Latches

Latches are a type of mechanical device used to fasten doors, windows, cabinets and any other items that can be either opened or closed.

Quick links to Latches Information

The History of Latches

Latches are an old form of hardware that, while changing and evolving over the years, have retained much of their original form. Among the oldest latch types are the Suffolk latch and the Norfolk latch. Both of these latch varieties originated in England in the 16th century, and they are still in existence today. Earlier examples of the iron latch, however, dating back to the 13th century, have been found in both China and Europe.

Traditionally, latches have been used only to hold doors in the closed position, not to lock them. Bolts, on the other hand, have been used to only lock, though bolt latches may serve only as fasteners. More recently, however, latches have emerged that are able to both lock and fasten a door or other object. Some lock and latch assemblies feature not only mechanical components, but electrical ones as well, making the locking mechanism even stronger and more secure.

Latch Design

The majority of latches are manufactured using die casting, stamping or forging, with additional components being assembled or spot-welded as needed. When designing standard or custom latches, latch manufacturers consider material, mounting style and latching position. Such considerations are determined by the specifics of intended latch use (ex. applied force, operation intensity, potential exposure to environmental elements and weather, etc.).

- Material Design

- Most often, latches are made from metals like stainless steel, steel, aluminum alloy, cast iron and brass. This is because so many latches must be able to withstand high frequency use and high stress use. Of these, stainless steel latches offer the highest strength and corrosion resistance.

- Sometimes, manufacturers make latches from thermoplastics and thermoplastic elastomers instead. Plastic and rubber latch materials are lightweight and better at absorbing vibrations than metals. Using thermoplastics in the formation of latches offers the added benefits of flexibility and increased shock and impact resistance. In addition, plastic latches are easy to fabricate for custom fit and design.

- Mount Design

- The choice of mounting is based on use and spatial availability of the mounting surface, and the latch function and performance requirements. Common mounting options include: concealed mounting, edge mounting, side mounting, and single-hole mounting.

- Most latches consist of plates or brackets which are placed at corresponding points on two adjacent surfaces. A pin or post is attached to one bracket and the other bracket holds a notch, groove, or seal for the pin to be fed into. Once the pin is joining the brackets of the latch, the door, cabinet, gate or lid cannot be opened.

- Concealed mounting refers to the setup in which the latches and corresponding mounting hardware are hidden behind the panel. Edge mounting installs the latch components along the edge of the mating panels. When the latches are mounted directly on the front of the panel, this is called face mounting. Side mounting is when both the latch and the keeper are mounted on the back of the connecting panels and cannot be viewed from the cabinet or door front. Lastly, single-hole mounting involves mounting the latches in a single hole on the panel face.

- Note that, in order to customize your order, your hinge manufacturer can alter hole spacing in non-single hole mounting assemblies.

- Latching Position

- Latching position is also important. Primary latching position means that the door is securely held in a closed position, while secondary latching position refers to a latch that holds the door in a position that is not fully closed. Manufacturers will choose one position over the other, in order to fit your application.

Latch Images, Diagrams and Visual Concepts

Latches, mechanical components that allows for the temporary joining of moving parts relative to each other.

Latches, mechanical components that allows for the temporary joining of moving parts relative to each other.

