Tape Suppliers

Tape suppliers refers to both tape manufacturers and distributing tape companies that supply tape for a number of industries. Tape is a long strip of sticky or otherwise adhesive material.

Quick links to Tape Suppliers Information

The History of Tape Suppliers

Before adhesive tape, glue-like adhesives were the main option for mending and bonding. For example, between 618 and 906 B.C., the Chinese used adhesives made from materials like fish bladder and stag horns. The earliest recorded instructions for making adhesives date back to 2000 B.C.

Adhesive tape finally made an appearance in 1845, when Dr. Horace Day, a surgeon, applied a rubber-based adhesive to fabric strips. That day, he invented surgical tape. About half a century later, in 1901, a man named Oscar Troplowitz invented an adhesive patch called Leukoplast for the German company Beiersdorf AG. In 1921, after finding that Dr. Day’s surgical strips kept falling off his wife’s fingers, Earle Dickson, a cotton buyer for Johnson and Johnson, attached some gauze to a piece of cloth-backed tape and covered it in crinoline. Finding that it worked, Dickson took his invention to Johnson and Johnson, who called it the Band-Aid and made him V.P.

Another significant marker in tape history was in 1925, when Richard Drew, a fairly new employee of the then-sandpaper company, 3M, invented the first masking tape. He did so to make it easier for automobile painters to paint straight lines on two-toned cars. Today, this line is known as Scotch Tape. In 1942, Johnson and Johnson invented Duct Tape. Its original purpose was to give the military a way to seal, repair and waterproof ammunition cases. Today, duct tape manufacturers are widely recognized for their contributions of helping to hold our world together.

Today, tape is in higher demand than ever, and while the production process has remained much the same, there has been some advancement in the types of materials used in tape manufacturing. Increased abilities in substrate manufacturing capabilities have led to the development of thinner and thinner film and foil tapes, such as aluminum foil tape. Advancements such as this will keep the tape industry rolling forward into the future, always ready to provide for the world's taping needs. As the industry presses further onward, IQS Directory's company listings will evolve to match it.

Advantages of Tape

Choosing tape over adhesion options, like glue or staples, has many advantages. First, when properly used, tape does not damage surfaces or items it holds together. Second, tape is easy to manufacture and inexpensive to purchase. Third, when working with a tape supplier, you have many customization options.

Purposes of Tape

Tape is primarily used in a wide variety of binding, sealing and fastening applications. It is one of the most relied upon utilities in both the home and a wide range of commercial and industrial processes. Common tape applications include: jacketing, mending, labeling, marking, protecting, surfacing, color coding, and decorating.

Some of the industries in which they are used include: kitchen, commercial packaging, construction, paint, office supply, furniture manufacturing, aerospace, automotive, sports and recreation, arts and crafts, all types of electrical applications, and healthcare.

While households typically source tape supplies from their nearby hardware and grocery stores, commercial and industrial tape users get their bulk requirements from established tape suppliers.

Design of Tape

Tape is made in a process called coating, which involves the application of an adhesive to the carrier material.

A carrier material is typically a moderately thin and flexible material. Examples include films (ex. polyimide film tape), paper tissues, cloth or metal foils. Typical adhesives include: PTFE, PVC, silicone and acrylic adhesive.

Manufacturers rely on three main methods of coating: solvent coating, water-based coating and hot-melt coating.

- Solvent Coating

- During solvent coating, tape suppliers start by dissolving the adhesive into a solvent. This creates a relatively non-viscous, coatable liquid, which they then apply to the carrier material. To remove the solvent from the coated tape, they pass it through a heated oven.

- Water-Based Coating

- During this process, tape suppliers mix adhesive with water. This forms emulsions, or small glob suspensions of one liquid inside the other. Once they’ve finished, they apply the new solution onto the carrier material.

- Hot-Melt Coating

- In the hot-melt coating, tape manufacturers heat adhesive until it melts and coats the carrier material. After the hot liquid has thoroughly covered the carrier, manufacturers allow the coated tape to cool.

- After they’ve created a finished sheet of tape, tape suppliers can put the sheet through any number of converting processes, which are usually performed with the help of a CAD cut machine. These include winding, slitting, and die cutting. During winding, the sheet of coated tape is wound and formed into a large roll of tape. The slitting process involves taking the huge.

- roll of coated tape that is created during coating, and cutting it down into smaller strips of tape for sale. Once slit, the tape strips must undergo rewinding so that they are once more formed into rolls of tape. Die cutting can serve as an alternative to slitting.

