Ropes

Ropes are woven or twisted cordage varieties that have been used as hauling, suspension, watercraft mooring line and in many other capacities since before recorded history. Ropes are composed of fibers that are twisted together. Those twisted fibers are then twisted together to make strands, which are then twisted or braided together to create rope. The direction that the fibers are twisted is often opposite of the direction in which the strands are twisted in order to cause internal friction, which reinforces the rope's strength.

Quick links to Ropes Information

History of Ropes

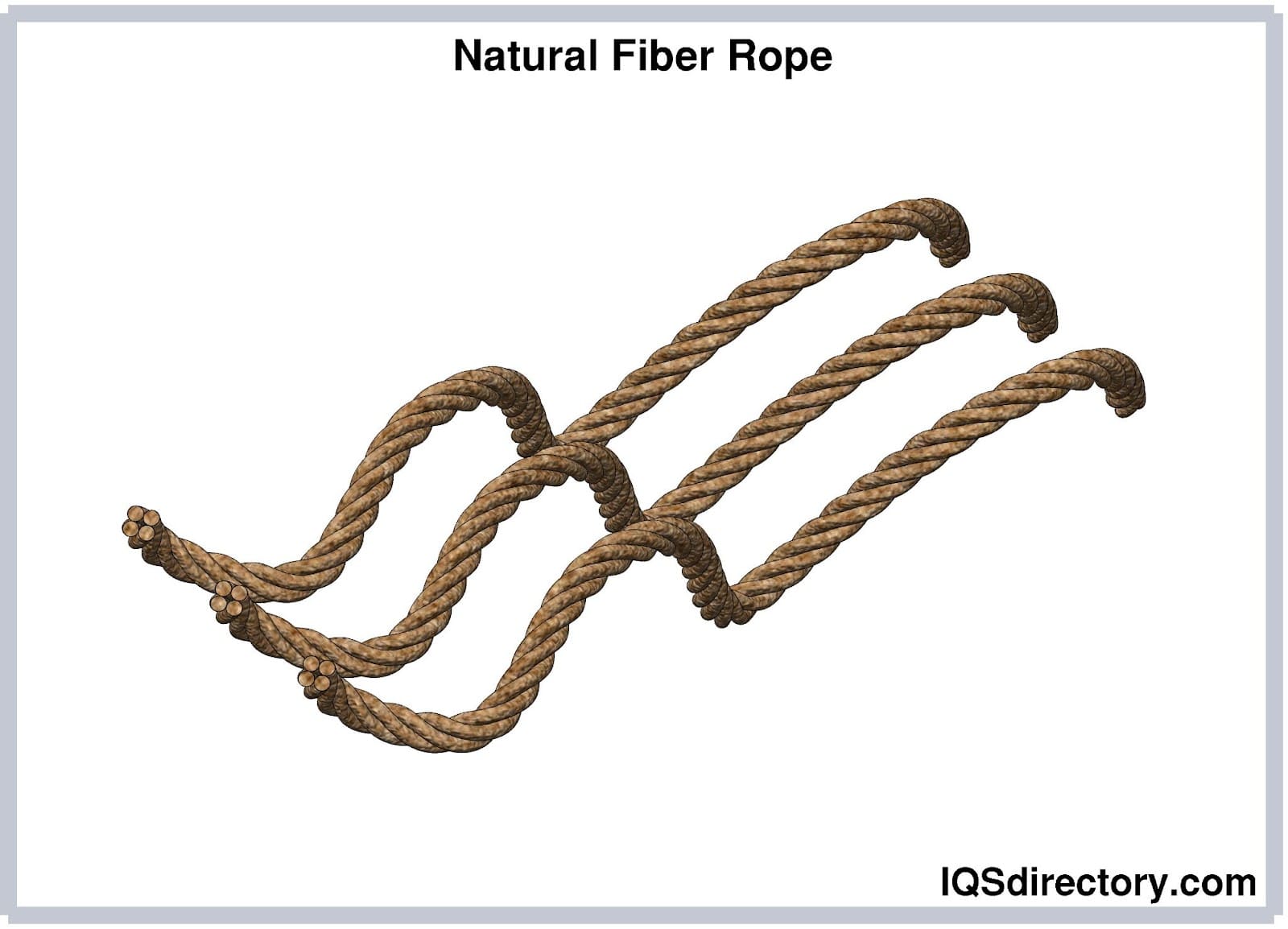

Although the origin or rope is debatable, the Egyptians were the first people known to develop special tools to make rope. The earliest known fossilized fragments of ropes and knots date back to 15,000 to 17,000 years ago. Originally made by hand, ropes were made with natural fibers. Ropes today are predominantly made with machines and utilize many newer synthetic materials to give them improved strength, lighter weight, and better resistance to rotting. Some early applications rope was used in includes fishing nets, hunting traps, tying stones to sticks to make spears and harpoons, the construction of bows, building shelters, making baskets, fastening clothes and many more. Some ropes are still made from natural fibers, such as coir and sisal, but synthetic fibers such as nylon and polypropylene have become increasingly popular since the 1950s.

Applications of Ropes

- Purpose

- Rope was designed to help with dragging and lifting, but is too flexible to provide compressive strength. As a result, it cannot be used for pushing or similar compressive applications. Rope has been used by humans for thousands of years for purposes like hunting, carrying, lifting, and climbing. Ropes used to be made exclusively by hand, but with modern roping technologies and synthetic materials, they are stronger, lighter, and have better resistance.

