O-Rings

O-rings are round, ring-shaped mechanical seals used to prevent leakage of media in and from mechanical parts. Examples of the types of media these flexible mechanisms seal include gas, air, liquid and chemicals.

Quick links to O-Rings Information

The History of O-Rings

The very first O-ring patent was awarded in Sweden to a man named J.O. Lundberg on May 12, 1896. The first American O-ring gasket patent, however, was not awarded until 1936; it was given to a man named Niels Christensen. Interestingly, during WWII, after his patent had been violated by large corporations, the US government bought the O-ring patent as a critical war-related item. They then gave other organizations the right to manufacture the rubber seals for use with military airplane hydraulic systems. For his trouble, Christensen later received a lump sum payment of $75,000.

After the war, use of Christensen’s rubber seal gaskets expanded to industrial manufacturing. The seals were particularly valued in automotive manufacturing, industrial hydraulics and farm equipment manufacturing. Between the 1950s and the 1970s, scientists and engineers rapidly developed synthetic rubber and polymer types. This led to the many high-performance elastomers to which manufacturers have access today.

The disaster of the space shuttle Challenger takeoff in 1986 was traced back to a faulty O-ring. Due to below freezing temperatures the morning of the launch, the O-rings in the Challenger's solid rocket boosters had deformed permanently, failing to decompress and create an effective seal. Extreme temperature endurance had not been taken into account during the O-rings’ engineering, and as a result the Challenger exploded during liftoff, killing all seven of its crew members.

Since the Challenger disaster, the O-ring and gasketing industries have made extensive investigations into material properties and endurance under harsh conditions. Regulations have been made regarding O-ring packaging and labeling, expiration dating and quality control. O-rings used in critical applications, such as aerospace or aviation, are examined under UV lights before distribution for any stresses or fractures that might cause sealing failure. These safety precautions exemplify the care and precision that quality products require of manufacturers, which is true of the manufacturers and suppliers of O-rings.

Advantages of O-Rings

There are many reasons to choose O-rings over other seal types.

- Flexibility Advantage

- They are flexible, which allows them to take the form of the part surfaces that you join, even if they are imperfect or uneven.

- Airtight Seal

- When an O-ring gasket deforms, it takes on the shape of the cavity and fits into it perfectly, creating a vacuum and airtight seal.

- Low Manufacturing Costs

- O-rings are manufactured by a relatively cost-effective process, making them a simple, fairly cost-effective solution for machinery and equipment manufacturers who require seals between parts where leaks are likely to occur.

- Range of Sizes

- O-rings are available in a wide range of standard and custom sizes. Learn about standard and custom O-ring sizes from a company’s O-ring size chart.

- Temperature Range

- O-rings can be engineered to sustain a broad range of temperatures, from the very low to the very high.

- Pressure Tolerance

- An O-ring seal displays superior pressure tolerance to other gaskets. Sometimes, manufacturers design them to withstand pressures upwards of 100 bar.

- Structural Damage

- Thanks to the fact that they do not generate critical torque under high pressure, O-rings are not at risk, nor do they put their application at risk for structural damage.

- Reusability Advantages

- Some O-ring types, such as metal, rubber and polymer O-rings, can be used over and over again in industrial applications. This benefit is twofold, as it saves you money, and is good for the environment.

O-Ring Design

- Manufacturing Process

- Manufacturers may produce O-rings via one two processes: compression and injection molding. During compression, they simply compress the material between the two sections of the mold. The process is not particularly popular though, because it is time-consuming and is also only suitable for the production of limited quantities.

- Injection molding, on the other hand, is highly popular. With it, O-ring manufacturers can produce large quantities of O-ring products in a comparatively short period of time. To do so, they inject heated and pressurized material into a mold. The mold is full of cavities designed in the shape and size of the O-rings to be produced. The material fills out the cavities, and then is allowed to cool. After that, it’s ejected.

