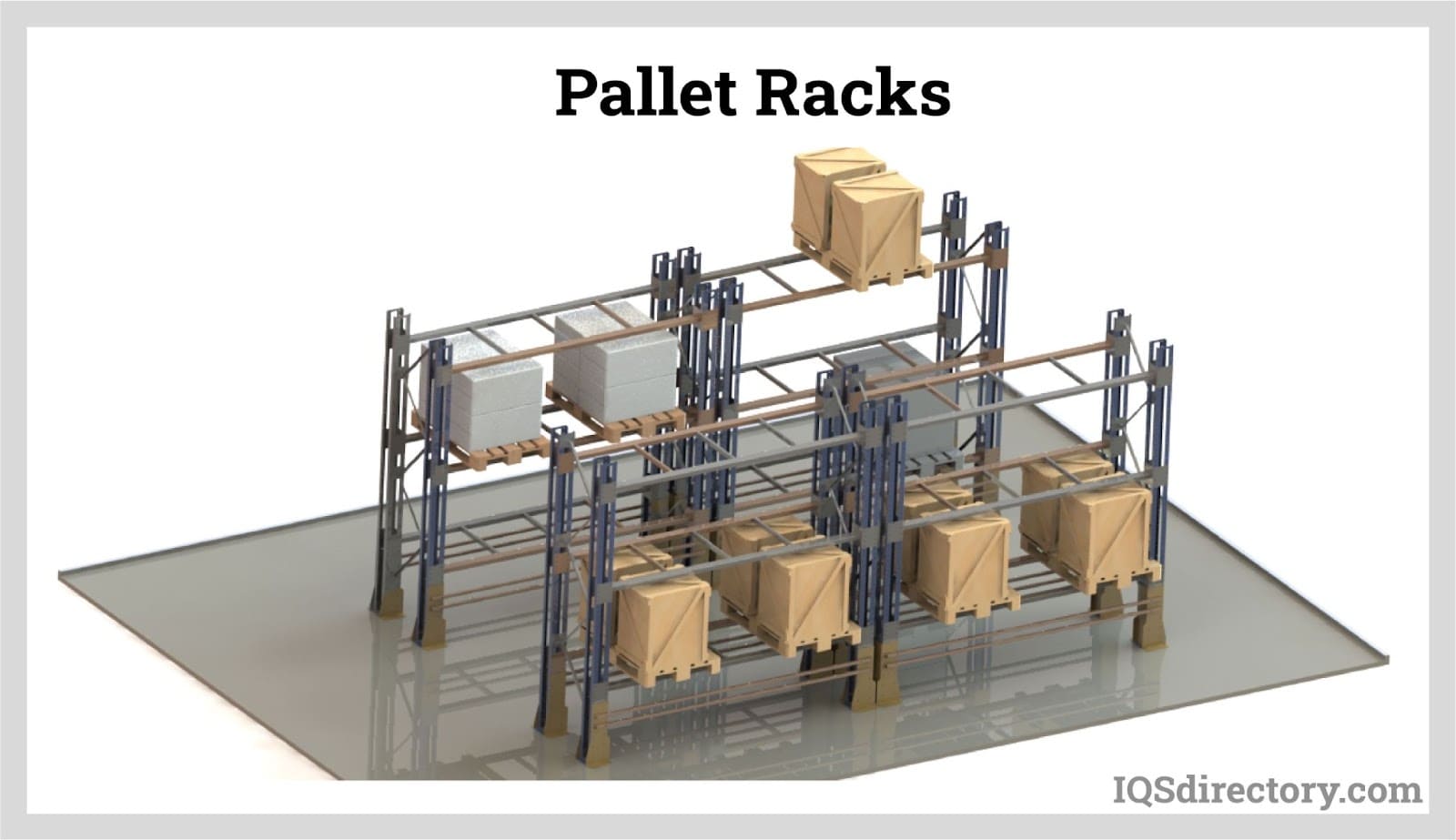

Pallet Racks

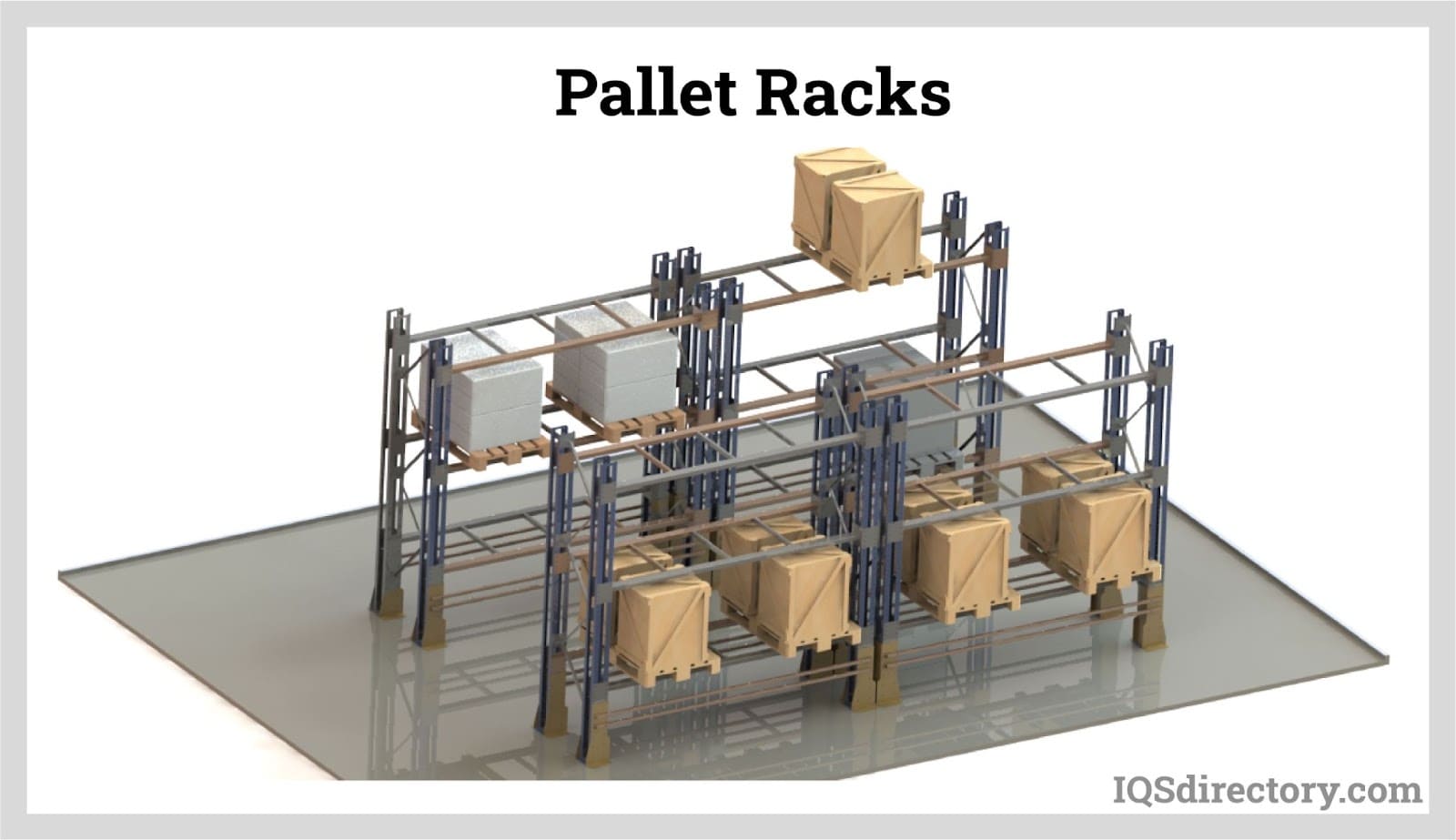

A pallet rack is an upright structure made of steel framing with beams and connectors that are bolted, welded, or clipped together to form a shelving unit to store inventory and equipment. In warehousing, pallet racks are…

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

Information concerning the unique nature of carton flow racks and their use with a list of manufacturers.

You will learn:

