Screw Machining

Screw machining, also known as Swiss screw machining, is a popular industrial process for manufacturing a broad range of precision metal parts. It relies on screw machines, a type of automatic metalworking lathe, and is valued for its efficiency and high output rates.

Quick links to Screw Machining Information

The History of Screw Machining

Screw machines were invented in Switzerland in the 1800s. (For this reason, they are also known as Swiss screw machines.) They developed as a response to increasing industrialization, which produced a new commercial need for many interchangeable – but precise – mechanical parts. At this time, Switzerland was a pioneering center of industrial products such as optic equipment, microscopes, measuring instruments, scales, and similar products. Early types of automated metalworking lathes were thus developed by Swiss watchmakers, who mounted pieces on rotary slides and produced a variety of precision components.

In the 1870s, these early machines were enhanced by the introduction of the collet chuck (which enabled the use of bar stock) and features which allowed the headstock worked on in the machine to move. Computer numerical controlled (CNC) screw machines first appeared in the following century, during the 1940s and 1950s. The CNC version of the Swiss machine appeared in the 1970s. At first, Swiss-type screw machines were used primarily in the semiconductor and electronics industries (1980s). Soon after, their use in other industries – such as industrial, medical, and aerospace – grew in accordance with enhancements in design and operation (1990s).

Advantages and Disadvantages of Screw Machining

- Advantages of Screw Machining

- Screw machining is considered one of the fastest and most cost-effective methods of small rotary part manufacturing due to a number of factors. CNC machining and turning equipment are known for operating very efficiently. For example, one piece of equipment may machine up to six parts simultaneously due to a high number of tools. (Some machines may have up to 20 tools in the tooling area.) Not only are screw machines capable of machining several parts simultaneously, but they also achieve high production rates and slash cycle times, making it possible for manufacturers to make a large number of uniform precision machined parts with very little process time. Since multiple screw machines can be supervised by a single operator and perform secondary operations, they reduce labor costs associated with a large workforce. Without Swiss screw machining, high-quality metal parts that are commonplace today would be far too expensive to produce and obtain en masse.

- Screw machining offers design capabilities and structural benefits that cannot be cost-effectively reproduced with any other manufacturing method. Very few other metal forming and metal fabrication processes come close in precision to screw machining. Thus, precision turning and machining processes are often required for the construction of products typically associated with screw machining (e.g. specialty fasteners). Some types of metal stamping can reach tolerances close to those of screw machined products; however, for products such as minute precision tools used in critical medical applications, screw machining is the only practical means of manufacturing.

- Screw Machining Disadvantages

- Screw machining does not come without disadvantages. An obvious disadvantage is the setup time that precedes machine operation. Unlike manual lathes and non-CNC machines, multi-spindle CNC screw machines require a lengthy set-up process involving part design and system programming, including CAD design. It is not uncommon for setting up a Swiss machine to take one to two hours. This disadvantage means that long runs are typically most cost effective. However, no dies or hardware must be created custom for custom screw machine parts, making even short run screw machines a relatively cost effective means of precision production. A secondary disadvantage of screw machining is the mass creation of scrap. As much as a foot of scrap can be left behind from each individual bar that is screw machined.

Overview of Screw Machining

Virtually any metal may be manufactured by screw machining. Common screw machined materials include steel, stainless steel, brass and aluminum. Titanium is often used for sanitary and miniature medical tools. Even non-metal plastics such as PTFE and nylon are able to be screw-machined. It is important to note, however, that the quality of any screw-machined product ultimately depends on the quality of the original material, no matter its type.

The defining feature of a Swiss machine is its ability to move the headstock (in contrast to traditional lathes). In essence, these machines manufacture parts by shaving metal workpieces down. Disc cams in automatic screw machines rotate a variety of machining tools to a bay, where they can operate on the workpiece (which is held in place by a chucking collet). These same cams are also responsible for modifying the position of the headstock if it proves necessary. The machine motor, located at the base of the machine, is the central power source for all operations and will vary in horsepower, depending on the size of the machine, speed and stock to be machined. The main drive shaft of a screw machine provides power to the machine bed's lead work shaft and controls the two front cam shafts.

CNC Swiss machines typically contain even more tooling than automatic Swiss machines due to the sophistication of their computerized control unit. Such screw machines may have more than eight spindles, all of which operate simultaneously. Each spindle is often programmed separately to function at different speeds. Round, square or hexagonal metal bar stock is attached to the spindles' spring collets, which spin as multiple automated cutting, drilling, notching and knurling tools attached to the screw machine work the bar stock into parts by shaving away excess material, smoothing and drilling. These tools operate on the stock very close to where the stock enters the work bay through the guide bushing. The stabilizing action of the guide bushing minimizes any deflection caused by the cutting force and enables a high degree of precision and accuracy for the entire screw machining process.