- O-Ring Material Design

- O-rings are made from a wide range of synthetic and natural elastomeric compounds, each of which carries different application-specific properties; all of them carry properties of both rubber and plastic. Overall, rubber is the most popular type of elastomer used for O-ring manufacturing. The most common types of rubber O-ring materials include: viton, Teflon-o-rings, neoprene, silicone and nitrile rubber. They are also made from elastomer materials like fluorocarbon elastomers. Learn more about rubber by contacting a rubber manufacturer.

- Because rubber O-rings cannot sustain high temperature ranges without additives, manufacturers sometimes make O-rings from metal or alloys. Other O-rings that require extremely high temperature resistance are made from materials like silicone, EPDM, perfluoro elastomer and fluorosilicone.

- Design Considerations

- When designing O-rings, manufacturers decide specifics like: inner diameter, cross-sectional diameter, material hardness, material durability, shape, and size. They consider all of these factors and customize them per the intended application of the O-ring. The material to be used, for instance, will vary depending on chemical compatibility, sealing pressure, temperature, and lubrication requirements as well as others.

- O-rings are also made according to metric or nonmetric measurements.

- While standard O-rings have round, donut-like and thin profiles, manufacturers can also create custom O-rings with square, rectangle or otherwise shaped profiles. Furthermore, some flat O-ring or square O-ring gasket styles perform exactly the same functions as regular O-rings, and so manufacturers may recommend those instead.

O-Ring Images, Diagrams and Visual Concepts

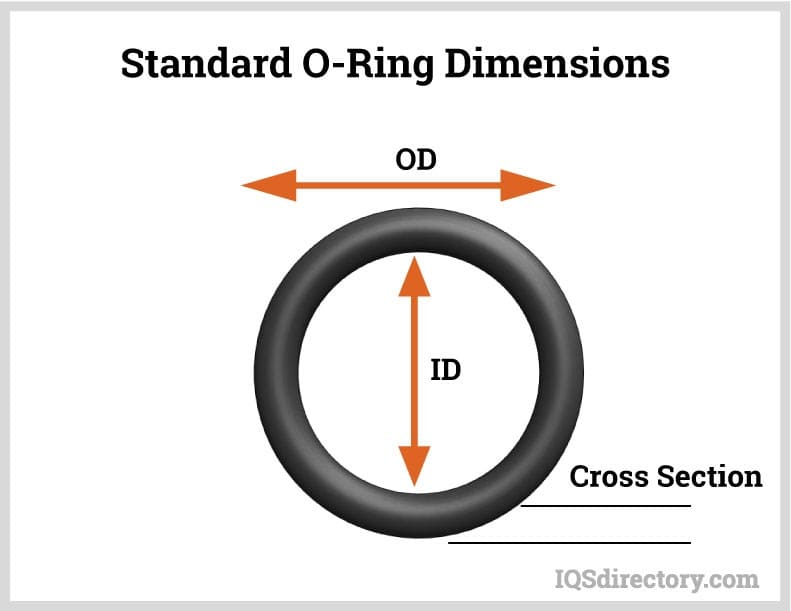

The standard dimensions of an o-ring includes inner diameter (ID), outer diameter (OD), and cross sectional (CS) diameter.

The standard dimensions of an o-ring includes inner diameter (ID), outer diameter (OD), and cross sectional (CS) diameter.