- Product Use

- Since there is such a wide range of rope use, rope condition, and exposure to various factors and elements affecting the rope, it is impossible to make blanket recommendations for the correct rope choice. Uses include hauling and lifting, construction, seafaring, sports, fastening, theatre, and rock climbing, just to name a few.

- Rope manufacturers supply a few specific types of rope that are unique and application-specific. Twine is thinner twisted rope usually made from natural fibers such as cotton or linen. Twine is applied in many ways. In kitchens and butcher shops, it is used to tie stuffed poultry together. It can also be used as a clothesline or as package tying material. Twine is also used to make sporting goods such as hockey goal nets and basketball nets. Elastic cords contain a multi-strand rubber core and are able to stretch up to 125% of their original length. The core coverings are braided and made of synthetic fibers such as nylon, plastic or natural cotton. Marine rope is rope that is often used on boats, barge crafts, or in docking. It must be made of material that fares well even when exposed to salt and water. Proper storage and care are important in order to maximize the lifespan of a rope and to ensure its continued safety. When properly matched to their applications and carefully maintained, ropes are indispensable utilities.

Rope Design

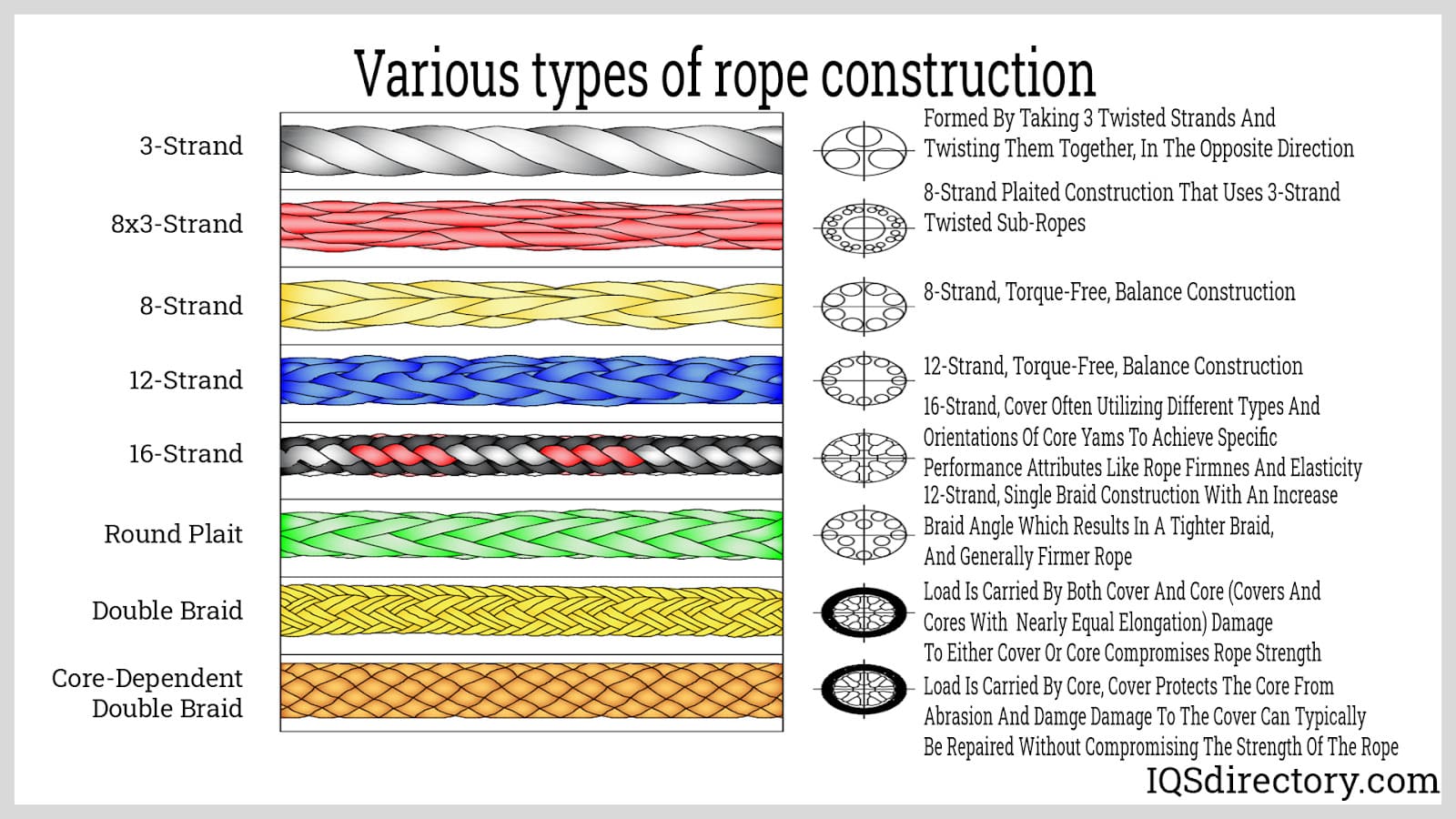

Fibers and filaments are first formed into yarn. The yarn is twisted, braided, or plaited depending on the type of rope being made.The two main types of rope construction are twisting and braiding. Twisting involves coiling three or more strands tightly in the same direction, although the yarn within the strands must be twisted in the opposite direction. This counter-twisting produces an all-around balanced rope that will stay together without kinking. Once twisting is complete, each end must be fused to prevent unraveling. Historically, twisting has been the most popular form of rope construction. However, rope braiding has become much more common over time.

