Oil Fryer Systems: Types, Applications, and Design Considerations

Introduction

This article contains everything you will need to know about fryer oil systems and their use.

You will learn:

- What is an Oil Fryer System?

- Types of Oil Fryer Systems

- Uses for Oil Fryer Systems

- The Oil Fryer System Process

- And much more …

Chapter 1: What is an Oil Fryer System?

An oil fryer system involves heating, cooking, and drying food by immersing it in hot oil. During this process, heat is transferred to the food, enhancing its taste and texture. Oil absorption occurs at different phases, initially on the surface, with some removed through vapors. The amount of oil retained in fried food varies according to the food's shape and the specific oil removal methods employed in the oil fryer system.

Oil fryers are primarily categorized into continuous and batch systems. Batch fryers are ideal for small-scale production and niche products, where oil is brought to frying temperatures for cooking small amounts of food items at a time. On the other hand, continuous oil fryer systems are designed for high-volume production, where food is introduced at one end and comes out at the opposite end. Various strategies are applied to ensure the product is evenly and consistently processed within a continuous oil fryer system.

Chapter 2: What are Batch Oil Fryer Systems and How Do They Work?

Oil fryer systems are essential equipment in commercial and industrial food processing, and are primarily divided into two general categories: batch oil fryer systems and continuous fryer systems. These commercial frying systems break down further by their methods of power supply—most commonly electric fryers or gas fryers—and by construction type. Batch-style fryers are typically compact, manually operated, and are ideal for small-volume food production, while continuous fryers are engineered for high-capacity environments and demand significantly more energy, footprint, and setup. Understanding the differences and benefits of each style is critical for food manufacturers, restaurant owners, and catering operations seeking to optimize cooking efficiency, product consistency, and operational costs.

A vital element in maximizing the performance and lifecycle of any industrial oil fryer is its oil filtration system. Proper cooking oil filtration not only reduces operating costs by extending oil life, but also ensures superior food quality and greater equipment efficiency. Cooking oil in commercial fryers degrades with each cycle, affected by the amount and weight of food processed. To maintain the ideal fry quality, operators should monitor the oil turnover rate—a calculation based on usage volume and frequency. Routine oil filtration and replenishment of fresh oil are recommended to achieve optimal taste, food safety, and equipment longevity. High-performance cooking oil filter systems are especially important in fast-paced kitchens, large-scale snack production, and food manufacturing plants.

Batch oil fryer systems are engineered to cook food products in comparatively small batches, allowing for greater control over the frying process. Standard features of commercial batch fryers include removable fry baskets or racks for easy loading and unloading, precision temperature control, integrated or modular oil filtering systems, and efficient draining mechanisms. Batch fryers are available in a diverse array of designs, from compact countertop fryers for limited spaces to robust floor models for high-demand operations. The advanced filtration options for batch oil fryers often feature built-in filtration systems or the flexibility to pair with external mobile oil filter units, maximizing productivity and minimizing downtime.

One of the most significant advantages of batch oil frying systems is their energy efficiency and reduced oil consumption compared to larger continuous systems. These fryers offer improved control, as food is prepared for precisely timed intervals at a consistent and uniform temperature, promoting both high-quality output and lower operating costs. Batch fryers also excel in product versatility, ease of operation, and safety, making them a top choice for food preparation across snack foods, specialty products, quick-service restaurants, and institutional kitchens. Their adaptability makes batch fryers a favorite among chefs and food technologists focused on quality and flavor consistency for a wide variety of fried products.

A key subcategory within batch oil fryer design relates to heat transfer methodology: direct heating and indirect heating. With the direct heating method, the heat source comes into direct contact with the frying oil, commonly found in rectangular and circular commercial fryers, resulting in faster temperature response. Indirect heating, on the other hand, utilizes a heat exchanger that separates the heat source from the oil, thereby reducing oil breakdown and substantially increasing the operational life of the cooking oil—a critical factor in industrial-scale operations where oil replacement costs and waste reduction are important.

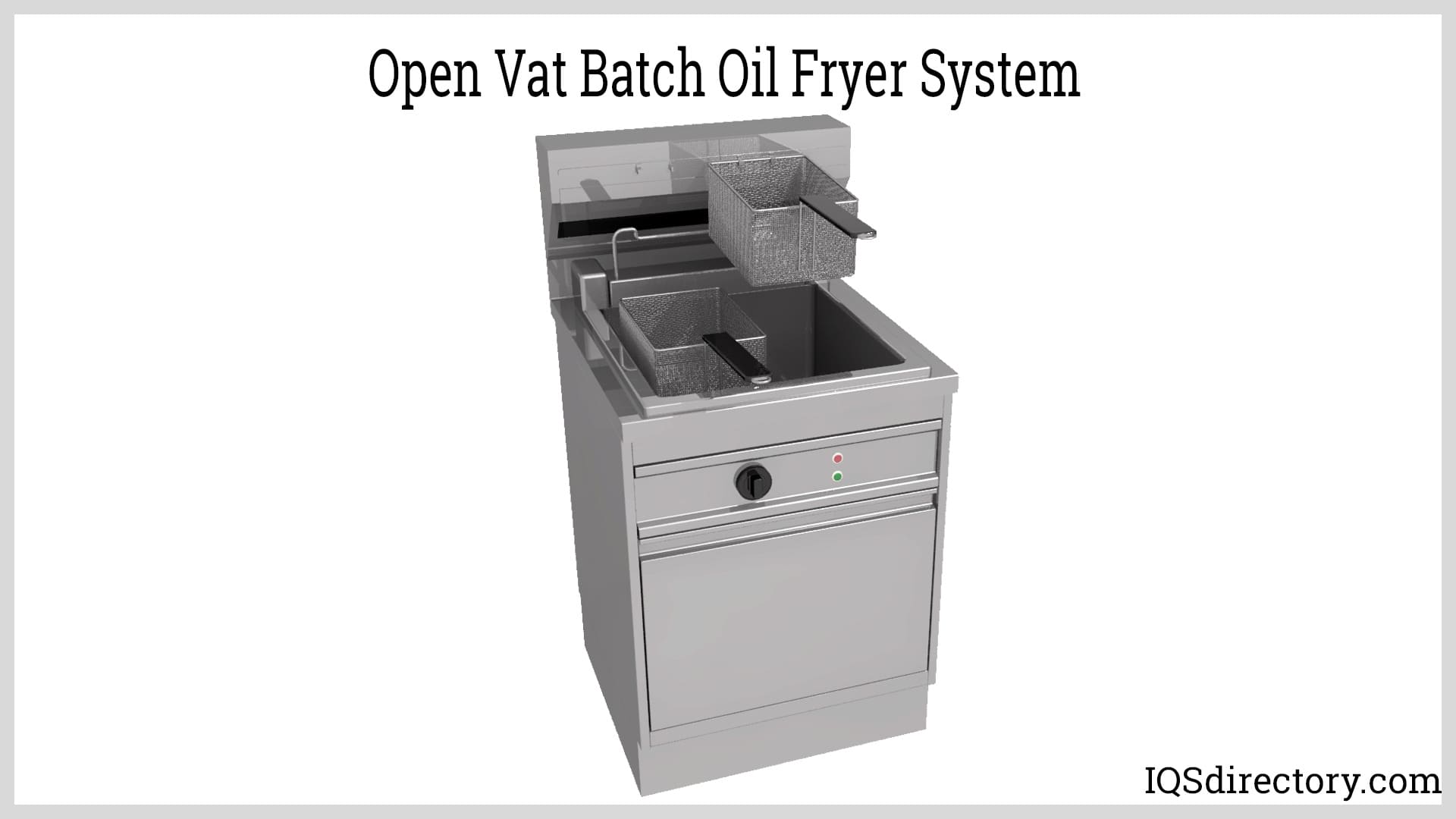

Open Vat Batch Fryer System

Open vat batch fryers are a widely used type of industrial fryer and are recognizable by their large, open vats. Similar in concept to residential deep fryers but on a far larger scale, these units enable food baskets to be lowered directly into the heated oil. Open vat fryers accommodate medium to large volumes and are valued for their rapid cooking times, minimal oil filtering cycles, and straightforward cleaning procedures. Both gas-fired and electric open vat fryers are available, allowing flexibility based on operational requirements.

Advanced open vat systems are equipped with computerized temperature controls that can quickly detect drops in oil temperature—such as when a new batch of food is introduced—and automatically signal the heating element to restore optimal frying temperatures, ensuring consistent product quality. Many open vat fryers feature multiple baskets for high-throughput cooking and stainless steel construction to comply with stringent food safety and sanitation standards required by health regulators and certification agencies.

