Expanded Metals

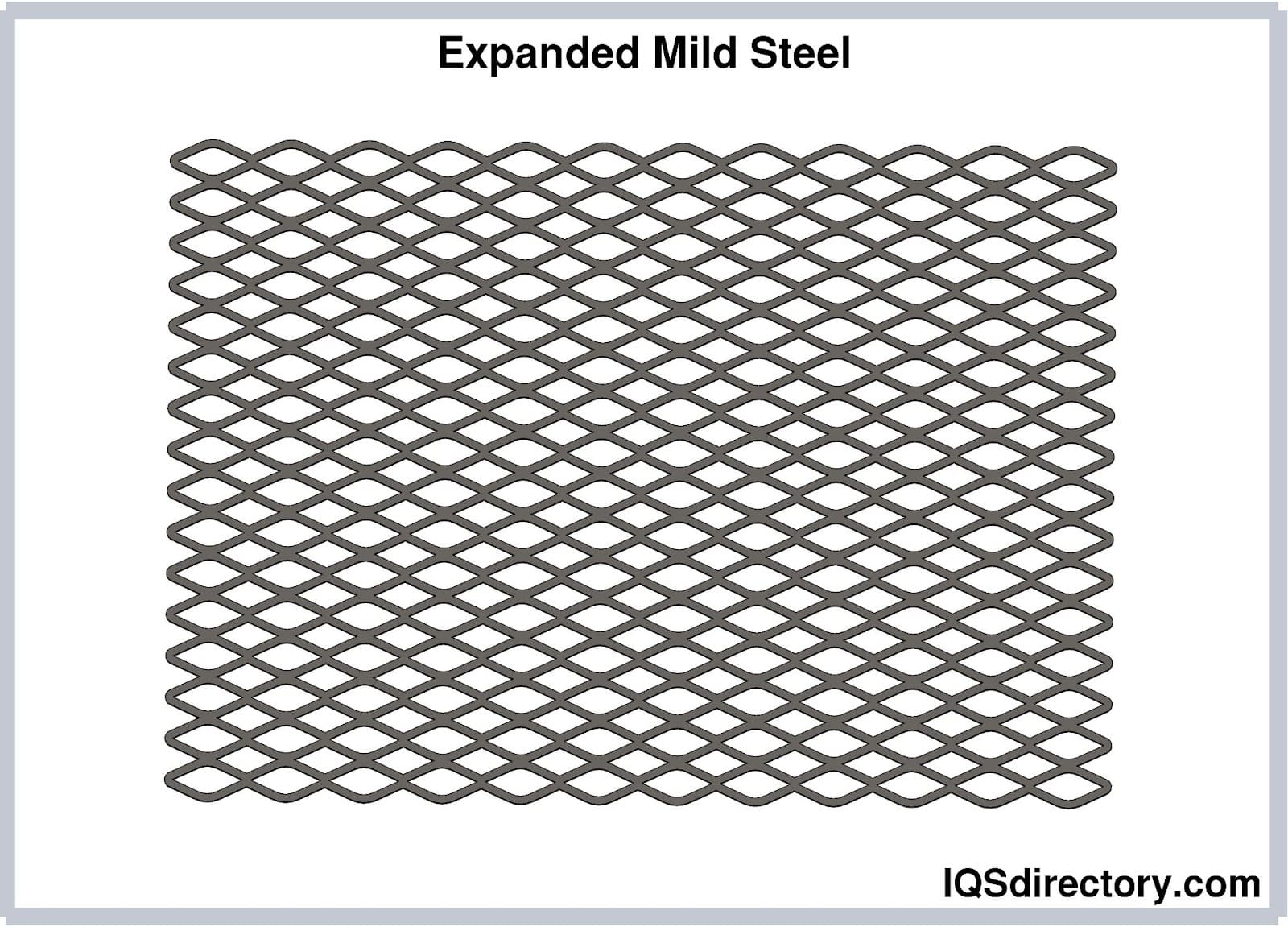

Expanded metals are made from plate or sheet metal that is perforated by a series of slits, cut along parallel lines, and then pulled or stretched into a mesh. The resulting piece may be as much as ten times its original width, depending on the length of the cuts, width of the metal between the cuts, and the amount of stretching. It is a light weight, less expensive alternative to solid plates and sheets, and it will not unravel.

