Industrial Furnaces

An industrial furnace is a heat source for performing a wide range of industrial applications that include testing, sintering, and tempering of materials. They are known as direct or fire heated furnaces, and they provide heat higher than 752 °F (400 °C). The general term “industrial furnace” is a descriptor for several types of furnaces, each of which provides heat using different fuel sources.

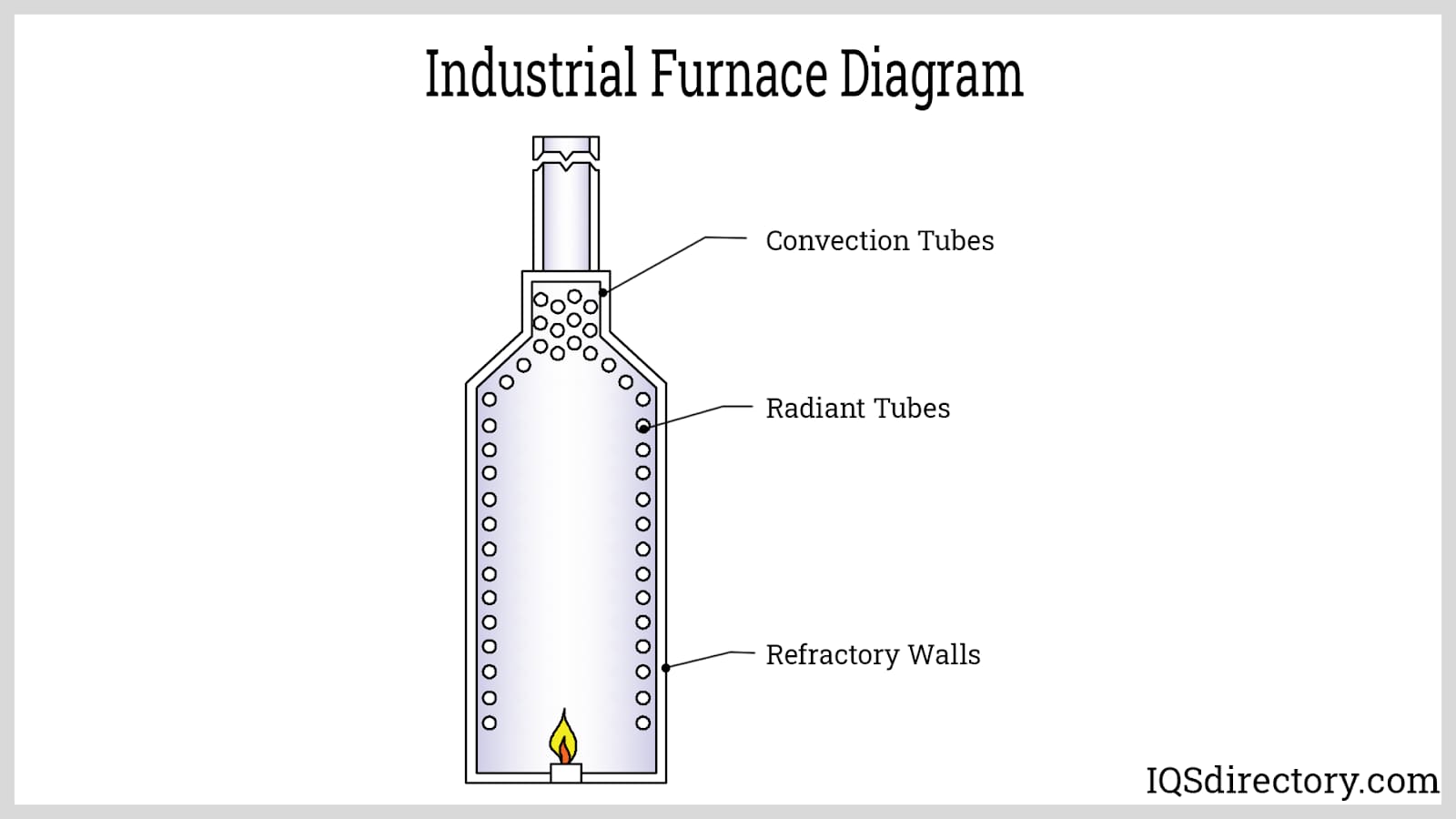

Different fuels for industrial furnaces include gas, oil, electricity, and wood. The three configurations for heating materials are direct contact, indirect contact, or muffled. Regardless of the different fuels and heating methods, all industrial furnaces have the same components, which are radiant section, convection section, the burner, flue gas stack, and insulation. The differences between the types of industrial furnaces is how the components are engineered and designed.

Components of an Industrial Furnace

Although there are different types of industrial furnaces, the basic components of all furnaces are the same since their function is to be a heat source for manufacturing applications. Aside from the different types of industrial furnaces, each furnace serves the needs of a particular application using the same mechanisms.

In order for an industrial furnace to be able to generate heat, it has to have some form of power source, which can be electricity or a combustible fuel. Heat sources include radiant, natural gas, conduction, electricity, and dielectric, with each method having its benefits and limitations. The type of fuel and the design of an industrial furnace determine the power that the furnace will generate.

Radiant Section

The radiant section of an industrial furnace is where the heating element is located, which is some form of flame. Coils made from steel are placed vertically or horizontally in the radiant section to be heated by the heat source. The coils are arranged as individual cells or placed along the walls of the radiant section. The placement of the coils can take several forms, from a single pass configuration to a multiple pass design.

Convection Section

Directly above the radiant section is the convection section, which is cooler and is used to recover additional heat by convection. The coils from the radiant section continue through the convection section but are finned to increase the rate of heat transfer. A soot blower uses water or air to remove soot that accumulates on the tubes in the convection section.