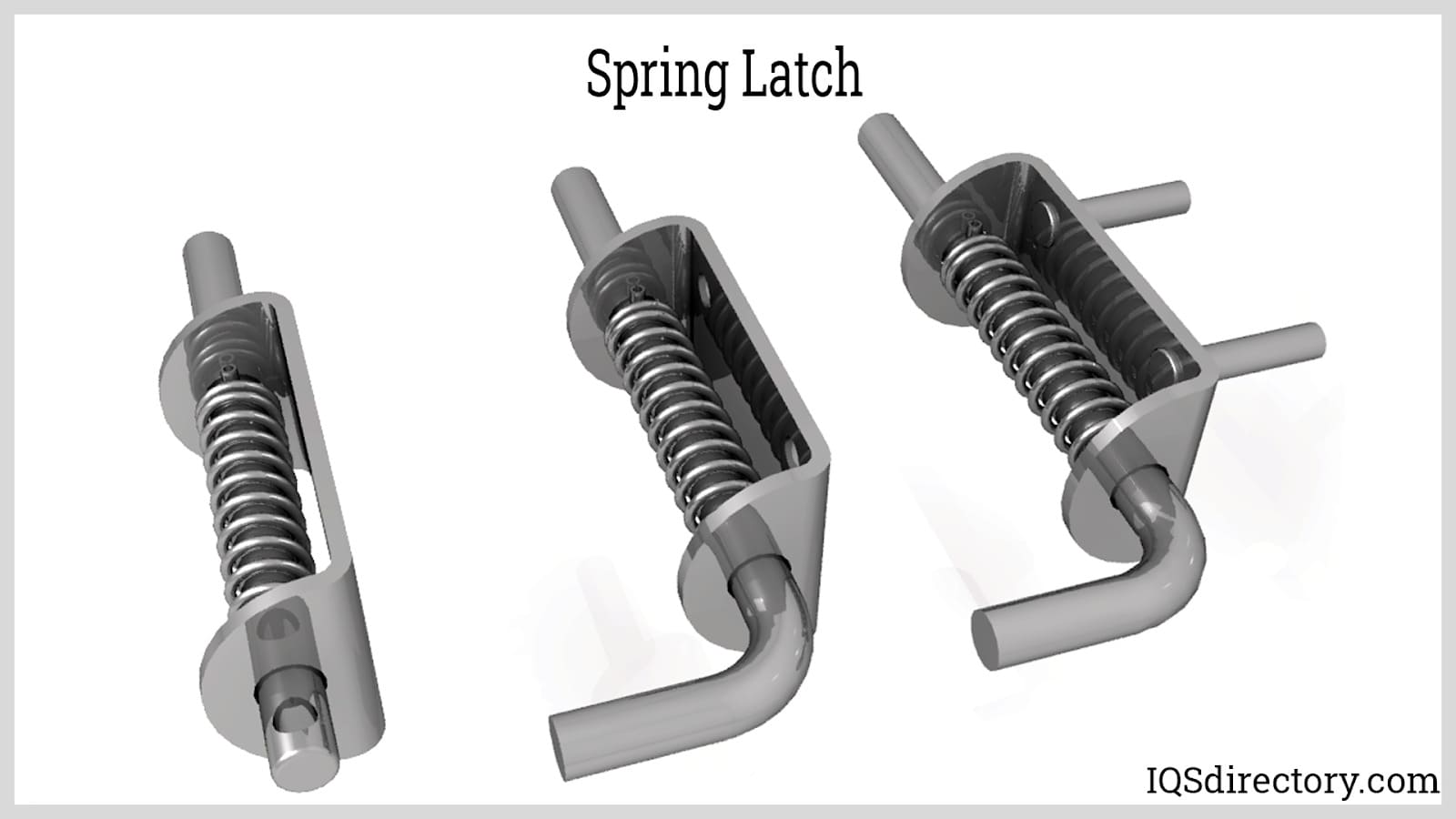

Spring latchs join two separate components to prevent movement or opening.

Spring latchs join two separate components to prevent movement or opening.

