Tube Fabrication

The term “tube fabrication” broadly refers to a variety of techniques used to shape, bend, enlarge, and cut tubes of all sizes and metals into parts, components, and consumer products. Tubes are long, hollow cylinders. They can be used to convey gases or liquids, to protect electrical wires and components, or they may simply serve as supports for structures. Tubes are often referenced interchangeably with pipes, and while a pipe usually has looser engineering requirements than a tube, the two are essentially the same thing. For this reason, tube fabrication is also known as pipe fabrication.

While tube fabricators are not generally involved in forming raw metal materials into tubes, tube fabrication services are an essential part of the process of tube and pipe manufacturing. In turn, tube and pipe manufacturing are so important because tube assemblies are used to serve many functions, in particular, containment, support, transportation, and protection. The variety of industries that use tube fabrication services include automotive, aerospace, sports and recreation, retail, plumbing and sanitation, support and structure, HVAC, and hydraulics.

Some of the most commonly used, everyday items created via precision tube fabrication include steel handrails, bicycle frames and exercise equipment, tent frames, point of purchase displays (POP), plant hangers and outdoor patio furniture. A great example of a precision tube that serves many of these purposes is the telescoping tube. Telescoping tubes are common in consumer and business applications such as stands, tripods, and adjustable furniture, and automotive manufacturers and specialty body shops use swaging to control vehicle exhaust fumes.

Quick Links to Tube Fabrication Information

The History of Tube Fabrication

Tubing and piping have been around for a long time. Archaeological evidence suggests, for example, that the Chinese were using pipes made from reeds to convey water as long ago as 2000 B.C. Later on, some of the Roman aqueducts featured inverted siphons that transported water to pipes, to be carried across the empire.

As is often the case with industrial items, the modern age of tube and pipe fabrication began in the 1800s. One of the early tube fabrication methods was born in 1824 when a British man named James Russell patented his method. This method involved folding and welding heated flat iron strips, then passing through a groove and rolling mill. The next year, another inventor came up with an improved method, known as the butt-weld process. The modern methods for making pipes is based upon this.

Superior methods for bending came in the early 1900s when a method for hot forming tube elbows was invented. This allowed for tube bending on a mass production scale. Then, in the 1960s, a high frequency induction bending machine was invented. Since then, engineers have continued to hone their craft by finding ways to make the processes more precise, portable, and fast. The introduction of CNC technology, in particular, has made it possible for manufacturers to fabricate a high volume of tubes with tighter bend radii, more complex cuts, thinner walls, etc.

Advantages of Tube Fabrication

Tube fabrication offers its customers so much. First, because there are so many manual, mechanical, automatic, and CNC machining processes involved, for all intents and purposes, there is nothing you can’t have made. You can ask for any bend radius, wall thickness, length, tolerance, color, or coating. In addition, you aren’t restricted to just cylindrical tubes. You can also order a square tube, a rectangular tube or an irregularly shaped tube.

Tube Fabrication Design

To design your tube with unique qualities, tube manufacturers rely on a few specific aspects of tube forming. These include tube cutting, tube flaring, tube swaging, and precision swaging.

Tube cutting typically involves activities like notching, punching, or drilling. When performed for precision applications, these processes are often done by CNC machining. Creating a tube cut part with CNC machining ensures accuracy, as well as a secure fit between the tube ends. Most other tube cutting can be done by a blade as it makes a full rotation around either the interior or the exterior circumference of the tube.

Tube flaring and swaging are both typically cold forming processes. They use high pressure to expand the diameter of a certain length of tube or pipe. A tube end forming process, flaring is applied only to the end of a tube, usually to make the end of the tube capable of connecting tightly with another tube for hydraulic applications. Swaging is a more involved process; it expands the diameter of an indefinite length of tube. Its goal is to create sections of thin wall tubing without compromising the integrity of the material. The swage, or the diameter by which a tube is expanded, must be precise in order for one tube to slide snugly inside another tube or tube end.