- If you’re interested in a custom roll of tape, you’re in luck. There are many ways in which your supplier can make your tape a perfect fit for your application. Common customizations include those related to: shaping, colors and patterns/prints, widths and thicknesses, sizes, and strengths.

Tape Supplier Images, Diagrams and Visual Concepts

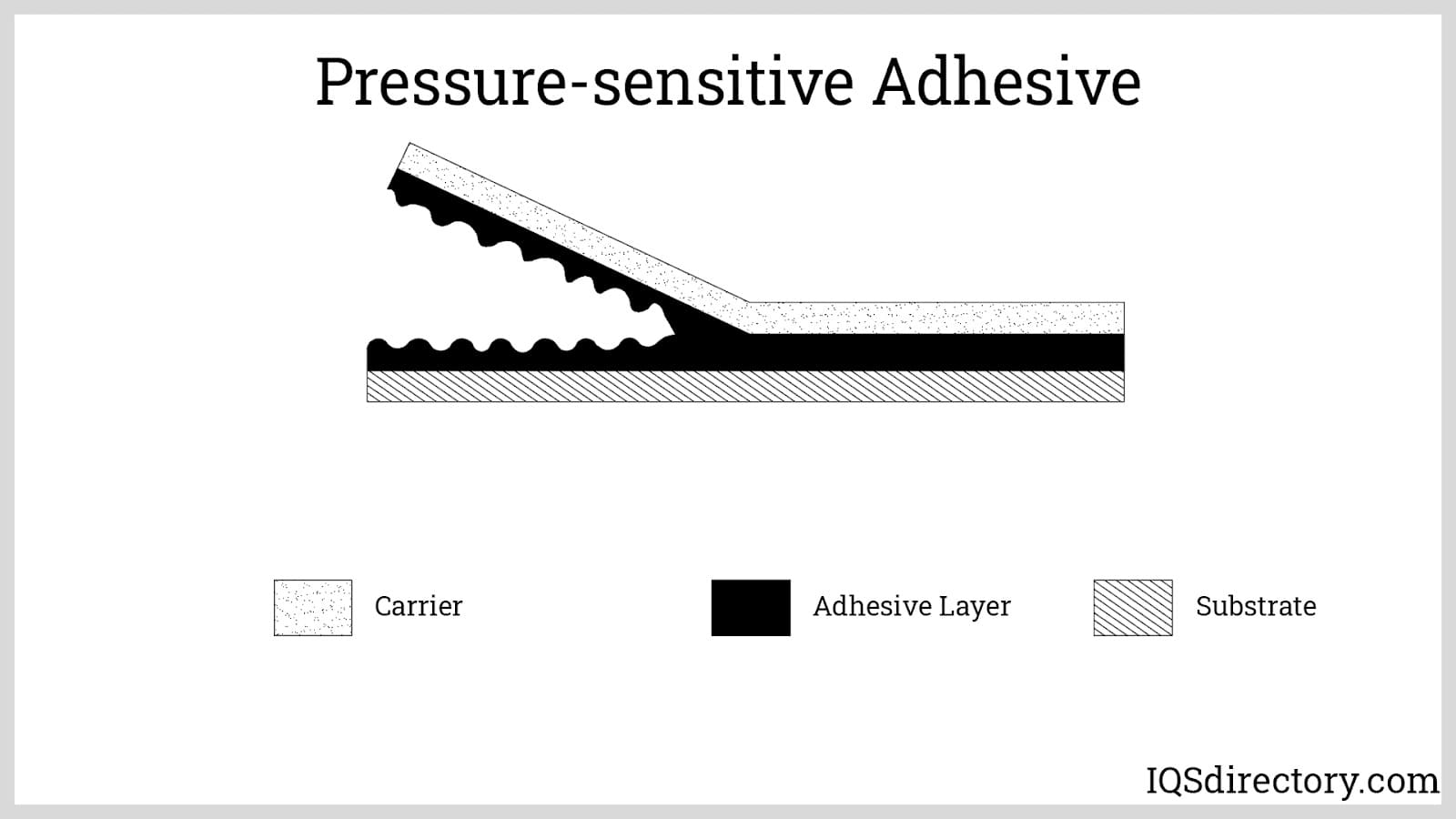

Pressure sensitive tapes are heat-activated tapes.