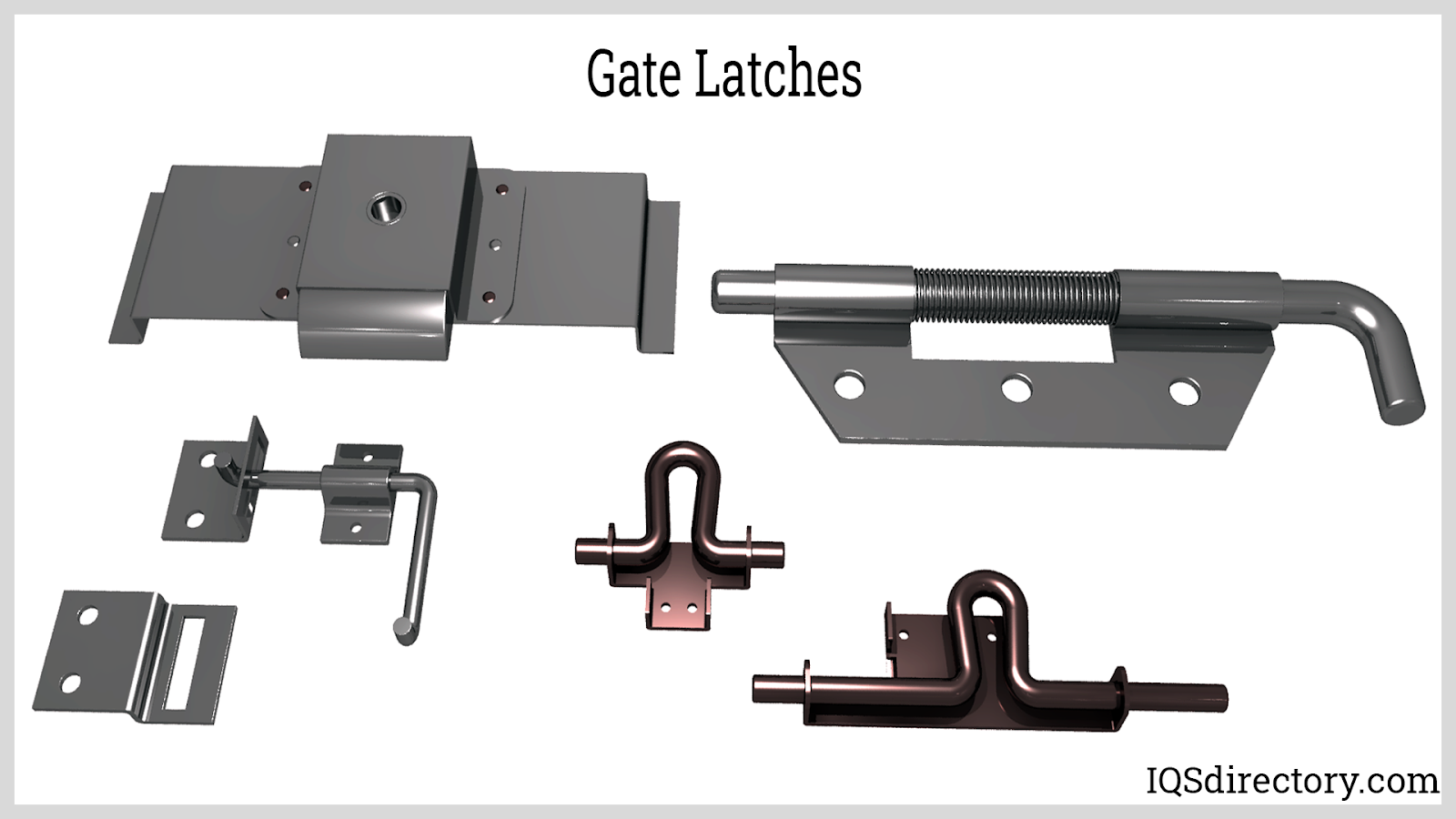

Gate latches are made from highly durable materials, come in several different styles, and with right or left hand orientation.

Gate latches are made from highly durable materials, come in several different styles, and with right or left hand orientation.

Band Clamps is an example of the different methods of design and style of latches

Band Clamps is an example of the different methods of design and style of latches