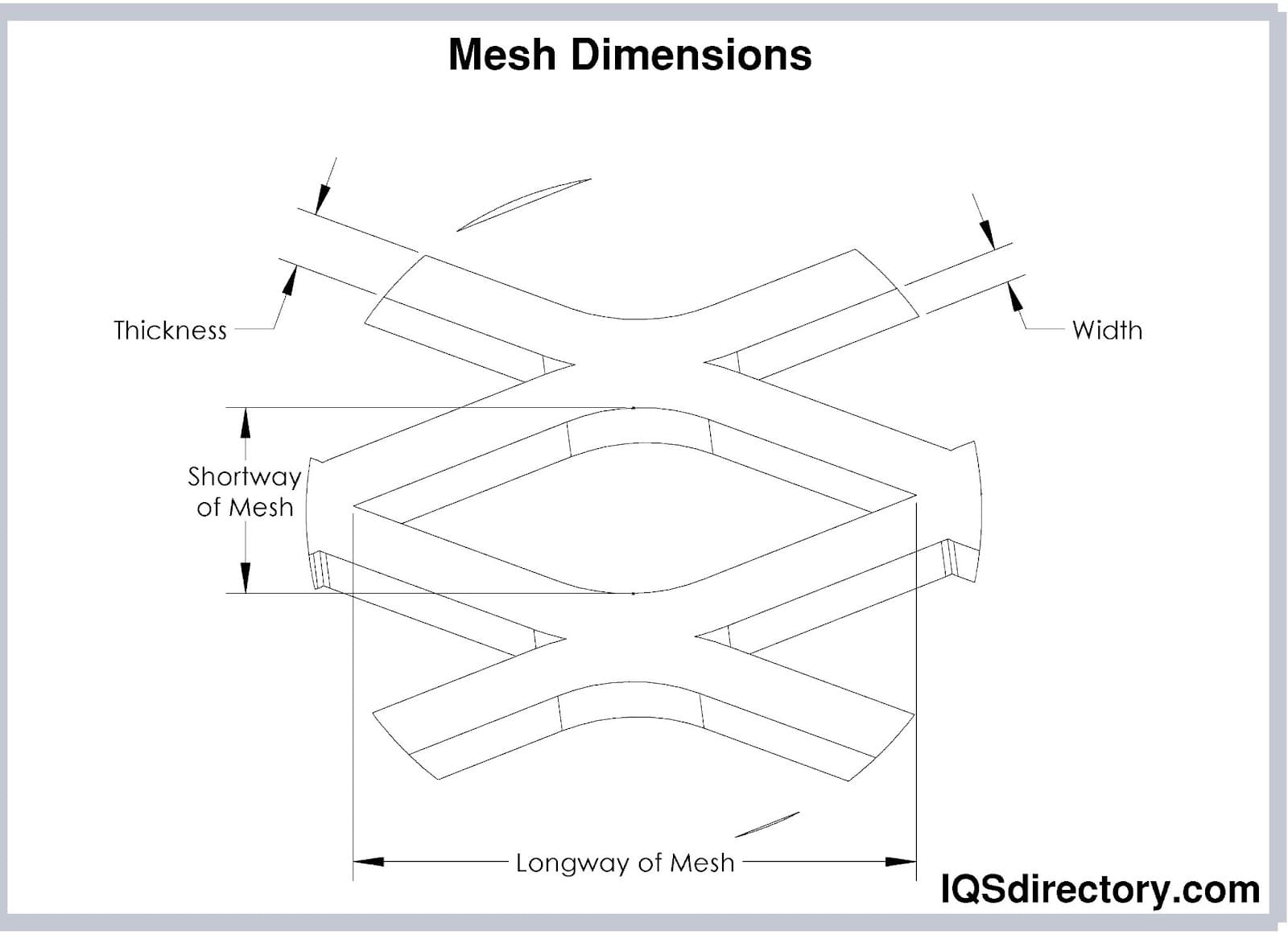

The perforation lines may be staggered, which provides the greatest open area when stretched, or the fine lines may be evenly spaced. Typical metal mesh patterns reveal holes with diamond shapes, but other patterns may be produced, as well. Measurements are based on long way diamond (LWD) and short way diamond (SWD) specifications. The size and shape of the opening will be determined by the necessary requirements of the final application.