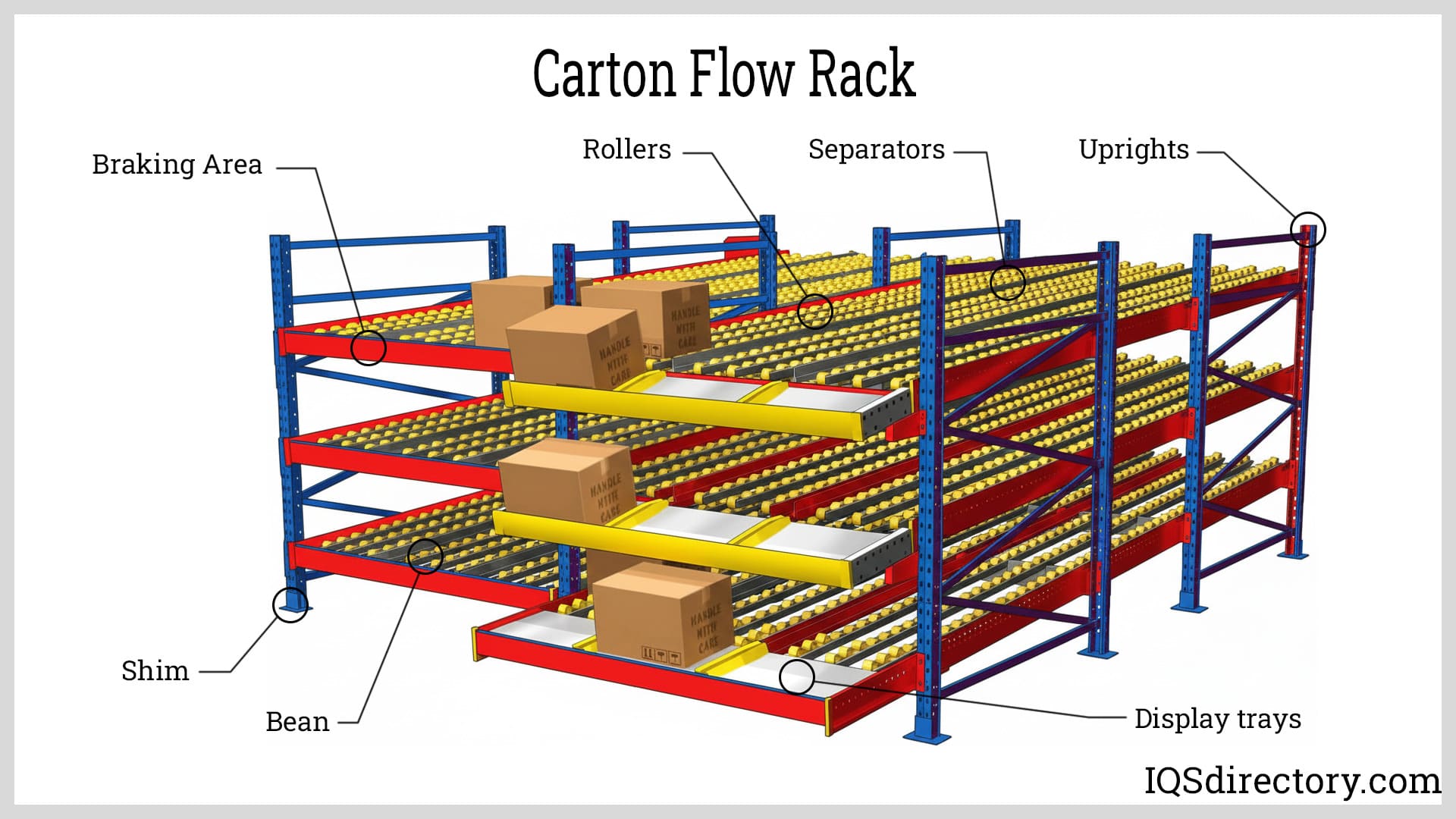

Carton flow racks, sometimes referred to as gravity flow racks, are material handling tools that make efficient use of space and allow for resourceful handling of warehouse supplies. They are a dynamic warehousing solution that enhances the use of space and makes order picking easier, quicker, and efficient. Carton flow racks have gravity fed storage lanes that feed products from the load face to the pick face. As products are taken or picked from the pick face, new inventory smoothly glides forward from the load face.

Although carton flow racks may seem to be a generic type of shelving tool, for the racks to be the most efficient, they have to be configured to the inventory specs, such as pallet size, style, and load weight. These basic factors determine the choice of carton flow rack that is customized to meet the requirements of an inventory system.

A critical aspect of warehousing is access to easy access to inventory for product movement. Carton flow racks maximize storage capacity, increase throughput with consolidated picking, lower the need for equipment, reduce labor costs, and provide better inventory control, a factor that motivates all warehouse managers. All forms of carton flow racks have an abundance of accessories that are used to customize and specialize the functioning of a carton flow rack.

The foundational components of any material flow system are carts, workstations, packaging, and flow racks. Most people are well aware of carts, workstations, and packaging but may not be aware of carton and pallet flow racks. They are known by several names that serve as descriptors of their function. Some of their names are gravity feed racks, gravity flow, flow chutes, roller racks, pallet flow racks, and flow racking. Regardless of how they are named, carton flow racks dramatically improve material handling, flow and movement while improving the usage of space.

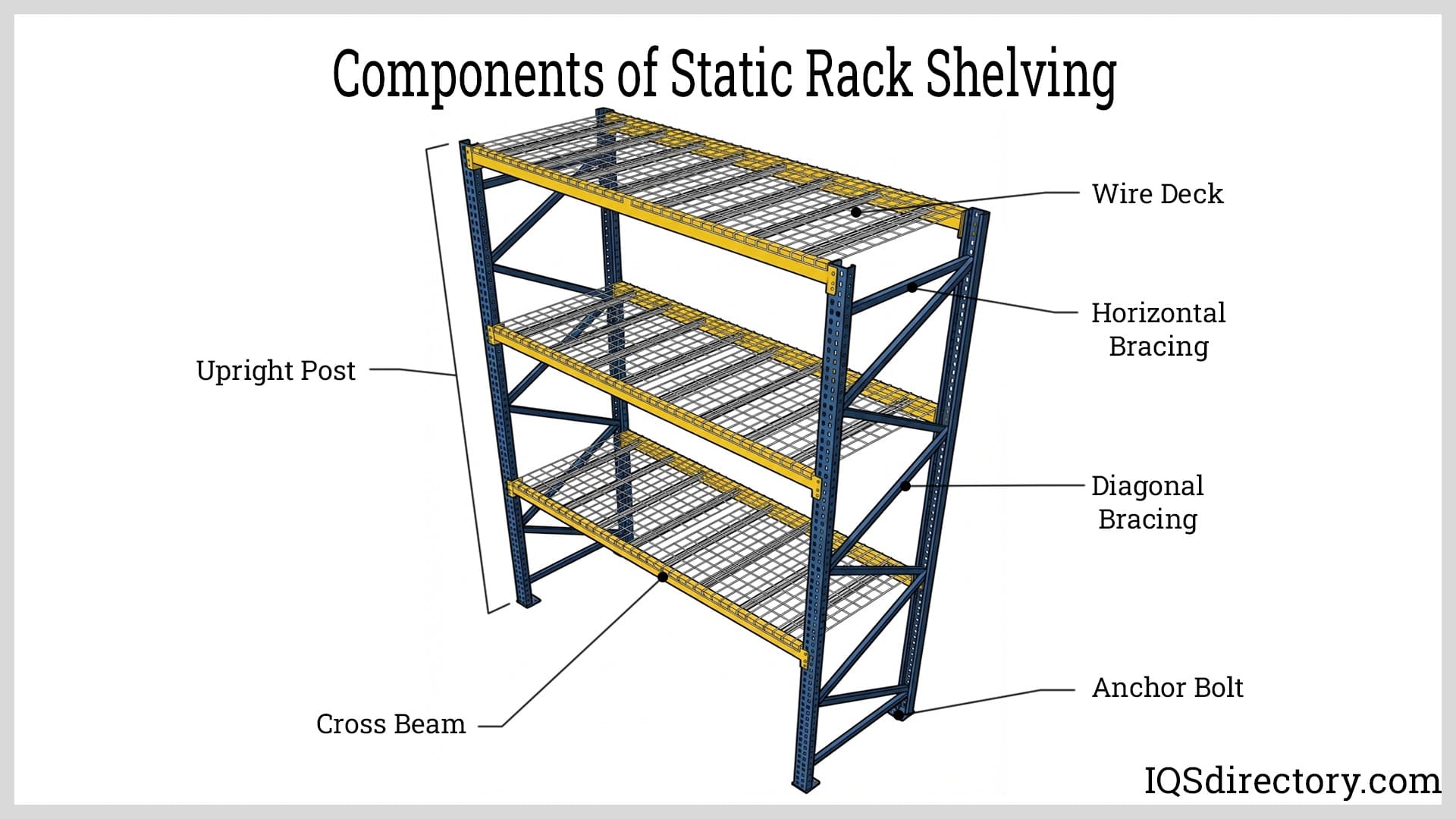

Methods for inventory storage shelving fall into two categories, static storage flow and dynamic storage flow. Everyone is aware of static storage flow, which is placing inventory on pallet racks and shelving. It is a storage mechanism designed to hold materials in horizontal rows of multiple levels of shelving for dissemination to production, personnel, and in line users. It is an inexpensive method that has been used for centuries. The essence of static shelving is a set of shelves or racks that are anchored to the floor and do not move but provide a stable, reliable, permanent method for inventory.

Dynamic racking, which includes carton flow systems, pallet flow systems, and push back racking systems, is a storage system that uses gravity or mechanical energy to automatically flow items. They eliminate the need for forklifts and enhance the efficiency of picking. The goal of dynamic racking systems is to facilitate product, materials, and other items movement toward picking or toward storage.

The three main types of dynamic racking systems are:

The popularity of dynamic systems is due to how they improve efficiency, optimize the use of space, and reduce warehousing costs. Dynamic systems are customizable, which makes them adaptable to any product movement system. The use of a dynamic system radically improves the speed and accuracy of picking while keeping inventory moving, which removes the problem of inventory stagnation.