Materials Used in Tubing

Tubing can be formed from a wide range of metals (usually in the form of sheet metal), such as aluminum, brass, bronze, copper, carbon steel, stainless steel, titanium, and a host of alloys. Material choice depends on your intended use of the tubing and where you intend to use it. This is because these metals and metal alloys can vary greatly in terms of durability, density, and hardness, and it’s important to match your tube with a metal with appropriate qualities. Let’s take a quick look at those metals mentioned above to learn a little more about them.

- Aluminum Metal

- Aluminum is a naturally-occurring, highly ductile metal. It is also soft, lightweight and recyclable, but durable. It is also corrosion and oxide resistant.

- Brass Alloy

- Brass is an attractive alloy made up of copper and zinc. It is highly malleable with a low melting point, making it quite castable. It also has an antimicrobial effect on pathogens and microorganisms. Its composition can be altered in order to change its properties, such as its level of corrosion resistance, strength, machinability, etc.

- Bronze Alloy

- Bronze is an alloy of copper and tin. Bronze is ductile, resistant to seawater corrosion and durable.

- Copper Metal

- Copper is a naturally occurring element, found in its metallic form. It is known for its softness, malleability, ductility, thermal conductivity and electrical conductivity.

- Carbon Steel

- The term “carbon steel” can either refer to a steel with a carbon content of up to 2.1% by weight, or any steel that is not stainless steel. Carbon steel is durable, strong and hard. The higher level of carbon it has, however, the lower its level of ductility.

- Stainless Steel

- Stainless steel is a steel alloy that contains at least 10.5% chromium by mass. It is highly resistant to corrosion, oxidation and most acids. It’s incredibly strong and durable, and it’s hypoallergenic.

- Titanium Metal

- Titanium is a transition metal. It’s resistant to corrosion from saltwater, chlorine and aqua regia. In addition, it’s strong and lightweight with low levels of electrical and thermal conductivity.

Tube Fabrication Images, Diagrams and Visual Concepts

Tube bending, a mechanical process used to deform tubes from straight tubes into curved shapes.

Tube bending, a mechanical process used to deform tubes from straight tubes into curved shapes.