Pressure sensitive tapes are heat-activated tapes.

Masking tape, a pressure sensitivetape that is thin, very adhesive, and easy to tear.

Masking tape, a pressure sensitivetape that is thin, very adhesive, and easy to tear.

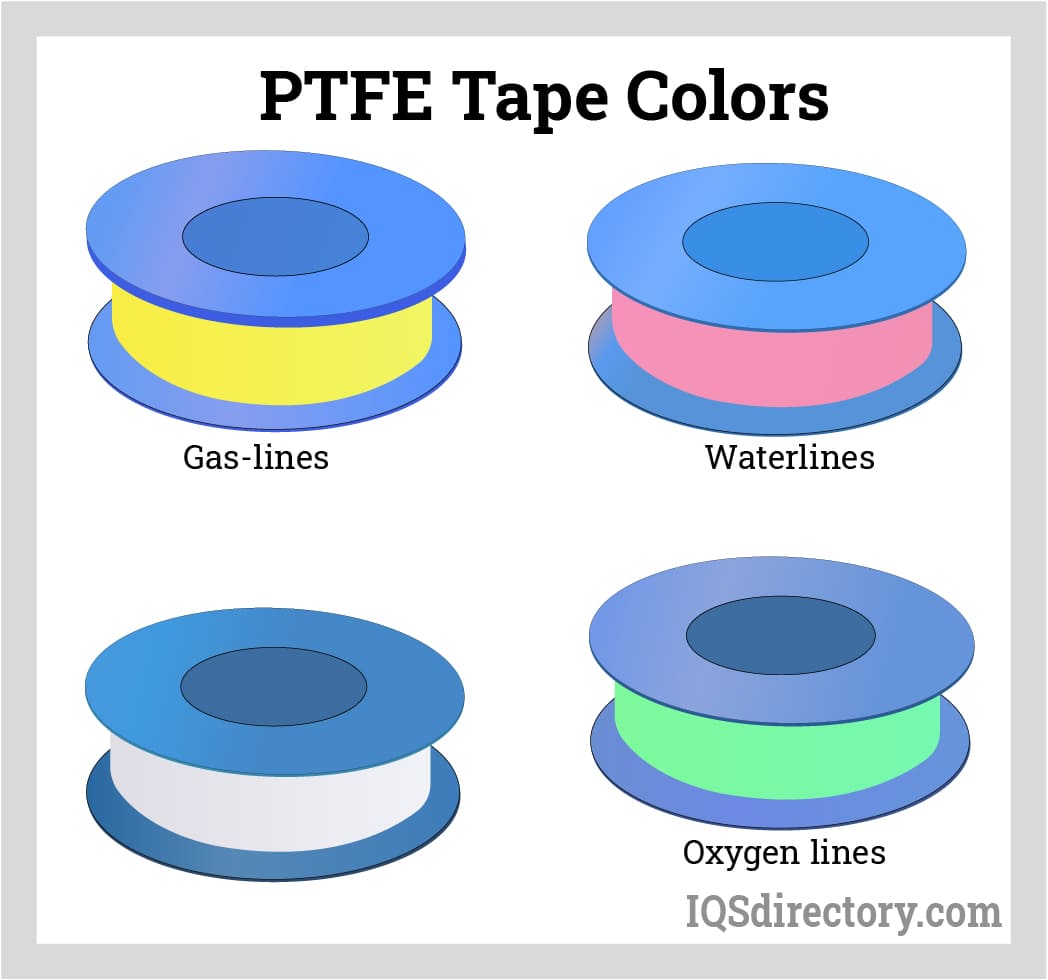

The different colors of PTFE tape are used to seal different materials.

The different colors of PTFE tape are used to seal different materials.

Electrical tape is known as a carrier tape because of its durability and semi-permanent bond.

Electrical tape is known as a carrier tape because of its durability and semi-permanent bond.

Types of Tape Suppliers

- Sealing Tape

- Also known as seal tape, is a pressure sensitive adhesive tape that is used for closing or sealing slotted containers such as packing cartons or corrugated fiberboard boxes. It also, in general, helps join two or more materials or surfaces. Adhesive tape products that fall under this category are particularly useful in warehousing industries, but are also used often for domestic and industrial purposes.

- Common sealing tape varieties include: acrylic carton sealing tape, hot melt carton sealing tape and printable carton sealing tape.