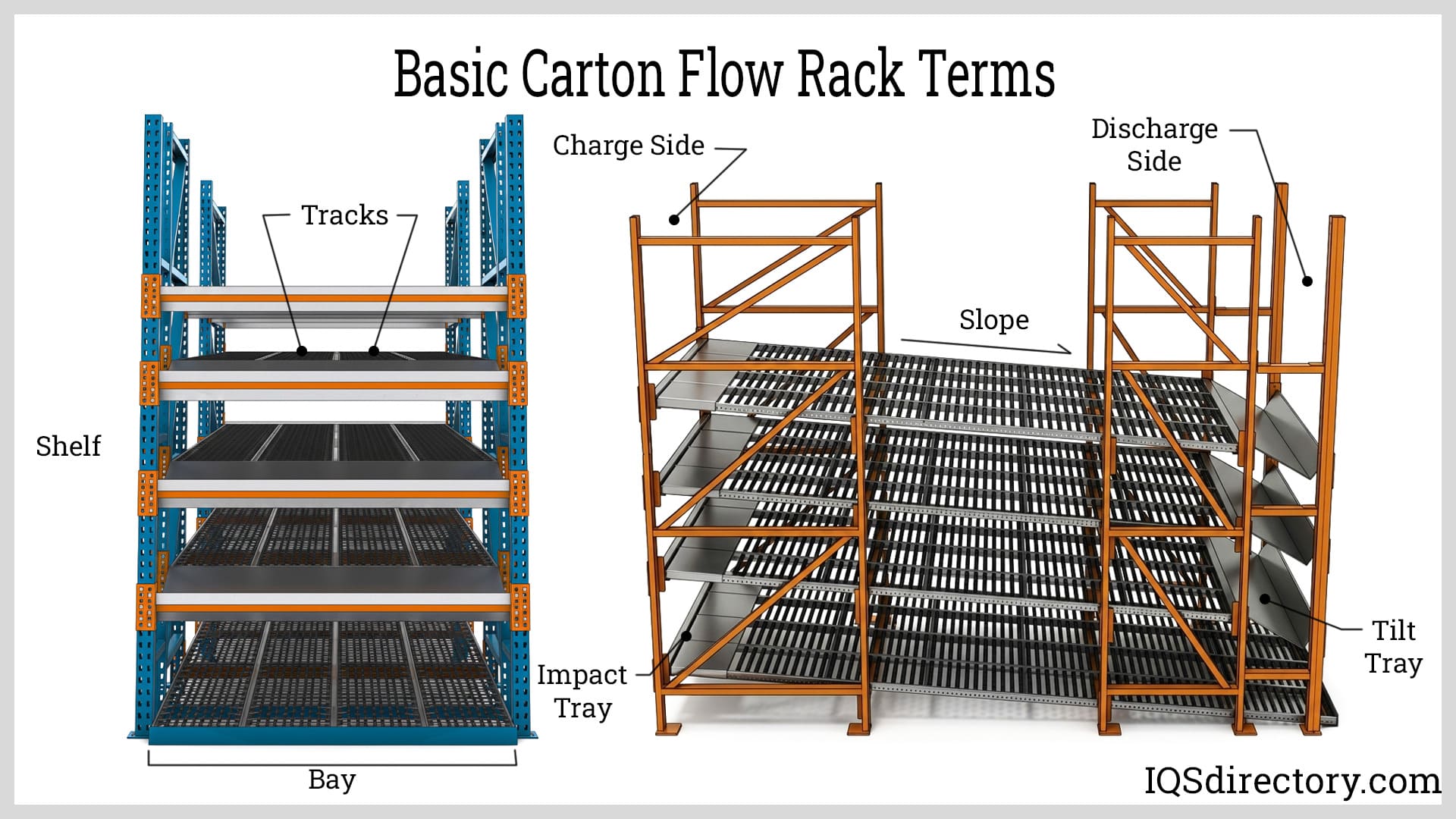

The concept of a flow rack system is built on the function of a conveyor belt system. Materials are loaded at the back end and gently move or flow down the racking system to the front end. The basic idea is First In, First Out. The front end of the system is the picking face or pick rack that includes a bracket, metal strip, or other form of stopping mechanism.

The structure of a racking system is made up of the racking frame and shelving with rollers, wheels, and brakes. The various components of flow racks are part of what determines the type of flow rack with the method of movement being the main feature of the racks. Although the function of a flow rack system is rather simple, its structure, design, and components are engineered and constructed much the same way that other forms of industrial pieces of equipment are.

Base plates stabilize and anchor flow racks to the floor. They are engineered to distribute the weight of the columns and are known as footplates or footpads. They come in sets and serve as the feet of the column posts on to which braces, beams, and shelving are placed. The size of base plates is determined by the types of loads that will be placed on them and the seismic force presented by the loads. In most cases, the design of a flow rack begins with the base plates. Due to the different demands placed on flow racks, base plates take different forms to meet the demands. In some instances, they are welded to the support column to form a solid metal support.

Flow racks are part of large industrial operations that involve the rapid movement of personnel, equipment, and materials. All of these functions make the base plate vulnerable to impacts, collisions, and damage. To overcome the potential damage from such incidents, engineers add protectors to base plates that can be welded as part of the column structure or be screwed on.

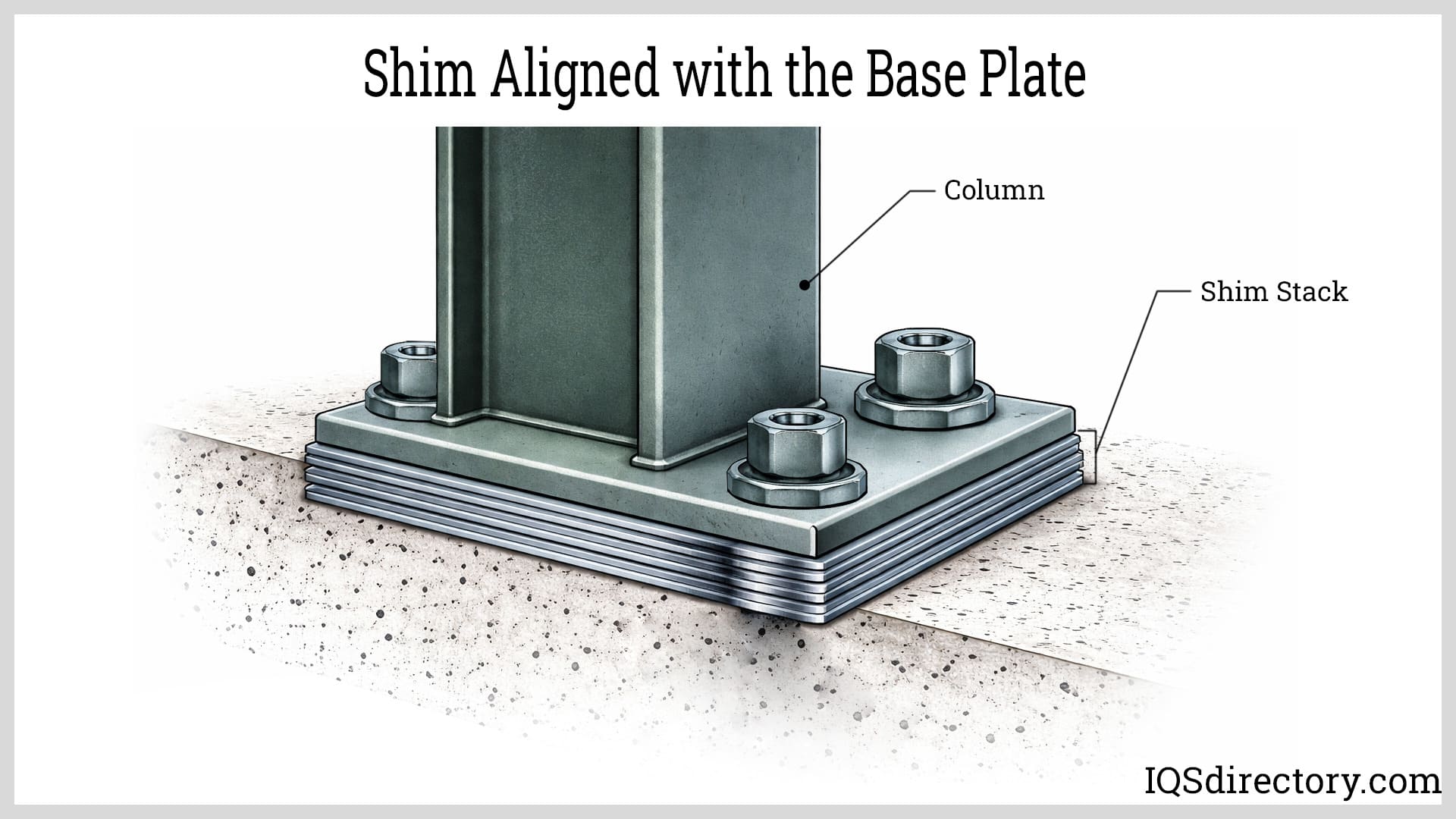

As anyone who has ever worked on the concrete floors of a warehouse knows, the floors are not totally level. Although the floors are uneven, they aren’t off by much but are sufficiently off to cause imbalances, which requires the use of shims to balance flow racking that requires perfectly level positioning. Unlike the shims used for carpentry, shims for carton flow racking are made of metal and match the shape of the base plates. Out of necessity, they are thin pieces of metal that come in various thicknesses and are placed under the base plates.

The columns and beams of storage racking have to be straight and plumb in order to transfer the weight of their load to the flooring. Shims level the racking, adjust angles, and assist in suspension response, aside from removing gaps, unevenness, and instabilities. The result is smooth movement of products, faster runs, and consistent contact with the angled surface of the racking.

Beams are basic structural elements of carton flow racking. They are horizontal components that support the weight of the unit loads. Beams come in various types which are selected in accordance with the types of loads carton flow racking moves. They have connectors at each end that allow them to perfectly fit into the holes of the columns. Spacers that are part of the columns help the beams and columns to form a sturdy structural frame. The beams, after proper placement, support the load and stiffen the racking to ensure the stability of the frame and facilitate easy loading and unloading of products.

With carton flow racking, beams are placed along the sides of the frame to connect the columns and provide support for the angled shelves. Beams located at the charge and discharge positions have the function of supporting impact trays and tilt trays. They have a different form from that of the beams that support the sides of the frame. The Z configuration is common for additional support for heavy loads at the left and right sides of the frame.

Gravity shelving for carton flow racks is the heart of the racking system. The shelves are placed on an angle such that materials move from the loading side to the picking side, smoothly and quickly for easy access. The design of the shelves enhances their efficiency and eliminates some of the issues associated with static shelving. The term gravity shelving or racking is a general term that covers a variety of types of racking each of which is designed to meet load requirements, space requirements, and product needs.

A central key to the success of carton flow racking is the mounting brackets used to place the racking. Mounting brackets secure the rollers of gravity fed carton flow systems. Due to the nature of the racking, mounting brackets come in several styles in order to meet the needs of different racking systems. The structure of the frame determines the placement, type, and design of the mounting brackets.

The function of mounting brackets is to physically attach the flow rails to the support beams. They adjust the pitch of the racking to create the slope at which products will travel through the racking. The types of brackets include retention angle, waterfall, and end brackets, each of which serves a specific purpose, especially in regard to the pitch.

Skate Wheel Flow Racks – Skate wheel flow racking is commonly used with pallet flow racking and consists of wheels that are placed in a single line or groups of wheels that are staggered in a line. The structure of the racking includes metal rails with wheels compacted between the rails or placed on the sides of a single rail.

Each wheel of the structure has a capacity of 100 lbs. When the rails are placed together in an assembly, their total capacity is up to one and half tons. The term skate wheel comes from the appearance of the racking, which is similar to the wheels on roller blades. Aside from the term skate wheel racking, the system is also referred to as gravity roller conveying. In the case of carton flow racks, the rails with the wheels are placed in the racking where pallets can place products for FIFO serving.

