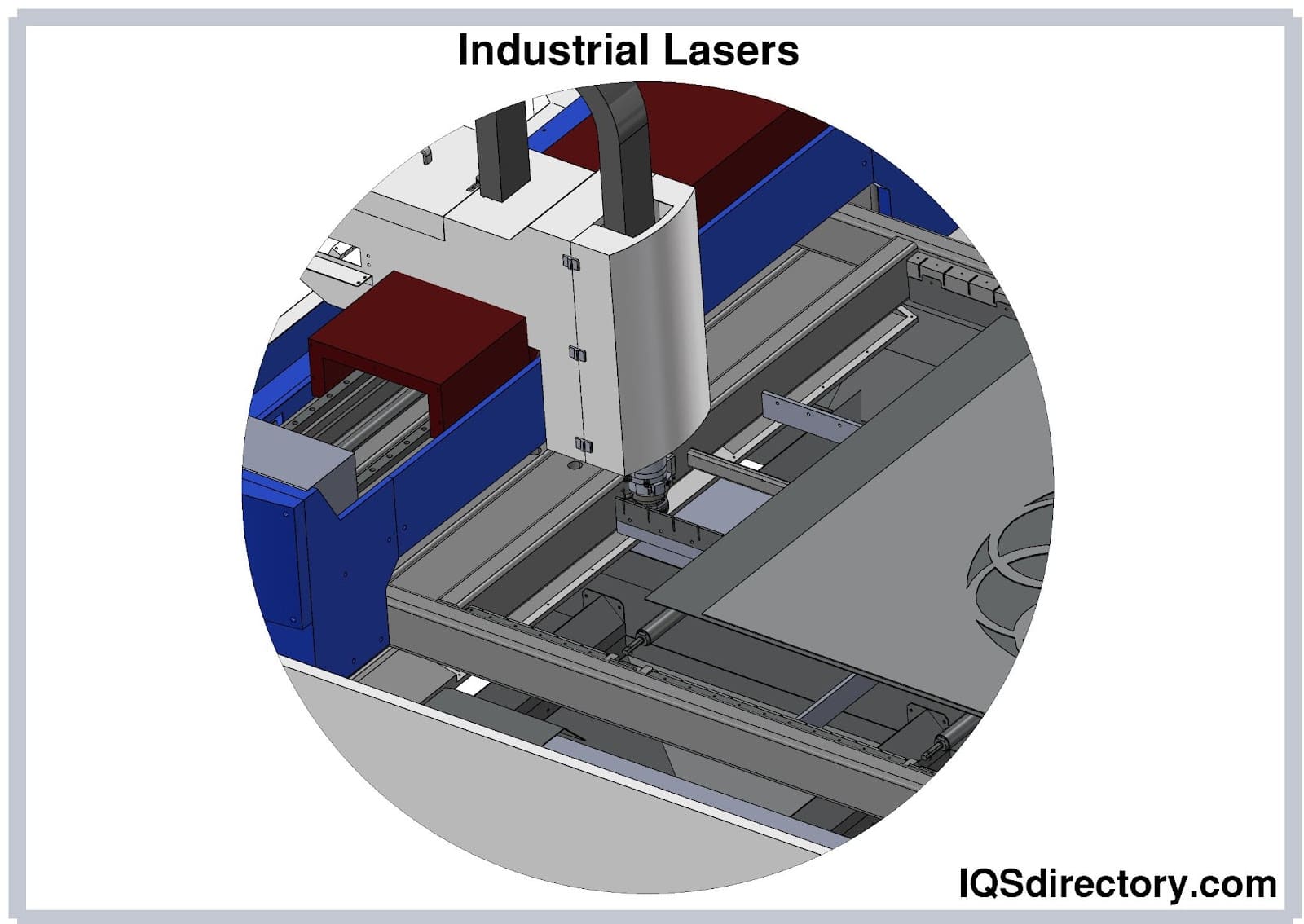

Industrial Lasers

Industrial lasers are employed for various tasks, including cutting metals and fabrics, marking tracking codes for industrial traceability, precisely welding metals, cleaning metal surfaces, modifying surface roughness, and measuring part dimensions. Although lasers exist in various powers, colors, and beam widths, they all operate according to the same principles. So what is an industrial laser, and how does it operate? Using a laser, common in several industries like the EV and primary metals industries, could be advantageous in various industrial applications.