Flue Gas Stack

The flue gas stack is a type of pipe, channel, or chimney through which flue gasses are exhausted from an industrial furnace. The gasses are produced by the igniting of the fuel for the furnace and are composed of carbon dioxide (CO2), water vapor, nitrogen, and oxygen leftover from the combustion air. One of the main environmental concerns regarding the flue gas stack is the presence of pollutants such as carbon monoxide, nitrogen oxide, and sulfur oxide.

Flue gas stacks can be several meters high to disperse the exiting gasses over a wider area. In recent years, several methods have been perfected to control flue gasses in order to meet federal and local air pollution standards.

Insulation

Of the many components that make up the structure of an industrial furnace, insulation is one of the most important ones. Industrial furnaces produce a great deal of heat as part of their function. High temperature insulation ensures the safe operation of industrial furnaces and helps maximize their efficiency.

The outer body of an industrial furnace becomes extremely hot during operation. Employees that work around the furnace, moving materials in and out, can be subjected to the effects of the extreme heat. Insulation is applied to contain heat inside the furnace and protect its effects on workers.

Types of Industrial Furnaces

The full use of industrial furnaces began during the first industrial revolution, but industrial furnaces have existed for thousands of years as a method for melting and sintering metals. The full realization of their use began at the beginning of the 20th Century when their use for other purposes was added to industrial processes.

From their crude beginnings, industrial furnaces have grown, developed, and changed into valuable tools for the production of effective and useful products. In the midst of the Great Depression of the 1930s, engineers discovered processes for hardening of metals using industrial furnaces. Part of this adaptation was required due to the rapid growth of the automobile industry that needed sturdier and more durable metals.

Since the early part of the 20th Century up to the present, different types of industrial furnaces have been engineered to meet the specific needs of a product or application. This has led to the introduction of a wide assortment of industrial furnaces and industrial furnace fuels.