Braid rope is popular because they do not spin or untwist while holding a load. Braided rope falls into three categories: hollow diamond, diamond with cores and solid braid rope. Hollow diamond braids do not have a core and are manufactured by weaving strands over and under each other. Diamond braids with cores contain a solid material in the middle, underneath the braid, in order to increase strength. Solid braided rope is tightly woven with a lock-stitch construction that does not unravel when cut. Solid braids and diamond braids with cores cannot be spliced. Splicing is a useful way to create a joint between two ropes or two ends of the same rope by interweaving the strands together. The strongest and most expensive type of rope is called a double braid, in which the rope and the core are braided.

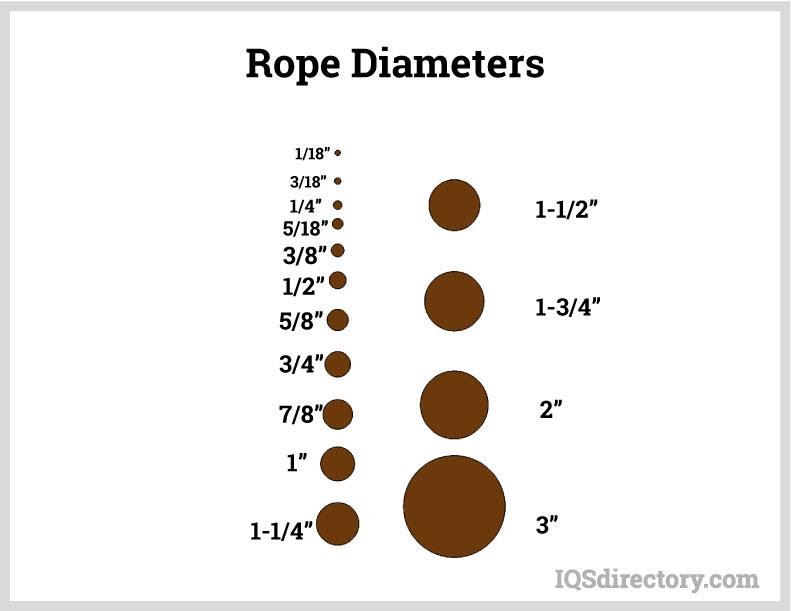

Diameter of the rope is determined by the diameter of the yarn, the number of yarns per strand, and the number of strands or braids in the finished rope. If the rope is being made from natural fibers, the fibers are first to be lubricated with a natural oil. They are then fed into a series of machines that remove any dirt, straighten the fibers, spread them apart, and comb them with several sets of steel-toothed combs. Synthetic fibers follow a similar process, but tend to align more easily. If the rope is to be made from long filaments of synthetic material, several filaments are grouped together in a process called doubling or throwing. Finished yarn is wound on spools, called bobbins. At this point, the yarn may be dyed various colors to produce a strand, or an entire rope, of a particular color.

Rope Images, Diagrams and Visual Concepts

The different types of rope construction strand sand methods to create them.

The different types of rope construction strand sand methods to create them.

The diameter of a rope is determined by its maneuverable, the ease of handling, comfort, and safety.

The diameter of a rope is determined by its maneuverable, the ease of handling, comfort, and safety.

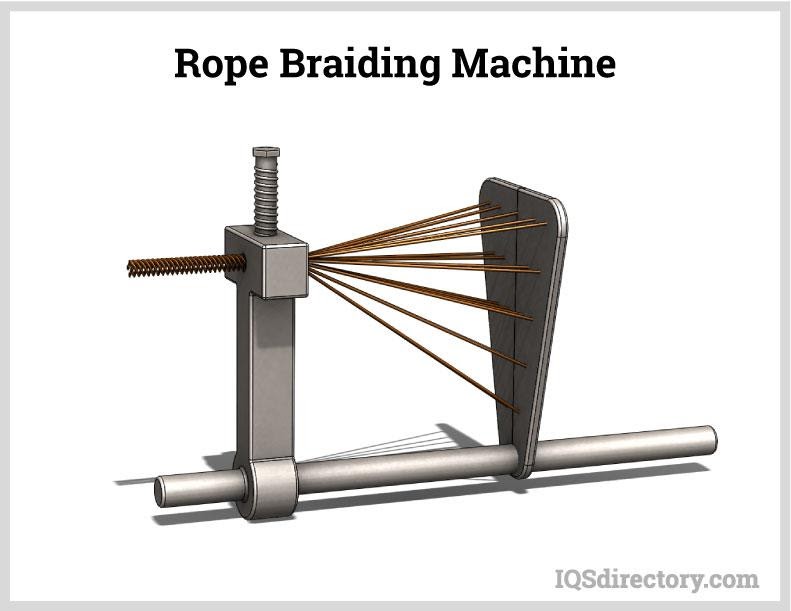

The forming of ropes starts with feeding the strands into a compression tube which twists the them before placing on the bobbin.

The forming of ropes starts with feeding the strands into a compression tube which twists the them before placing on the bobbin.