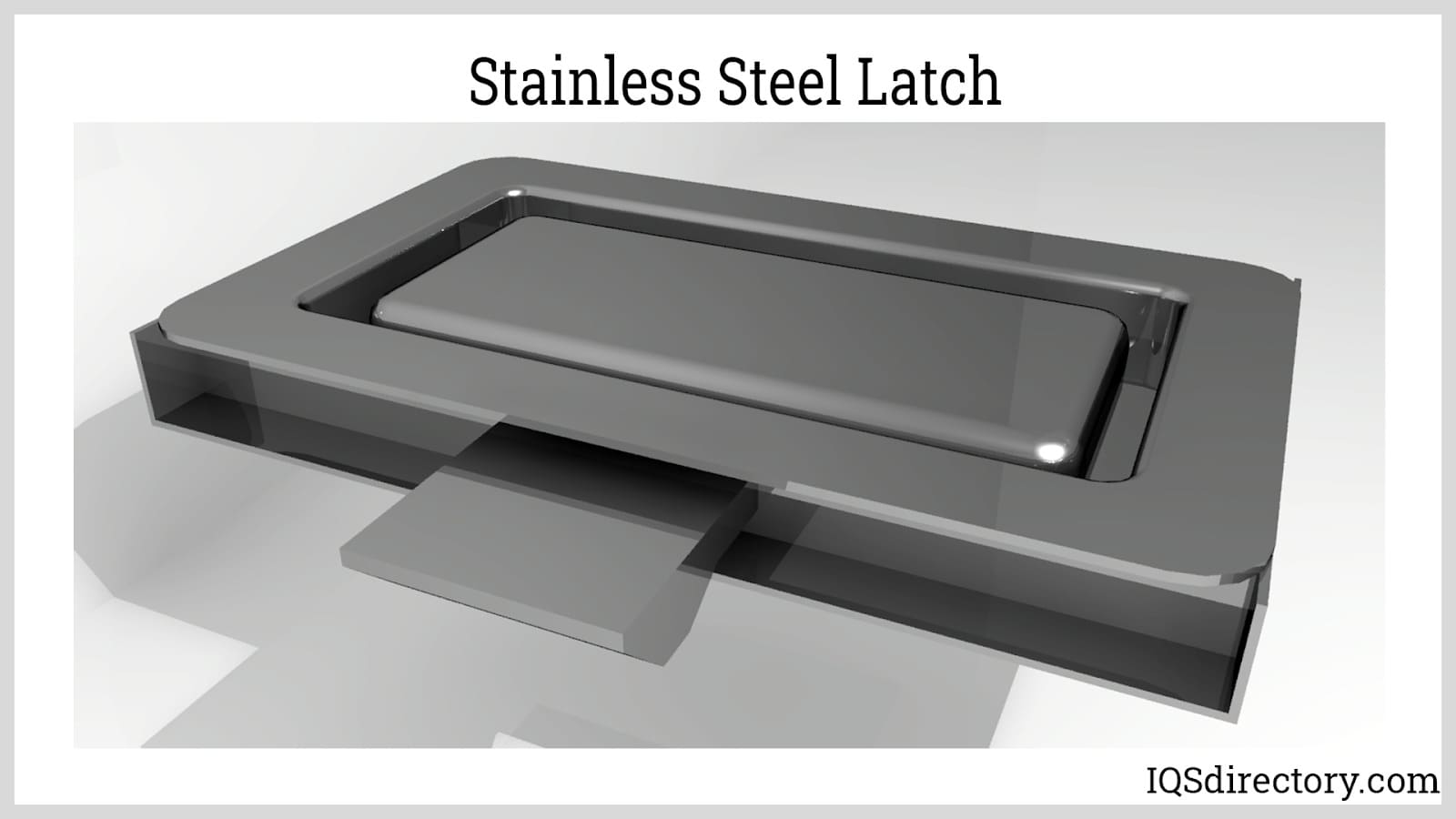

Latches can have different design features and be made from different materials based on the application.

Latches can have different design features and be made from different materials based on the application.

Swinging latches are push-to-close which automatically activate once the door is closed.

Swinging latches are push-to-close which automatically activate once the door is closed.