Properties of Industrial Lasers

An industrial laser is a light beam; for it to work well, it should have the following light properties.

- Single Direction

- Monochromatic

- Coherent

Single Direction

The laser beam has a modest, nearly constant beam diameter across a vast area and is pointed in a single direction. As a result, lasers can generate extremely high power levels when light is concentrated in a single direction.

Monochromatic

Laser light is monochromatic, meaning its color is limited to a single distinct hue. The wavelength of the electromagnetic waves that make up light determines its color. The beam can be visible, infrared, or ultraviolet. The wavelength of a typical industrial red laser (helium-neon, for instance) lies between 632.800 and 632.802 nanometers.

Coherent

The word "coherent" refers to the synchronization of all the light rays within the beam. As a result, they share the same polarity and phase. The beam's tremendous strengths are also made possible by this coherence.

Components of Industrial Lasers

- Gain Medium

- Energy Source

Gain Medium

The substance utilized in the laser cavity is known as the gain medium. It can be a liquid (like a dye solution) or a gas (like a ruby crystal) (a helium-neon mixture). The crucial characteristic is that it emits light with the desired wavelength when activated.

Energy Source

The gain medium in the laser cavity emits light from the energy source. Diode lasers are frequently used as an energy source because they convert electricity into light. For example, a short electrical discharge in a CO2 laser can make the gas emit light.

Industrial Laser Applications

Numerous industrial areas employ lasers as manufacturing tools. Some of these applications are listed below.