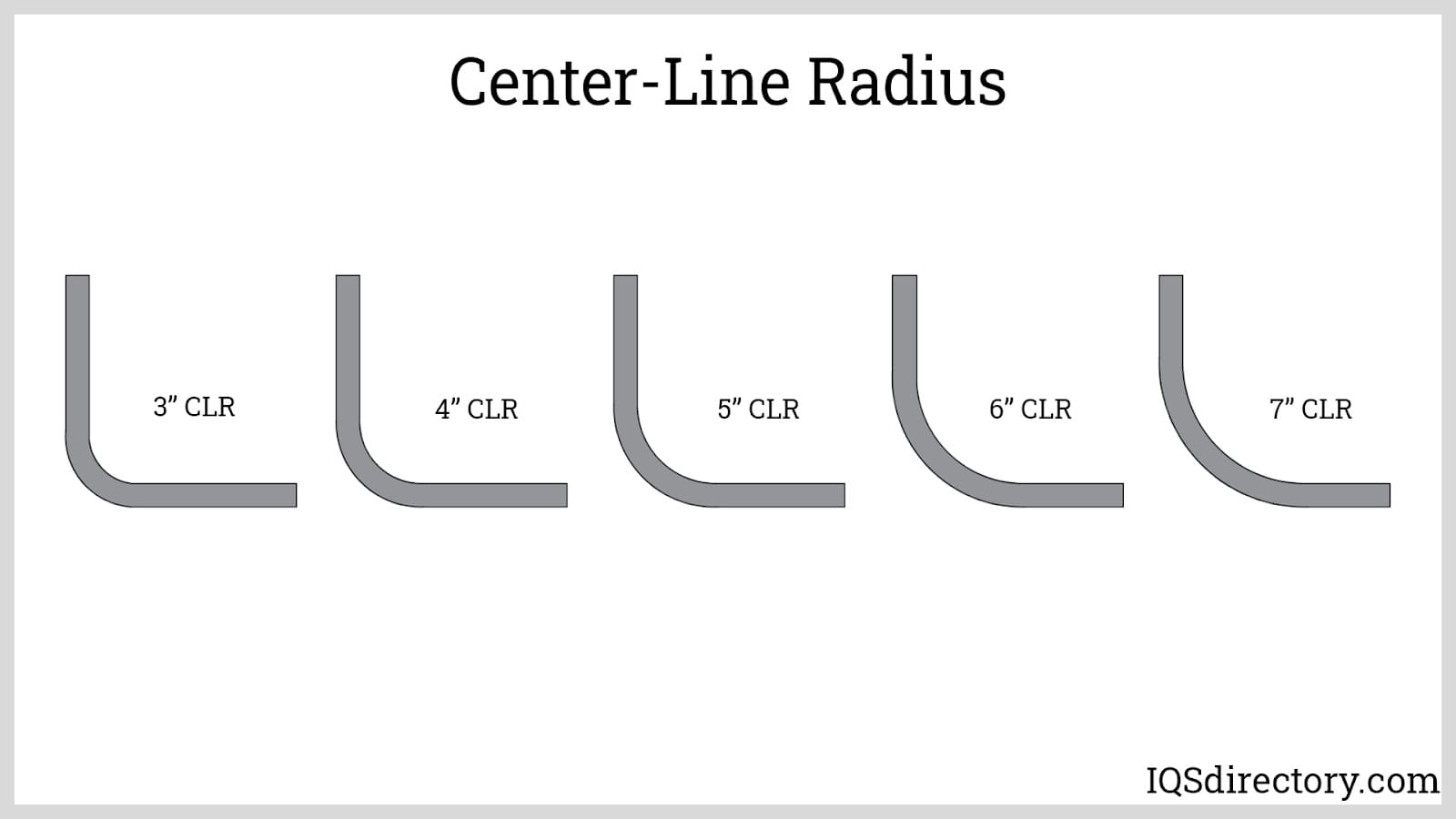

Center-line radius is the distance from the center of the curvature to the centerline of the tube.

Center-line radius is the distance from the center of the curvature to the centerline of the tube.