Quick Links to Expanded Metals Information

Expanded metal was invented in 1884, in Hartlepoole, UK, by John French Golding. It was developed as metal grating to sort coal for mining industries. Previous sorting processes used woven wires or strips of metal to screen the ore. Golding's expanded metal screens, made from a single sheet of metal, were more durable, and the open areas remained uniform with use.

In 1889, Golding joined W.B Close, Mathew Gray, Christopher Furness and Robert Irving Jr. to form the British Metal Expansion Company. They held sole rights to all expanded metal manufacturing in Europe. In 1894, the company name was changed to the Expanded Metal Company Limited, of London.

American industrialist Eli Hendrick created a metal punching machine in the 1890s that soon developed into a prototype for the modern perforating punch. The ability to make expanded metal more efficiently allowed mining operations to function more effectively and caused a boom in the construction industry, as the mesh proved to be an excellent lath for artistic expression in plaster and stucco walls.

The first US patent for expanded metals was granted in 1910, to Charles H. Schrammel. His improvements included angling the plane of the mesh dividers, giving the surface a gripping texture, and a method of rolling up the metal sheets, which made them much easier to handle.

Demand for expanded metals increased over the decades, but very little about it changed, other than the scope of its applications. As a novel building material, it was used extensively in construction through the first half of the 1900s, but its popularity waned with the development of modern products, such as plastics, which were being developed at the time.

Shortly after the turn of the twenty-first century, digital perforation was developed, but in spite of technological advancements, the process is still very similar to the original.

Between 2005 and 2015, an architectural revival emerged, bringing decorative expanded products, such as gates, window coverings, and building facades, back into style.

Expanded metals are cost effective. By stretching the solid sheet into a larger piece of fabric, less metal can be used to accomplish a specific goal. There is no waste created in the manufacturing process, making it very efficient. Patterns for products made with mesh materials may be designed for maximum utilization of the fabric, much like sewing patterns make efficient use of cloth.

Because expanded metal retains its solitary structural integrity, it may conduct electricity, heat, or magnetic flux quite well. The solid structure provides reinforcement in concrete, glass, or other building components, while keeping weight to a minimum. Its high tensile strength makes it an excellent choice over woven metals and welded joints in many applications.

Perforations in the metal allow light and air to flow freely, while still providing protection from the sun, falling or flying debris, and blocking sight.

Expanded metals require very little maintenance. There are no moving parts, the entire piece is one unit that cannot "come undone". Typical maintenance will consist of hosing down the component and possibly scrubbing with an appropriate brush and cleanser.