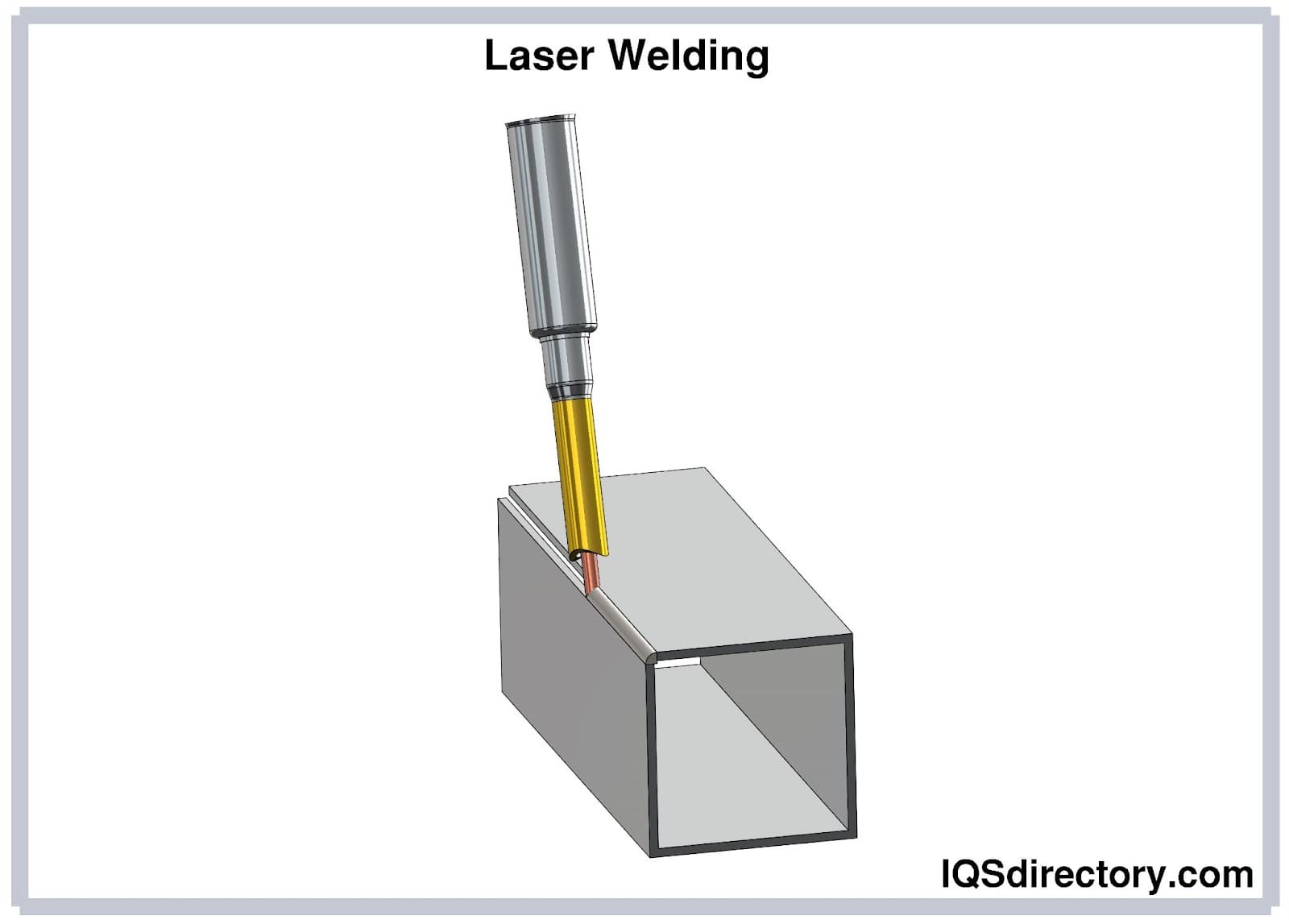

Laser Welding

Laser welding produces strong welds and high-quality joints even when joining incompatible materials. Laser welding is highly suited to production processes with repetitive operations due to consistent accuracy.