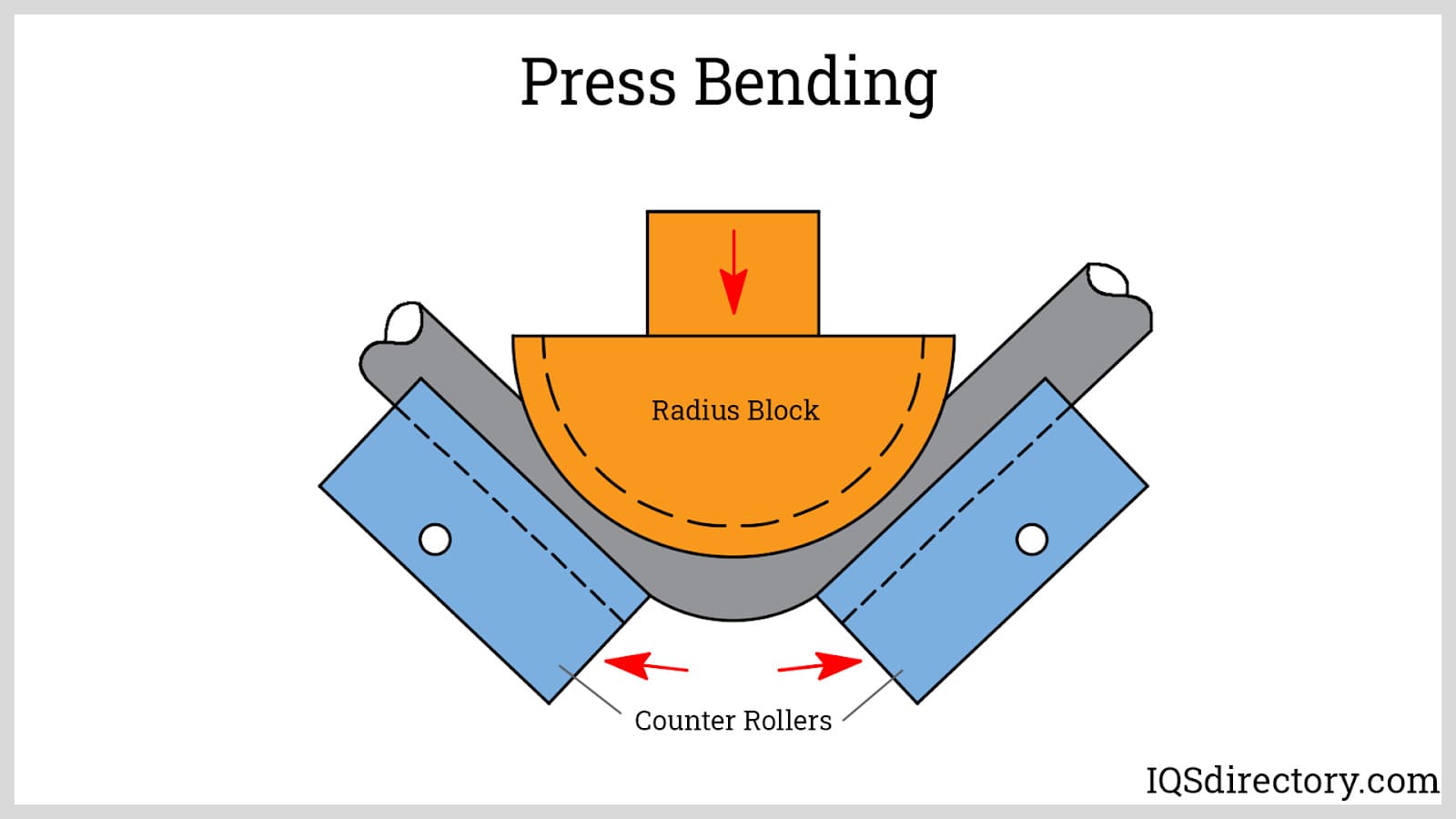

Press bending, the tube is fixed at two points and the bend die is forces the tube to bend into shape.

Press bending, the tube is fixed at two points and the bend die is forces the tube to bend into shape.