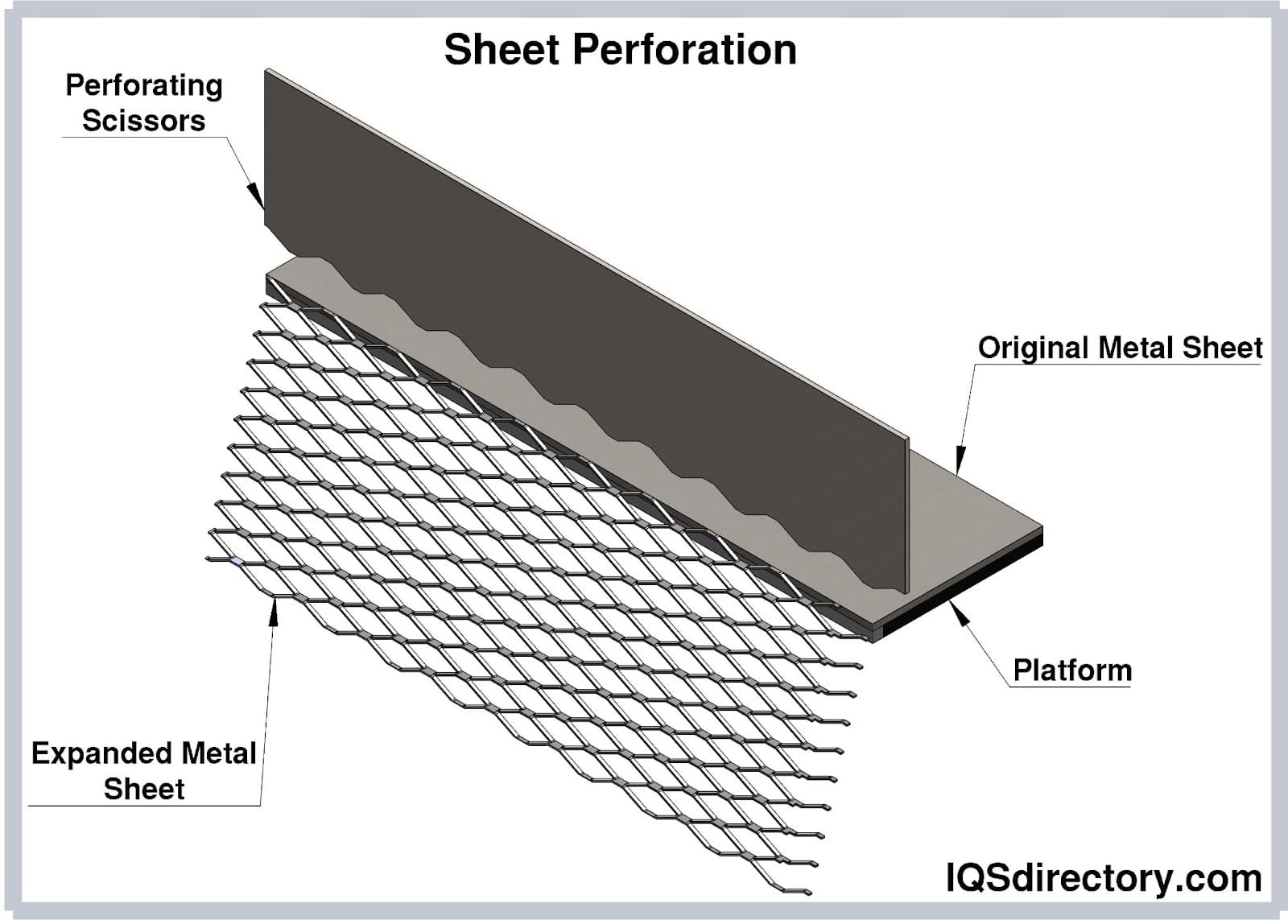

Solid metal sheets or plates of varied thickness are fed through an expansion press that simultaneously slits the metal along thin lines. The cuts are facilitated by mechanical knives that produce uniform slits for consistent openings. A stretcher bar pushes the metal outward, forming voids in the perforated metal, linked by unbroken lines called bonds and strands. Expansion presses may be manually operated or programmable, automated CNC systems.