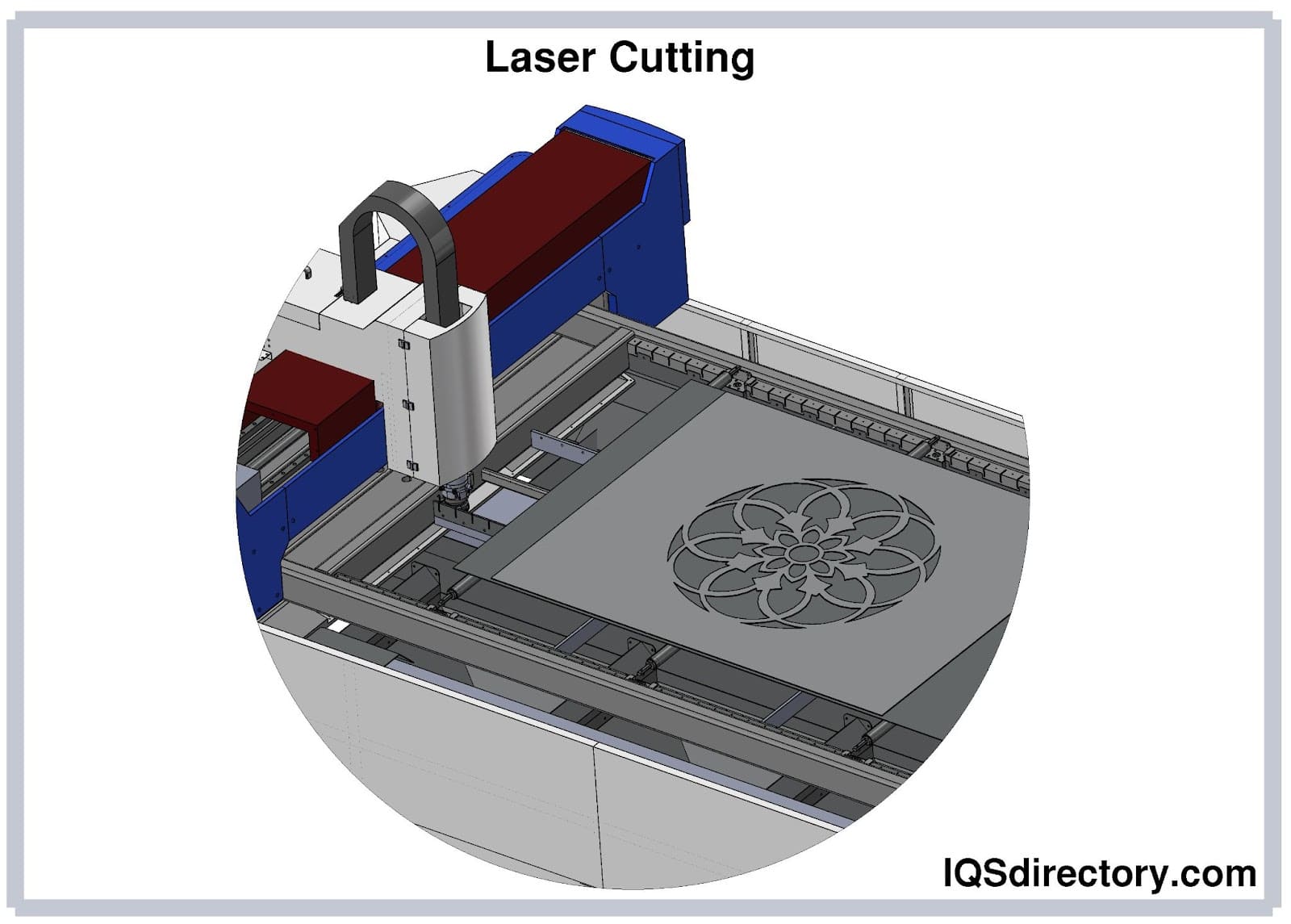

Laser Cutting

The output of a powerful laser is focused on the material to be cut in a laser cutter. The targeted region can be heated, melted, or vaporized by a powerful beam of coherent light, which also leaves a smooth, burr-free edge with a superior surface finish. Although modern laser-based cutting systems can process steel up to one inch thick, lasers are normally employed to treat thinner materials.

Additive Manufacturing

A laser beam forms a melt pool on a metal substrate or other material in additive manufacturing applications like 3D printing and laser deposition. Layer by layer, the finite component is constructed.

Laser Marking

The use of a laser to leave a permanent mark on almost any surface or material is now common in factories. Compared to other techniques, this one is high resolution, suitable for metals and plastics, and incredibly quick.