Additional features often include particle screens to capture food debris, further protecting oil quality and simplifying maintenance. Open vat batch fryers are the go-to choice for restaurants, catering kitchens, and food processing lines requiring reliable performance, easy maintenance, and compliance with the latest food hygiene standards.

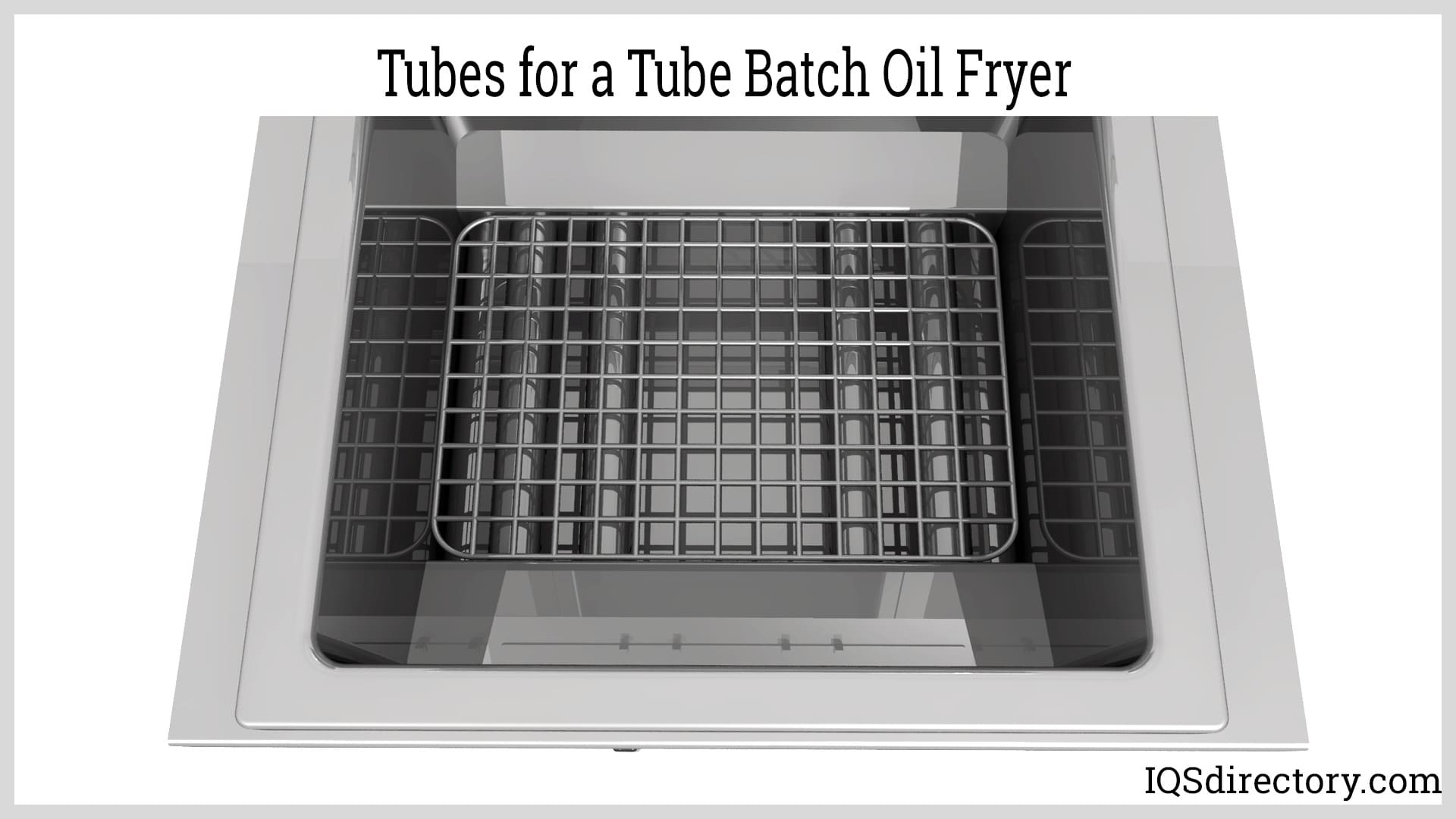

Tube Batch Oil Fryer System

Tube batch oil fryers are a specialized form of vat fryer, popular in commercial kitchens and food factories, known for their efficient gas heating technology. Heat is applied via tubes located at the vat's bottom, distributing warmth uniformly throughout the oil for consistent cooking performance and exceptional energy efficiency. Notably, tube fryers have a well-designed cold zone situated beneath the heating tubes, where food particles and sediment collect, preventing oil contamination and prolonging the useful life of cooking oil—a crucial feature for operations that prioritize cost reduction and quality control.

Construction details such as welded burner tubes and precision baffles enhance direct heat transfer and rapid recovery rates, making tube batch fryers a preferred solution for busy foodservice environments and large-scale snack manufacturing. The cold zone's impact on sedimentation reduces frequent oil filtration intervals, while the design maximizes oil yield and product quality. These features make tube batch oil fryers an optimal choice for businesses seeking both durability and efficiency in food frying processes.

Flat Bottom Batch Oil Fryer System

Flat bottom batch fryers utilize heating elements located underneath the fry pot, transforming the entire base into an efficient heat transfer surface. However, due to the absence of a cold zone, food fragments and sediment continue to cook and burn, requiring frequent oil filtration and generally limiting these fryers' applications to low-volume, specialty products such as tortilla chips, tempura, and other delicate snacks.

Operators benefit from a wide, unobstructed cooking area, as heating elements are external to the oil vat. This arrangement is ideal for preparing large, flat products or items that need even heat exposure. While flat bottom fryers are relatively high-maintenance due to increased cleaning frequency, their expansive cooking surface and precise temperature control make them well-suited for boutique food manufacturers and commercial kitchens producing artisan fried foods.

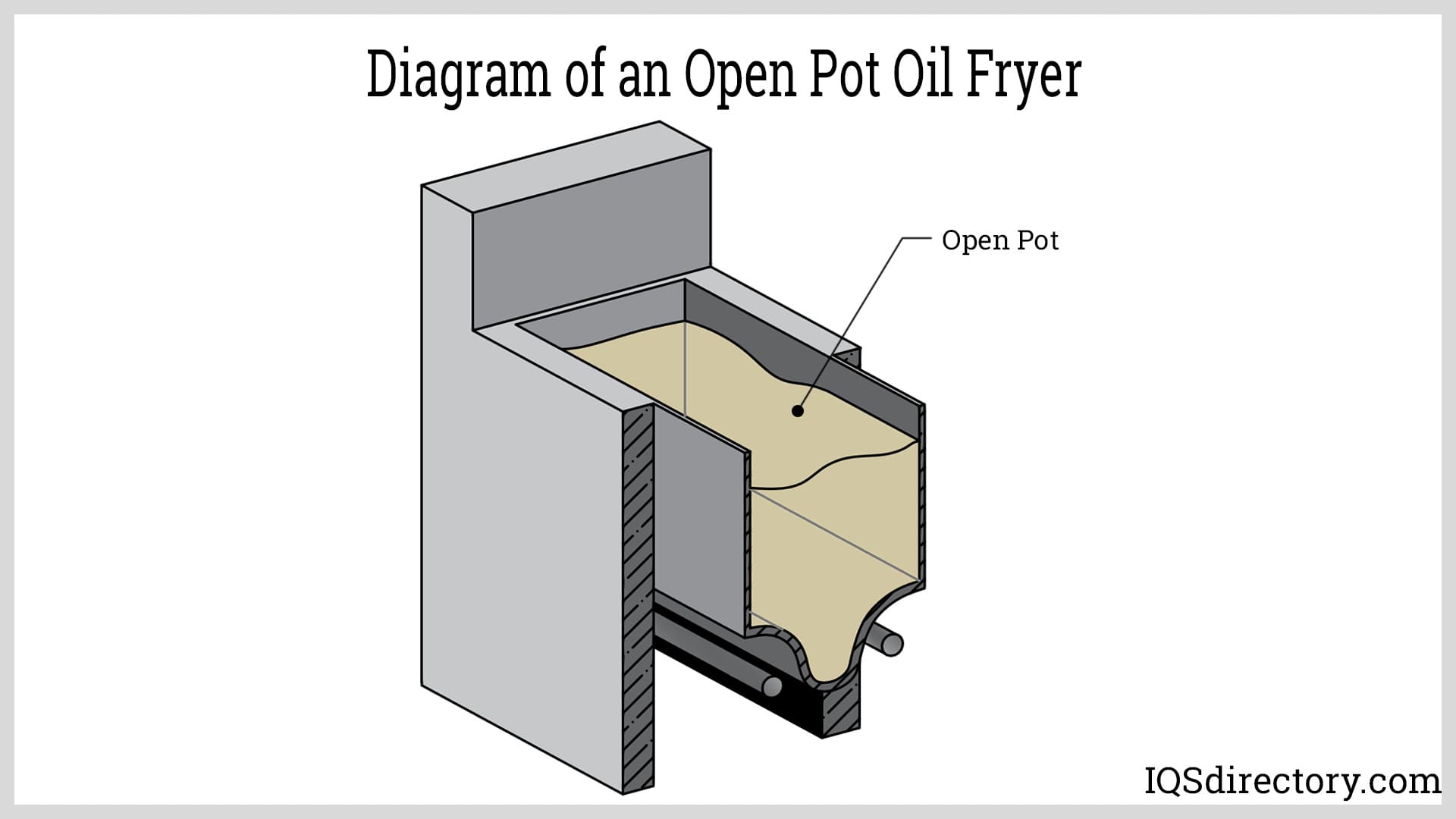

Open Pot Batch Oil Fryer System

Open pot batch oil fryers feature exterior heating elements, strategically positioned along the pot's rounded bottom but outside the main cooking area. This engineering creates a small cold zone at the base of the pot, below the heating elements, which helps trap sediments and minimizes oil degradation for products with lower particle output. Open pot fryers are easier to clean due to their accessible interiors and convenient drainage systems, reducing downtime and facilitating quick batch turnover.