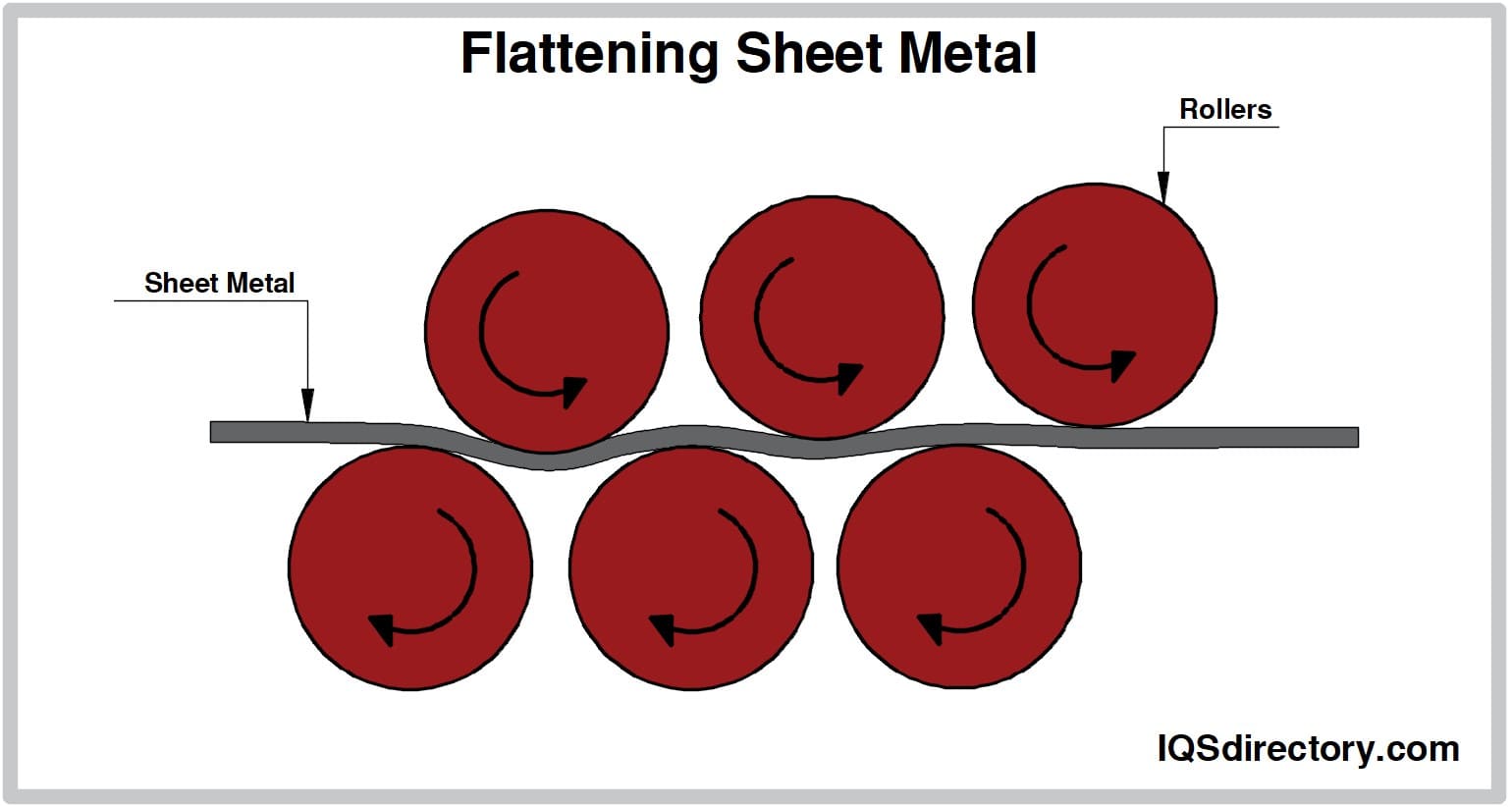

Once the sheet has been completely perforated and stretched, it may be sent for sizing, or cold rolled to press it flat and smooth. The flattening press consists of parallel cylinders that squeeze the plate as it is rolled between them. After it has reached sufficient smoothness, it will be cut to size, and PVC, paint, anodized, or other veneers may be applied. The metal may be annealed or treated for corrosion resistance at this time.

The pattern and size of holes will depend on the metal product's applications. Walkways are often made from carbon steel, with diamond shapes in the grating. The cuts may be two inches long, providing openings that are one-inch LWD by one half inch SWD, once the stretching process is complete. Metal fences may be created with much larger apertures by making longer cuts along finer lines. Variations to the diamond pattern may be produced by making alternate lengths of slits in the solid sheet, at alternate widths, or by using shaped knife blades.

Standard expanded metals may be manufactured from different thickness of plate or sheet metal with a variety of opening sizes. The SWD bonds and LWD strands that divide the apertures are set at a uniform angle, offering increased rigidity with maximum flow. Because the metal remains a single piece, it provides much higher tensile strength than woven wire of equal weight.