Natural ropes are made from natural products that are environmentally friendly examples are cotton, hemp, or sisal.

Natural ropes are made from natural products that are environmentally friendly examples are cotton, hemp, or sisal.

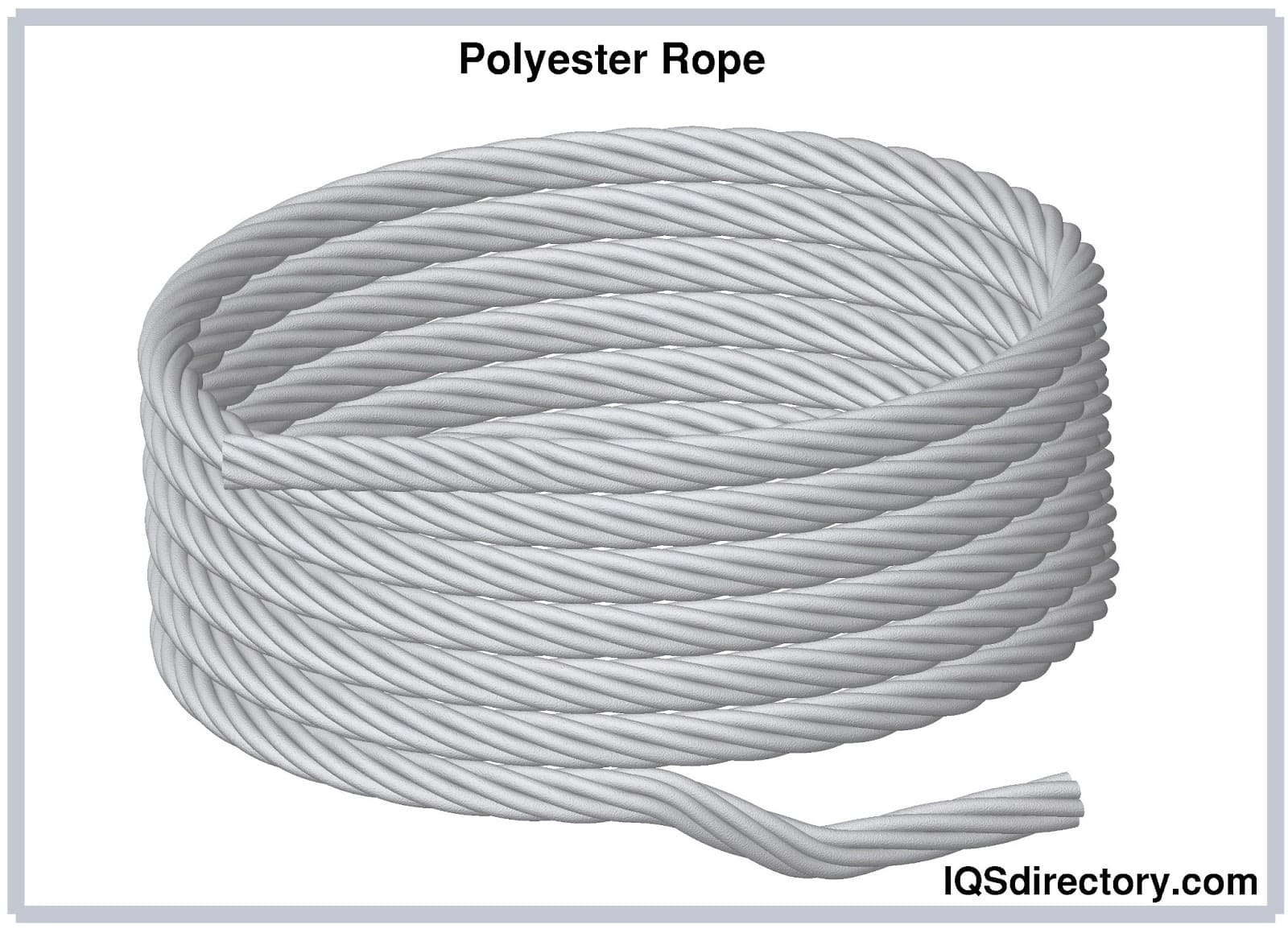

Polyester is the best synthetic fiber since the material is UV and abrasion resistance.

Polyester is the best synthetic fiber since the material is UV and abrasion resistance.

A bungee cord, a rope that is composed of two or more elastic strands coated with a woven fabric and hooks placed on both ends.

A bungee cord, a rope that is composed of two or more elastic strands coated with a woven fabric and hooks placed on both ends.