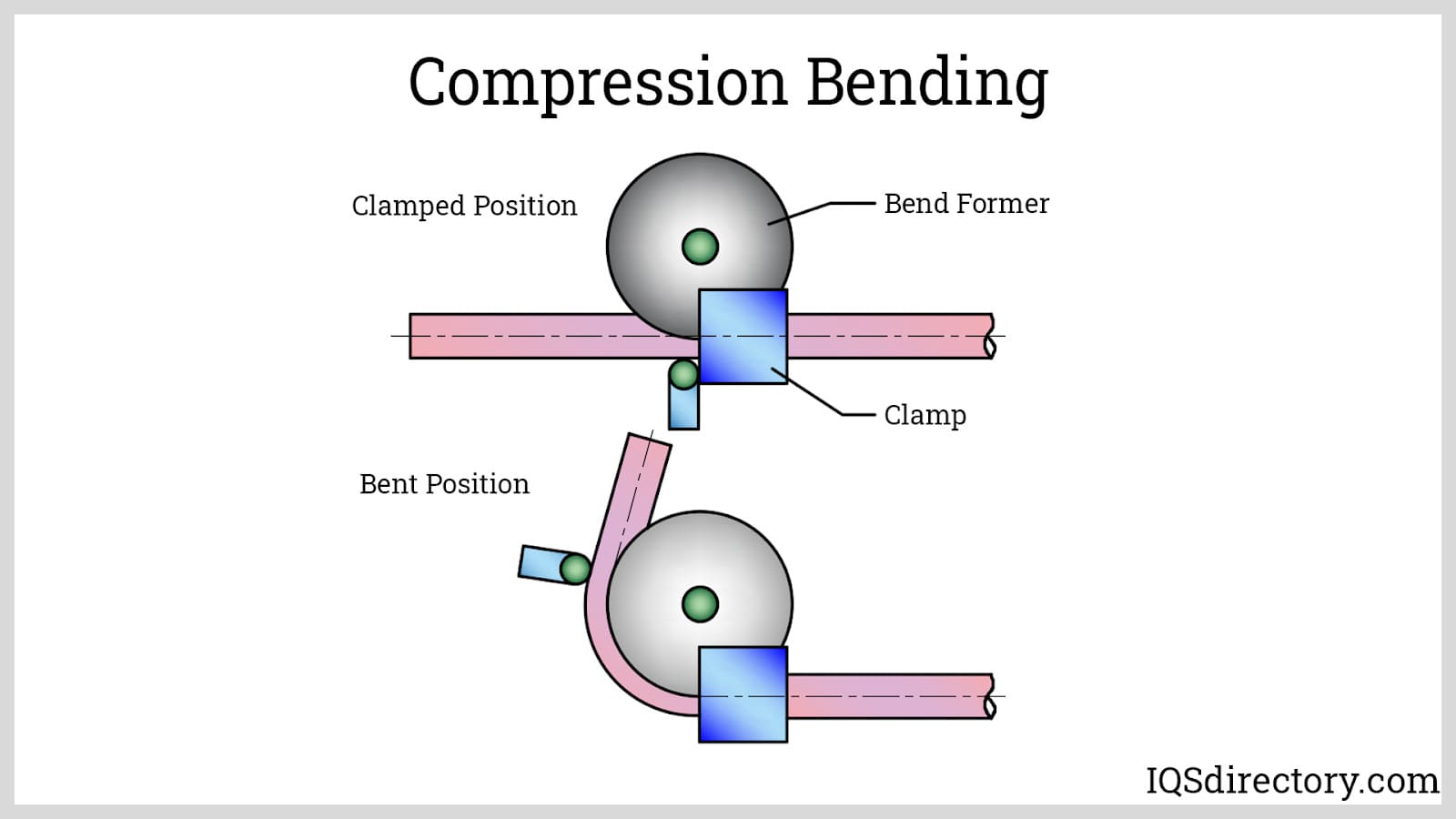

Compression bending is cheaper than rotary draw bending but is limited to circular hollow sections.

Compression bending is cheaper than rotary draw bending but is limited to circular hollow sections.