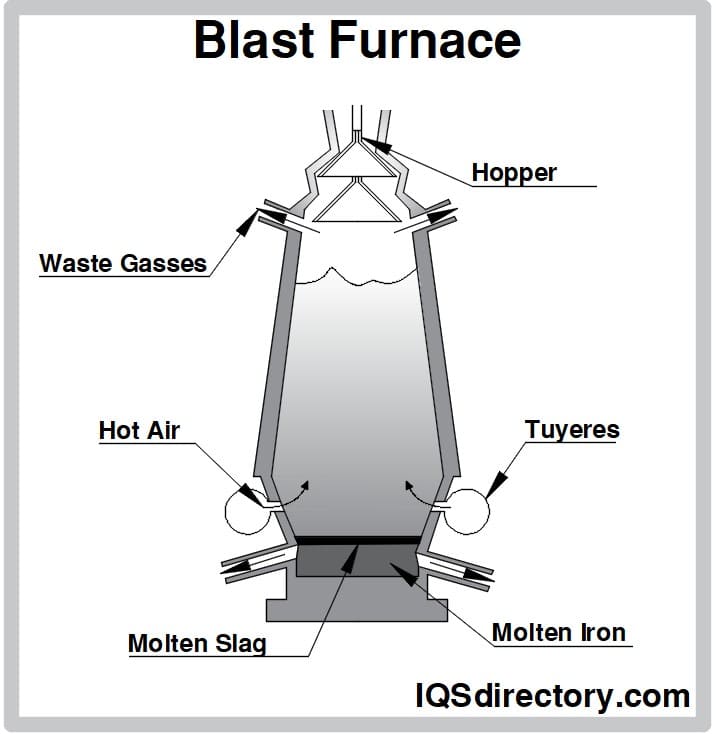

Blast Furnace

The name blast furnace refers to the method that a blast furnace uses to create high temperatures by ejecting a blast of hot air. The concept of a blast furnace is to change the chemical relationship between three elements, which can be an ore, a fuel, and limestone or flux.

As the three elements move down the cylinder of a blast furnace, the elements are pushed out, leaving molten metal and slag at the bottom of the furnace as the flue gasses go out the top. Blast furnaces are popular due to the speed at which they can smelt metals.

Electric Industrial Furnaces

The power for electric industrial furnaces is created by electrical resistance using heat resistant materials. The material, a gas, or air are heated to the programmed temperature directly or indirectly depending on the design of the electric furnace. Two types of electric furnaces are arc and induction. With an arc electric furnace, the material to be heated is exposed to an electric arc. For an induction furnace, the material is heated by eddy currents.