With a design optimized for oil savings and ample space to accommodate larger batch sizes, open pot fryers are well-suited for high-volume, low-sediment foods and are commonly found in quick-serve restaurant kitchens and cafeterias. However, the limited cold zone restricts their use for products that generate significant sediment or breading. Their versatility and ergonomic configuration make open pot batch oil fryers a smart investment for efficient food production and streamlined maintenance.

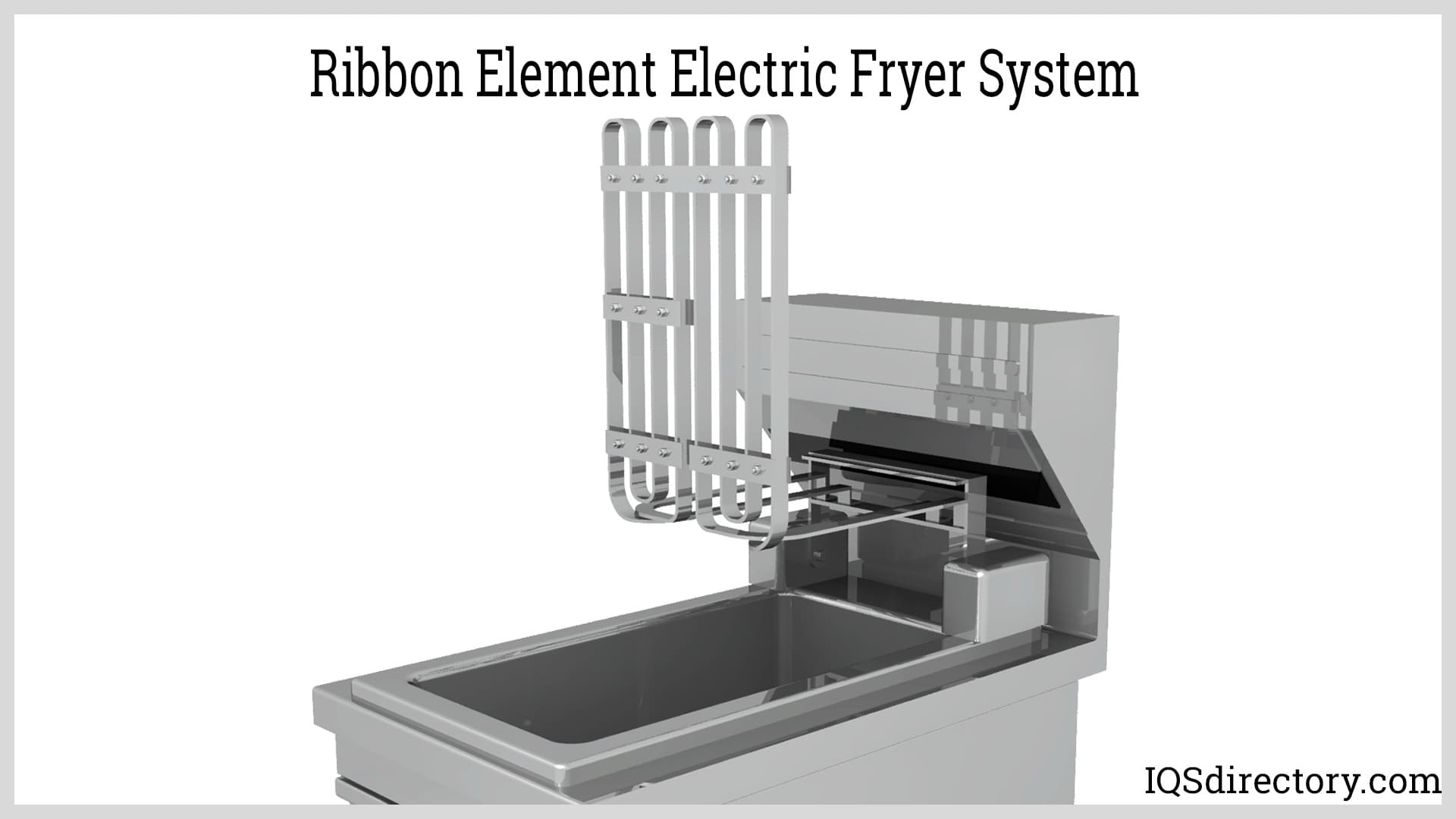

Ribbon Element Oil Fryer System

Ribbon element oil fryers merge the benefits of tube and flat bottom fryers by featuring a shallow vat and a ribbon-shaped electrical heating element beneath the oil. This innovative design achieves fast, uniform heating and rapid recovery—qualities highly valued in both food manufacturing and commercial restaurant operations. Ribbon fryers often have expanded fry pot widths, supporting higher batch volumes and enabling efficient cooking for products prone to flotation or clustering.

Powered exclusively by electricity, ribbon element batch fryers deliver quick heat-up times, reduced energy consumption, and straightforward maintenance due to the uncomplicated layout of the heating elements. These fryers are especially prevalent in high-output environments, such as snack food factories, commissaries, and specialty food kitchens, where speed, efficiency, and product consistency are top priorities.

The five types of batch oil fryer systems described above represent just a selection of the many available fryer technologies. Businesses today can choose from a wide spectrum of commercial batch fryers, with custom-engineered solutions available to address unique production requirements. Regardless of the batch fryer type, core features remain consistent: an oil vat or fry pot, a robust heating mechanism (electric or gas-powered), and advanced drain and filtration systems that ensure lasting performance.

Snack Fryer Systems by PPM

Snack fryer systems are a special form of fryer system that fries different types of snacks. They are a continuous flow system with temperature controls, oil filtration, and de-oiling. A typical snack fryer line includes an incline belt, in-feed conveyor, fryer, de-oiling belts, and system control mechanism. In cases where products require post processing, such as coating and seasoning, specialized drums, seasoners, oil applicators, and slurry applicators are available that apply dry powder, liquid, and various forms of slurry.

BatchWright Kettle Chip Fryer

Kettle chip batch fryers require precision control over the frying temperature to achieve the distinctive crunch of kettle chips. During the cooking process, it is essential that the exact oil temperature be maintained. When the product enters the oil fryer, the temperature drops, then stabilizes, and rises to a consistent and uniform temperature as the product moves through the system. The close attention to control produces kettle chips with the proper texture, color, and quality for all batches.

A kettle chip processor system is designed for chips made from potatoes, sweet potatoes, parsnips, carrots, and root vegetables. It is an immersion tube heating system with a burner that can be customized and has high fuel efficiency. A necessary feature of kettle chip processing systems is an agitator that prevents chips from clumping to ensure uniform cooking. An extra protection for cooking quality is a non-stick stir arm mounted on a trolley that is used to prevent product from derailing during processing.

Kettle chip processor systems feature a hood down structure that prevents oil splashing, increases operator safety, and removes the need for replacement ventilation. Aside from its other special features, the hood down design of kettle chip processor systems helps lower installation costs and makes the fryer immediately available. The fully enclosed hood protects workers from being exposed to hot oil.

The lifting drum filter of the BatchWright kettle chip fryer provides continuous sediment removal enabling the fryer to run for ten days before being cleaned. The uniquely designed process preserves oil quality, which extends the operational life of the BatchWright kettle chip fryer.

Seasoning and Coating

A critical aspect of snack frying is the addition of coatings and seasonings that enhance and add to the flavor of snacks. PPM has a full line of seasoning and coating equipment that provides a high performance and cost effective solution for difficult food industry applications. The design of PPM seasoning and coating equipment provides accuracy, consistency, and exceptional repeatability, whether it is applying oils, powders, slurry mixture, or particulates.