- Acrylic Carton Sealing Tapes

- Considered suitable for taping both light and heavy applications. Made from acrylic materials, they can be customized to handle a wide range of temperature settings. Acrylic tapes also efficiently resist UV contamination and sustain extremely high and low moisture conditions. This is why these sealing tapes are preferred by packaging businesses that have to seal their shipments according to product type.

- Hot Melt Carton Sealing Tapes

- Designed for high tensile strength and quality, hot melt carton tapes are suitable for both lightweight and heavyweight applications. While this industrial tape variety is mostly used for sealing cartons, it can also be used for general purposes such as the packaging of fruits and vegetables.

- Printable Carton Sealing Tapes

- Products are a utility for packaging and shipping businesses who want to promote their name through their shipments. Because you can print your brand logo and message on them, they not only look professional, but they also help broaden your market visibility.

- These adhesive tape products are customizable by size, thickness and adhesiveness. In addition, you may get them in premium grades or industrial strength grades.

- Marking Tape

- Or mark tape, is used to clearly identify areas and equipment in facilities such as manufacturing workshops and nuclear power plants.

- Gaffer’s Tape

- Typically used in the entertainment industry for applications such as securing cables and laying blocking markers.

- Printed Tape

- Distinguished by the printing on the tape rather than a specific material construction. One of the most common types of printed tape is tamper evident tape, which is most often used in security and containment applications.

- 3M Tape

- Differs from these other tapes because, rather than referring to one tape product, 3M refers to many tape products. This is because 3M tape is a brand of tape that encompasses a whole line of products used in many different industries.

- Vinyl Tape

- Or PVC adhesive tape, is made for clean removal and excelled dead stretch. Thus, it is ideal for applications such as: color coding, decoration, safety marking and identification.

- PTFE Tape

- Made from polytetrafluoroethylene (PTFE) film that has been cut in thin strips. PTFE tape products are used primarily for sealing pipe threads.

- Foam Tape

- Products are particularly useful for gasketing, baffle, cushioning, sealing, insulation and other soundproofing applications. They’re also useful in the medical industry.

- Foil Tape

- Named after its carrier material, which is most often aluminum foil or copper foil. It’s employed in industries like aerospace and electronics, for applications like plating and shielding, because of its strong resistance to chemicals and extreme thermal conductivity.

- Masking Tape

- Also known as mask tape, consists of an easy-release pressure sensitive adhesive that makes it easy to tear. Mask tape is often used around the house and for painting, where it serves as a cover for areas not to be painted.

- Packaging Tape

- Or packing tape, is used in shipping applications to secure packages like large envelopes, bags, cartons or boxes. To do so successfully, it uses heavy-duty pressure sensitive adhesive that prevents tearing, breaking, bursting or loosening.

- Electrical Tape

- Also known as electrical insulation tape, is made from materials that do not conduct electricity. Tapes in this category, like PVC electrical tape (PVC insulation tape), use a pressure-sensitive adhesive that insulates conduits like electrical wire. This tape can also be used to color-code wires for easier accessibility within electrical systems.

- Duct Tape

- Consists of a tacky and soft pressure sensitive adhesive that allows for versatility and holding power useful in applications such as water-resistant sealing for military equipment. The number of applications for duct tape is endless.

- Paper Tape

- Tape made with a paper carrier material. Paper tape varieties are lightweight, breathable and frequently hypoallergenic. For this reason, they’re used quite extensively as bandaging tape for wounds and skin irritations.

- Cloth Tape

- Another lightweight tape variety often used in wound care. Durable and flexible, it’s often made as a pressure sensitive tape so that it adheres better. It can also be used for applications such as wall sealing and plumbing.

- Side Tape

- Or edge tape, is a specialty tape used for winding around sports equipment, such as tennis racquets. They’re available in many different shapes, sizes and colors.

- Acid Free Tape

- As its name suggests, is an adhesive tape variety that does not contain any acids. This is important to artwork and photos, as acid, given enough time and exposure, will leave marks on the paper. Also, some people are sensitive to acids and must avoid them.

- Magnetic Tape

- A medium for magnetic recording, made of a thin, magnetizable coating on a long, narrow strip of plastic film. It’s used for audio recording, video recording and data storage.

- Double-Coated Tape

- Also known as double-sided tape or adhesive transfer tape, is an adhesive tape used to stick two lightweight surfaces together, like paper, plastic or cardboard. Manufacturers make this tape by coating both sides of the carrier with adhesive, laminating one of the two coated sides with two layers of silicone release paper, and placing a tape backing, or liner, in between the two surfaces.