Applications and Products of Screw Machining

The products of screw machining are often described as CNC turned parts or precision turned parts. Specialty fasteners and screws are a very common type of product manufactured by the process of screw machining and include button machine screws, hex machine screws, pan machine screws, truss machine screws, and many others. Military examples of products which depend on screw-machined creations include combat helmets and military rifles. However, fastening instruments are far from the only type of product produced by such screw machining methods. Metal knobs, miniature medical instruments, bio implants, tire gauges, threaded rods, splines, spindles, fittings and a limitless variety of custom metal parts can be machined to precision tolerances by turning. Generally speaking, Swiss screw machining is particularly apt for manufacturing any product that is either long and slender, or small and complex.

Once a screw machine tooling process has produced screw machined parts, the possibilities for that equipment are extensive. Some of these possibilities include crucial applications such as precision medical tools, automotive tools, laboratory tools, electronics components (for both IT and consumer purposes), appliance components, military parts and many others. Swiss screw machines’ ability to work both common and exotic metals (as well as non-metal materials like plastic) make them very versatile and play a large role in their importance for these various industries.

Screw Machining Images, Diagrams and Visual Concepts

Carrying multiple spindles simultaneously and can manufacture up to six pieces at once for more consistent, intricate, and exact parts.

Carrying multiple spindles simultaneously and can manufacture up to six pieces at once for more consistent, intricate, and exact parts.

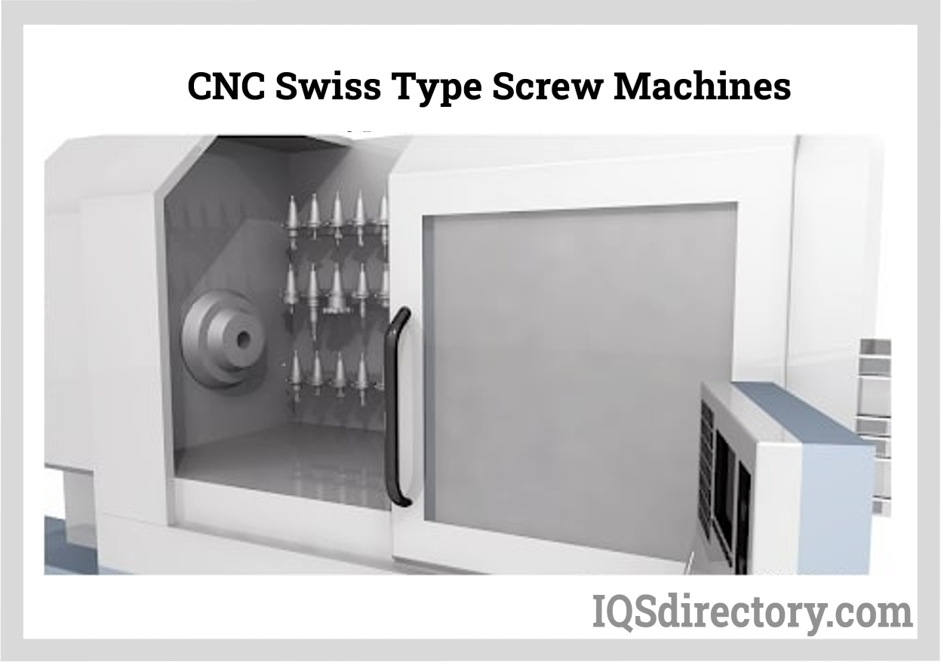

Swiss type screw machines effectively mass-produced screw machined goods because the metal bars stock moves using rotary slides.

Swiss type screw machines effectively mass-produced screw machined goods because the metal bars stock moves using rotary slides.

A screw machine which specializes in the creation precise medical components.

A screw machine which specializes in the creation precise medical components.

Screw machined products can be created a range of specialty fasteners and screws.

Screw machined products can be created a range of specialty fasteners and screws.

These are produced with incredibly tight tolerances, which is helpful for turning huge quantities of parts.

These are produced with incredibly tight tolerances, which is helpful for turning huge quantities of parts.

Screw Machining Processes

Different kinds of screw machines are capable of different processes. Some of these processes include knurling, thread rolling, among others.

- Knurling Process

- The process of creating a patterned texture on the surface of a metal to provide grip. Common knurling applications include tool handles, metal flashlights, knurled nuts and knurled knobs. Knurled patterns are achieved with specialized CNC turning tools.

- Thread Rolling and Forming

- Processes are employed in the formation of screw heads. Both processes involve pressing a shaped die against a work piece. Thread rolling and forming are cold forming processes, which requires a minimum threshold of ductility from the involved work pieces. In other words, metals formed by thread rolling and forming processes must be able to be formed by compressive force at low temperatures.

- Surfacing Metal Parts

- Not only can metal parts be shaped by screw machining, but they may also be surfaced. Turning can produce a smooth, near-polished finish or it can produce a knurled finish. Secondary operations are sometimes accomplished by a second spindle in a double spindle CNC Swiss screw machine (as opposed to an actual operator).