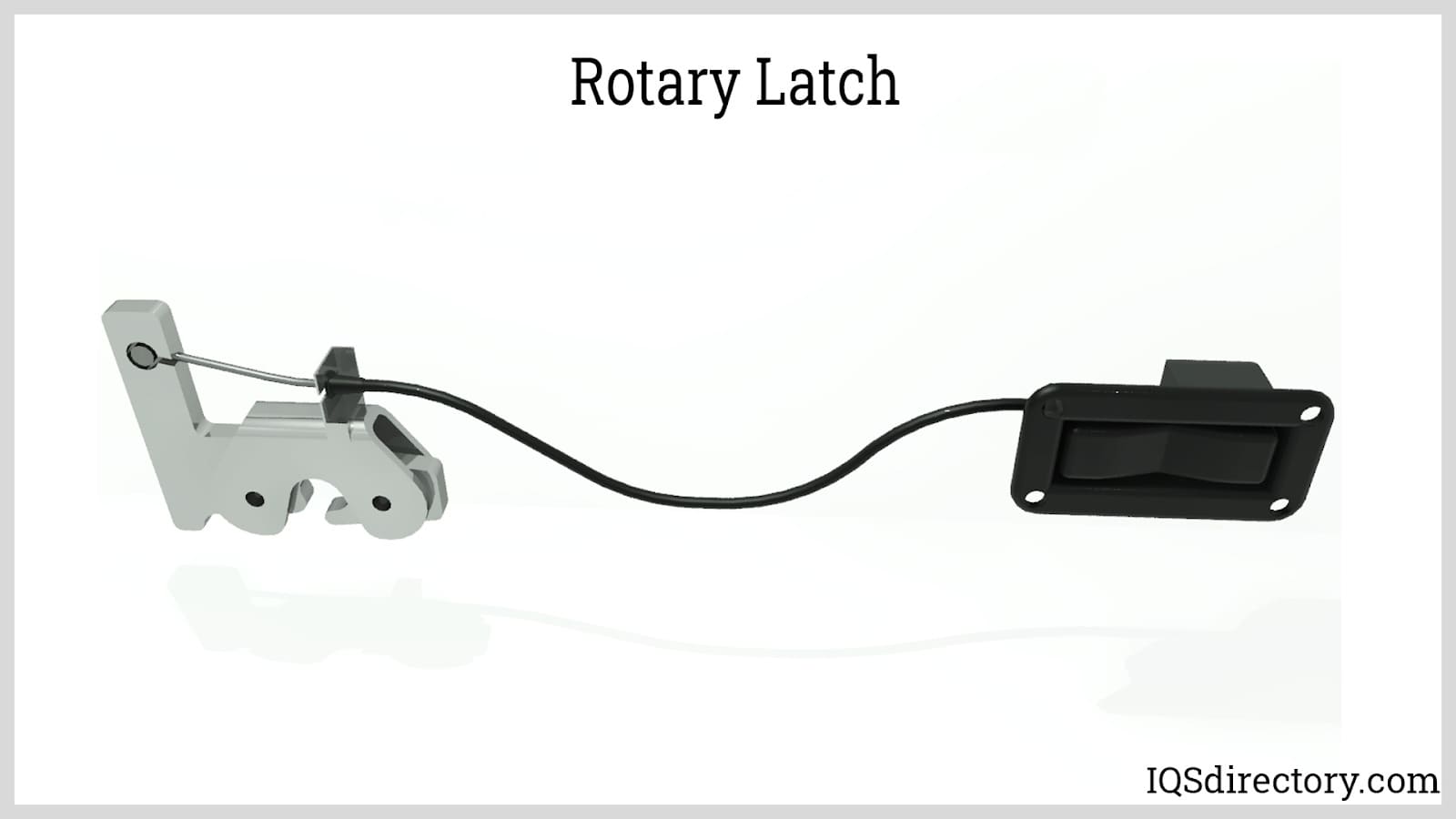

Rotary latchs uses a spring loaded mechanism which enables a push to close function.

Rotary latchs uses a spring loaded mechanism which enables a push to close function.