-

Coating Drum - Coating drums are made from plastic or stainless steel with different diameters and lengths to fit the requirements of an application. A critical part of the construction of a coating drum is its flight angle for optimal distribution of coatings or seasonings. Coating drums are customizable and can be mounted on casters for portability, which allows for adjustment of the discharge angle.

PPM Coating Drum

-

Flavor Seasoner - Flavor seasoners are designed to dispense free flowing seasonings, salts, and small particulates. PPM flavor seasoners have two variable speed drives for efficient speed control for the ingredient agitator and dispensing auger. Due to the nature of the products a flavor seasoner dispenses, it has quick access for cleaning, sanitation, and changeover of products. In accordance with FDA regulations, the flavor seasoner design has a bottom dump door, quick release auger and agitator, dual sight windows, and top fil grate, which can be easily cleaned and sanitized.

PPM FlavorWright Seasoner

The flavor seasoner and coating drum are examples of the types of equipment that work in tandem with snack fryer systems to flavor and coat snack products. In addition, for special applications, standard seasoning and coating equipment can be customized and adapted to meet the requirements of unique and unusual applications.

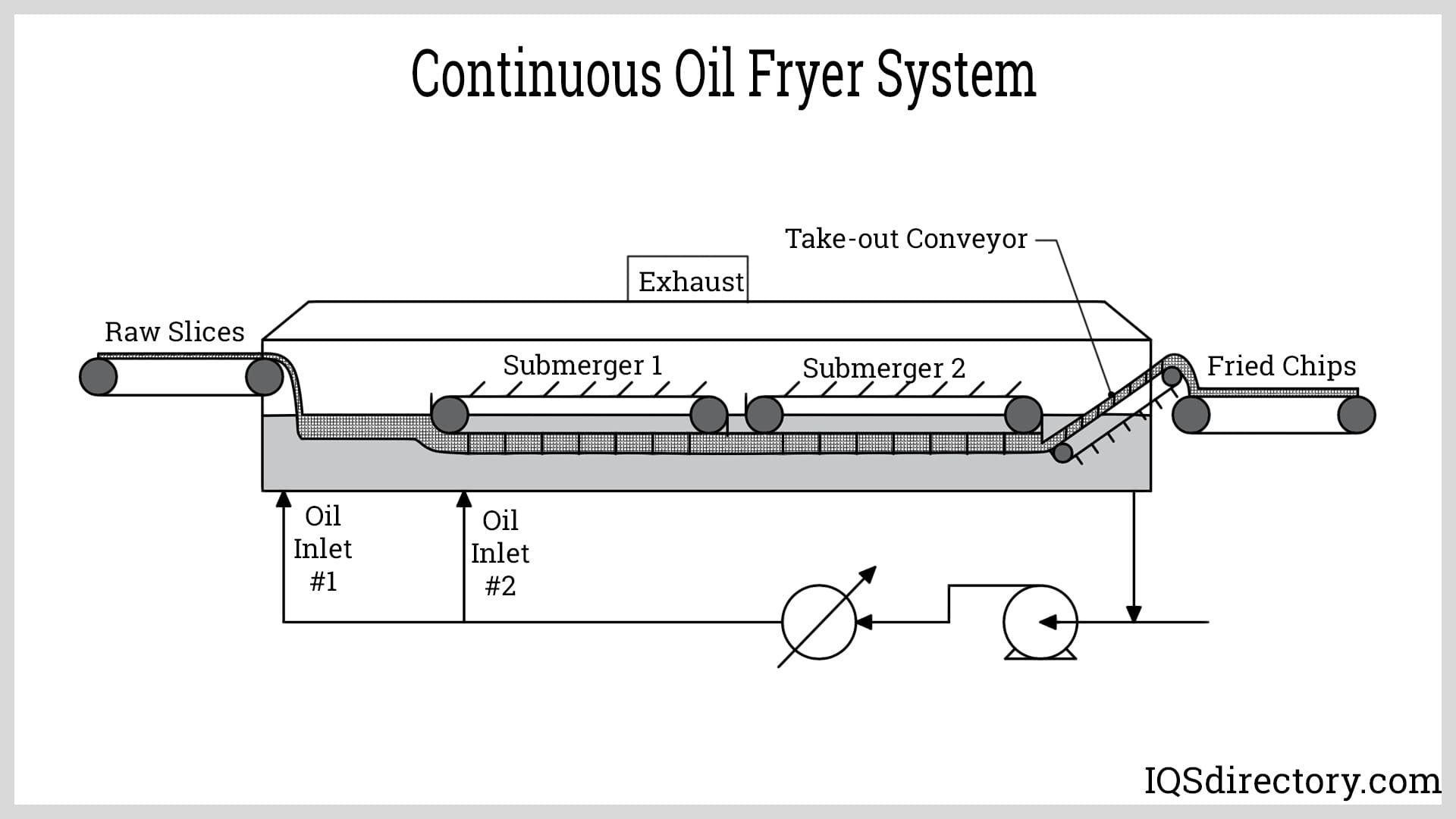

Chapter 3: What are Continuous Oil Fryer Systems?

In contrast to batch oil fryer systems, continuous oil fryer systems are large industrial deep fryers designed for uninterrupted, high-capacity food frying. These advanced fryer machines are essential in modern large-scale food processing, enabling consistent, efficient cooking for commercial kitchens, quick-service restaurants, industrial snack production lines, and global food manufacturing operations. Utilizing a sophisticated oil recirculation and filtration system, continuous oil fryer systems not only maximize the quality and safety of fried food products, but also significantly reduce operating costs through oil life extension and energy efficiency. These fryer systems play a pivotal role in maintaining product consistency, minimizing labor, and meeting growing consumer demand for high-volume fried foods like potato chips, chicken nuggets, and snack pellets.