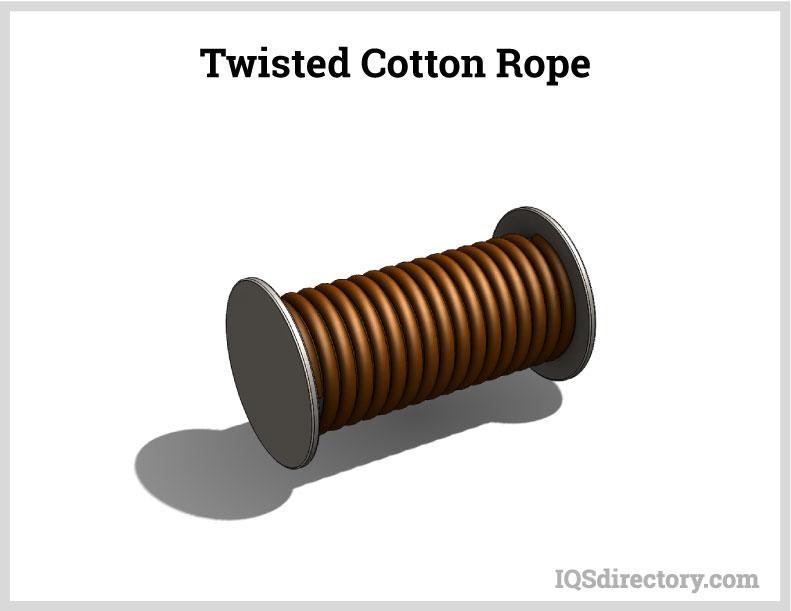

Cotton ropes are stretchy and flexible as compared to other natural fibers, however is not very durable.

Cotton ropes are stretchy and flexible as compared to other natural fibers, however is not very durable.

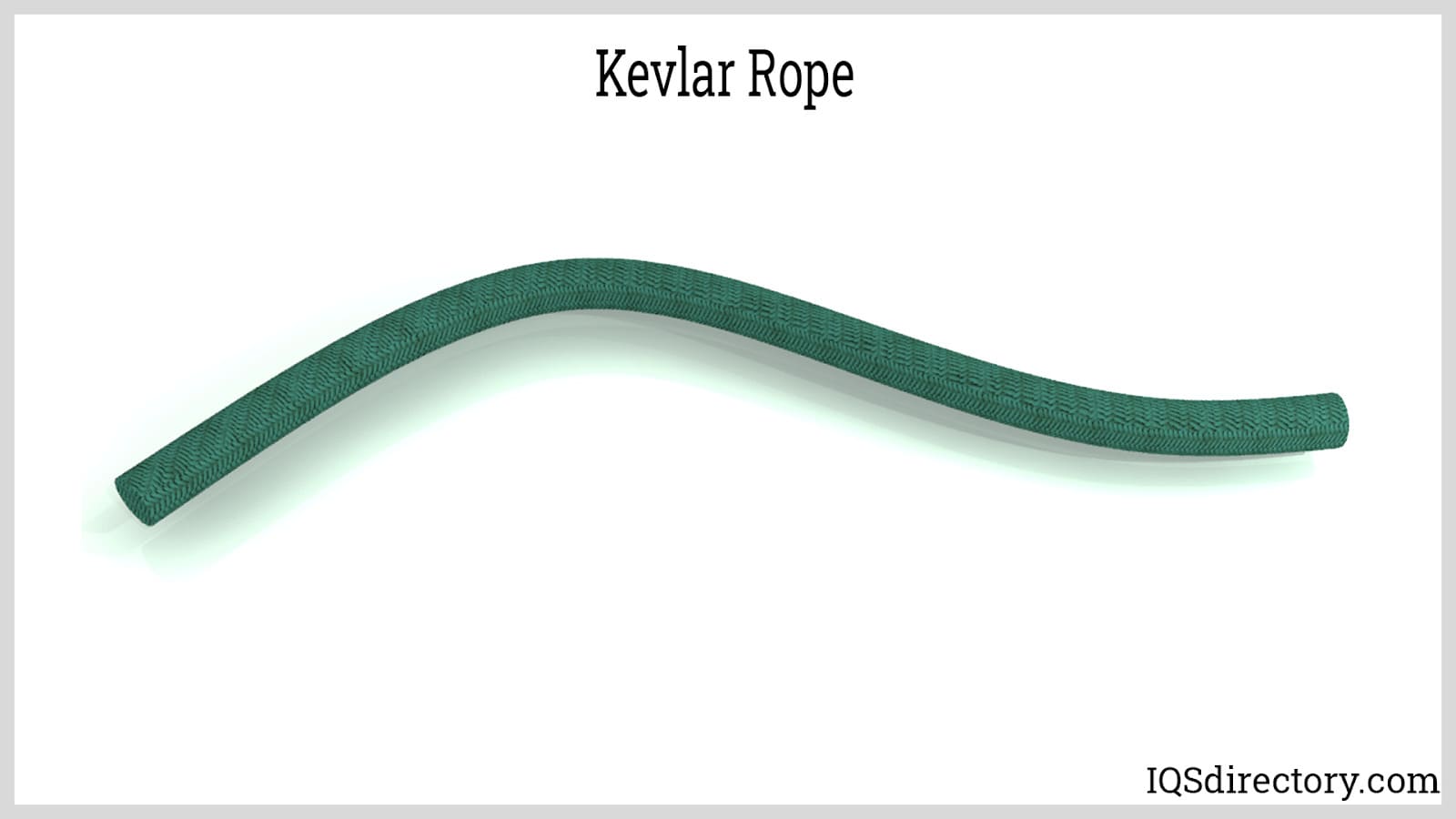

Kevlar has high strength, exceptional stiffness, toughness, and thermal stability, which the material gets stronger in subzero temperatures.

Kevlar has high strength, exceptional stiffness, toughness, and thermal stability, which the material gets stronger in subzero temperatures.

