Gas Springs

Gas springs are versatile mechanical devices that store energy pneumatically and operate via high-pressure gas housed within a cylinder. Also known as gas struts, gas pistons, or gas shocks, these devices are commonly used in conjunction with or in place of traditional mechanical springs. Their basic function is very similar to air cylinders, since a piston is either compressed or extended based on the pressure differential between the gases within the chamber and those acting upon its exterior. The number of practical applications almost always involves exertion of force by way of the gas-filled cylinder as well as oil-based shock absorption. (In this context, such shock absorption is known as damping.) Gas springs are used to optimize various opening, closing, lifting, lowering, adjusting and damping actions.

Quick links to Gas Springs Information

The History of Gas Springs

Gas springs were initially conceived and designed by a French engineer named Paul Giffard in the late nineteenth century. They could be found in the United States by 1875. At the beginning, the role of pressure within a gas spring’s operation was focused on to the neglect of other aspects (e.g. material aspects of construction design).

The automobile industry spearheaded the rapid development and customization of gas springs toward the latter half of the twentieth century. Gas springs first widely appeared in car trunks and hoods. Over time, gas spring manufacturers began to develop on both sides of the Atlantic and produce gas struts in large quantities. Today, they are a common mechanical facet in virtually every industry.

Advantages of Gas Springs

Gas springs are often preferred over traditional mechanical springs because they offer several significant advantages. Air springs are overall more cost effective than metal coils due to several related reasons, which can roughly be grouped into two categories:

- Superior Performance

- Gas springs generally perform superior to mechanical springs due to a number of characteristics. The cylinders and pistons used in these springs (combined with their damping properties) allow for easily adjustable and controlled movement when compared with their metal counterparts. This adjustability also provides room for correction should gas leak out of the main chamber over time whereas worn coils will need to be replaced. Furthermore, gas springs tend to exhibit greater force or strength as well as reliability. Finally, gas springs are very, very durable. Since they are so precisely designed, gas springs tend to be high quality and able to last for years.

- Ease of Use

- Gas springs are simply easier to use than most mechanical springs. Generally speaking, they are more compact, as well as easier to mount or install (with the use of socket joints, etc.). Additionally, due to their general high quality and lack of certain types of power sources (e.g. electrical), gas springs require virtually no maintenance.