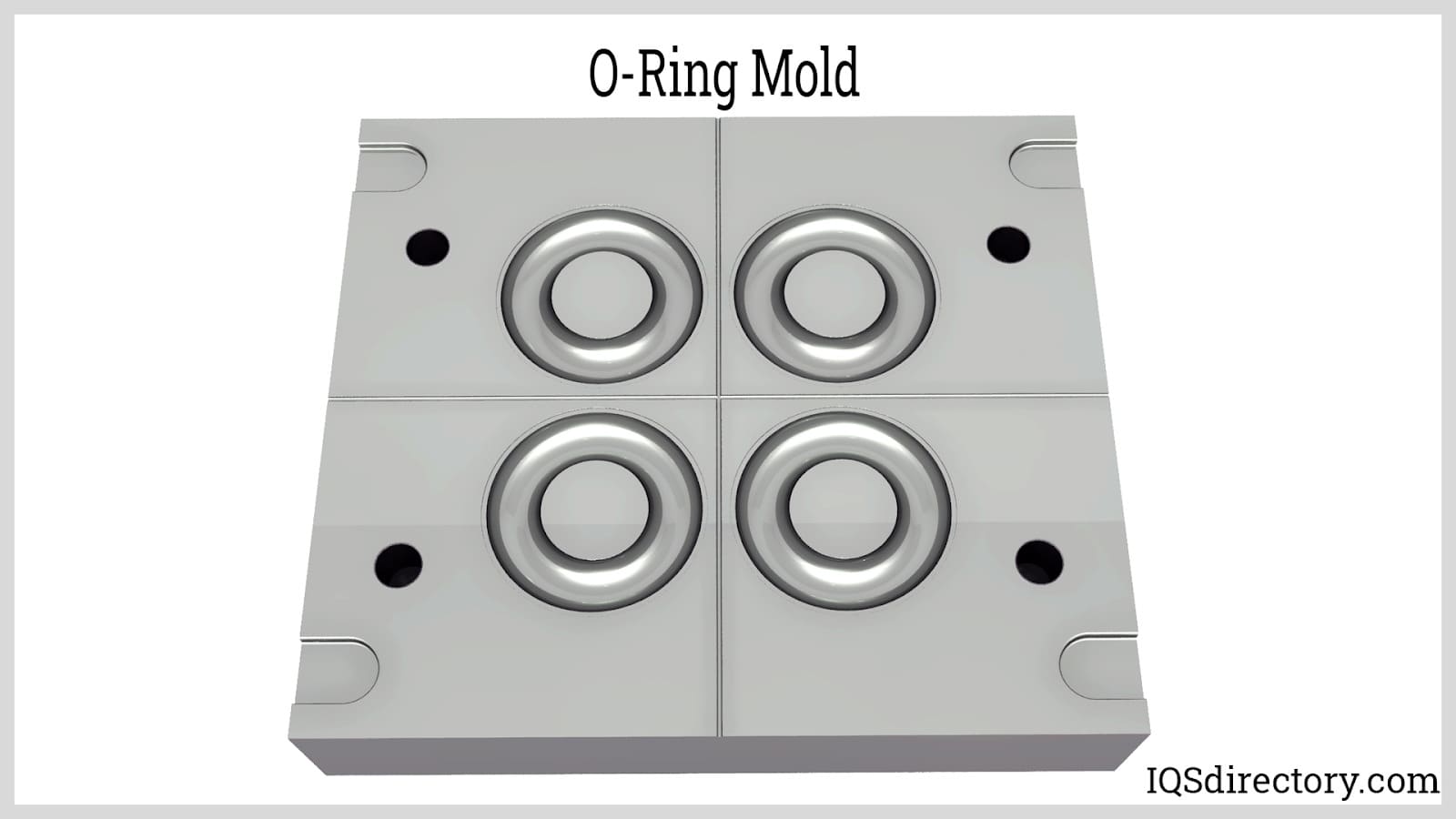

The material use for the o-rings are made from two halves and then compressed.

The material use for the o-rings are made from two halves and then compressed.

Silicone is resistant to chemicals, heat, ozone, corona, and solvents which makes in useful for different applications.

Silicone is resistant to chemicals, heat, ozone, corona, and solvents which makes in useful for different applications.

A synthetic fluoropolymer elastomer rubber used for stressful, harsh, and rigorous conditions, which maintains performance in extreme temperature.

A synthetic fluoropolymer elastomer rubber used for stressful, harsh, and rigorous conditions, which maintains performance in extreme temperature.

A synthetic rubber which is wear resistance and the effects of oil.

A synthetic rubber which is wear resistance and the effects of oil.

A terpolymer made from ethylene and propylene with a monomer, which makes it resistance to the elements and has good flexibility when exposed to low temperatures.

A terpolymer made from ethylene and propylene with a monomer, which makes it resistance to the elements and has good flexibility when exposed to low temperatures.