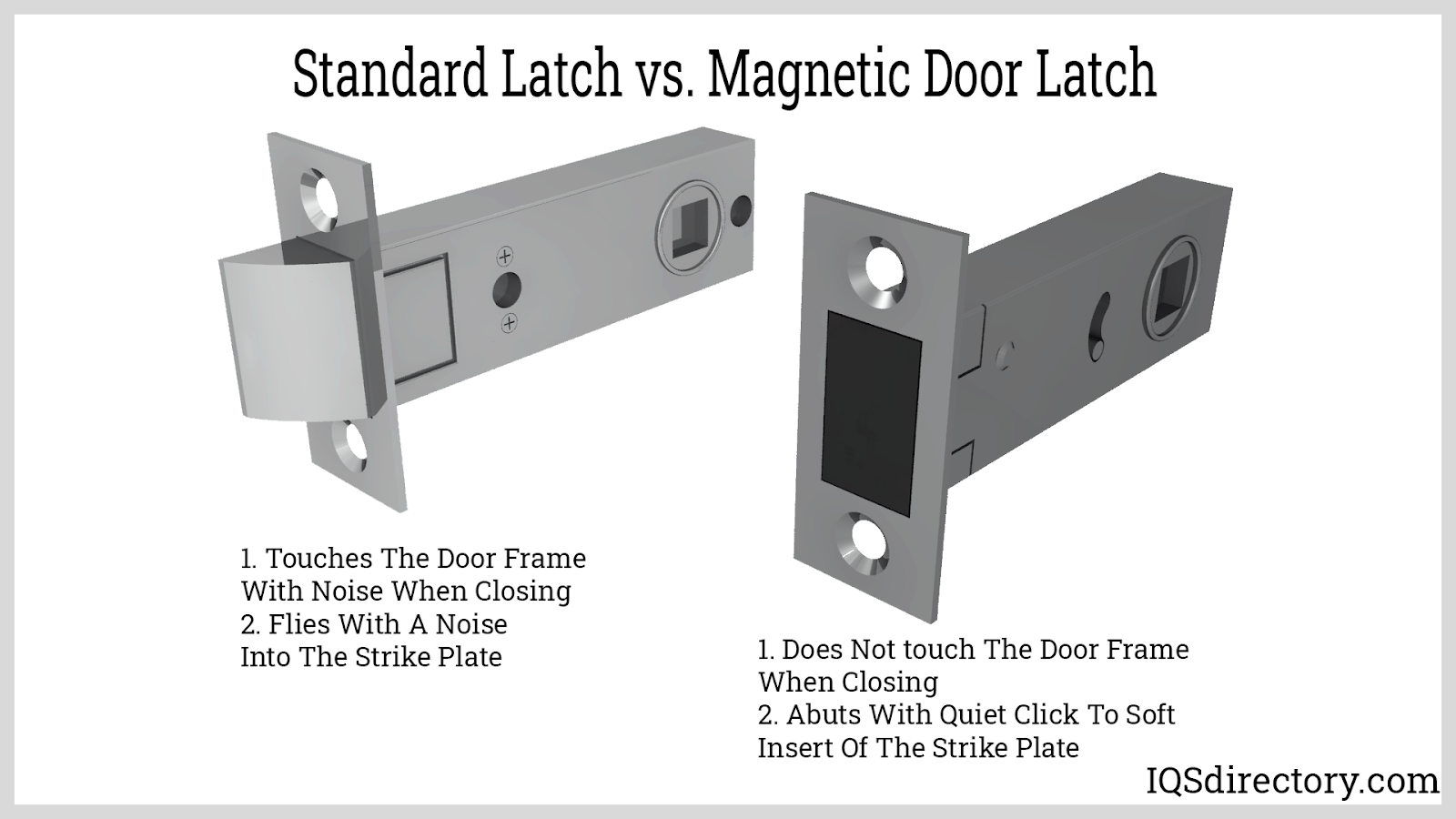

A magnetic door latch consists of a striking pad and a magnet to lock versus using a a standard latch.

A magnetic door latch consists of a striking pad and a magnet to lock versus using a a standard latch.

Types of Latches

- Bolt Latch

- Can be single bolt, double bolt and are typically used on doors and gates.

- Spring Latch

- Incorporate an angled bolt edge that engages the spring when the door is closed to secure it. In order to disengage the latch, you must turn a handle, which retracts the spring latch assembly, allowing the door to open.

- Draw Latch

- Also known as tension or toggle latches, are designed to pull surfaces together and secure them. Consisting of two plates and a joining strap or pin, this type of latch is versatile and can be used in a variety of household and office products such as suitcases and briefcases, trunks, tool and jewelry boxes. They can also be used in corners and hinges.