By cold rolling the expanded sheets, they are flattened to create a smooth surface. This process can further extend the length of the piece by as much as five percent.

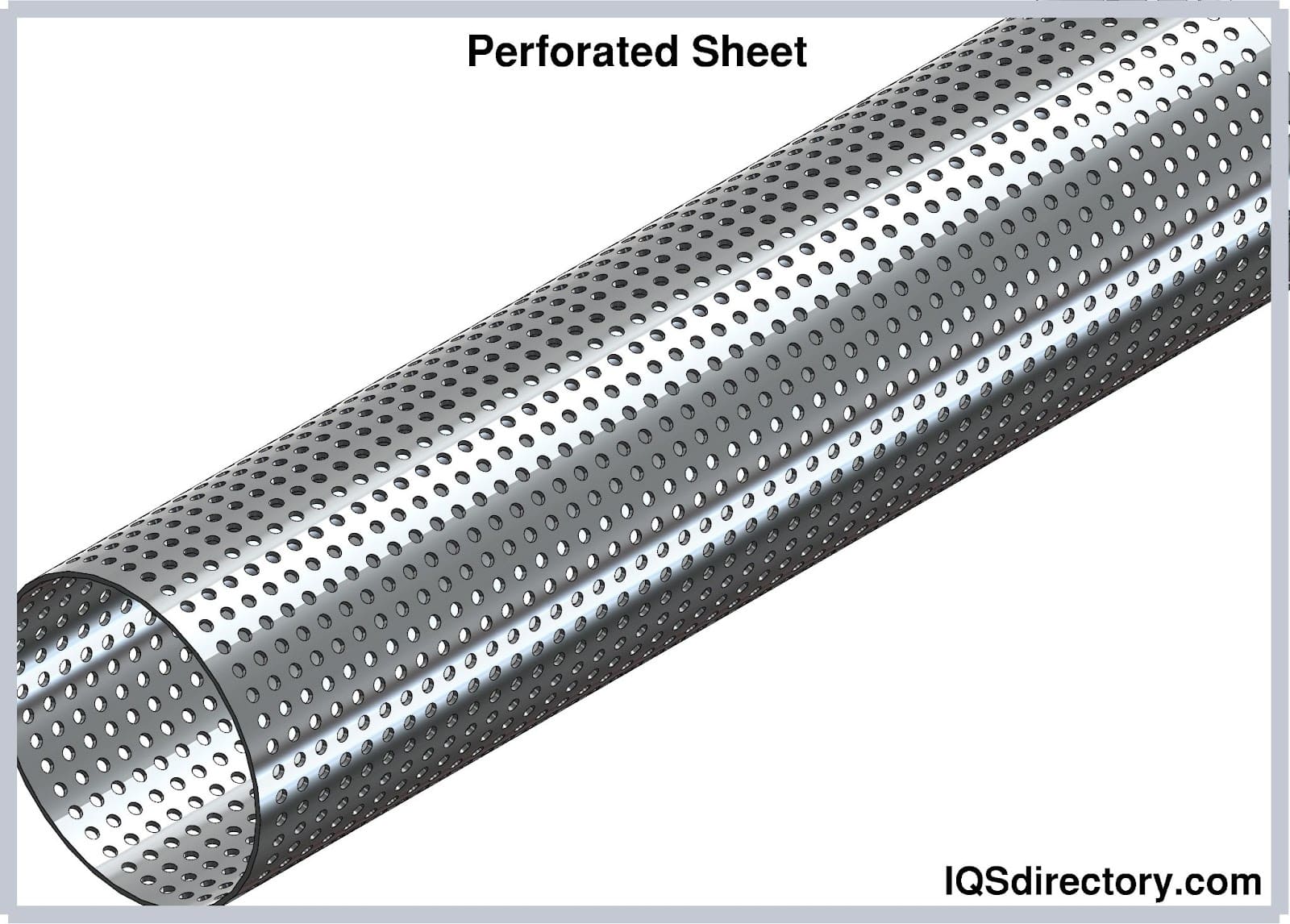

Perforated metals, not to be confused with expanded metals, are solid metal sheets that have holes of specific design punched out. The material is not stretched in any way. Their uses are similar, but the expanded sheets weigh less, inch for inch, and provide more flexibility.