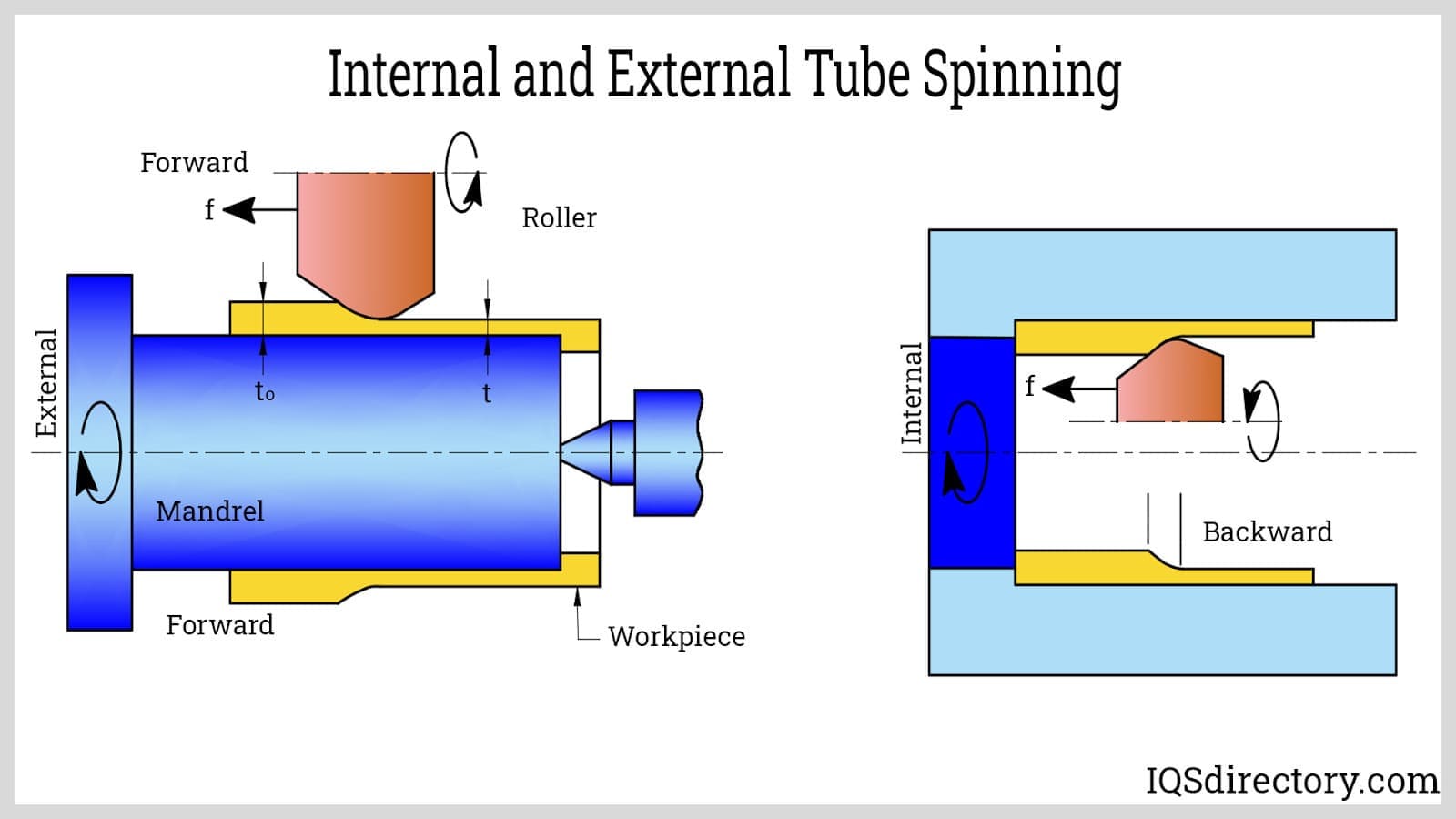

Tube spinning, a flow forming process used to elongate tubing and alter tubing wall thicknesses.

Tube spinning, a flow forming process used to elongate tubing and alter tubing wall thicknesses.

Outer wall thinning is a result in the outer side bend receives tensile forces and causes elongation and wall thinning.

Outer wall thinning is a result in the outer side bend receives tensile forces and causes elongation and wall thinning.

Tube Fabrication Types

- CNC Tube Bending

- Bends tubes and pipes using computer-controlled machines that ensure the quality and efficiency of a product. Today’s modern CNC technology has made it possible to produce high volume, close tolerance, tubular metal parts quickly and economically.

- Custom Tubing

- Well-known term, referring to any hollow cylinder used to convey fluids or to protect electrical or optical cables and wires. A tube generally has a certain level of rigidity and permanence. This contrasts with the hose, which is generally flexible and portable.

- Hydro-Forming

- A metal fabrication method of forming tubular metal parts within a die cavity. This high-pressure method forces fluids inside the die so that the part expands into its final shape.

- Mandrel Bending

- Also known as mandrel tooling, is a sub-process of tube bending.