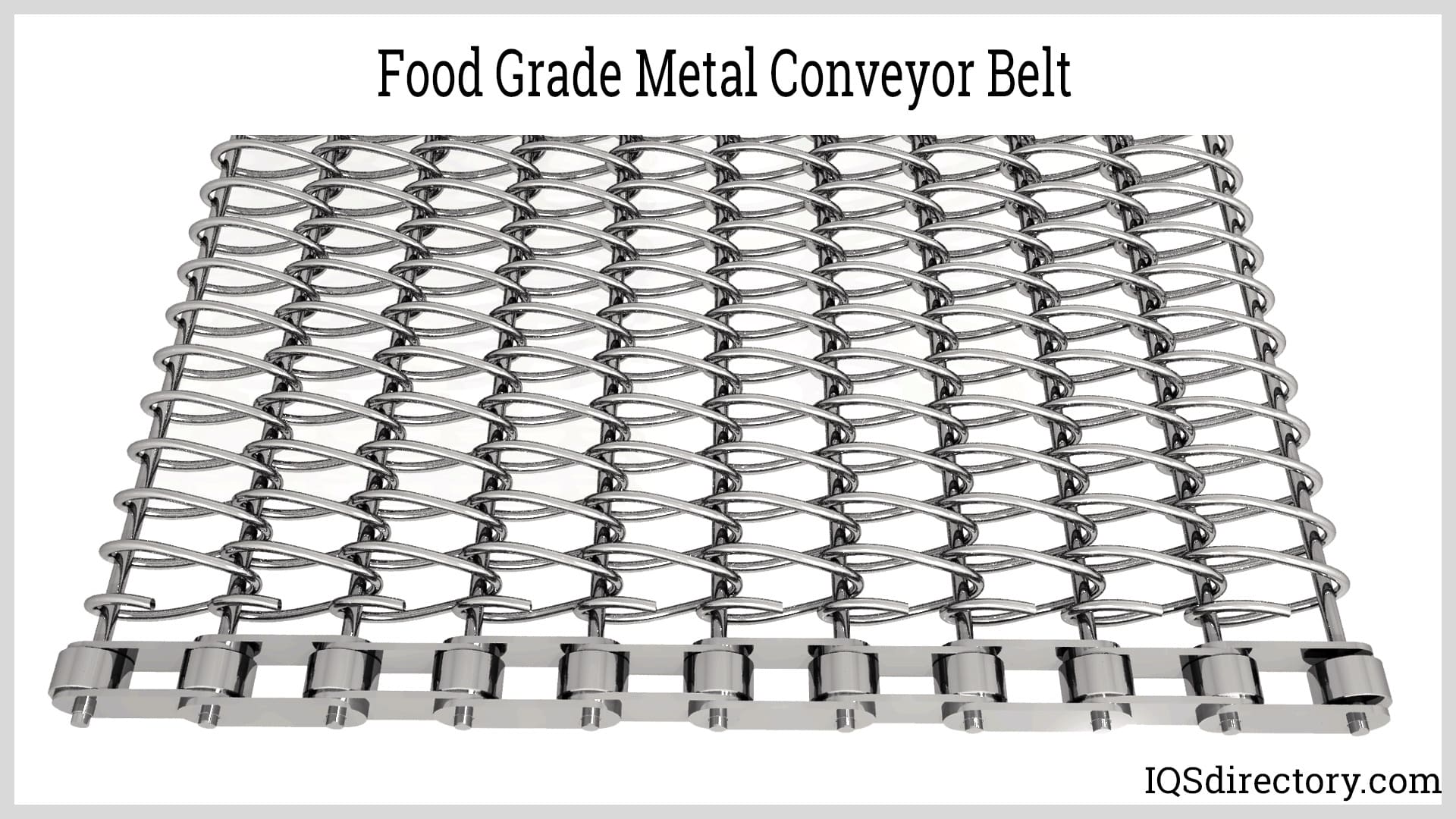

Conveyor Belt System

The feeding mechanism for a continuous oil fryer system features an industrial-grade metal conveyor belt engineered to transport food products smoothly into the oil bath. Conveyor belt systems built specifically for the food industry are fabricated from galvanized steel, carbon steel, mild steel, or corrosion-resistant stainless steel, all of which provide exceptional durability, food safety compliance, and high thermal endurance. These metals withstand oil frying temperatures exceeding 600°F (315.6°C) and comply with stringent FDA food handling standards, ensuring reliable performance during continuous operation.

Automated loading of food items onto the conveyor belt allows for even distribution and optimized product throughput. Food can be deposited from upstream conveying systems or via manual placement, depending on the desired level of food processing automation. As the conveyor belt continually moves forward, it lowers the evenly spaced food pieces into the heated oil bath, initiating the immersion frying operation and promoting optimal oil contact and airflow for uniform cooking.

To keep food fully submerged and prevent floating or clumping during frying, an upper restraining conveyor belt system runs parallel above the loading belt. This ensures even exposure to cooking oil, resulting in consistent product quality. The synchronized speeds of the dual conveyors are critical to control fry time, allowing precise temperature profiling and cook control across the fryer length.

Oil Bath

The oil bath, or oil tank, serves as the core cooking zone within a continuous oil fryer system. Here, food is completely immersed in hot, filtered cooking oil—typically maintained between 350°F and 375°F (175°C to 190°C) for optimal frying results. Adjustable conveyor belt height and customizable belt speed accommodate a wide variety of food products, from battered proteins to extruded snacks and coated vegetables. Continuous oil filtration systems draw oil from the bath, process it through advanced oil filters, and promptly return clean oil to maintain both oil quality and food flavor integrity during nonstop production.

Cooking

Food loaded onto the conveyor moves into the oil bath, where it is immersed and fried through direct contact with hot oil. This method, known as immersion frying or submersion frying, rapidly cooks food by removing surface and internal moisture, facilitating even heat transfer and the formation of a desirable crisp coating. The fast cooking process not only locks in flavor and juices, but also delivers the crispy texture and appetizing appearance consumers expect from premium fried foods. This high-efficiency frying technique minimizes oil absorption, helps extend oil life, and supports consistent, reproducible product results.

Cooling

After leaving the hot oil bath, fried products enter a controlled cooling zone that rapidly reduces their temperature. Efficient cooling is vital for food safety, preventing overcooking or oil retention, and preparing products for subsequent processing steps such as seasoning, inspection, or automated packaging. Modern continuous fryer systems may utilize air cooling tunnels, conveyorized cooling belts, or chilling zones—each monitored with temperature sensors and feedback controls to ensure production throughput and quality assurance in commercial food manufacturing environments. Continuous monitoring of the cooling phase contributes to safe handling and long-term product shelf life.

Continuous Oil Fryer System Filters

An advanced oil filtration system is essential for continuous fryer operation, removing particulate matter and maintaining high oil quality across multiple cooking cycles. Integrated fryer filtration systems or self-contained filter units continuously circulate oil from the oil bath, eliminating food debris, carbon particles, and burnt residues that could impair product taste, cause oil degradation, and increase maintenance requirements. Continuous filter mechanisms, including gravity-fed or vacuum-assisted filter paper systems, offer enhanced filtration efficiency and operational cost savings—critical for industrial food processors demanding stringent hygiene and product consistency.

Specialized continuous fryer oil filters extract micron (µ) and submicron-sized fines by running heated oil over conveyor-driven filter paper or mesh filter belts. The gravity settling and filtration action separates impurities, ensuring only purified frying oil returns to the tank. As filter paper becomes saturated, the system automatically advances fresh paper for uninterrupted filtration. This process not only preserves oil clarity and extends oil replacement intervals, but also helps comply with environmental and food safety regulations regarding fryer oil management and waste disposal.

Oil filter systems are configurable for different fryer models and food products by selecting suitable filter paper porosity, belt material, and filter bed configurations. The combination of heat-compatible steel rods and tightly woven mesh patterns supports reliable filtration at scale, making continuous oil fryer systems a preferred choice for high-volume frying applications such as potato chips, tempura products, tortilla chips, and plant-based snacks. Proper oil filtration also reduces carbonization, lowers operational costs, and supports sustainable food production practices.

This type of oil filtering method represents just one approach in a spectrum of industrial oil filtration technologies, which include centrifugal filters, pressure leaf filters, and magnetic oil purification systems. Many advanced continuous oil fryer systems integrate inline filters and easy-clean filter access, contributing to reduced downtime, minimal oil wastage, and maximum output efficiency.

Monitoring and Control

Continuous oil fryer systems are sophisticated industrial frying machines equipped with state-of-the-art automation and process controls for precision cooking. Temperature management, product dwell time, conveyor speed, and oil quality are monitored by advanced sensors and programmable logic controllers (PLC). This real-time data-driven control ensures repeatable fry results, food safety compliance, and energy efficiency vital to large-scale food operations.

Automatic control systems adjust oil temperature, monitor and display live process metrics, and issue alerts for deviation or maintenance. Integrated touch screens or HMI interfaces allow operators to configure, monitor, and modify fryer performance parameters to suit various product specifications and production schedules. Automated cooking time tracking guarantees accurate immersion periods, crucial for safe food processing and product consistency.

Unlike manual batch fryers, continuous oil fryer systems provide far greater operational oversight, limit risk of human error, and support smart factory integration for data logging, quality assurance, and remote diagnostics. Continuous monitoring of oil health—such as measuring free fatty acid content, color indexes, and filtration effectiveness—helps processors proactively manage production quality, extend oil life cycles, and achieve higher output yields with reduced waste.

These robust automation and monitoring technologies make continuous oil fryer systems indispensable for food manufacturers aiming for high throughput, consistent quality, food safety, and cost optimization in their frying operations.

Frequently Asked Questions

What is the key difference between batch and continuous oil fryer systems?

Batch oil fryers cook food in small quantities with enhanced control and energy savings, while continuous oil fryer systems are engineered for uninterrupted, high-volume production, utilizing conveyors for nonstop frying and automation for consistency.

How do oil filtration systems improve fryer performance?

Oil filtration systems remove food debris and contaminants, extending oil life, maximizing food quality, and increasing equipment efficiency. Advanced filters minimize waste, support food safety, and ensure reliable and cost-effective frying operations.

What specialized batch fryer designs are best for delicate or sediment-heavy foods?

Open vat, tube, and flat bottom batch fryers each offer unique benefits. Tube fryers utilize cold zones for sediment control, while flat bottom fryers suit delicate snacks but need frequent oil filtration due to sediment accumulation.

How does automation enhance the operation of continuous oil fryer systems?

Automation integrates programmable controls for temperature, dwell time, and oil quality in continuous fryers. These systems maintain product consistency, reduce human error, enable real-time monitoring, and support efficient, large-scale food production.

Which oil fryer features are important for commercial kitchens seeking operational efficiency?

Features such as rapid heat recovery, built-in filtration, adjustable temperature controls, multiple baskets, and easy-clean construction are crucial. These promote energy savings, quick turnaround, product versatility, and compliance with food safety standards.

What are the main considerations for choosing an oil fryer system for a U.S. commercial food business?

Key considerations include production scale, available space, energy source (gas or electric), filtration capabilities, compliance with FDA and food safety standards, and the diversity of products to be fried within U.S. regulations.

Chapter 4: What are the Different Types of Fryer Oil Filters?

The types of fryer oil filters are divided into manual, mechanical, and types of filtering methods. The determination of the type of fryer oil filter is dependent on the size of an operation and the quantity of fryer oil used. Small, mom and pop kitchens can filter their fryer oil manually since they normally have a single fryer that uses a small limited amount of oil. Large, fried food producers with continuous oil fryers require technologically advanced fryers that use a high volume of fryer oil.