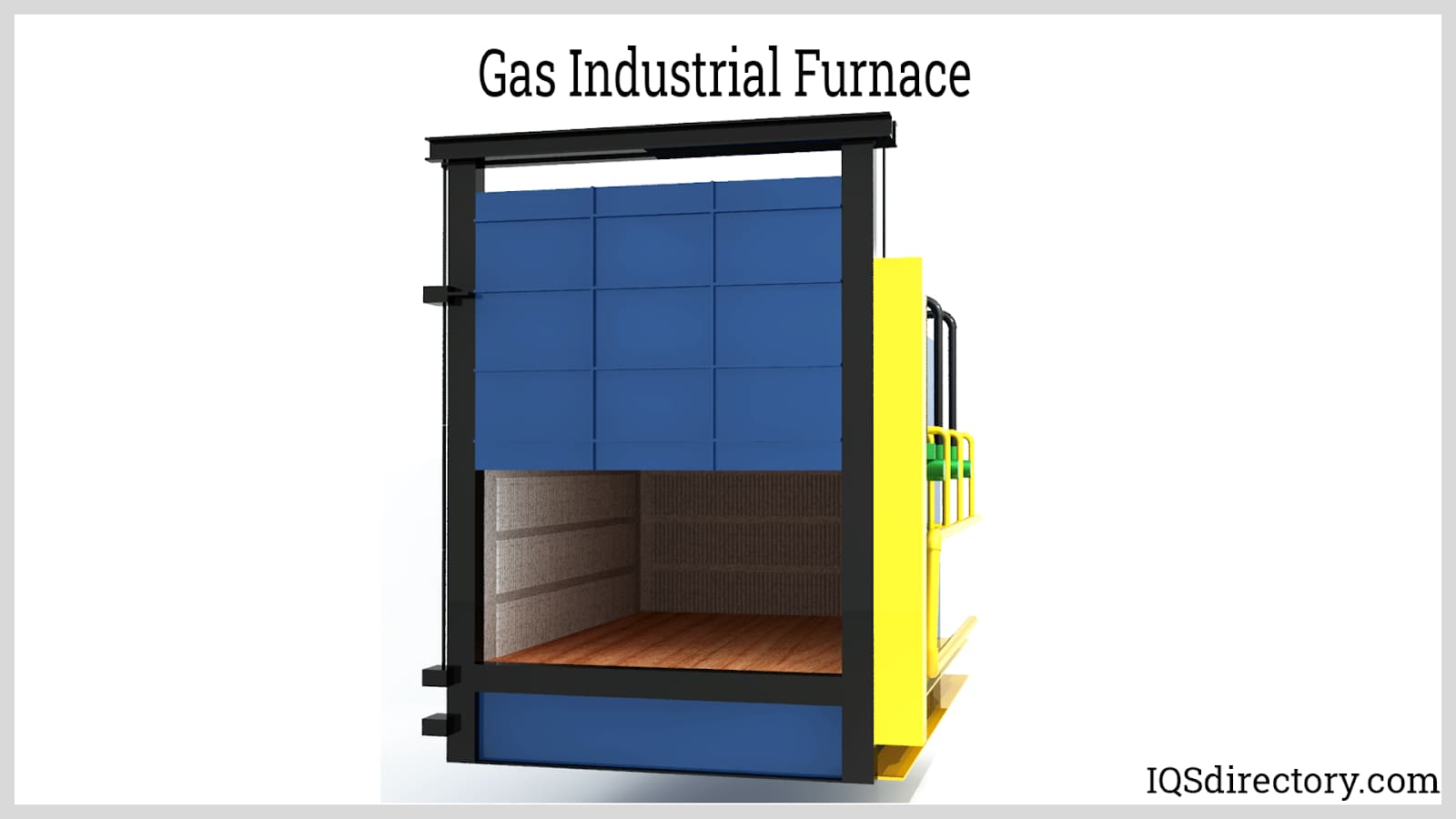

Gas Industrial Furnaces

Of the various types of industrial furnaces, gas furnaces are the most widely used. They are less expensive to operate than electric furnaces and are easier to use. Gas furnaces are made from heat resistant materials, which enables them to have a long, useful life. The heat for the furnace is created in the combustion chamber using one or more burners.

The main concern with gas industrial furnaces is the pollutants they exhaust, which are regulated and suppressed using various airflow cleaning methods.

Uses for Industrial Furnaces

From the days where furnaces were used to melt metals, industrial furnaces have rapidly progressed into a variety of applications and uses, with new furnaces being developed to meet changing needs.

- Ashing – used to determine the amount of ash that forms in a sample.

- Calcination – used to prepare materials for processing.

- Tempering – a process of heating iron based alloys after hardening or quenching.

- Annealing – softens metals for working, machining, and improves mechanical and electrical properties.