- Pipe Bending

- A process that uses computerized machines to bend pipes. Pipe bending can be performed manually using a hand-held mandrel, but most tube fabrication facilities have semi-automated and automated equipment which is faster and more precise. To create a simple pipe bend, the machine clamps down the length of tubing and either forces it to take on the shape of a die or feeds it through rollers.

- Pipe Elbow Fabrication

- Commonly used in flow and hydraulic applications such as plumbing, require both mandrel bending and flaring or swaging. For these types of applications, mandrels are placed inside the tube in the area being bent, or the tubes are packed with sand before the bending process. Mandrels are typically a rounded-tip steel rod, linked ball bearings or unlinked steel balls; the straight mandrel, called a plug mandrel, is used on normal bends, while ball mandrels with linked or unlinked ball bearings are used to form critical precision bends. Mandrels and sand are essential parts of the tube fabrication process as they preserve the interior shape of the pipes around the curve.

- Any tube fabrication process, particularly tube cutting, can result in surface imperfections. If this is the case, manufacturers may finish off your product with sanding or polishing. If they are working with stainless steel tubing, they may also anneal it for strength.

- Pipe Fabrication

- Processes that involve the shaping, cutting, bending or size alteration of pipes formed from various materials for wide-ranging applications.

- Roll Forming Metal

- The tube fabrication process that is most common, although it is not used for thicker metal tubing. It involves rolling a strip of sheet metal and curing it.

- Rotary Draw Bending

- Employs mandrels and various dies to manage and control metal flow during the bending process. In this process, a precision mandrel is positioned inside the tube, while a pressure die, wiper die, bend die and clamp dies surround the outside of the tube.

- Thin Wall Tubing

- Tubing with very little wall thickness, typically ranging from .001 in. (.0254 mm) to about .065 in. (1.65 mm).

- Tube Bending

- Uses computerized machines to bend tubes. CNC tube bender machines, which are often powered hydraulically for extreme torque power, are capable of forming complex tubing shapes such as coils and zigzags with extreme precision and short processing times, although all these processes may still be performed manually on traditional tube benders with longer process times.

- Tube bending performed without a mandrel forms wrinkles in the inside of the tube's curve which can affect the flow capacity of a pipe, and by distorting the interior structure of the pipe create potential weak spots. Although wrinkled tube bends are acceptable for some low-performance and non-aesthetic applications, high performance mufflers, hydraulic piping and decorative handrails require smooth, unobstructed tube bends.

- Tube Cutting

- A process that uses computerized machines to cut pipes and tubes.

- Tube End Forming

- Refers to various processes that are used to shape, cut, bend or enlarge the inside or outside ends of tubing.

- Tube Fabricating

- Employs a variety of techniques to shape, bend, enlarge and cut tubes of all sizes and metals into parts and products.

- Tube Flaring

- A process used to form an extremely tight seal at the end of a tube.

- Tube Forming

- Can refer to several processes that are used to form raw metal materials into tubes.

- Tube Rolling

- The process of producing tubular parts through heat curing materials that have been wrapped around a circular mold, then removing the mold.

- Tube Swaging

- Uses high pressure to shape tubes.

Machinery Used in Tube Fabrication

Examples of machinery and tools used during tube fabrication include: mandrels, CNC machines, bend dies, roll forming machines, benders, hydraulic tube benders, CNC mandrel bending machines, swaging machines, coating machines, and more.

In addition, to fabricate a custom tube, manufacturers may perform any number of secondary processes or tooling processes. These include painting, powder coating, chrome plating and zinc plating, among others. In addition, they can fabricate the tube to virtually any diameter and length.

Things to Consider When Choosing Tube Fabrication

Selecting the appropriate tube fabrication service requires an analysis of both the physical properties of the tubing and the production capabilities of the manufacturer.