Skate wheel flow racks are used where there is high product flow. They are designed to allow the movement of products of many sizes and widths. Although they are more expensive than other forms of carton flow racking, they are highly durable, long lasting, and can be configured for any type of product.

Roller Bed Racking – Roller bed racking, also known as wheel bed racking, uses a combination of rollers and sloped surfaces for the movement of products. The surface of each of the shelves is composed of rollers or wheels. When products are loaded onto the shelves, they roll, by the force of gravity, from the load side to the unload side. As with all forms of shelving, the beams, bases, and columns of the frame support the shelves and handle the weight of the load. The shape of loads for roller bed racking is a key to the system. All loads must be rectangular and have a large enough surface to have a sufficient number of rollers under the rectangular surface.

The main selling points for roller racks are their efficiency, safety, and easy FIFO rotation, regardless of the setting. Braking rollers at the unload side of the racking slow the load to prevent impacts and control product movement. Roller or wheel bed roller racking is used for order fulfillment, part picking, and is very common at retail and warehouse outlets.

Full Width Roller Racking – Full roller racking is unlike roller bed racking in that the rollers are longer with lengths that range from 6 inches up to 12 inches or longer. The term full width roller racking is a descriptor for several types of roller racking systems. The different forms have different size rollers and capacities that can fit any number of spaces and environments. Full width roller racking systems have rollers that go from edge to edge of the support frame, which is unlike roller beds that involve the use of several rollers.

The use of full width roller racking is due to several factors. Full width rollers are capable of handling loads that are non-standard and vary in load weight. The rollers provide more contact between the surface of the rollers and the product being moved, which increases the flow rate. In order to protect the rollers from rust and corrosion, they are made of galvanized steel. Speed control of the flow rate is attained by the pitch of the lane or the addition of speed controllers. The versatility of full roller systems makes them applicable to a wide range of inventory systems.

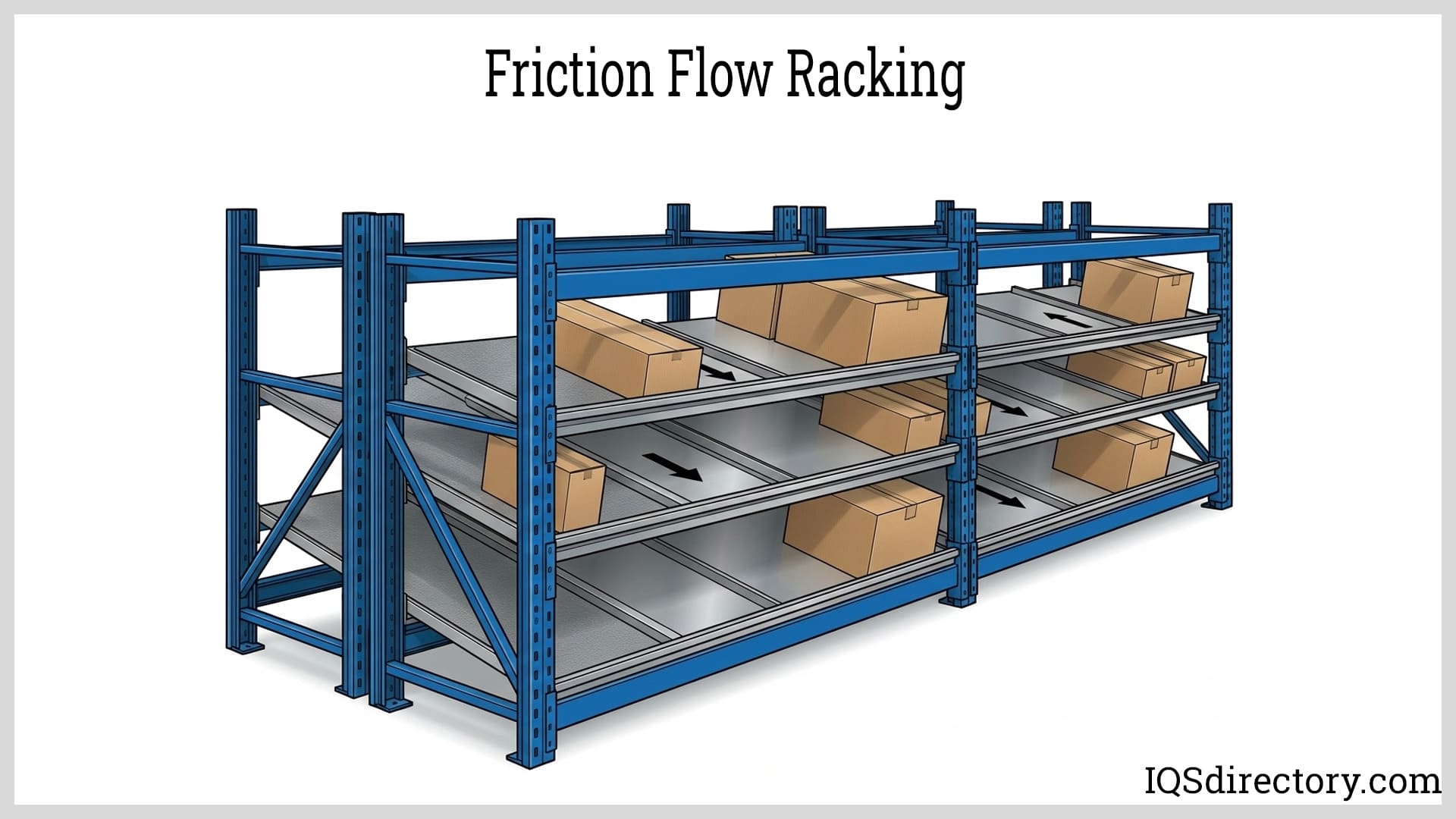

Friction Flow Racking - Friction flow racking does not have rollers or wheels but consists of a flat, smooth, metal surface over which cartons or packages flow or slide. The absence of rollers requires that the shelves be severely inclined to allow for efficient product movement. Unlike roller type shelving, friction flow racking is only able to move items over short distances but still has the advantage of optimizing storage space and enhancing the efficiency of picking. The racking system is designed for small items and can include tubs, cartons, and other types of containers for transporting products.

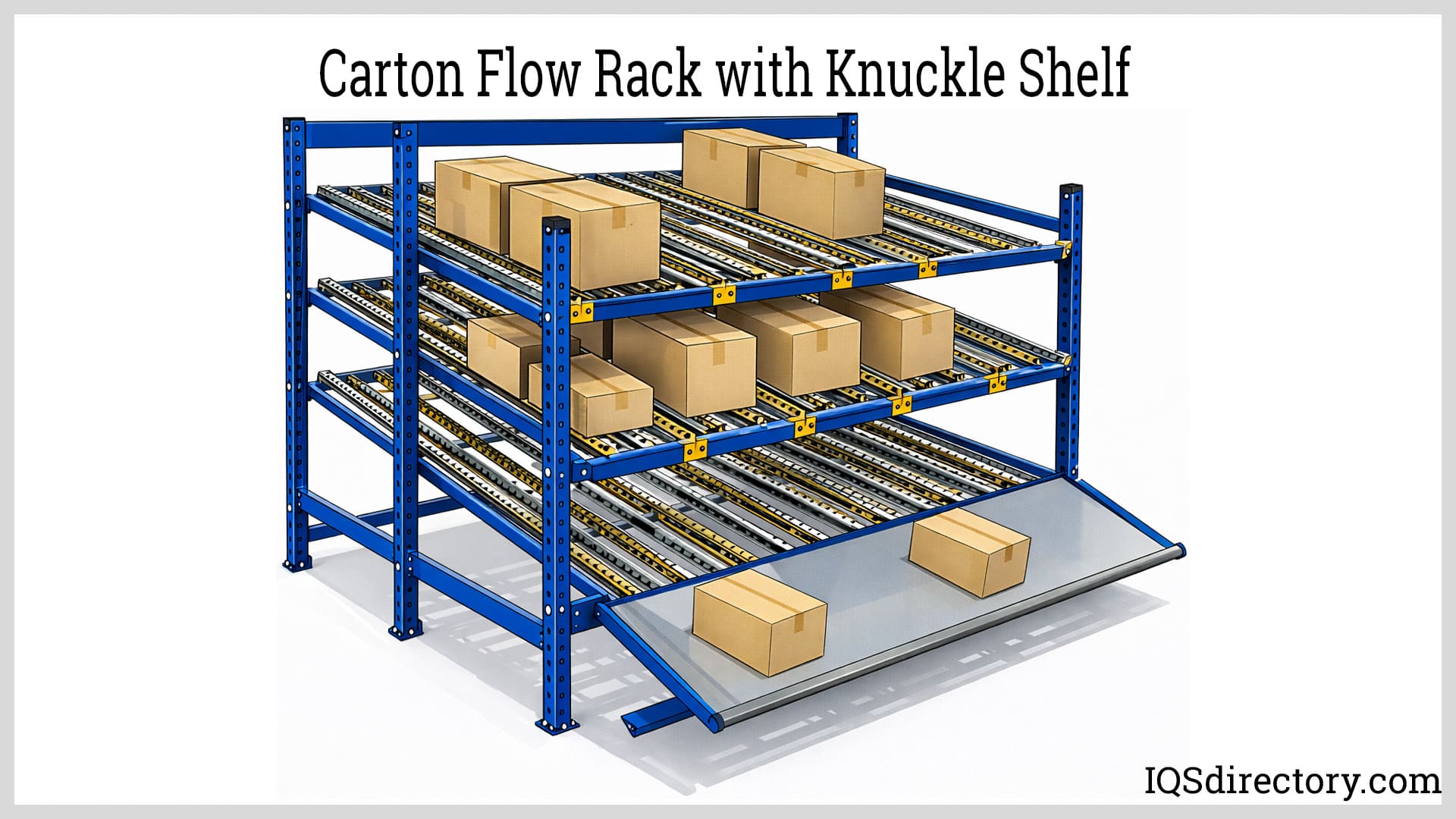

Knuckle Shelf – In addition to the rollers that move items from the loading side to the unloading side, there are knuckles added that angle cartons or loads for visibility and easy picking. Knuckle shelves are placed at the unloading side and are angled or bent forward to make picking easier. They are an extension of all types of shelving and designed to increase efficiency.