O-Ring Types

- Clear O-Ring

- These O-rings are made from materials like silicone, Teflon or polyurethane; these materials are able to be produced as semi-clear without any additives, though with additives, some can be made ultra clear. Clear O-rings are especially valued in the food and medical industries, where it’s important that you be able to see the substance inside.

- Silicone O-Ring

- Especially resistant to UV weathering, dry heat and wide temperature swings, O-ring silicone products are popular in the medical and heating industries.

- Neoprene O-Ring

- Often used to seal refrigerants such as Freon in liquid chiller systems and heat exchangers.

- Nitrile O-Ring

- The most popular standard O-ring product out there. They’re known for resistance to oils and fuels.

- Static O-Ring

- Used to seal two rigid, non-moving parts. They may be made from any appropriate rubber product or metal product. Because they remain stationary, they do not require any lubricants.

- Metric O-Ring

- O-rings with measurements specified in metric units. O-ring metric specifications are used with global O-rings and most O-rings used outside of the United States.

- EPDM O-Ring

- Used with solvents, as they are extremely resistant to polar solvents like MEK, acetone and alcohol. It should be noted, though, that they have poor resistance to greases and petroleum oils.

- Viton O-Ring

- Known for their extreme upper process temperature limit and their good chemical resistance.

- Metal O-Ring

- Valued for their increased resistance abilities. For this reason, they may be used with applications with a wider temperature, corrosion, and/or process range.

- O-Ring Cord

- A special type of O-ring product that is sold by the foot. You can splice them for a quick fix to large diameter, static applications.

- Oil Seal

- An O-ring designed 1) to keep lubricant inside any static or dynamic equipment from escaping, 2) keep contaminants like dirt from seeping into the machine, and/or 3) keep fluids like oil and water from mixing.

- Large O-Rings

- The most massive sized O-rings available for sale. Some are offered through sizing charts and mass produced, while others must be custom made to fit certain dimensions. They are made out of elastomeric rubber or thermoplastic materials like silicone, Teflon or Viton, and exhibit the same properties.

- Backup Ring

- A ring made from hard, extrusion resistant material like high durometer nitrile, nylon, or PTFE. The back-up ring is designed to fit between the O-ring and the extrusion gap, in order to prevent the extrusion of the O-ring.

Applications of O-Rings

O-rings are produced to not only prevent leaks, but also create a strong seal between two joining parts in an application.

Known as the smallest gaskets, these small elastomer loops are one of the most widely used seals for machine design as they are simple to produce, economical, and reliable. Available in a variety of sizes and materials, O-rings are used in many different industries, such as food, healthcare, manufacturing, hydraulics, pneumatics, vacuum flow, aerospace and aviation, petrochemical and oil, chemical processing, and water treatment.

They can be found in dynamic applications such as hydraulic cylinder pistons and rotating pump shafts as well as in static applications such as water bottle lids and gas caps. In addition, aerospace and aviation industries rely on O-rings in critical applications, such as engine turbines and brake systems.

Features of an O-Ring

Viewed at a cross-section, O-rings are disc-shaped; when users place one within a groove between two joints, then apply pressure, the disc-shaped cross-section deforms. This compression deformation is what causes O-rings to create a seal. As users apply more pressure within or without the seal, the O-ring deforms even more, further reinforcing the seal.

Together with creating a strong and airtight sealing, O-rings also generate an insulating effect with its elastic deformation feature. It hardens the sealing and keeps the application safe. When the circular cross-section deforms, the seal tends to become elliptical. Because of the twist in the shape of the O-ring, the gap between the two surfaces of the application is filled or closed. This is when an insulating effect generates.

O-Ring Installation

O-rings are easy to install and replace. To start, lightly coat your O-ring with a lubricant that is compatible with your system (unless you are working with an O-ring type that does not require lubricant). Then, if necessary, cover any sharp edges that might cut or otherwise damage your O-ring seal.

If you choose to install a backup ring with your O-ring, make sure it is installed on the low-pressure side of the system. This ensures that the high-pressure side of the system pushes the O-ring against the backup ring. After this, you can consider your O-ring installed; it’s that easy!