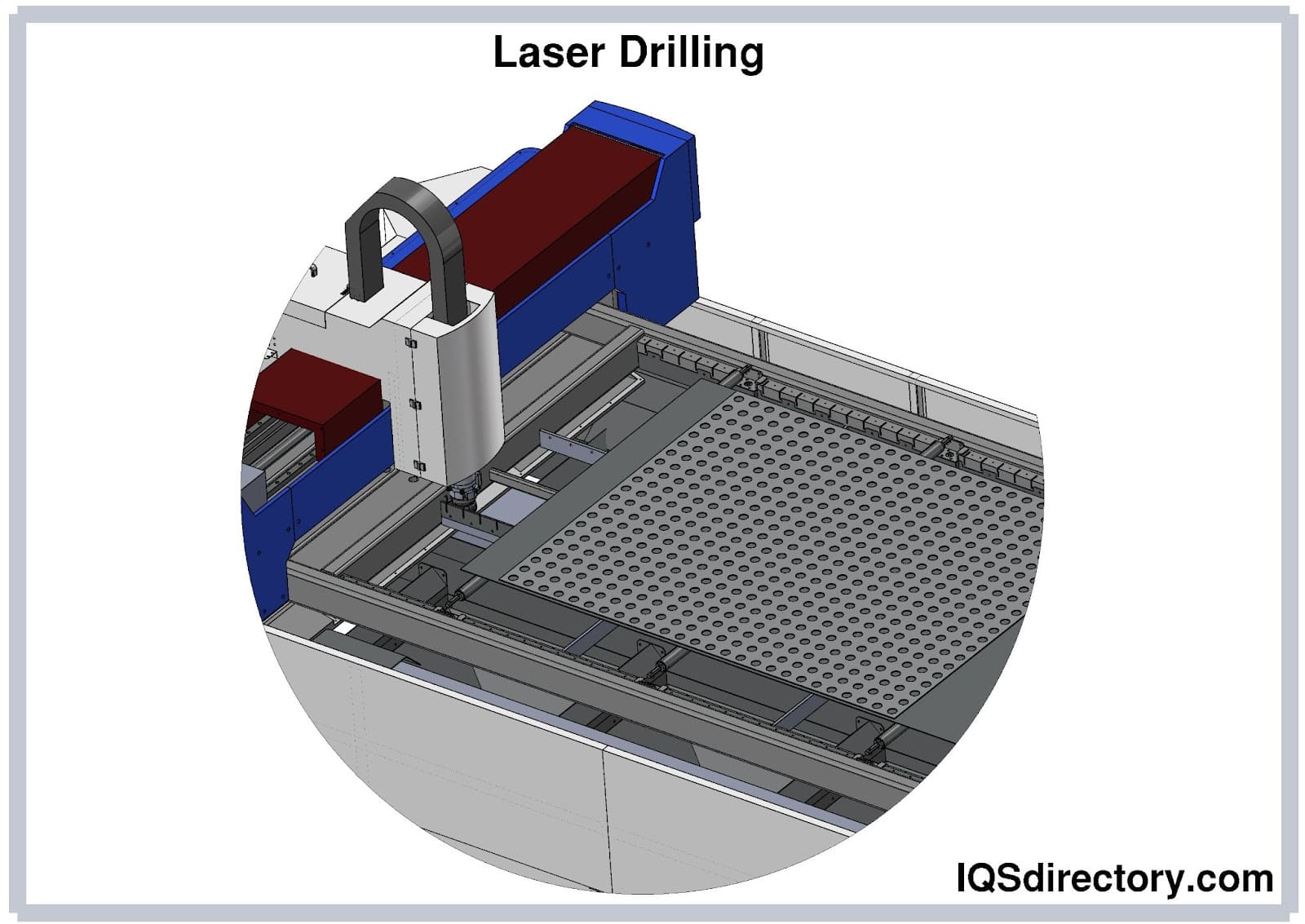

Laser Drilling

Laser drilling has become a useful technique for making tiny holes, as small as 0.0005" in diameter. A laser can drill holes, to be more precise than other options.

Benefits of Industrial Lasers

Better Accuracy

The fine focus of modern laser beams is one-thousandth of a millimeter. The laser allows measuring, marking, or cutting to be carried out with the highest level of accuracy. After a laser cut, the material is completely free of deformation and burrs.

Automation Benefits

Shorter cycle times, reduced maintenance, and more cost-effective production are all benefits of using lasers in manufacturing. Operations previously time-consuming and prone to error can be completed quickly and perfectly. In addition, processes can be done at astounding speeds when automation and laser technology are used together. On the production line, lasers are now the fastest way of cutting and welding.

Environmental Benefits

Compared to their conventional equivalents, lasers require a small amount of energy. As a result, lasers can replace production processes that use wasteful consumables like welding fluxes, steel grits, ink, and labels. By doing this, significant waste is prevented during these other processes, along with the emissions brought on by the production and transportation of the goods required to perform them.

Disadvantages of Industrial Lasers

Cost

It costs money to stay current with the technology, adding to the cost.

Increased Intricacy

Design intricacy depends on laser or other equipment, increasing treatment complexity and duration.

Cutting Cycle Issues

In the cutting cycle, the laser bar is delicate to handle. A slight error in adjusting the temperature and distance may cause the metals to copy or discolor. Additionally, more force is needed throughout the cutting cycle.

Harmful to People

People are harmed by them. Industrial lasers frequently eat into people with which they come into contact.

Choosing the Proper Industrial Laser Supplier

To ensure you have the most productive outcome when purchasing an industrial laser from an industrial laser supplier, it is important to compare several companies using our directory of industrial laser suppliers. Each industrial laser supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each industrial laser business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple industrial laser companies with the same form.