Although straight shelves are the most common form of picking shelf, knuckled shelves are used for their usefulness in regard to picking individual items. The structure of knuckled shelves includes a metal plate that tilts the roller track forward over the support beam. This enables personnel to observe what is in a container and pick required items. The design presents items closer and at a better angle, which increases their visibility. The angling of the load brings the front of the carton slightly down and out.

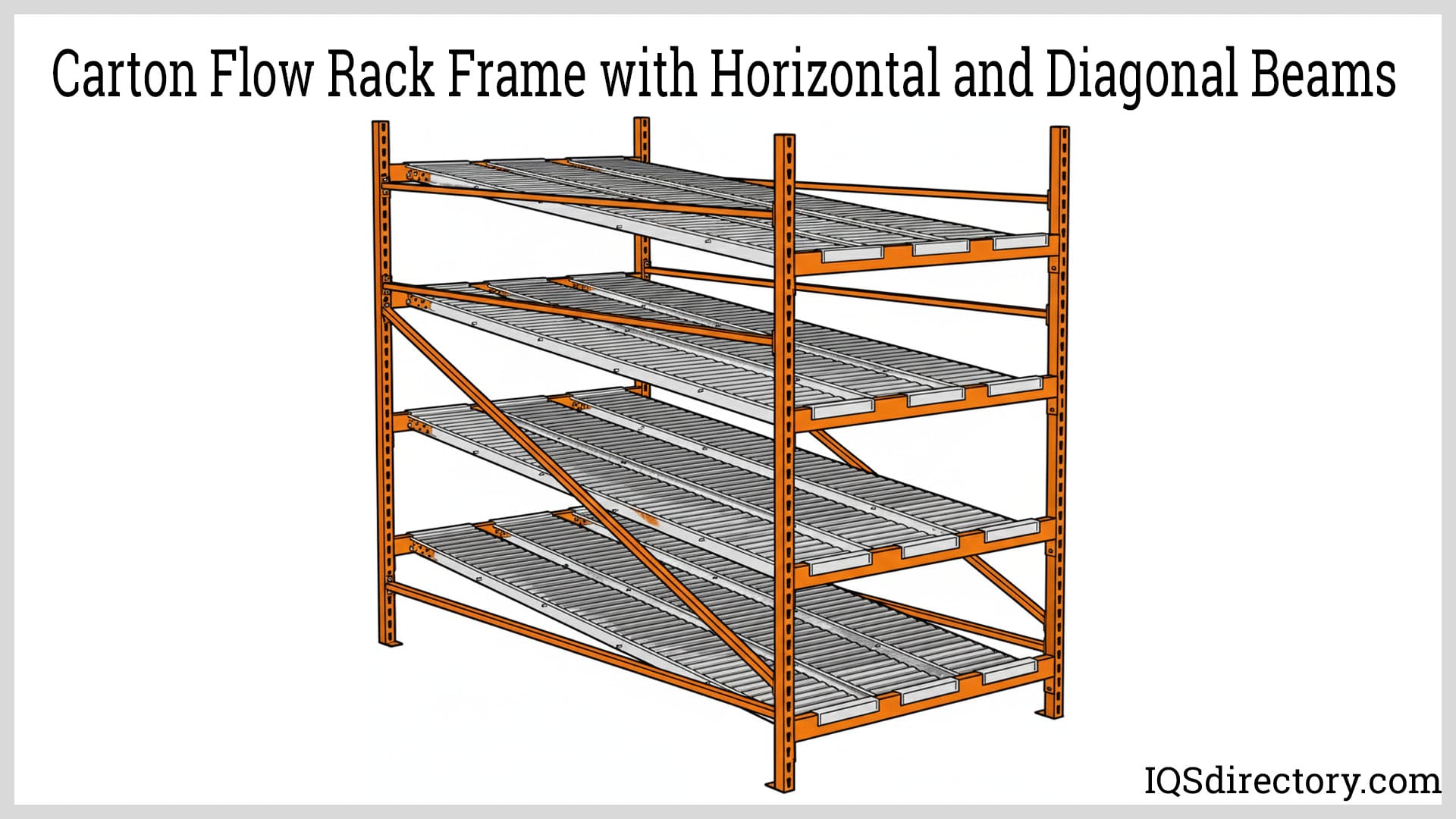

Every aspect and component of a flow rack is dependent on the frame that supports the loads of the system. It is the basic supporting structure of the racking. Carton flow racks have square front framing and layback framing types, which differ in their style and structure. Square front framing follows the traditional framing method that is vertical with angled shelving. It is used for full case picking and takes up more floor space. Layback framing has a backward tilted frame that supports the angled shelving. The structure of layback framing has some of the qualities of knuckle shelving in that the angle of the shelving allows for easy access and visibility.

With both forms of framing, the beams attach to the columns allowing the transfer of the weight of the load to the columns. Support beams are located between the columns to provide horizontal bracing. Aside from their horizontal configuration, they can be connected diagonally to form a Z type pattern. The structure, with the diagonal and horizontal beams between the columns, is referred to as a vertical truss.

As can be assumed from the above information, carton or pallet flow racking is more than a simple product movement system. The design and planning of a racking system involve several factors that influence the structure and design of a system. The type of shelving, frame, and beams are the key components of a system. These essential structural features are supported by other components that enhance the efficiency and performance of a carton flow rack system.

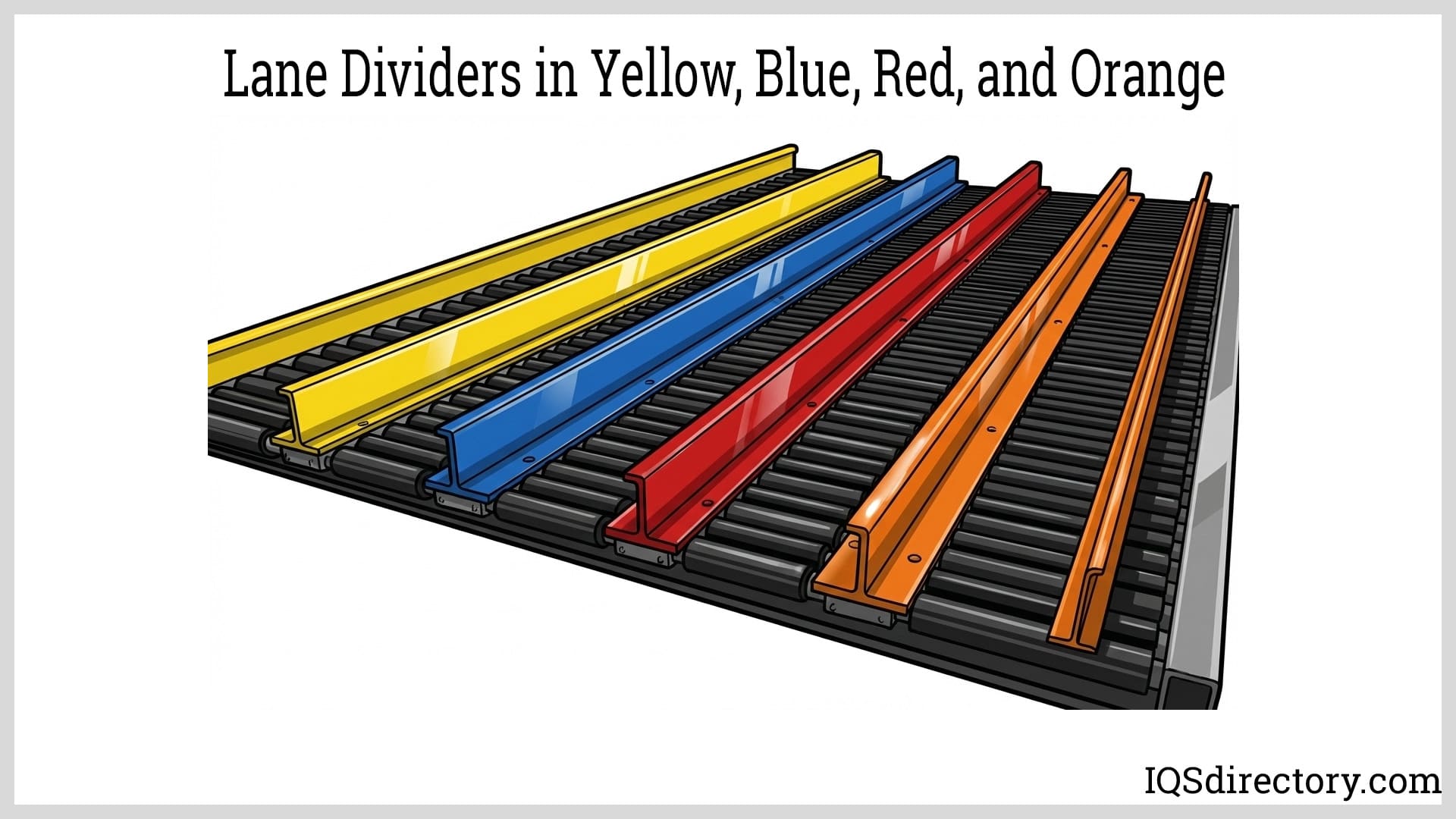

Lane dividers are pieces of metal that are placed between the rows of rollers to segment the load and prevent products from sliding into other lanes. The use of lane dividers increases efficiency by separating SKUs into different lanes and prevents the mixing of items. Each lane becomes a separate channel for flowing the load to the discharge face.

Entry guides are designed to ensure products are perfectly aligned with the left and right side of the charge lane. They are placed adjacent to the outside rails to assist in proper product placement. Aside from guiding product placement at the charge end of the racking, entry guides serve as a visual aid for speeding up the loading process.