- Compression Latch

- Similar to draw latches which form a tight connection, and in addition are often used in applications requiring a seal along the two edges of the adjacent components.

- Door Latch

- Latches that hold doors shut. All types are composed of two plates, a bar and a hook or a pin.

- Ring Latch

- Also known as a ring gate latch, is a latch with a large ring that you lift and twist in order to unlock it. This latch type is used mostly in low security settings, like garden gates, where it adds a splash of rustic whimsy.

- Latch Bolt

- Latches that feature a spring-loaded bolt that is angled at its top edge. When you close the door to which the latch bolt is attached, the angled side will make contact with the strike plate, and then retract. Once the bolt goes far enough, though, pressure will release and it will fully extend and lock into the strike plate. Here, it will secure the door and hold it closed.

- Rim Latch

- Another old-fashioned latch type, with their roots in Colonial times. Featuring a surface mounted box and latch that hooks into the doorframe keeper, a rim latch isn’t good for locking unless you purchase it as a part of a hinge and lock assembly.

- Lever Latch

- Provide reliable access restriction to overhead bins in buses and RVS, and compartments in vehicles. They can be customized with different trigger actuation styles and key/tool access features. This latch type is sometimes also known as the push button latch.

- Slam Latch

- Work just how you’d think; they lock when you slam (or just shut) the door.

- Thumb Latch

- An old-fashioned type of latch that features a liftable bolt mechanism. They are mostly found holding closed gates and residential doors.

- Cabinet Latch

- Used to secure cabinet doors. They can also hold shut other storage items, like cupboards and drawers.

- Gate Latch

- Keep the entrances and exits of fencing shut.

- Paddle Latch

- Utilize a specific flip-out latch handle mechanism that allows the operator to close the latch tightly and open it when required.

- SR Latch

- Or set-reset latch, is a type of flip-flop. A flip-flop is a circuit with two stable states, both of which can be used to store state information. (In this context, the terms latch and flip-flop can be used interchangeably.) This type of latch is used in digital electronic systems. Using signals and outputs, it locks and unlocks.

- Touch Latch

- Have no visible hardware. Instead of using a handle mechanism, they allow you to open and close cabinetry with a gentle push. Usually, touch latches have a spring load, with either magnetic or mechanical elements. They’re aesthetically pleasing, and work best with cabinets and cupboards.

- Industrial Latch

- Typically large and durable, making them well suited to transportation uses which include latches for the aerospace and automobile industries, as well as for recreational vehicles, railway, marine and off-highway uses.

Applications of Latches

Latches are particularly efficient in applications which call for the controlled operation of closing and releasing two adjacent surfaces. However, they serve a wide range of applications, from simple to incredibly intricate.

Most often, their applications come from the transportation, home, building and construction, and furniture industries.

Installation of Latches

Every latch type has a different installation procedure. However, in general, the process goes something like this:

Place the latch in place on the edge of the door.

Clean out the center with a chisel.

Start cleaning out the interior of the perimeter with the chisel.

Check and make sure the depth is correct.

Install the latch. Note that this is the procedure for a mortise latch; for exact instructions, talk to your manufacturer. Also, many manufacturers offer installation kits.

Note that this is the procedure for a mortise latch; for exact instructions, talk to your manufacturer. Also, many manufacturers offer installation kits.

Proper Care for Latches

To keep your latches looking shiny and working smoothly, we recommend a few different simple cleaning methods. For clear-coat finished latches, we recommend simply washing them once in a while with a mild, non-abrasive soap and a soft buffing cloth. You can also consider shining them up with a protective, non-abrasive car wax.

To care for a bronze finish, which is more sensitive than many metal coatings, wipe it with (just a little!) vegetable oil or a small amount of household detergent.

Chrome finished latches can simply be wiped down with a damp cloth.

Latch Standards and Specifications

The best latches and locksets will be certified by ANSI (American National Standards Institute) and BHMA (Builders Hardware Manufacturers Association). Both of these standard sets ensure overall quality and safety. Depending on your application, there may be other standards that you need to consider. For example, if you are purchasing latches for a handicap accessible door, your latches will need to be ADA (Americans with Disabilities Act) compliant.