Once you get your O-ring installed, make sure that it is uniformly stretched, as opposed to just stretched on one side. Make sure to minimize the installation stretch to less than 50%. Finally, check to make sure that the seal is not twisted in the groove or gland. This is important because, for long life, the seals need to be installed correctly between the joining parts. Any miscalculation can result in application damage or the under performance of the application.

Standards and Specifications for O-Rings

Because of the demonstrated tragedy that can happen if an O-ring malfunctions, governments and industries take O-ring standard requirements very seriously. Common standard requirements include those put out by ISO and SAE International (including the Aerospace Standard). To find out the standards to which your O-rings must adhere, talk to your supplier.

Things to Consider When Purchasing O-Rings

To get O-rings per the specifications of your application, it is important to get these O-ring seals from a reliable O-ring manufacturer or supplier. While you can quickly get a long list of potential suppliers by performing a Google search, it will be difficult to discern which businesses that this search yields are reliable or trustworthy. So, instead of Googling manufacturers, we recommend you go with a trusted directory, like this one. Here at IQS, we’ve already figured out which businesses are reliable and which ones are not. Check out our top picks by scrolling up near the top of this page. There, you’ll find important supplier and manufacturer information, such as company website, profile, phone numbers, coverage, and products. To compare their services and prices in just a few minutes, check out their respective websites. For more in-depth information, and to choose the right supplier, use the following tips:

- Ask if they can deliver to your site.

- Tell them your exact requirements, including the pressure and temperature tolerance, size and shape of O-rings. Also, mention the quantity that you need, while requesting for a quote.

- Convey the time by when you need your order delivered.

- Check if they have customization options to meet your requirements.

- Using these guidelines, we know you’ll find the O-ring manufacturer for you.

Proper Care for O-Rings

To increase the life of your O-ring, consider having it covered or encapsulated within Teflon. This protects weaker O-ring materials from natural deterioration and harmful chemicals. In addition, make sure to never use O-ring lubricant that is made from the same materials as your gasket, as doing so can cause erosion of the O-ring.

To be extra prepared, we recommend you pick up a set of O-rings, so that you can replace yours quickly if needed. You can find these inside an O-ring kit.

O-Ring Terms

- Adhere

- When materials stick or cling to one another.

- Aging

- When a material undergoes physical changes over time.

- Back-Up Ring

- A hard ring that is placed in the gland between the o-ring and the groove walls in order to prevent extrusion.

- Batch

- The resulting product from a mixing operation.

- Cell

- A small cavity that is surrounded either completely or partially by walls.

- Elastomer

- Any of the various materials that are elastic and resemble rubber. Elastomers can be used instead of springs as energizers.

- Energizer

- A device used in some o-rings that acts to retain the ring’s natural shape. Often, either a spring or an elastomer serve as the energizer at the core of the o-ring.

- Friction

- The resistance to motion when two or more surfaces rub against one another.

- Gland

- Cavity into which an o-ring is installed, which also has the groove and mating surface of the second part.

- Inside Diameter

- The size measured from any inner point of an o-ring to the inner location on the direct opposite side, creating a straight line.

- Lubricity

- The slippery, lubricated qualities an o-ring material has.

- Memory

- A material’s tendency to resume its original shape after deformation.

- Mil-Spec

- O-rings that meet and/or surpass standards of the United States military.

- Off-Register

- When a mold is misaligned and causes an out-of-round cross section of an o-ring.

- Outside Diameter

- The size measured from an outside point of an o-ring to that same point on the direct opposite side, creating a straight line.

- Overflow Groove

- A groove around the mold cavity of an o-ring that is used to accept excess material from the cavity in order to create a better fit.

- Parting Line

- A line outside of o-rings that is left-over from when the two mold plates met.

- Polyurethane

- Any of various resins that vary in flexibility and are used in chemical resistant coatings, foams and adhesives.

- Squeeze

- Cross-section compression of an o-ring gland assembly that shows between the surface of the groove bottom and surface of the mating metal part.

- Vulcanized

- Improved strength, lubricity and resiliency by combining sulfur and/or other additives with both heat and pressure.

- Water Swell

- The bulging or increased size of an o-ring due to water intake.