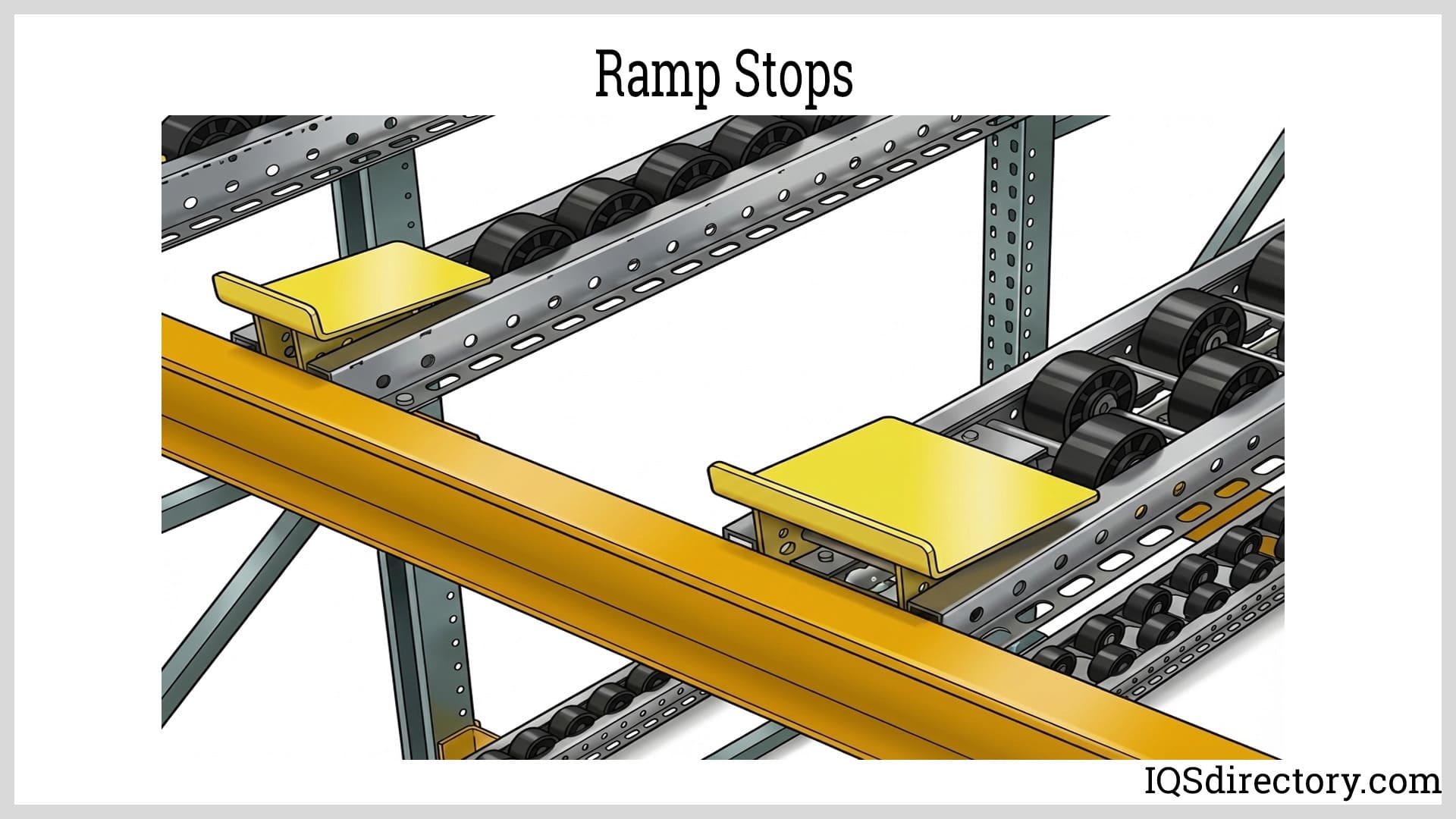

Ramp stops, referred to as end stops, prevent products from hanging over the end beam of the racking or falling off the shelving. The incline of the shelving necessitates that a provision is made for gently stopping products as they roll down the shelving. Ramp stops slow product movement and safely stops products at the discharge side of the racking. Due to the nature of the function of ramp stops, they are made of heavy-duty steel to ensure that they are durable enough to last. In most cases, ramp stops are brightly colored and are bolted to the columns of the frame.

All of the various components of carton flow racks are configured and engineered to meet the requirements of an application. The variations in the types are in regard to the types of products that are handled. Although the functionality of carton flow racks is the same for all versions, the differences between them are the size of products, types of containers, pallets, and the type of racking.

Carton flow rack systems are a storage method that moves items across shelving by the force of gravity. They are an essential tool used in inventory operations where efficient, accurate, and rapid picking is necessary. Carton flow racking solves the problem of outdated inventory being overlooked at the back of a static shelf. Since products are constantly in motion, older products move to the front as new products are loaded at the back.

The design of a carton flow rack system reduces the shelf time of inventory through continuous rotation. The process increases storage capacity, radically influences efficiency, and lowers inventory costs by preventing the need to liquidate outdated products.

The picking process for carton flow racking is divided into split case picking and full case picking. With split case picking, knuckle shelving displays the items to be picked in a carton or container. Required pieces are taken from the container to fulfill an order. In the case of full case picking, instead of taking one item at a time, a full carton or case is removed.