Regardless of the size of an organization, the filtering of fryer oil is a necessity, cost saving, and environmentally responsible. Unlike fryer oil that is used for home cooking, organizations that use frying oils to produce their products purchase fryer oil in bulk, which can cost from $36 a container up to over $100 a container depending on how many pounds of frying oil is purchased. Being able to reuse frying oil, by filtering and cleaning it, can help a company realize substantial savings.

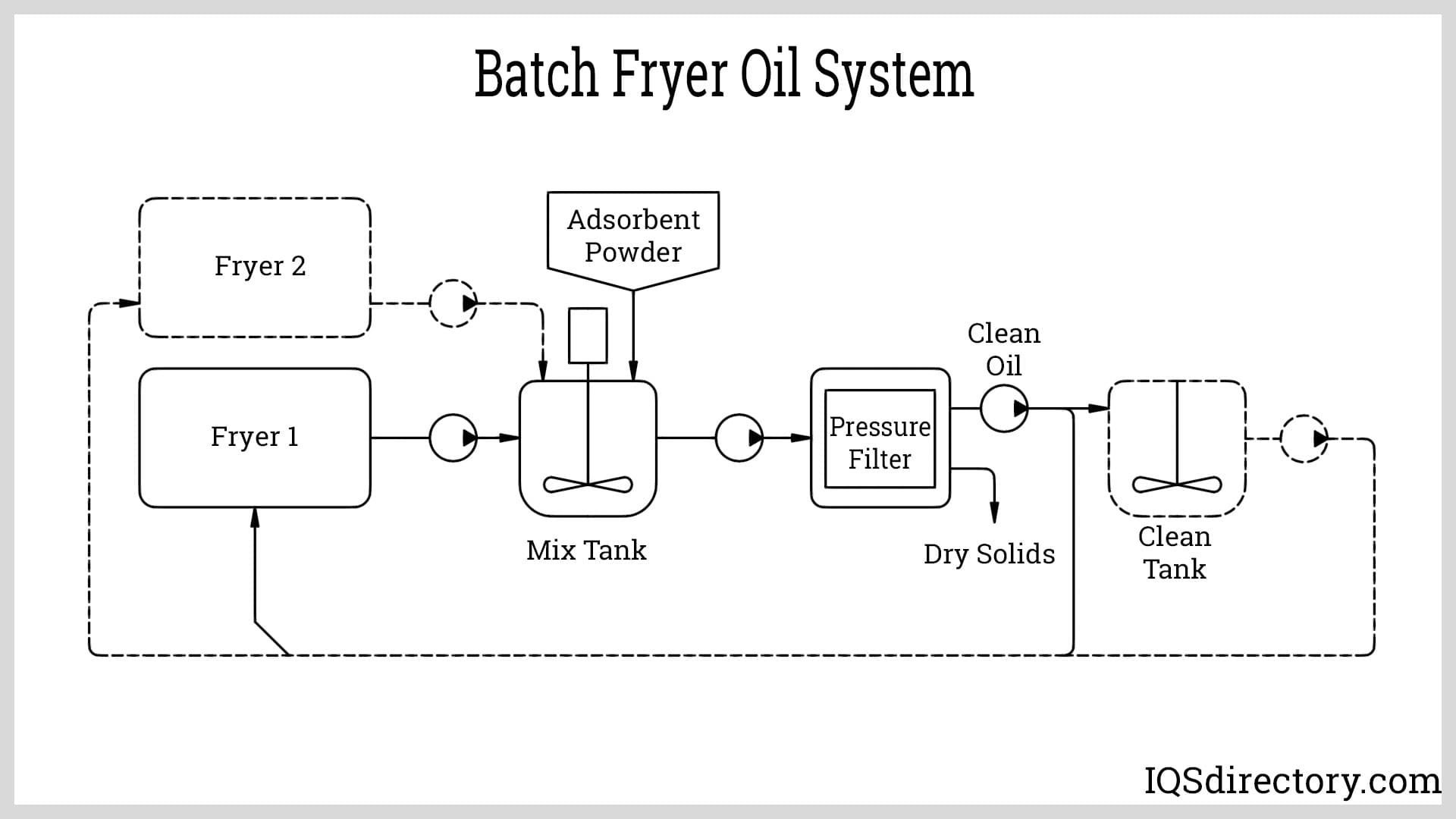

Continuous Fryer Oil Filter System

Continuous fryer oil filter systems are a high-capacity filtering system that is similar to the continuous fryer oil filter system. The continuous fryer oil filter treatment method has a complex set of steps that is used with high volume fryer oil filtering. The system is very similar to an industrial process and is designed for filtering fryer oil from industrial cooking and kitchens. The goal of the process is to remove free fatty acids (FFA), fines, and other impurities.

The structure of a batch fryer oil filter system includes a pressure filter, a mix tank, feed pump, and FFA powder. The system is designed for extremely high capacity and high-volume filtering. The process begins with hot fryer oil being sent from the fryer to the mix tank where it is exposed to FFA powder, which absorbs the free fatty acids. With the fatty acids removed, the fryer oil moves to the pressure filter chamber where 1 µ solid particles in the fryer oil are trapped and removed by the filter in the upper chamber of the pressure filter. The clean oil moves from the pressure filter tank to a clean fryer oil tank from which it is sent back to the fryers. Once the mix tank is refilled, the process is repeated.

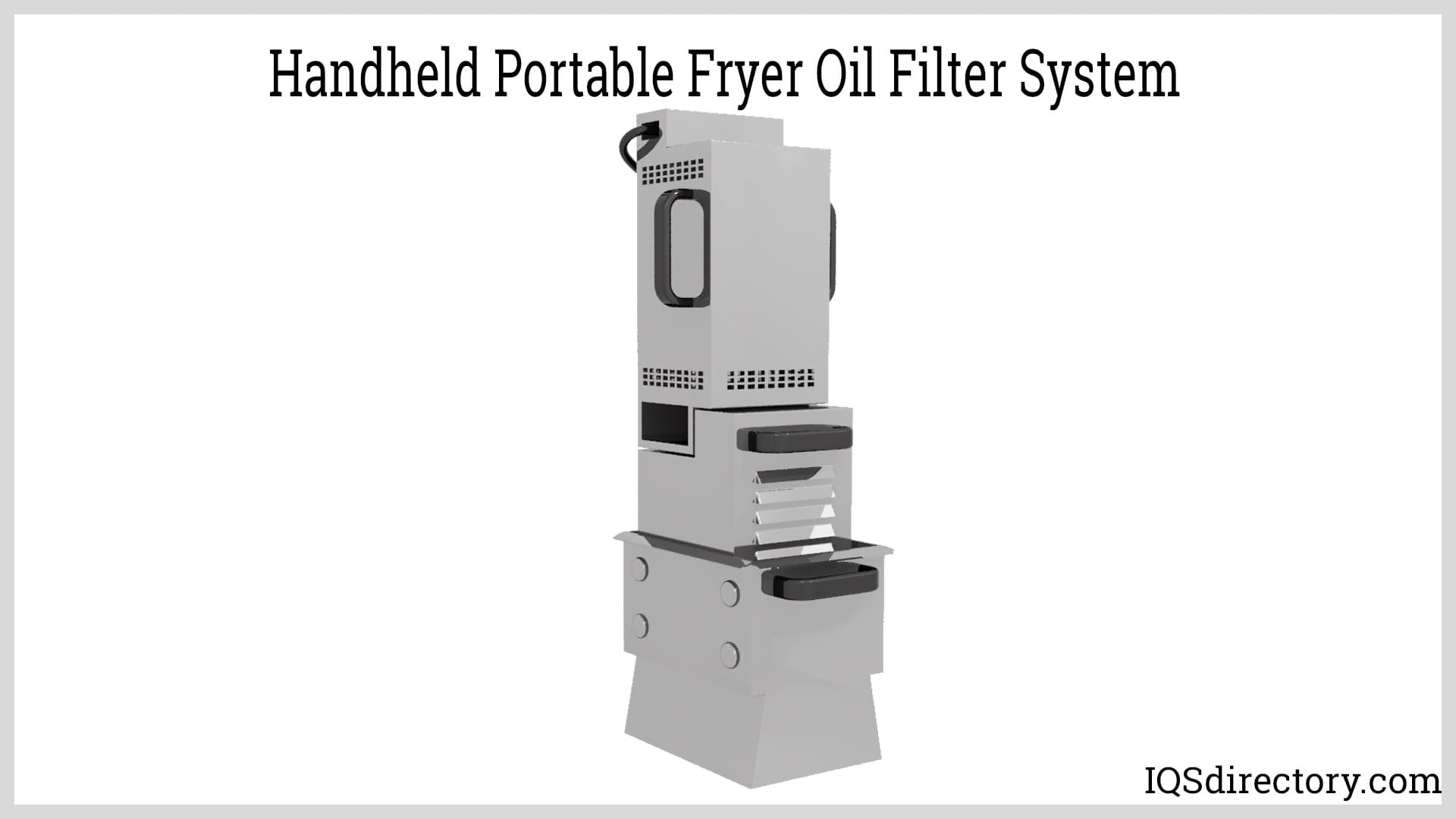

Portable Fryer Oil Filter System

Portable fryer oil filter systems are a high-performance fryer oil filter solution that is light enough to be used in any sized kitchen. They are available in several forms from hand held versions to ones that are on wheels. Portable fryer oil filter systems have a rotor that is similar to larger fryer oil filter devices and filtering mesh that is made of various types of filtering materials.