Expanded metal is a sheet metal mesh, made by stretching slitted sheets of malleable metal.

Expanded metal is a sheet metal mesh, made by stretching slitted sheets of malleable metal.

Perforation Sheet is a metal sheet punched with holes.

Perforation Sheet is a metal sheet punched with holes.

Malleable metals can be expanded, however many are not viably for industrial scale. Steel is the most common with it high strength and is cost-effective.

Malleable metals can be expanded, however many are not viably for industrial scale. Steel is the most common with it high strength and is cost-effective.

Dimensions of the mesh must include the total area, thickness, and the size of the cut for the mesh.

Dimensions of the mesh must include the total area, thickness, and the size of the cut for the mesh.

This process gives the expanded metal a flat surface finish, where such is desirable, which leaves a ridged surface or a rippled finish on the expanded metal.

This process gives the expanded metal a flat surface finish, where such is desirable, which leaves a ridged surface or a rippled finish on the expanded metal.

The thickness of the strands influences the percentage of open spaces on the metal sheet.

The thickness of the strands influences the percentage of open spaces on the metal sheet.

- Copper Expanded Metal

- Sheet or plate composed of copper or its alloys, such as brass or bronze, which has been slit and stretched simultaneously to create an open framework of solid construction.

- Expanded Aluminum

- Result of aluminum sheets or plates undergoing a machining process in which they are simultaneously cut and stretched to create an open grid of the silvery-white metal.

- Decorative Expanded Metal

- Comes with a variety of mesh patterns other than the standard diamond shape, and may also be produced using more decorative metals, such as copper or silver.

- Expanded Metal Fence

- Fencing produced from expanded metal. It offers strength, safety, durability and aesthetic qualities not found with many other types of fencing.

- Expanded Metal Grating

- Used for walkways and platforms designed for pedestrian foot traffic.

- Expanded Metal Mesh

- Used when smaller openings are desired, such as in filters.

- Expanded Metal Products

- Include all items made from or with components of metallic elements or alloys that have undergone a machining process known as expansion which simultaneously incises and stretches the material.

- Expanded Metal Screens

- Consist of a surface of light gauge sheet metal that has been slit and stretched to create a pattern of uniform small openings.

- Expanded Metal Sheets

- A framework of interlinked bars that create a uniform pattern of open space through the simultaneous cutting and stretching of a number of alloyed metal plates.

- Expanded Steel

- Can be found in a number of strengths for applications varying from walkways and fencing to corner netting for use under plaster and drywall.

- Flattened Expanded Metal

- Has been cold-rolled after expansion, providing a smooth, flat and level sheet. The metal’s thickness thus will be reduced by up to ten percent.

- Mini Mesh Expanded Metal

- Has very small openings in comparison to other types of expanded metals or mesh.

- Stainless Steel Expanded Metal

- A highly anti-corrosive sheet, mesh or grate of solid construction that is used in applications where volatile chemicals or hygienic cleaning occur.

- Titanium Expanded Metal

- A framework of interlinked bars and uniformly patterned open spaces. Titanium is a highly valued material known for its strength and durability.

- Unflattened Expanded Metal

- Comes directly from the press and has a raised pattern. The strands and bonds are set at a uniform angle to the plane of the sheet.

The mesh can be used to filter light, air, water, materials, sound, and the view. It is used for decking, fencing, screening, lath, or decoration. It can be made from aluminum, steel, mild steel, carbon steel, stainless steel, copper, or even plastics. A wide variety of finishes may be added, according to design.

A versatile, cost effective fabrication option for many types of projects, expanded materials are everywhere. Fences, vents, grating, and filters are parts of everyday life. Picnic tables, playground equipment, seating, barriers, and partitions of PVC coated mesh are found in many public places. As architectural screening, it can be used to maintain air flow and light penetration, while providing camouflage or visual intrigue through variations in the metal mesh pattern, surface shape, and finish.