Things to Consider When Purchasing Latches

When considering a latch purchase, there are a few things you should think about. These include: the number of latches you will need, the intended intensity of performance, the environment in which your latch will be installed (indoors, outdoors, near the sea, etc.), and the available mounting surface. These considerations will help you decide what latch will match your specifications the best.

However, for the best results, it’s best to consult with a reputable latch manufacturer and/or hinge manufacturer. Experienced manufacturers have certain knowledge that your average customer will not; they will be able to spot any possible issues with types and configurations right away, before you make a purchase. Plus, direct suppliers can offer you the luxury of customization. To find a quality manufacturer that will work hard for you, check out the list we’ve provided above. We feel confident that the right manufacturer for you is among this group. Browse their respective websites to learn more about each of them, and when you’ve found a few that you think may be right for you, reach out to them with your questions.

Latch Accessories

Latch accessories include: handles (ex. charge handle), anchors, springs (including the gas spring), strike plates, hinges and more. To learn what’s best for you, talk to your latch and hinge manufacturer.

Latches Terms

- Actuation

- The movement of the handle or latch portion, which is what causes the latch/unlatch function.

- Alike Change

- Multiple latches or locks that are able to use the same key.

- Anti-Friction Latch Bolt

- A latch bolt that is specifically designed to reduce friction.

- Architectural Hardware

- Hardware used in construction on movable components, such as doors, windows and cabinets.

- Axle

- A component that provides the bearing surface of the rotating rotor and latch mounting on a rotary latch.

- Back Plate

- The protective plate on the door onto which the moving parts of the latch are attached.

- Bevel

- A term that indicates the direction the latch bolt is inclined.

- Cam

- A tongue on the end of the plug of a latch.

- Case

- The part of the latch that contains the mechanism.

- Catch

- The part of the latch that allows for pawl retention.

- Clamping Force

- The force that is exerted from a latch, in order to draw two panels together.

- Coaxial Mount

- Allows for maximum strength of rotary latches by combining the standard mount with a second pivot on the bottom of the back plate.

- Deadlocking Latch Bolt

- A latch bolt with a plunger that is used to prevent the bolt from retraction by end pressure when the door is closed.

- Direct Release Actuation

- Unlatching by moving the handle or latch directly at the mechanism.

- Dogging Device

- A device used to fasten the crossbar in the depressed position to keep the latch bolt in the retracted position. This allows for free operation of the door on both sides.

- Drop Ring

- A ring handle that is attached to a spindle and is used to operate a latch. When not in use, the ring stays in the dropped position.

- Four-Point Actuation

- Unlocking by moving the handle or latch portion at multiple points.

- Front

- The area through which the latch bolt projects.

- Hinged/Swinging Latch Bolt

- A latch bolt that is hinged to the front and retracted by a swinging action.

- Hook

- A component that allows for a slam action function on a latch.

- Latch Bolt

- A spring bolt with a beveled edge that may be operated by a handle, knob or turn.

- Lip

- The projecting piece that the latch bolt strikes when the door is shut.

- Mortise

- The door cavity that receives the mortise latch.

- Plate

- The body of the latch, which provides the structural strength.

- Plunger

- A sliding component of a latch that provides retention for a strike.

- Roller Strike

- A strike with a rolling member that reduces friction at the point of the latch bolt contact.

- Snib

- A small switch on a nightlatch, which prevents the latch from being operated when closed.

- Springbolt

- A bolt that can be pushed back into the lock case and is able to return to the original position without assistance.

- Stop

- The button that locks or unlocks the latch bolt against the outside knob.

- Strike

- A metal plate used for protection, which is placed in the doorjamb and receives the latch when the door is closed. This is usually "t"-shaped and has a single hole.

- Template Hardware

- Hardware that is made exactly to template, precisely matching the spacing of holes and dimensions.

- Throw

- The maximum projection at which a bolt is fully extended.

- Transom Catch

- A fastener that is applied to the transom, and has a ring that is used to retract the latch bolt.

- Universal

- A latch or other piece of hardware that can be used on any door.