The different sizes of portable fryer oil filter systems make them adaptable for any size kitchen and frying application. Portable fryer oil systems are used with stand alone gas fryers, cooking centers, and pressure fryers. The key to any type of fryer oil filter system is the rate at which it filters fryer oil. Although portable fryer oil filter systems do not have the capacity of larger more complex filtering systems, they are capable of filtering fryer oil in minutes, which makes them ideal for a fast-paced cooking environment.

Paperless Fryer Oil Filter Systems

A common form of fryer oil filter system is a paperless system that uses layers of stainless steel to remove fine and impurities as small as 100 µ. They are a cost saving type of fryer oil filter system that efficiently cleans oil during the frying process. Paperless fryer oil filter systems have to be frequently cleaned using a dishwasher or scrubbing in hot water with dish soap.

The use of paperless oil filter systems is a cost cutting method that saves on the purchase of paper filters. They can be built into a fryer or come as part of a portable fryer oil filter system.

Lifting Drum Oil Filter

Lifting drum oil filters are an innovative filter design that removes solid matter from oil on snack fryer systems. Their unique design enables snack fryers to work continuously for long periods without the need of maintenance. Lifting drum oil filters are highly efficient and assist in maintaining oil quality during food processing. Their quick efficient action makes it possible for oil fryer systems to run continuously. The drum of the filter is covered with a fine mesh that enables it to capture and remove the smallest particulate matter.

Aside from their exceptional efficiency, lifting drum filters are capable of removing extremely fine particles to assist in cleaning frying oil. With oil fryer systems, lifting drum oil filters are fully automated, which makes them low maintenance. The compact design of lifting oil filters makes them ideal for oil fryer systems.

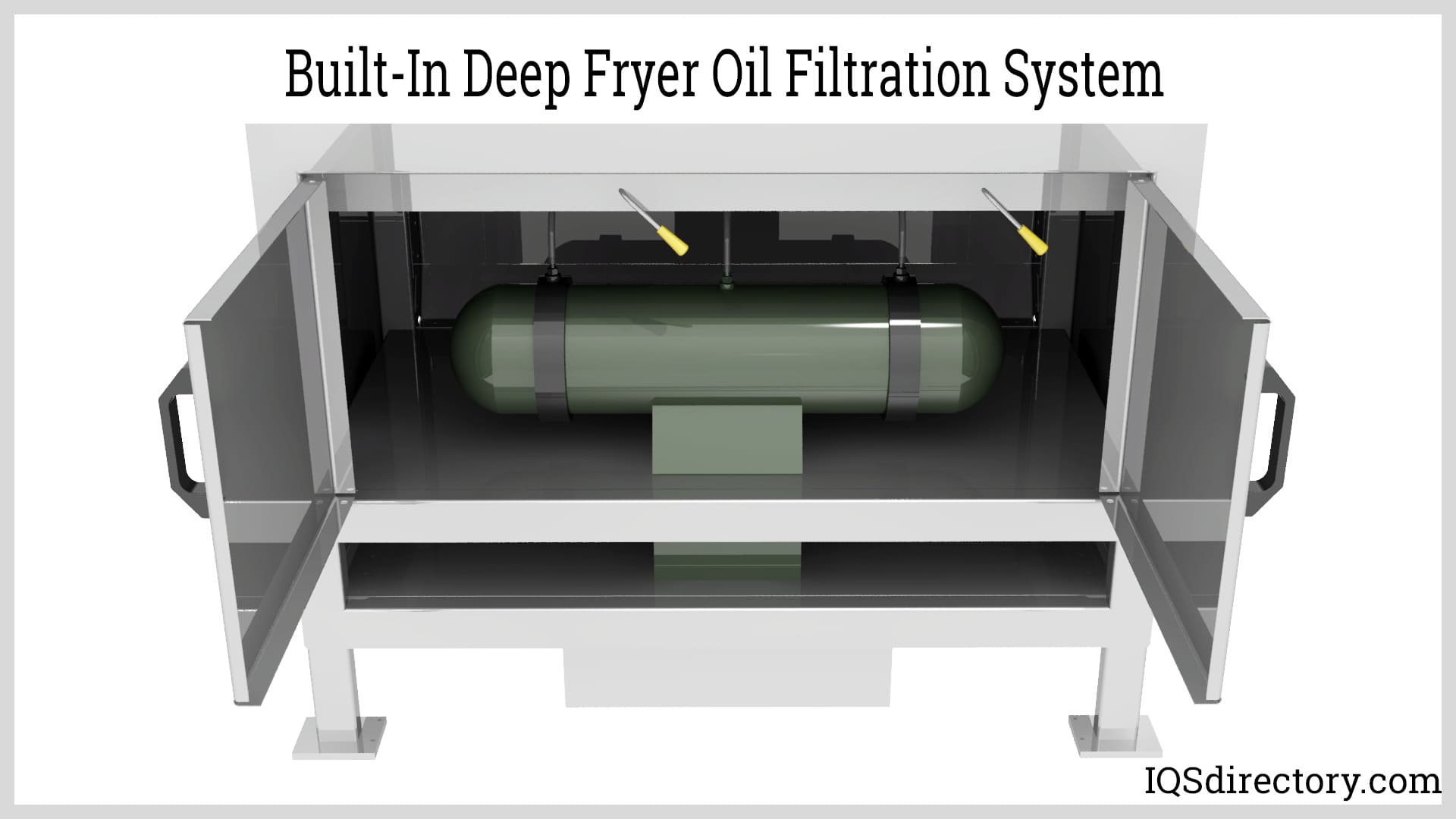

Built-in Fryer Oil Filter System

An efficient and high-quality method for fryer oil filtration is having the fryer oil filter system built-in to a fryer. Built-in fryer oil filtration systems are available for all forms of fryers. The filter system is connected to the fryer by a drain at the bottom of the fryer. The filtering process involves pulling a lever to drain the oil from the fryer into the filtering drawer and pulling a lever to open the return valve and activate the pump that returns the fryer oil to the fryer vat.

When the drain at the bottom of the fryer is opened, fryer oil passes through a drawer that contains a filter screen and filter envelope that catch residue, fines, and sediment that darken the fryer oil. The pump in the system returns the cleaned fryer oil to the fryer vat. Once the fryer oil has been returned to the vat, the frying process can be resumed. The large manifold of the system allows for fast draining. The filter system prevents pump clogs and allows for smooth movement of fryer oil.

One of the dangers of working in large kitchens is the handling of fryer oil. The use of a built-in system enhances the safety of the workplace and protects workers. The fewer times that fryer oil is handled increases safety and provides for a smooth and efficient frying process.

Portable Fryer Oil Filters on Wheels

Portable fryer oil filters on casters or wheels come in several forms with some having four wheels while others have only two wheels. In addition to the variations in wheels, there are differences in how they filter, the type of filter, the amount of power they require, vertical or horizontal orientation, and how many pounds of fryer oil they can process. Although there are similarities between manufacturers, each manufacturer has their own proprietary fryer oil filtering process.

The casters on portable fryer oil wheel filters make it easy to move the filter and position it for use with a lift off filter pan for easy cleaning or replacement of the filter. The flexibility of portable fryer oil wheel filters makes it possible to filter any type of fryer from counter top ones to floor models with or without drains. A differentiating factor for portable fryer oil wheel filters is their capacity, which can vary from 50 lbs. and 55 lbs. up to over 100 lbs. (22.67 kg and 25 kg up to over 45.36 kg).

The operation of a portable fryer oil filter on wheels includes placing the mobile fryer oil filter next to the fryer and draining the oil in the fryer into the portable fryer oil wheel filter’s crumb pan located above its filter, which can be a paper filter or metal mesh filter. Once the oil has been filtered, it is pumped from the portable fryer oil filter on wheels back through a hose and wand into the fryer.

Fryer Oil Filters Capacity

Part of the selection process for determining the right fryer oil filter for an operation, restaurant, or kitchen is knowing the required capacity for efficient fryer oil filtering, which is dependent on how often fried foods are required. More frequent frying requires the use of a fryer oil filter with a capacity well over 100 lbs. while less frequent frying can make use of a fryer oil filter that is less than 100 lbs.