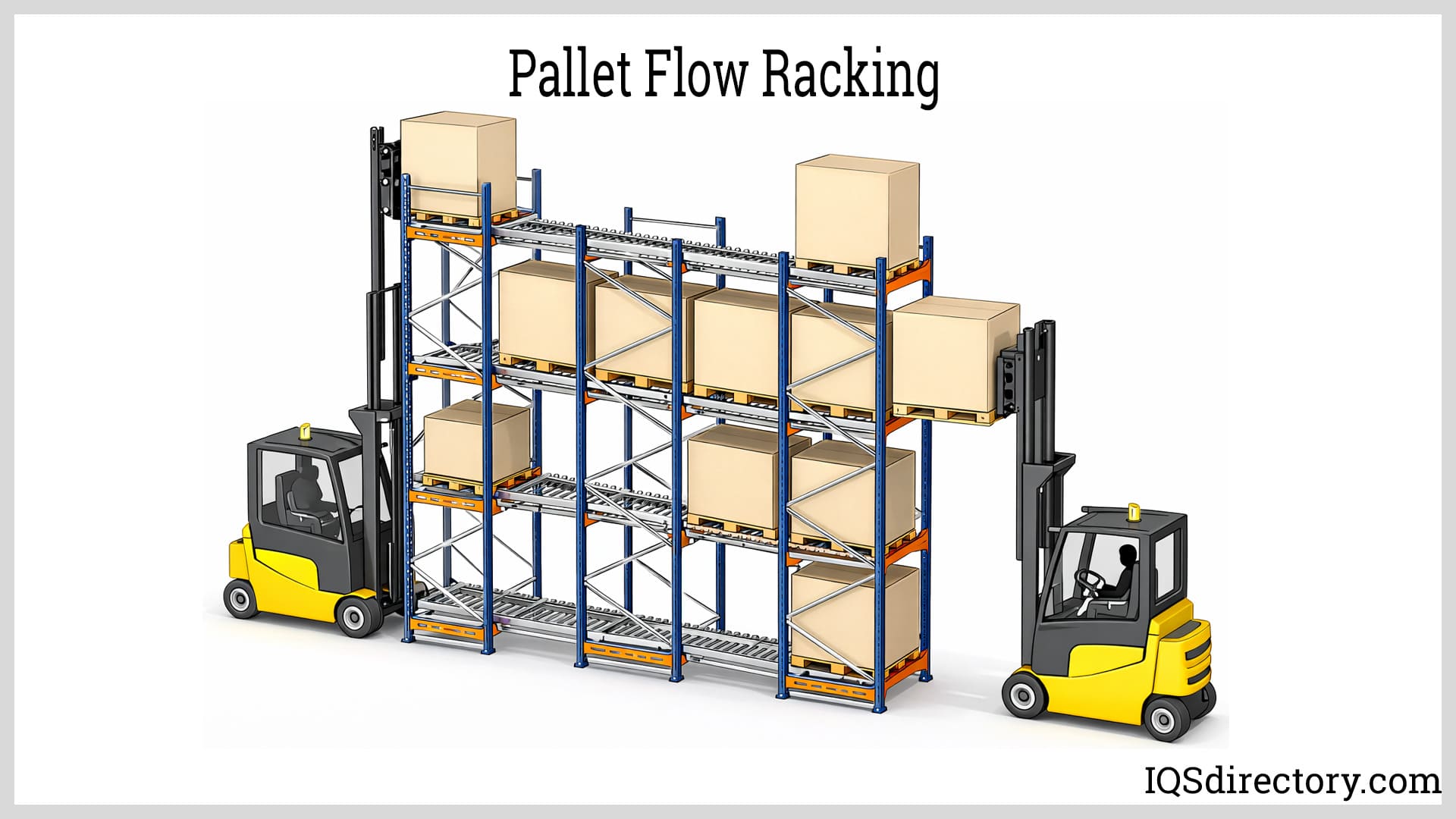

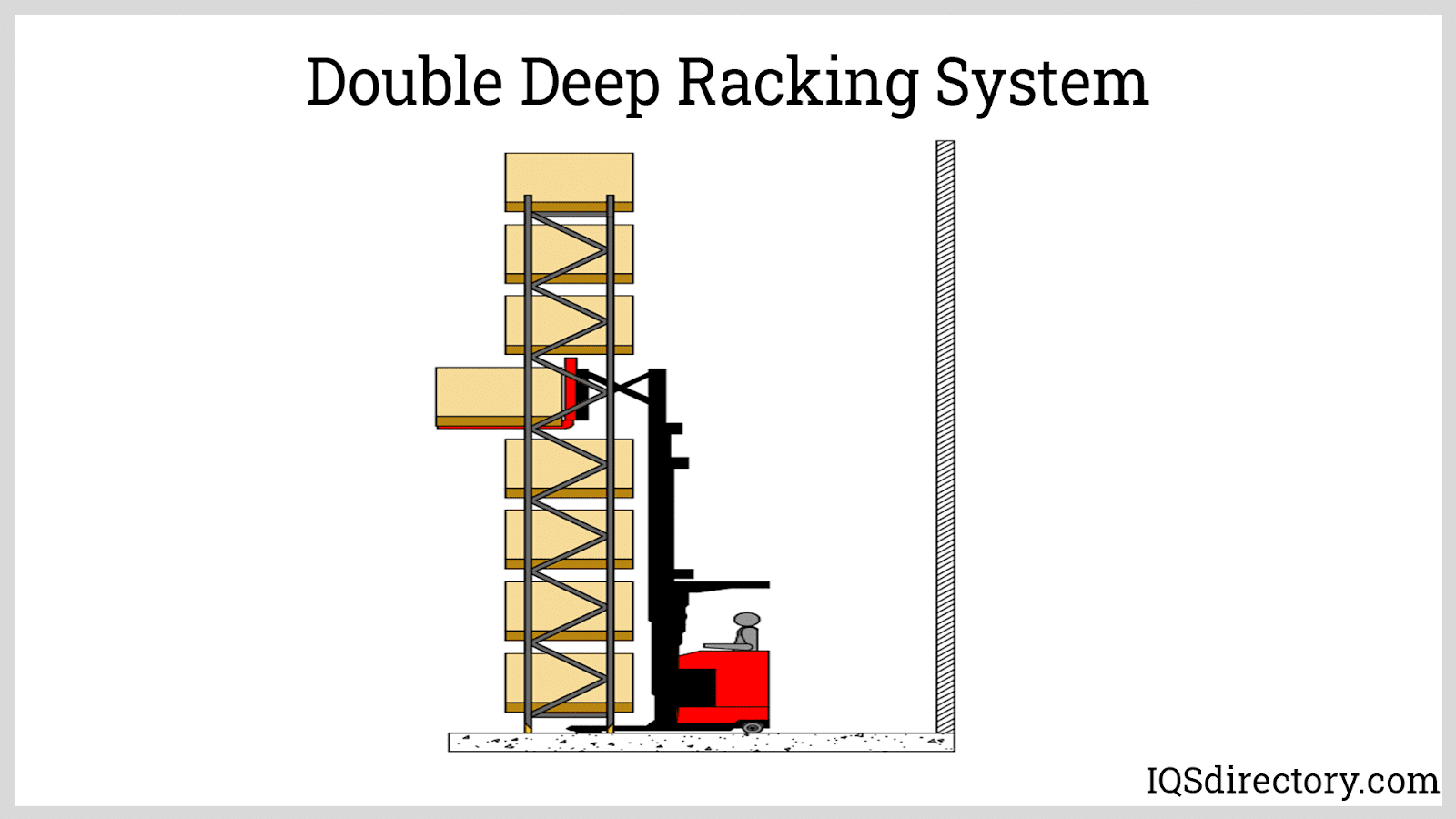

Pallet flow racking is a larger scale of flow racking compared to carton flow racking. In most cases, pallet flow racking has rails with rollers that swiftly move loaded pallets along the racking. As with carton flow racking, pallet flow racking is highly efficient and enables the quick and easy movement of inventory. Pallets are loaded at the charge side of the racking and move along rollers to the discharge side to be removed by a forklift when needed.

The design of pallet racking involves the inclusion of three aisles, one for inserting pallets, one for removing pallets, and a final one for safety placed in the middle of the racking. This design does not require any further access, which increases the safety and efficiency of the process. As may be assumed, the racking has to have substantial strength to handle the loads it must bear. Unlike carton flow racking, knuckles are usually not used due to the weight of the load and the nature of the items being moved.

Pallet flow racking is designed for high volume product movement. Palletized loads are loaded at the highest portion of the racking channel and move slowly to the opposite end of the channel. The process perfectly positions pallets for removal as needed. They are generally found in high density warehouses and storage facilities that handle perishable goods or where products are constantly in motion, being moved in and out of storage.

The pick to light racking system is part of the organizational design of storage facilities. The process includes a system of electronic compartment indicators that have a numerical display to assist in the location of items. Inventory software turns on the display of an item to assist a picker locate the proper storage channel and has an indicator of the quantity to be picked. Pick to light racking systems are found in very large storage facilities with exceptionally high inventories. The data indicator is located on the support beam in front of the storage container. The process is part of carton flow racking systems and does not include knuckle shelving. The remaining structure of the racking is as is found with other forms of carton flow racking.

Pick to light flow racking is commonly used to automate the picking process, whether it is split case picking or full case picking. The software removes the need for printed copies as a guide to finding items. The design is an automated storage and retrieval system that enhances supply chain operations. Carton flow racking is ideal for the process since it keeps items to be picked in constant movement.

Mobile carton flow racking is an ergonomic method for positioning materials to improve worker efficiency. Items to be used are positioned within easy reach near the work location. The pitched flow of the racking automatically advances items removing the need for workers to reach or stretch to get parts. As with all forms of carton flow racking, mobile units have a solid construction with wheels as the base for the racking.

Critical parts of mobile carton flow racking are foot brakes and stable reliable wheels that prevent the racking from moving during use. This aspect of the structure is a necessity as regards safety for workers. Foot brakes are easy to engage and access. They securely hold the load in place during worker activity. During the restocking process, the brake is released and the racking is replaced.

Push back pallet racking is a method of warehouse stocking that is the opposite of FIFO. With push back pallet racking, the last units that enter a warehouse are the first ones to go out. Referred to as the Last In and First Out (LIFO) method, products are prioritized in accordance with the last batch to enter the warehouse. Units are stored in the pallet racking system until there are no other items to go out.

The method of push back pallet racking is the least used of the warehousing methods and is mainly used in warehouses with homogeneous products that do not lose value over time, do not expire, and are not perishable. The push back pallet racking or LIFO is much like the standard static storage method but with pallet flow racking. The loading and unloading take place on one side of the shelving. As loads arrive, they are pushed up against the older units until a shelf is full. When needed, units closest to the front of the shelf are pulled for use.

As may be assumed from the description, items that use the push back pallet racking system are things like ceramics, metals, and other non-perishable, long lasting items. The structure of the shelving is similar to normal carton flow racking with the unique difference being the absence of a charge side to the racking.

It may be assumed after examining the examples presented above that these are not the only forms of carton flow racks. The technology and engineering that go into the development of carton flow racks and pallet flow racks takes several forms to meet the unique requirements of a vast number of storage and industrial applications. The concept that has to be retained in regard to every aspect of flow racking systems is in regard to its dynamic nature and the need to rapidly move inventory.

Inventory dynamics and supply chain parameters are fascinating topics that are an essential part of production and product development. Although molding, machining, and constructing are critical to the success of products, the proper control and movement of inventory decide the success of any product, completed or manufactured. Industrial operations depend on a clean and smooth supply chain to produce products. Commercial enterprises rely heavily on quick and efficient delivery. Every enterprise requires an efficient and capable inventory system to be successful, which is the reason that carton flow racking is so widely used and so valuable.

A problem that has faced storage facilities and warehousing since its inception is the amount of time it takes to pull items off the shelf for delivery. In the old days, workers went to the general location of an item and search through the stacks of static shelves. Over the years, and in realization of the dynamics of warehousing, engineers have developed various measures to decrease picking time and increase efficiency. A key factor in this development has been the introduction of carton flow racking that presents products for easy identification and swift picking.

People may imagine that the area of a warehouse is endless storage space that can be used for a wide variety of functions. In essence, storage space in warehouses is rather limited due to the types and sizes of the items being stored. What may be presumed to be endless lines of shelving that can be used in innumerable ways, actually breaks down into sectors and regions that are given descriptions that have to be adhered to for the purposes of picking.

The introduction of carton flow racking assists in warehouse organization and makes each of the picking areas economical and exceptionally accessible. Carton flow racks can be easily configured to fit any warehouse setting. The frames and shelving can be contoured and configured in various ways to flexibly fit any space. This aspect of the racking properties makes them applicable to any product or set of conditions.

As any warehousing manager will say, different items require different treatments and care. The handling of electronics is quite different from the handling of brake pads and gears. The racking for each type of item has to be sensitive and strong enough to deal with the individual nature and characteristics of items. Carton flow racking can be engineered to meet the needs of any product. It is one of the reasons you find the racking in a bakery and on a production line. Regardless of the design of carton flow racking, items are immediately available and ready for picking. In addition, carton flow racking presents a visual presentation of items in stock such that low stocks can be reported and ordered.

A fact in regard to inventory order fulfillment is speed. This aspect of the process is constantly emphasized in order to meet the needs and requirements of clients. A carton flow system, properly implemented, can double or triple the speed at which orders are fulfilled. A crucial benefit of carton flow racks is the immediate access to inventory without having to search for products. Every item to be picked sits on the edge of the rolling shelf.

As every manager, supervisor or foreman will tell you, ergonomics has become the by word for personnel protection. The dynamic nature of carton flow racks immediately improves the work conditions for employees. Bending, stretching, and reaching are nearly eliminated due to the easy access to products. The positioning and use of carton flow racks has been proven to reduce musculoskeletal disorders as well as the stress and anxiety related to product picking.

Prior to the implementation of carton flow racking, the travel time in search of products for orders would take several minutes or even hours. In some instances, workers would feel as if they were going on a wild goose chase as they wandered shelving in search of their order. The lengthened travel times and constant searching added to the stress of the work and exhausted workers. The installation of carton flow racking and its many benefits radically reduced travel time and provided improvement in efficiency.

As what happens with all industrial operations, the improvement in efficiency eliminates the need for extra personnel since fewer staff members are required to pick products. This factor lowers the overall cost of storage and warehousing making the management of a storage facility less expensive.

After studying carton flow racking, it is impressive to see how smoothly warehousing operates. Orders come in and the product is pulled within less than an hour. In fact, multiple orders can be pulled by one worker in the time it used to take to pull one order. Carton flow racking has radically improved the sequence from receiving an order to having it available on the dock for delivery. The smooth control of the process is impressive and money saving.