- To use it, firmly press the double side tape against your surface and then peel off the liner. With the liner gone, the other side of the adhesive is exposed, and you can press a second item against it. This second item, depending on the strength of the adhesive transfer tape, may be a dust cover, poster, mat blank, glue spacer, fillet, cardboard, artwork, or some other lightweight item.

- Self-Fusing Silicone Tape

- Does not use adhesive. Instead, it binds itself to surfaces when stretched and wrapped around a material. While it creates a strong, waterproof seal, when you’re done with it, you can easily cut it away. Also, it does not leave residue. Resistant to chemicals and UV rays, this tape type is mostly used for bundling, securing, clamping and sealing applications.

Standards and Specifications of Tape

Common adhesive standards include those put out by ASTM International and ISO.

ASTM standards help manufacturers test and identify properties such as: viscosity, adhesion, shear strength, shear modulus, strength, creep, fracture and more. They also help them determine what tape is best for what, like electrical insulation and sealing. ISO standard certifications offer endorsements for capabilities and characteristics like: peel resistance, tensile lap-shear strength, wood-to-wood adhesive bonds, thermal stability, durability, suitability for assembling PVC pipes, etc.

To learn what standards to which your tape needs to adhere, look up your industry and region requirements.

Things to Consider When Purchasing Tape

How do businesses and industries find high quality bulk tapes for their manufacturing needs? Furthermore, how do they find a tape supplier that is trustworthy and can meet their unique manufacturing requirements?

To answer those questions, we’ve outlined below a step-by-step process for finding a reliable wholesale adhesive tape supplier in your area.

- Check Your Requirements

- If you are looking for sealing or adhesive tapes for your industrial applications, it is important to review your exact requirements before selecting a tape supplier. Factors you need to consider include: what type of tape you need, what applications the tape will support, when you need the tape supply and what quantity you require. Note: For the continuity of your business process, it is advisable to have at least a week's extra supply stored at your facility.

- Find a Supplier

- The best way to find a supplier is by using a business directory like this one. That’s because we’ve already done most of the legwork in the search process; we’ve sorted through the overabundance of businesses out there and determined which ones are best. Plus, we’ve got them displayed all in one convenient place. In this case, that’s near the top of this page.

- Scroll up to our list of suppliers and browse their respective websites. Get an idea for the ones with whom you’d like to speak to, and then reach out to them with your questions. Explain your unique tape requirements and ask for a quotation. Make sure they supply tape materials directly within your area and that they can deliver the materials you need within a timely manner. Also, don’t forget to check that they can meet your standard requirements and budget requirements. Remember, the right manufacturer will work hard to make you happy, not just reach their own bottom line.

Tape Supplier Terms

- Abrasion Resistance

- Whether or not tape can still function properly after experiencing rubbing and friction.

- Adhesion

- When two surfaces are held together by the bond between a surface and an adhesive.

- Backing

- Part of tape that has adhesive applied. Backings may be paper, film, metal foil, cloth and more.

- Conformability

- Whether or not tape can make complete contact with a surface.

- Differential Adhesive

- The adhesion of both sides of double-sided tape is different.

- Flexible

- When a tape can be bent and flexed freely during an application, mostly in low-temperature use.

- Gapping

- Openings between layers of tape inside the roll.

- High Temperature Tape

- Include a variety of different kinds of tape, but all of these kinds of tape offer reliable performance at high temperatures. These types of tape can also be referred to as flame resistant tape and can be made from aluminum glass.

- Low Stretch

- Ability of tape to shrink back to original size once stretched.

- Ozone Resistance

- Resistant to cracking when exposed to the ozone for an extended period of time.

- Release Coating

- Thin coating applied to tape backing so that tape can be controlled as it is unwound.

- Substrate

- Surface tape is attached to.

- Suspension Polymerization

- A manufacturing process used to produce the PTFE on PTFE tape.

- Tack

- Sticky feeling of tape.

- Teflon Tape

- A type of adhesive that is primarily used to hold different forms of piping together, as well as seal different pipe joints where two pieces of pipe come together. Teflon is the brand name of formulas based on the synthetic fluoropolymer Polytetrafluoroethylene, more commonly known as PTFE.

- Telescoping

- When the tape layers are slid sideways and one over the other, in order to look like a telescope or funnel.