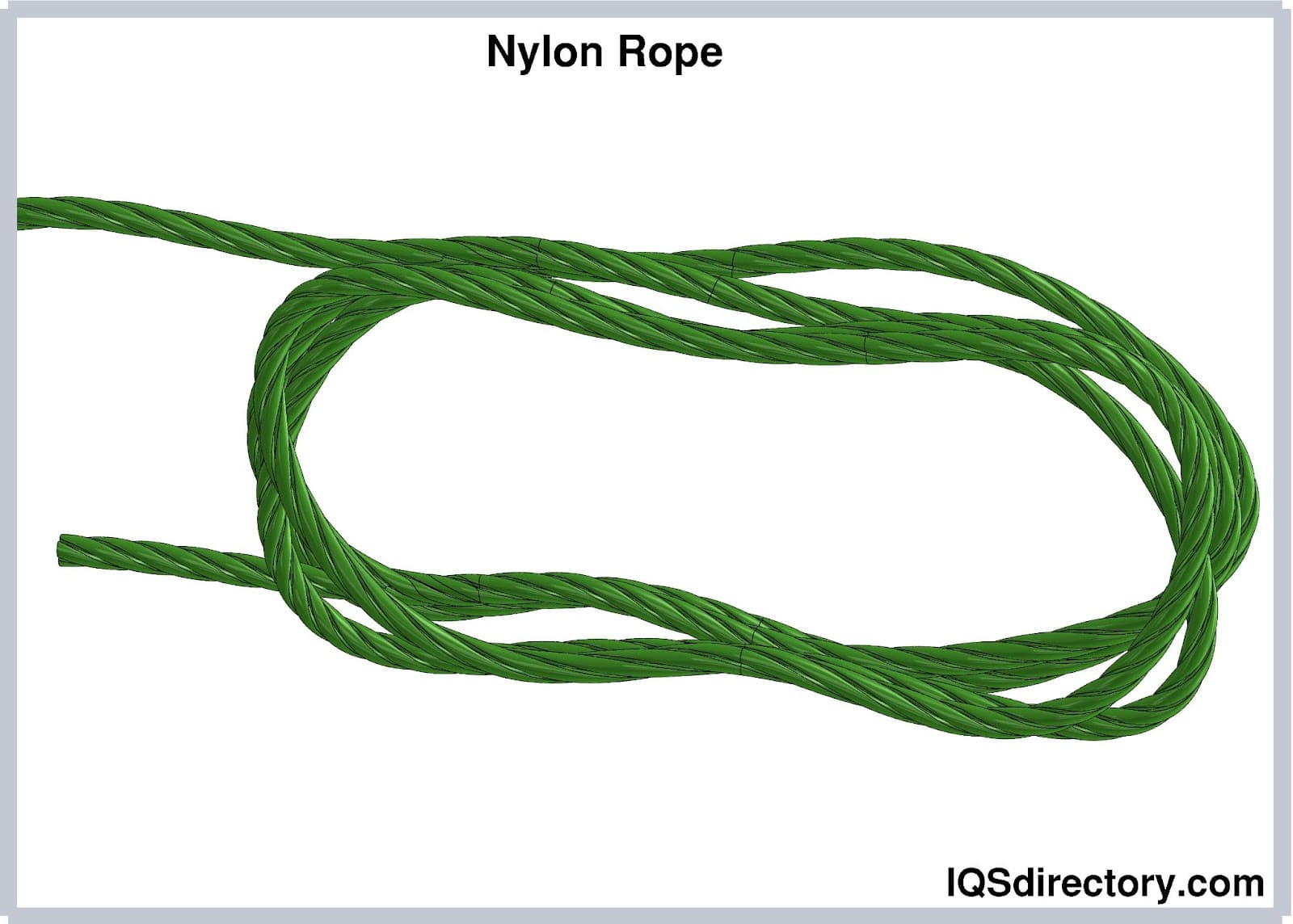

Nylon, one of the strongest synthetic fibers with exceptional elasticity and abrasion resistance.

Nylon, one of the strongest synthetic fibers with exceptional elasticity and abrasion resistance.

A shock cord is a cord that is made from top quality rubber core and a polyester cover.

A shock cord is a cord that is made from top quality rubber core and a polyester cover.

Types of Ropes

The general definition of rope is an assembly of strands that are interwoven together to form a thicker and stronger strand. Some ropes are strong as well as flexible, others are used for decorative purposes, and a number of ropes are used for industrial, mechanical and electrical applications. Rope suppliers offer a broad variety of ropes that households, businesses, and industries use for different purposes. This article, in the following sections, talks about a few types of ropes that we see or use in our everyday lives.

- Twisted Ropes

- Have three main strands that are woven together to form a rope that has a spiral look. Also known as laid ropes, these are those typical polymer-based cables that are used in outdoor and indoor areas to hang numerous items, such as clothes. These are actually made up of polypropylene material that helps the rope manufacturers keep their production cost down for twist rope. The polypropylene makes these cables more resistant to water and moisture. For that reason, these ropes are an ideal selection for wet areas. Thick and contrasting yellow-colored twisted ropes are used during rescue operations.

- Braided Ropes

- Interlaced with high-quality fiber strands. Also available is a variety called hollow braided ropes that can be smashed and made to resemble a flat pipe. Some braid rope suppliers can also provide you with double braided ropes that are largely used for operations that require strength and a dependable abrasion resistance. Double braided ropes are also present in the nylon make. These nylon ropes can be used as a replacement for twisted polypropylene ropes. Additionally, these cables have a nice grip, so that you can use them with your hands as well.