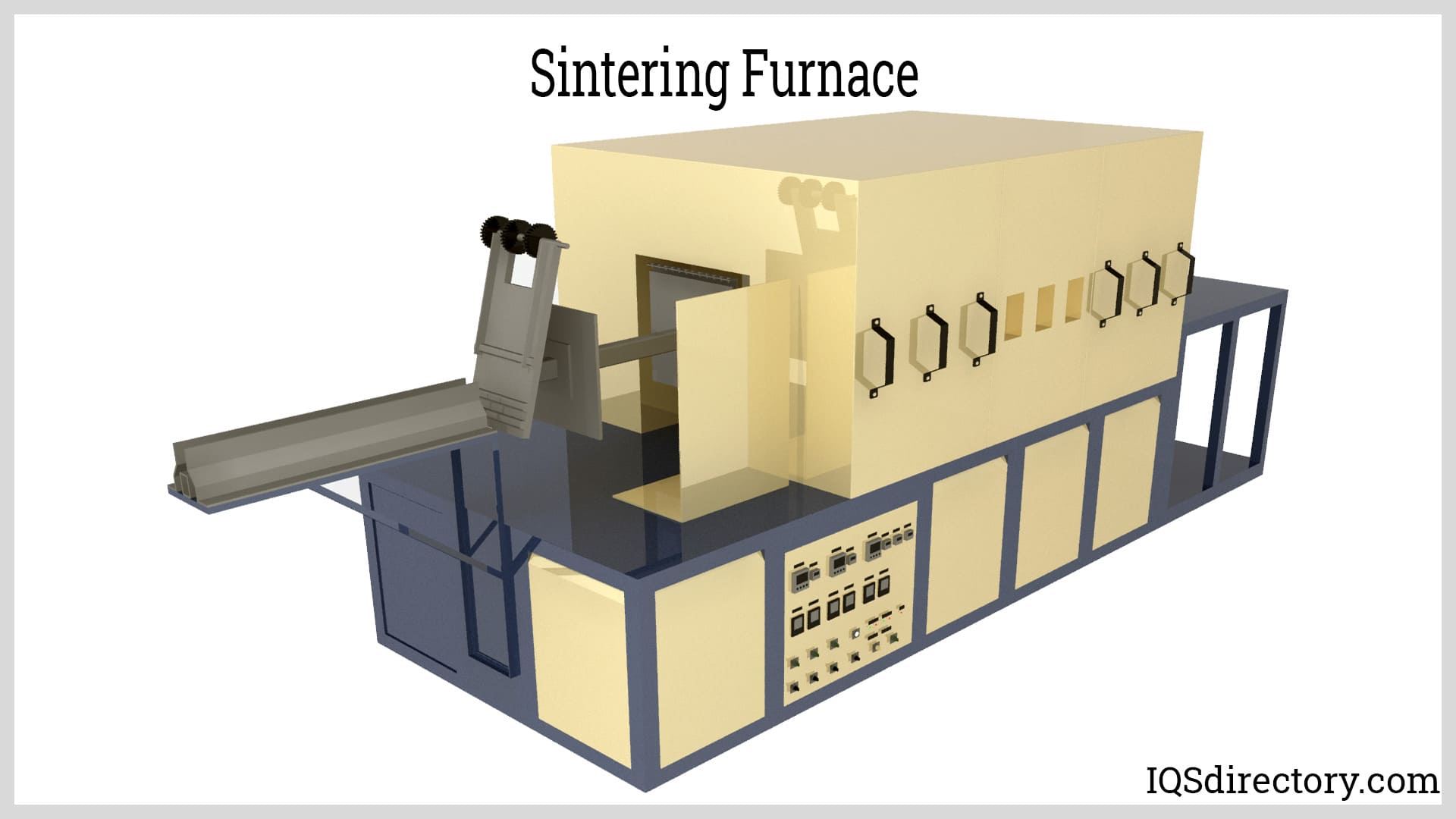

- Sintering – reduces the porosity of a material and improves specific properties.

- Tensile measurement – measures the tensile strength, yield strength, and strain hardening of metals.

This list above about the six uses for industrial furnaces is only a sample of the many ways they are used to improve and enhance manufacturing processes. As the types of applications have changed and grown, new furnaces have been developed.

Choosing the Right Industrial Furnace Manufacturer

To ensure you have the most productive outcome when purchasing an industrial furnace from an industrial furnace manufacturer, it is important to compare several companies using our directory of industrial furnace manufacturers. Each industrial furnace manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each industrial furnace company website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple industrial furnace companies with the same form.