When considering the nature of your tubing, think about things like your required production volume, the environment your tube will go in, industry standards, ductility requirements, the amount of pressure you will be using and what you will be conveying through your tubing or piping assemblies.

When looking for a manufacturer, your first thought may be that you want a manufacturer that has state-of-the-art equipment. However, equipment is only as good as the manufacturers who operate it. So, instead, look for a manufacturer that is truly interested in creating a high quality solution that will satisfy you. In addition, talk to your potential supplier about manipulation tests, which evaluate the quality of finished products. The right manufacturer will demonstrate that they have your best interests at heart. Find out who that might be for you by perusing the list of companies found near the top of this page.

Variations on Tube Fabrication

There are many types of tube fabrication, and some lend themselves better to certain applications than others. For example, precision swaging can be critical for certain applications, particularly in telescoping tube applications when one tube must slide within another tube. In addition, industrial and manufacturing industries use fabricated tubing and mandrel bent tubing extensively in hydraulic pipe applications such as automotive fuel lines, exhaust pipes, hydraulic cylinders, and shell and tube heat exchangers.

Two subprocesses of tube bending, mandrel bending (sometimes called mandrel tooling) and rotary draw bending, are used when manufacturers wish to create a precise bend free of wrinkles and kinks. In mandrel bending, a machine component inserts a mandrel (a metal rod or ball) into the tube while it is being bent. Similarly, rotary draw bending uses mandrels and various dies to manage and control metal flow during the bending process. In this process, a precision mandrel is positioned inside the tube, while a pressure die, wiper die, bend die and clamp dies surround the outside of the tube. Sometimes, a tube formed with a mandrel is called a mandrel tube or mandrel bend tube, and the bend created by a mandrel called a mandrel bend.

Tube Fabrication Terms

- Alloy Steel

- Steel that is alloyed with moderate amounts of chromium and other elements, such as molybdenum. Alloy steel is distinguished from stainless steel by good hardening characteristics and from tool steel by possessing better "toughness" after hardening.

- Annealing

- The heating and cooling of steel to remove stresses, alter physical, mechanical and metallurgical properties, increase corrosion resistance and thermally treat steel prior to age hardening.

- Arc

- The curved section of bent tubing.

- As-Welded

- Tubing that is not given heat treatment after the initial welding.

- Austenitic

- A family of chromium nickel stainless steels that have good corrosion resistance and good formability, but can only be hardened by cold working.

- Bend Die

- Less commonly known as the "bend form" or the "radius die," it is the primary tool on a rotary-draw tube-bending machine. The bend die is the form against which the tube is clamped and then drawn around to produce a bend.

- Bright Annealing

- The process of annealing in a controlled atmosphere so that dark, adherent oxides do not form on the metal.

- Burst Pressure

- The amount of pressure that will make tubing fail or burst by exceeding the tensile strength of the material from which the tubing is made.

- Camber

- A measure of warp in tubing material or the deviation from straightness.

- Cold Drawing

- The normal method of rotary-draw tube-bending, which is done without heating the tubing material.

- Ductility

- A measure of a tube's ability to deform without fracturing.

- Elongation

- The amount of permanent extension of the material before it fractures.

- Full-Finished

- A term that refers to the state of the tube after the weld has been processed to produce uniform strength and dimensions and the tube has been annealed for corrosion resistance.

- Manipulation Tests

- Tests used to evaluate the quality of finished products, such as crush, flare, bend, flange, flatten, reverse flatten, reverse bend and expanding.

- Ovality

- The deformation of round tubing into an elliptical shape or a symmetrical flattening of a round tube. Ovality is the measure of the difference between the maximum and minimum outside diameters of a round tube.

- Passivation

- A protective layer made of oxides, which is on the outside of tubing, that resists corrosion.

- Pickling

- The chemical removal of oxides on the surface of metals.

- Pressure Tubing

- Tubing specified for the containment of liquids and gasses, as opposed to structural or mechanical purposes.

- Tangent

- The unbent section of a bent tube.