- Guyline Ropes

- These cables can be used for lengthening or tightening an array of applications. The guy line ropes are made using materials that reflect light, making them ideal to work with in the dark. These ropes make the best selection for camping. Tents can be prepared from these cables.

- Bungee Ropes

- These ropes are also an ideal utility for tents. With these cables you can hold tent poles strongly at their place, as desired. You can easily find these strings in your nearby camping store. Also, you can get these special supplies from a reliable rope supplier. These cables are available in varying thickness and flexibility options. However, the brand and the quality of the rope should be checked well before the purchase. Bungee ropes are sometimes referred to as elastic cords, or more commonly referred to as "bungee cords". This type of rope is manufactured to include a multi-strand rubber core, which increases stretching ability, strength, and durability.

- Twine

- A strong type of cordage composed of two or more strands of thread or yarn to create a single thin cord that is used in a variety of applications.

- Wire Rope

- Consists of several strands of metal wire laid into a helix. Wire rope and the term "cable" can be used interchangeably, but narrower senses exist where "wire rope" refers to diameter larger than 3/8 inch, whereas sizes smaller than 3/8 inch are designated cable or cords. Wire rope has weight restrictions, the lbs force (lbf), weight can range from 5,480 lbf for 1/4" wire rope to 320,000 lbf for a 2" diameter wire rope.

Apart from these six, some other types of ropes are parachute, baling twine, mooring rope, hoist rope, static rope and tow ropes.

Materials Used in the Production of Rope

From homes to various industries, ropes have a pivotal role to play in our daily lives. For different purposes, we have different types of ropes. Some of the most common kinds of ropes are nylon ropes, polypropylene ropes, bungee ropes, braided and double-braided ropes, sisal, etc. You can find a wide variety of ropes at your nearby rope store or rope supplier. Ropes are made from various materials respective to the application or purpose for which they will be used.

The following subsections list a few materials that are used in the production of ropes of various kinds:

- Polypropylene

- A synthetic material that is light in weight and low in price. This material has a lower density than that of water, enabling it to float. Thus, it is one of the favorite tools of people in the marine industry. Additionally, polypropylene is resistant to water and weather. Polypropylene rope is an all-purpose rope, but it is less strong than nylon and polyester rope and will deteriorate when exposed to UV rays. Agricultural businesses use this rope as a replacement of baling ropes. Although not very strong and dependable, marine vehicles such as yachts and boats can be seen utilizing polypropylene ropes.

- Nylon

- Another popular material used for the manufacturing of ropes. Nylon is a synthetic material that boasts properties like shock absorption, durability, and resistance against UV light and various chemicals. Nylon rope is the strongest of all rope and is useful in applications that require high shock absorption. When stretched, it "remembers" and returns to its original shape. All these benefits make nylon ropes a preferred tool for many applications.

- Cotton

- Very soft, pliable and easy to handle, but it is not as strong or durable as other natural and synthetic ropes.

- Manila

- A very hard rope that is popular in construction because it is resistant to sunlight, stretches very little and will not melt when exposed to heat like some synthetic ropes. Its fibers are made from abaca leaves, which are very resistant to saltwater.

- Sisal

- A hard, natural fiber rope that is similar to manila rope, though it is not as strong as manila rope. However, sisal has a very good knot-holding capacity and thus is used in applications such as gardening and bundling, where high strength is not a requirement. Its fibers are taken from the agave plant.

- Polyester

- A type of polymer, just like polypropylene and nylon, that is also used in the production of ropes of varied thickness. This synthetic material is prepared from a group of chemicals both natural and artificial. Polyester can be engineered to be thermoplastic or thermoset, according to the need of the application. Thin strands of polyester are interwoven to create a thick rope. Like any other synthetic materials, polyester is also resistant to water and UV radiation, therefore it is popular in the boating industry.Polyester rope is almost as strong as nylon rope, but it does not stretch as well.

- High Molecular Density Polyethylene (HMDPE)

- Can be put into the category of an extraordinary material that is extremely strong, while being lightweight at the same time. In addition, HMDPE ropes are both flexible and stabilizing, rendering their candidature for a large number of applications. These can bear a very heavy load without the wear and tear. As the name suggests, HMDPE is also a man-made synthetic material, and that can be prepared to balance various load capacities and suit a large number of industrial, chemical and mechanical processes.

- Vectran

- Modern-day industrial requirements have changed significantly. For extensive applications that need reliability and strength, ropes of a new material known as Vectran is considered ideal. In terms of composition, Vectran takes the advancement of HMDPE to a newer level. Vectran is a Naphthalene-based Thermotropic Liquid Crystal Polymer (NTLCP), which is stronger than HMDPE and any other material used for ropes. Vectran is stretch and abrasion resistant; however, it lacks UV resistance. This is why Vectran ropes are excluded in many critical applications.

- Kevlar

- A cordage variety composed of Kevlar fibers; Kevlar is a synthetic polymer manufactured by DuPont. Kevlar rope has more strength pound-for-pound than steel.