A pallet rack is an upright structure made of steel framing with beams and connectors that are bolted, welded, or clipped together to form a shelving unit to store inventory and equipment. In warehousing, pallet racks are…

Storage rack, also known as racking, is a structure that stores items and materials and comprises at least two upright (vertical) frames, horizontal beams, and some sort of decking (bars, panels, meshes, or none)...

Warehouse racking, also known as storage or pallet racking, is a material handling system suitable for mass storage of goods unitized on skids or pallets. It allows efficient utilization of space while providing easy access to stockpiled items for better inventory control...

An adjustable work bench is a tool that allows the user to adjust and regulate the height of the work surface to a more ergonomic and comfortable position for the safe and effortless performance of work...

An AGV forklift is a driverless self-operating robotic device that has the ability to carry, lift, retrieve, and place loads for easy transfer from one location to another. An automatic guided vehicle (AGV) forklift is a computer controlled mechanism that...

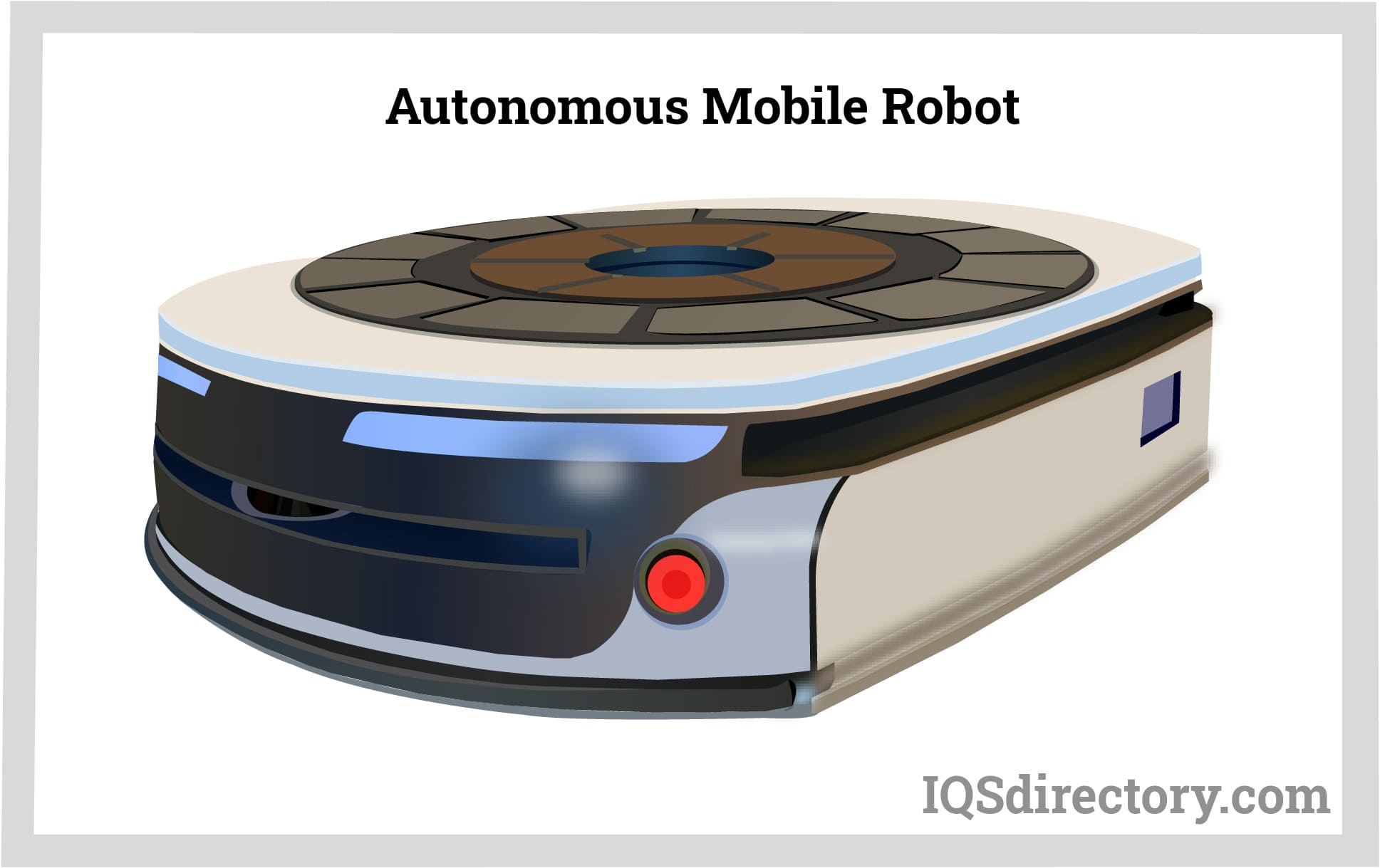

Automated guided vehicles (AGV) or mobile robots are types of guided robotic systems that are not bounded by a fixed range of motion. Rather, it is self-contained and can move along a line, surface, or space...

An autonomous mobile robot (AMR) is a self-propelled self-powered mechanism designed to perform repetitive tasks or organizational functions using an internal guidance system. They are able to navigate their...

A forklift truck is an electrical or gas powered industrial piece of equipment with a metal fork platform attached to its front that can be used to lift heavy loads by inserting the fork platform under cargo, pallets, or...

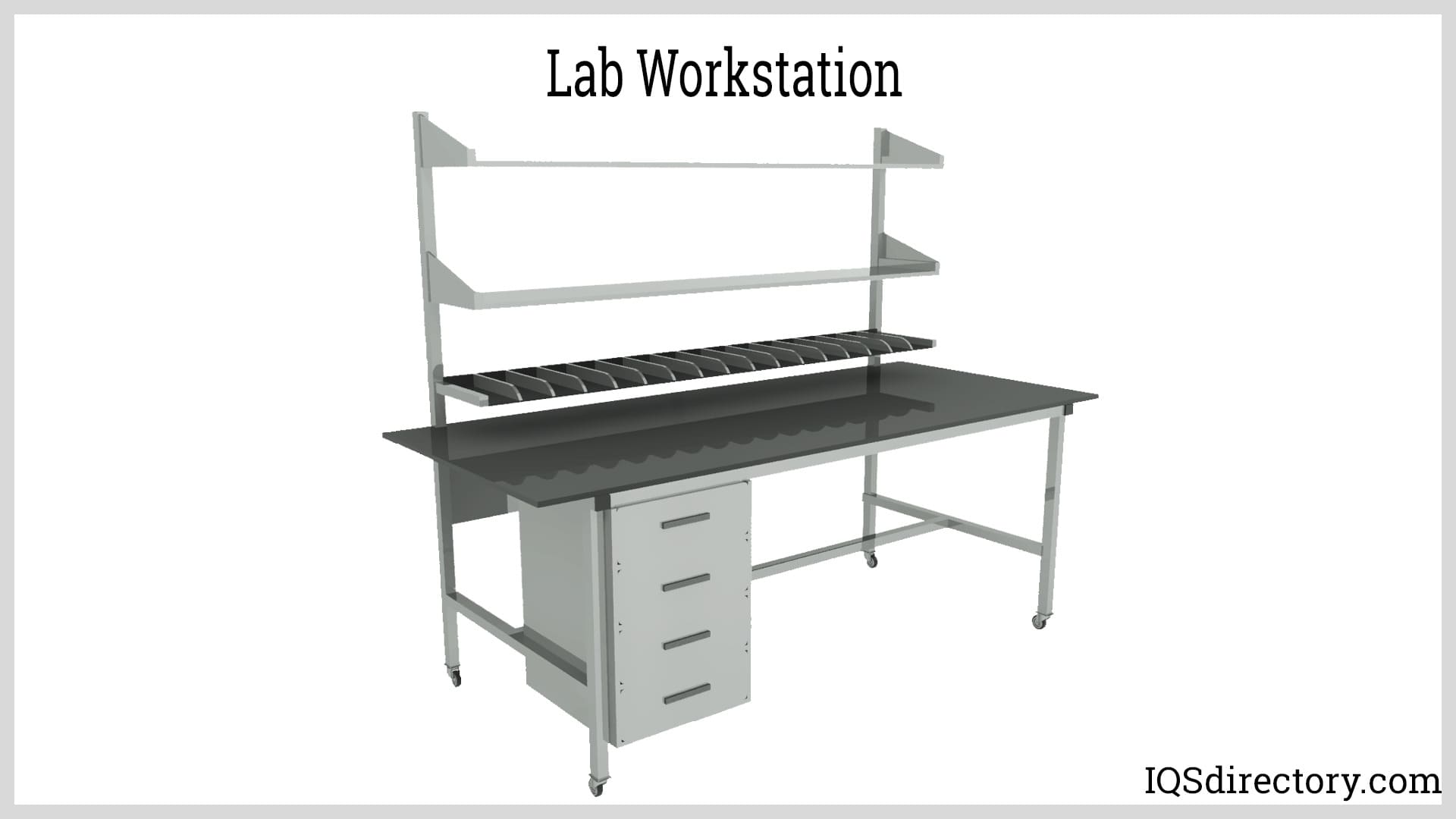

A lab bench is a specially designed bench or table that is able to assist in the performance of laboratory experiments and tasks, including the handling of reagents and test samples. Part of the design process for...

A pallet stacker is a machine designed to assist the user in lifting, moving and handling palletized materials with ease. A pallet itself is a flat and horizontal structure used to support goods in a sturdy fashion...

A portable workbench is a flexible and mobile work surface that is designed to function in multiple environments for the purpose of preparing, constructing, or servicing a wide variety of industrial and commercial applications...

A workbench is a sturdy flat, smooth, molded surface that comes in a variety of sizes designed for specific tasks. They can be very complex for engineering design work, complicated machining, and intricate precision tooling or be a highly finished wood table for woodworking, metal work, and project design...

In 1954, when Arthur "Mac" Barrett, of Barrett Electronics Corporation, unveiled the first AGV, he named it Guide-o-Matic and described it as a driverless vehicle...