Traditionally used as a metal lath underlayment for plaster and stucco, engineers have also discovered the benefits of using a lightweight outer skin of expanded metal for commercial construction. The advantages include reduced energy costs, lower exterior maintenance, and the ability to create multifaceted aesthetically interesting exteriors.

Expanded products provide excellent non-skid, aerated, drained, or raised flooring. Such products can be used as decking for walkways and bridges. It is often found on catwalks and stair treads used for maintenance access to buildings like grain silos or wind, water, and radio towers.

Expanded metals are used in the construction of industrial production facilities and equipment. They are used to create cages, shelves, lockers, cabinets, storage units, and safety barriers of all kinds. These metal products are strong, light, durable, fireproof, see through, and easy to maintain.

Heavy duty metal grates or metal fences are stronger than wire mesh barriers, and can be custom fabricated to fit any configuration, providing additional safety and security wherever they are installed. Metal grating is also used to sort materials of mixed sizes, such as ore, or to filter debris, as in storm drains.

Artists use expanded metals to create light and airy works or as bases for projects involving papier mache, plaster, clay, metal, or wax sculpting. The flexibility of the mesh provides a lightweight form to work with, saving material waste, costs, and in many cases, time.

Expanded copper is electrically conductive and may be used to form Faraday cages for protection against lightning, and to provide shielding from Radio Frequency Interference (RFI). It is made into spark arrestors for chimney caps and can be used to repel garden pests. Slugs and snails hate the feel of copper. Rodents cannot bite through it and birds cannot peck larger holes in the metal.

Micro mesh expanded foils are made from lighter gauge metal sheets and with small slits that produce tiny openings to be used in filtration systems. The sheets are flattened to provide thin, fine, polished products that may be used to filter air or liquids. They may be also used for acoustic screening panels, speaker covers for audio equipment, and sound proofing. They are also used to provide ventilation without visual exposure. These micro mesh foils are often made from stainless steel, brass, or aluminum.

Micro mesh foils made from expensive metals such as titanium, niobium, zirconium, and platinum, are used in fuel cells, hydrogen generation, oxygen generation, and batteries. Their material thickness may be as thin as .001 microns.

Most hardware stores, hobby & craft stores, and some department stores will carry limited supplies of standardized expanded products. These may be fine for blocking a hole where the mice get in, or making a cage around a prize begonia, but for larger projects requiring structural integrity, scientific accuracy, or high security, a manufacturer is who to see.

Many applications will require adherence to certain standards, whether ASTM, ANSI, FDA, or others. It is important to be aware of any regulations governing the end use of the material. With a trained design team, a good manufacturer can help determine what materials will best suit the needs of the job and make proper recommendations.

The designers will help choose the right metal, plate or sheet thickness, hole size, and configuration for maximum effectiveness and efficiency of the project. They will try to understand the needs of the client, the scope of the endeavor, and provide products in a timely manner at reasonable cost. They will stand behind their products and services after the sale, maintaining customer satisfaction.

- Blank to Size

- Custom size expanded metal part made to customer’s specifications.

- Bond

- The solid intersection of two strands of metal found in expanded metal.

- Bond Edge

- Manufactured closed perimeter diamond.

- Coil Product

- Expanded metal produced as one continuous coil of the material rather than in individual pieces.

- Diamond or Opening

- This is the description of the open area formed by strands and bonds. Normally the open area is diamond shaped.

- Leveling

- All expanded metal products except grating are leveled after having been expanded.

- LWD

- Long way of diamond or long way of opening is the dimension measured across the sheet in a direction parallel to the largest dimension of the diamond.

- Mesh

- This is the nominal distance from the midpoint of one bond to the midpoint of the next bond measured across the SWD. Mesh is expressed in inches.

- Percent Open Area

- The total open area of a section of expanded metal. Found by calculating two times the strand width, divided by the short way of diamond (SWD), and then taking the inverse of the resulting number.

- SWD

- Short way of diamond or short way of opening is the dimension measured across the sheet in a direction parallel to the smallest dimension of the diamond.

- Strand Thickness

- Thickness of base metal when in the unflattened state.

- Strand Width

- The dimension associated with the thickness of one strand of metal.