Things To Consider When Purchasing Ropes

Working load is one of the biggest decisions you have to make when deciding which rope is right for you. It is impossible to establish recommendations regarding working loads for all ropes, due to the wide range of rope use, rope conditions, exposure to several factors affecting rope behavior, and the degree of risk to life and property involved. Rope should always be inspected for abrasion. There are numerous factors which can cause abrasion such as rubbing against rough surfaces or sharp edges. Heat and UV rays can also cause abrasion on certain ropes and chemicals are also known to cause abrasion. Synthetic ropes, such as nylon, polyester, polypropylene, polyethylene, Kevlar and various co-polymer blends, tend to be stronger than natural ropes. Things to consider while considering a rope manufacturer include qualifications, industry certifications, experience, supervision, insurance, and documentation. Things to consider while choosing the appropriate rope include the rope strength, fatigue resistance, crushing resistance, resistance to metal loss and deformation, and resistance to rotation.

Maintenance Tips From Rope Suppliers

Did you know that by conducting proper and timely maintenance for your ropes, you can prolong their life and endurance? That is what most rope suppliers and manufacturers suggest. This article underlines some of the best practices that will help you in taking care of various types of rope, including nylon ropes, polypropylene ropes, fiber ropes, etc.

- Damages

- Spot damages before every use. The importance of a rope is directly proportional to the task or application you are going to use it for. Prior to use, you should ensure that your rope is not damaged. The key is to make certain what you are using is in acceptable and safe-to-use condition. Run your hands all over the rope to sense breakage, cuts, and damages on its upper surface. Slight cuts and damages can be overlooked, however, they should be looked at very closely, so that you can repair or replace them before they get bigger and more dangerous.

- How to fix minor damages, if they are near the corners of the rope: A few DIYs to fix the cuts and curls on the rope.

- If the cut or damage is close to either end, you can remove the damaged section, and get a complete (but shorter) rope, once again.

- Use a sharp knife, or scissors to accomplish this minor task.

- Melt the cut with a lighter or candle, to prevent the opening of the rope strands.

- Alternatively, you can also apply molten wax on the cut, however, this trick would not be suitable for all the conditions and types of rope.

- Ropes that have a cut in the middle cannot usually be repaired because of safety concerns. However, they can be used for light applications. If they are made of synthetic polymer, then you can melt the cut part to circumvent the spreading of the cut or opening. But again, do not use the rope for major and heavy applications.

- Upkeep

- Tips for proper upkeep of climbing ropes: When not properly maintained, climbing ropes tend to rot faster than their actual life span. The following pointers guide how to take care of your climbing ropes:

- Get a rope bag. You can ask your rope supplier to provide you with a rope bag. This bag should have sufficient space to store the rope. In addition, you can carry the bag as a backpack.

- To avoid entanglement, it is always better to fold the rope in loops.

- Do not forget to tie both the ends of the rope. It will help you unfold the rope the next time you use it.

- Do not place your rope(s) or rope bag in a moist surrounding. No matter how strong your water resistant rope is, you should never keep it in a moist surrounding.

- Say no to leaving the rope in sunlight. To further maintain the robustness and endurance of the rope, you should never leave it, openly, in the sunlight.

Rope Terms

- Abrasion Resistance

- A rope’s ability to hold up under internal and external wearing.

- Acceleration Stress

- Extra stress placed on rope due to increasing load velocity.

- Bend

- A knot that joins two ends together from a single or two separate ropes.

- Bight

- A loop in any part of a rope.

- Bitter End

- When splicing or tying knots, the end opposite the end that is in use.

- Blend

- A rope’s composition of various synthetic fibers.

- Bonding

- A liquid coating on rope that prevents absorption of water and provides abrasion resistance.

- Capstan

- A rotating cylinder used to wind rope.

- Cordage

- A term that refers to rope, line or string with a small width.

- Creep

- The gradual increase of a synthetic rope’s length over time while under high temperature or load stress.

- Dock Rope

- Primarily used to secure a marine vehicle, such as a sailboat, to a dock.

- Elastic Recovery

- The degree to which a rope will return to its original shape after being stretched.

- Elongation

- A rope’s deformation in the direction of the load.

- End

- The end of the rope that is in use.

- Fiber

- Natural or synthetic material that can be spun into yarn.

- Flexibility

- A rope’s agility and ease of handle under working conditions.

- Hand

- A rope’s feel, determined by touch.

- Heavy Duty Rope

- Contributes greatly to the endeavors of the modern world, not just in architecture, but also in landscaping, recreation, leisure and even exercise.

- Nylon Cord

- Braided, which increases its strength.

- Rigging

- The ropes and apparatuses used on sailboats that transfer wind to the ship, moving it forward through the water.

- Sliver

- A continuous strand of overlapping parallel natural fibers that is ready for twisting.

- Safety Rope

- Straps on to a harness and is designed to bear the weight of a person in case they slip or lose their footing and fall.

- Splice

- The joining of two ropes by interweaving different strands and braids.

- Strand

- Yarn that is twisted together. A rope is made from strands that are twisted or braided together.

- Strength

- A measure of a rope’s ability to lift a load or do work.

- Tensile Strength

- The load amount at which a rope will break under tension.

- Towing Rope

- Used to pull vehicles and equipment during towing or when something becomes stuck in mud or snow.

- U.V. Resistance

- A rope’s ability to resist damage from the sun’s ultraviolet rays.

- Water Repellency

- A rope’s ability to keep from absorbing water and swelling.

- Winch Rope

- Specialized, heavy rope, often used with gas-powered winches and remote, electric winches.

- Yarn

- Fibers that are twisted together.