Equipment for Screw Machining

In general, screw machines are simply specialized, non-manual versions of metalworking lathes. By definition, lathes are industrial machines which shape a workpiece while rotating it around some type of axis. Both regular lathes and screw machines are used to produce screw machined parts. Unlike lathes, however, screw machines are capable of carrying multiple spindles and are therefore more commonly used for mass production.

Screw machines can further be categorized in two separate ways. The prior categorization emphasizes a screw machine’s physical orientation, while the latter categorization emphasizes a screw machine’s method of control.

- Turret Type Machines

- Screw machines are generally identified as either turret or Swiss. Turret type machines are marked by vertical rams which insert a workpiece into the machine. Swiss-type machines, however, are distinguished by the rotary slides which appeared at the beginning of their invention.

- Swiss Type Screw Machines

- Swiss type screw machines can be further divided into automatic and CNC screw machines. This division is based on differing methods of control. The first non-manual metalworking lathes – or screw machines – were operated mechanically by cams and associated equipment (e.g. levers, clamps, etc.). Although all screw machines are automatically operated, automatic screw machine still refers primarily to this earlier type of non-manual screw machine. CNC screw machines, on the other hand, are controlled by sophisticated computers which have been pre-programmed to perform some type of sequence.

- These screw machining variations have greatly expanded on the overall manufacturing capabilities for screw machining in general. Even more variations – such as “hybrid” type screw machines that blend features of classic automatic machines and newer CNC machines – exist. For clarity, the focus of this article will be on Swiss and CNC type screw machines.

Screw Machine Products

- High Precision Screw Machine Products

- Produced to extremely close tolerances, which is particularly useful when producing large volumes of turned parts. Close tolerances are achieved through the use of high-grade metals and close inspections during production stages.

- Medical Screw Machine Products

- Used in a variety of applications in the medical, scientific and pharmaceutical industries. Precision medical components include spinal implants, screws and dental implants.

- Stainless Steel Screw Machine Parts

- Provide superior corrosion and chemical resistance. Stainless steel screw machine products are useful in industrial applications in which they will be exposed to temperature extremes, moisture and chemicals.

Things to Consider When Choosing Screw Machining

It is always recommended to take the time and invest in finding a manufacturing supplier who has both the expertise and the willingness to devise a custom solution for your specific needs. With regard to screw-machining suppliers, several factors should be taken into consideration including the origin and quality of screw machined material, the level of product customization available, reputation for turnaround and shipping times to meet business deadlines.

As a screw-machining manufacturer or supplier, similar factors come into play when considering your operations. In terms of machine investment, flexibility is an important but overlooked characteristic. As Swiss screw machining continues to develop, it is recommended to invest financially in sophisticated machines (e.g. CNC machines with many tooling options) that are more likely to be adaptable to unforeseen future developments. This stands in contrast to a more conservative business strategy that is more inflexible with machinery and ties projected growth to consistently high production runs. As a general rule, Swiss screw machines are more precise than turret screw machines, while CNC Swiss machines are more precise and fast than automatic Swiss machines.

Screw Machine Products Terms

- Acorn Die

- A threading die used in screw machines whose cutting portion has a shape similar to that of an acorn.

- Broaching

- A machining process in which the interior and exterior surfaces of a part are altered to meet design requirements by the pushing or pulling of a cutter, called a broach, through the part surfaces. Broaching is particularly advantageous when machining complex parts.

- Button Die

- A tiny, adjustable die that is supported in a ring holder. Button dies are used in screw machines and for other work of the same type.

- Cams

- The components of a screw machine that move the slides and turret in order to feed cutting tools to the work. Cams control the automatic movements, depth and duration of every cut.

- Chuck

- The part of the lathe of a screw machine that grips the part to be turned, holding it in place while it is rotated and shaped.

- Collet

- A type of chuck on a screw machine that provides a solid grip on the turned part. A collet holds the part in place during rotation without leaving any defective marks on the part.

- Cross Slide

- A cam-driven slide that carries tools at right angles to the spindle. Cross slides operate through levers to give each tool the proper feed.

- Lathe

- A screw machine tool onto which a part is placed and rotated in order to shape it.

- Mechanical Safety Clutch

- A device that protects the mechanisms of a screw machine by disengaging, in order to stop the main drive shaft in the event of overloading or jamming.

- Milling

- A machining process that involves the shaving of a layer from the metal part.

- Precision Machine Screw

- A slotted, machined screw that is milled from bar stock. The thread is then cut and the screw is machine-finished.

- Screw Stock

- Typically, a free-machining type of alloy, in the shape of a wire or rod, that is used to form screw machine products.

- Spindle

- A screw machine part that consists of a rotary shaft about which a screw machine part rotates.

- Turning

- A machining process, used to form screw machined parts, in which a blank is rotated about a stationary piece of equipment.

- Turret

- A component of a screw machine that is driven by cams to bring each tool into position automatically.