-

40 to 80 Pound Fryer Oil Filters – Fryer oil filters with a 40 to 80 lb. (18 kg to 36kg) capacity are used with drain type fryers. They are compact, which makes them ideal for small kitchens and small operations. To comply with health requirements, smaller fryer oil filters are made of stainless steel with hoses, pumps, and motors that are able to withstand high temperatures. Small fryer oil filters are easy to assemble and operate. Regardless of their small size, they work quickly and efficiently with a sturdy hose assembly and easy access to the filter and crumb pan.

-

130 to 210 Pounds Fryer Oil Filters – The choices for high capacity 130 to 210 pounds (59 kg to 95 kg) fryer oil filters include extremely high-capacity fryer oil filters that function like large production machines. The varieties of fryer oil filters with high capacity include large continuous fryer oil filters and extremely high-capacity batch fryer oil filters that process several hundred pounds of fryer oil and large portable fryer oil filters that function like smaller fryer oil filters but with a higher capacity.

Higher capacity fryer oil filters tend to be more complex than small portable fryer oil filters and require oversight and monitoring. In many cases, they process fryer oil faster and more efficiently and return oil to storage tanks. This type of fryer oil filter involves several steps with each step planned and programmed into the system.

The fryer oil filtering methods described above are a small and general description of the many different fryer oil filtering methods that are available from manufacturers who work with their clients to find fryer oil filter solutions that perfectly fit the client’s needs. The fryer oil filtering process is a valuable tool for lowering costs, improving fried products, and increasing efficiency. Working closely with manufacturers and distributors, restaurants, kitchens, and food producers are able to find fryer oil filtering processes that fit their fryers and the needs of their workers.

Oil Fryer System Filter Process

There are several factors that define and characterize the fryer oil filter process. In many cases, the method of filtering, manual or electric, is the initial parameter that determines how fryer oil is filtered. In all cases, the goal of fryer oil filtering is to clean, purify, and prepare fryer oil for frying high quality foods.

In general, fryer oil filtering is a passive process, active process, or a combination of active and passive with the passive process involving the use of a filter while the active process involves the use of chemicals. In either case, the end goal is to remove contaminants, impurities, fines, and other matter from fryer oil.

The process of fryer oil filtering is an essential part of food preparation since its effects influence several aspects of food preparation. The foundational principles upon which fryer oil is filtered are cost savings and quality. It is very obvious that changing fryer oil after each time it is used is inefficient and expensive since fryer oil is one of the most expensive costs of an industrial kitchen.

The quality of prepared food and its taste is what keeps customers coming back, which is a foundational principle of running any business. Used and unclean fryer oil produces off flavors and is dirty and contaminated, a combination of factors that lowers the quality of food. Fryer oil filters ensure exceptional quality, high performance, and customer satisfaction.

The conceptual framework in regard to quality frying is built on six elements, each of which refers to proper care and maintenance of frying equipment with the final two elements being removal of contaminating materials from fryer oil and proper filtration. Of the six basic ideas, the proper and efficient filtering of fryer oil yields the greatest benefits and rewards. Passive filtration and active filtration are the general forms of fryer oil filtration.

Passive Filtration

Passive filtration is defined as a mechanical process where fryer oil is passed through a filter made of paper, fabric, or metal screen. The passive process is able to remove particulate matter as small as 2 mm, 4 mm, or 50 µ. Various forms of mechanical filters have the potential of filtering particles lower than 1 µ.

The passive filtering process can be completed using one of the various types of fryer oil mechanisms or by simply pouring fryer oil from the fryer, by hand, through a filter into a bucket or barrel. Passive filtration is completed frequently on a regular schedule, which is determined by how much is being cooked and how often.

The steps for passive filtration involve removing fryer oil from the fryer through its drain valve from which the fryer oil empties into the fryer oil filter device. During the process, the fryer is off. The fryer oil unloads into the filtering mechanism, which can take several shapes and forms and is dependent on the size and type of kitchen. Draining of the oil is the first of other steps that are necessary for the filtering process with each step designed to ensure the oil and fryer are cleaned of impurities.

Active Filtration

The active filtration process is referred to as fryer oil treatments and is a complex and intricate system for removing particulate matter and oil soluble matter. Active filtration involves the use of powders, impregnated paper or pads, and paper coated with active powder. The process for active filtration reduces oil impurities physically and chemically while removing suspended materials in fryer oil.

Fryer oil filtering is a method for repurposing and reusing fryer oil. It does not return fryer oil to its original condition since initiating frying permanently damages fryer oil, a process that cannot be reversed. The use of active and passive treatments and filters slows the degradation of fryer oil, makes it usable, and extends fryer oil’s useful life.

Chapter 5: What Are the Different Fuel Types for Oil Fryer Systems?

The choice of fuel or power for an oil fryer system is dependent on a few factors beginning with the availability of fuel types in a company’s area. The two basic types of fuel for oil fryer systems are electricity and gas that are contracted with local energy providers. A third type of fuel that can serve as an alternative to the common fuels is propane.

Natural Gas

Natural gas tends to be the first choice for a fuel source for oil fryer systems since it puts out high amounts of heat (BTUs) that is easily absorbed by the oil by direct or indirect heat from the natural gas. The wide use of natural gas is due to how quickly and efficiently it heats the oil to the needed cooking temperature. In addition, it maintains the temperature throughout the cooking process with exceptional consistency.

A restriction on the use of natural gas as a fuel source is access to a hardline since it is not portable. In many instances, buildings will have multiple electrical outlets but no gas connections. Working with utility companies and natural gas providers, it is possible to examine alternative methods for getting natural gas service.

Continuous oil fryer systems depend on natural gas as their heat source since natural gas is less expensive than electricity and heats up rapidly. All high volume food production facilities that use continuous fryers are hardlined to natural gas lines.

Electricity

Electricity is universally available and easily accessible. It is normally used for batch oil fryers with low capacity. Electricity is the most versatile of the fuel choices due to its wide availability. Of the various methods used for oil fryer systems, electricity is the least efficient since it takes the longest to heat cooking oil and has long recovery times at temperature drops. Electricity is a highly efficient fuel source and does not produce any pollutants. The restrictions on its use are in reference to the amount of oil to be heated with 30 lbs. or more of cooking oil needing a more powerful fuel source such as natural gas.

Liquid Propane

Propane has the same advantages as natural gas with the added advantage of being portable to make it universally available. It is the main source of fuel for oil fryer systems that are located in remote rural areas that do not have access to natural gas. Manufacturers provide conversion kits for clients to convert their natural gas oil fryer to a propane gas fryer.

The negative aspect of propane is its high cost, which is far higher than natural gas. Part of the high cost can be balanced against the easy availability of propane and its flexibility. Since it provides the same speed, heat, and efficiency as natural gas, it is an excellent alternative.

| Fuel Comparison Chart | ||

|---|---|---|

| Fuel Type | Pros | Cons |

| Natural Gas |

|

|

| Liquid Propane |

|

|

| Electric |

|

|

Fuel Supply Types

The fuel supply types align with the different types of oil fryers, since the fuel supply type, in some cases, determines the type of fryer. The heat from the fuel is supplied directly or indirectly depending on the design of the fryer where the direct method includes direct contact with the oil while the indirect method provides heat to the oil through heat transfer or heat exchange.

- Open Pot - With open pot fuel supply, the heating elements are on the outside of the fryer and supply heat through heat transfer.

- Flat Bottom - Flat bottom heating elements are under the bottom of the fryer pot and supply heat to cooking oil through heat transfer.

- Tube and Baffles - Tube and baffles are submerged in the fryer pot at its bottom and make direct contact with the oil.

- Ribbon Elements - Ribbon elements are used in electric oil fryers and are curled electric elements that use the heat transfer method.

Conclusion

- Oil turnover is a critical part of the success of any oil fryer. The rate of oil turnover is determined by the amount of oil in the system and the rate at which it is removed through frying. With a more frequent turnover rate, products are more consistent and have a better shelf life.

- The three power sources of fuel for oil fryer systems are propane, electricity and natural gas, which are applied directly or indirectly depending on the design of the oil fryer.

- Oil fryer systems are used by the food industry to produce pre cooked foods, snacks, and meals and can contain up to 5000 gal (18927 L) of cooking oil and reach temperatures of 670°F (354.4°C).

- Part of the popularity of oil fryer systems is due to the flavor and texture the process adds to food products.

- There is a wide assortment of oil fryer systems with all versions and types being batch type oil fryers or continuous oil fryers. These two general categories divide into multiple oil fryers with different designs, heat sources, and cooking methods.