Design and Features of Gas Springs

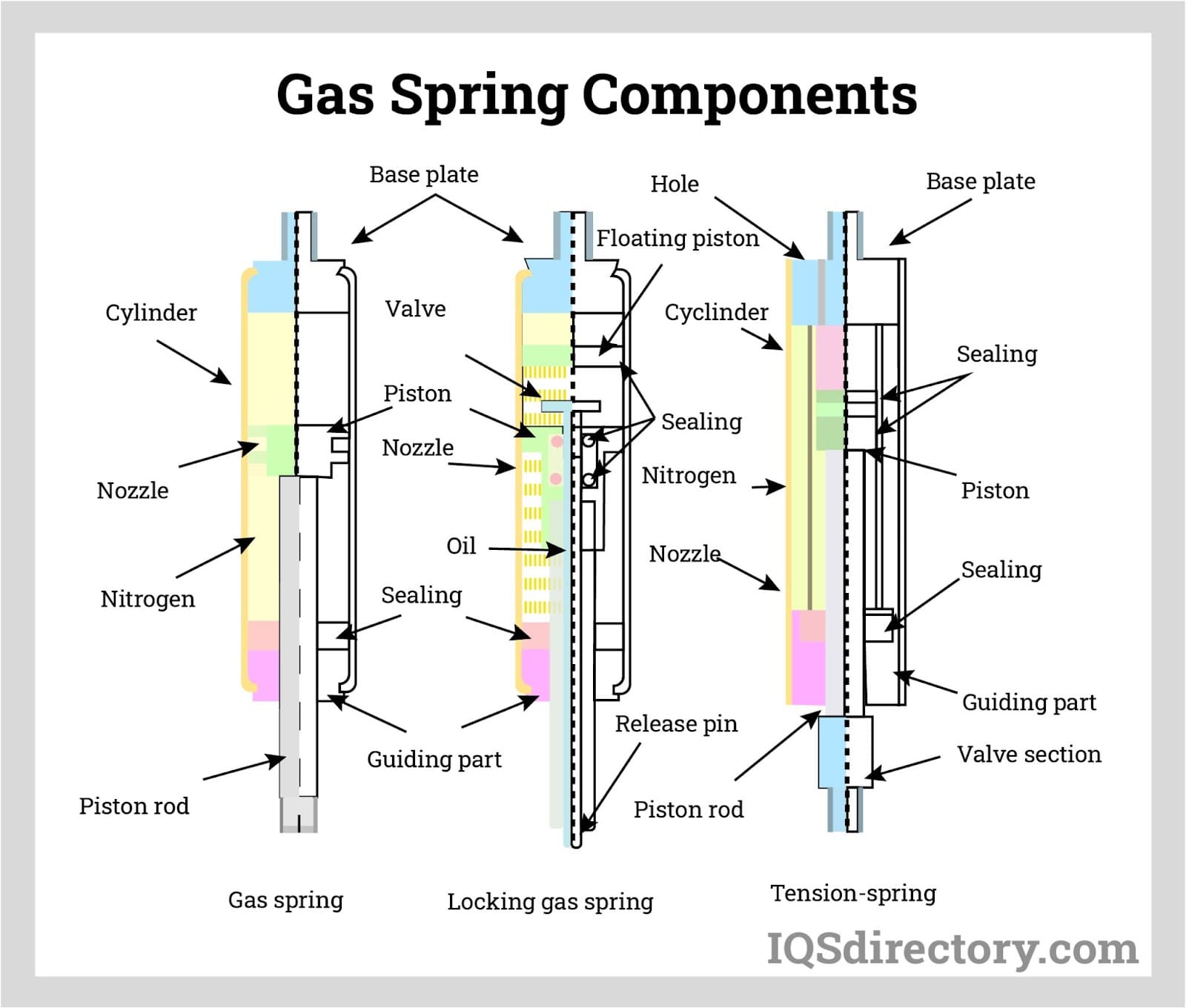

Gas springs are well suited for and employed in a wide range of industrial, commercial and domestic applications. Despite this broad range of variance, however, they all function under the same basic design and principles of operation. Generally speaking, gas springs share all the same basic components:

- The cylinder (also called the tube or body) is the "external" portion of the gas spring. The cylinder houses all other components and has a polished interior to reduce friction.

- A combination of piston and rod. The rod is attached to the piston and extends out one end of the cylinder. The piston head rests perpendicular to the rod within the cylinder. Together with the seals, the piston creates an airtight barrier which divides the cylinder into two compartments.

- O-rings (or some other type of sealing system, such as radial shaft or lip seals).

- Intake and Outlet Valves.

- A gas charge or reservoir. Nitrogen is widely used in gas springs because of its inert nature (i.e., it is generally not reactive with other chemicals).

- A Small Amount of Oil.

While the above design pattern may seem relatively simple, most manufacturers use 3D CAD drawing and other design software in the construction of application specific gas springs. This is important because, despite its relative simplicity, the operation of these pneumatic devices relies on a high degree of precision among its various parts.

How Gas Springs Work

- Gas Springs and Physics

- Gas springs are fundamentally based on a simple physics formula: force equals the product of pressure times area. Although the terms force and pressure are often used interchangeably, there is a technical difference between them. From a physics standpoint, force can simply be defined as a one-directional push or pull on an object, while pressure can be defined as a specific type of force – specifically, force acting over an extended surface area. Gas struts are usually simply described as functioning by increasing the gas pressure inside the cylinder. Based on the above distinction, however, it is more accurate to say that it functions by modifying the area that pressure acts on within the cylinder – thus producing both a difference in pressure and a net force that moves the spring.

- When force is exerted or a shock encountered, the rod attached to the external mechanisms protrudes deeper into the cylinder’s chamber, moving the piston head towards the cylinder’s opposite end. It is important to note from the outset that, although the piston is the main agent of gas compression within the cylinder, it does not compress gas by somehow "squeezing" it from above as it slides down the cylinder. Rather, a piston compresses gas within a cylinder by simple displacement; in other words, it takes up room within the cylinder and leaves less room for the gas that was there previously to occupy. Once the volume of the cylinder is reduced, the gas becomes compressed.

- To be even more specific, pistons are equipped with holes or valves that allow gas to flow through (or around) them and occupy both sides of the piston within the cylinder; and since no gas actually leaves the sealed cylinder, gas exists at an equal pressure on both sides of the piston within the cylinder. But once a piston intrudes into a cylinder, it causes equal-pressure gas to act over a greater area (specifically, the inside of the piston). This difference in pressure creates a net force within the cylinder – specifically, a net output force directed away from the greater (inside) area within the cylinder. This output force is far greater than normal atmospheric forces acting on the part of the rod that is outside the cylinder. Thus, the output force within the cylinder causes the rod in the spring to extend outward, toward the area of lower pressure.

- Using Oil in Gas Springs

- Oil is a crucial component in the function of a gas spring. When oil lubricates the cylinder, it creates damping (or cushioning) effects which check a gas spring’s overall force and increase the ease of controlling its movement. Oil is able to lubricate a cylinder by flowing through the same piston holes or valves that enable gas flow. (Hydraulic damping refers to oil flow through holes or bores, while dynamic damping occurs via bypassing valves in the wall of the cylinder.) Damping actions especially occur near the end of both compression strokes (inward movements) and extension strokes (outward movements). Resistance is created by the presence of oil, allowing the spring to absorb some force and the rod to slow before it can reach other more sensitive components of the machine. A great example of this effect can be seen in the shock absorbers or suspension system of an automobile.

- Pistons in Springs

- Pistons are carefully designed to control the overall flow of fluid – both gas and oil – as a gas spring operates. Often, they are designed to make the flow of both fluids relatively slow. This is important because the rate or speed of gas spring movement is directly proportional to the amount or speed of the fluids flowing within it. The controlled (i.e. slow or delayed) flow of fluids within a gas spring translates into the overall controlled movement of the gas spring itself – and ultimately, the control of products that depend on gas springs. For example, gas springs that function with controlled (rather than choppy or unpredictable) motions enable a door to be closed smoothly rather than slammed shut.

Gas Springs Images, Diagrams and Visual Concepts

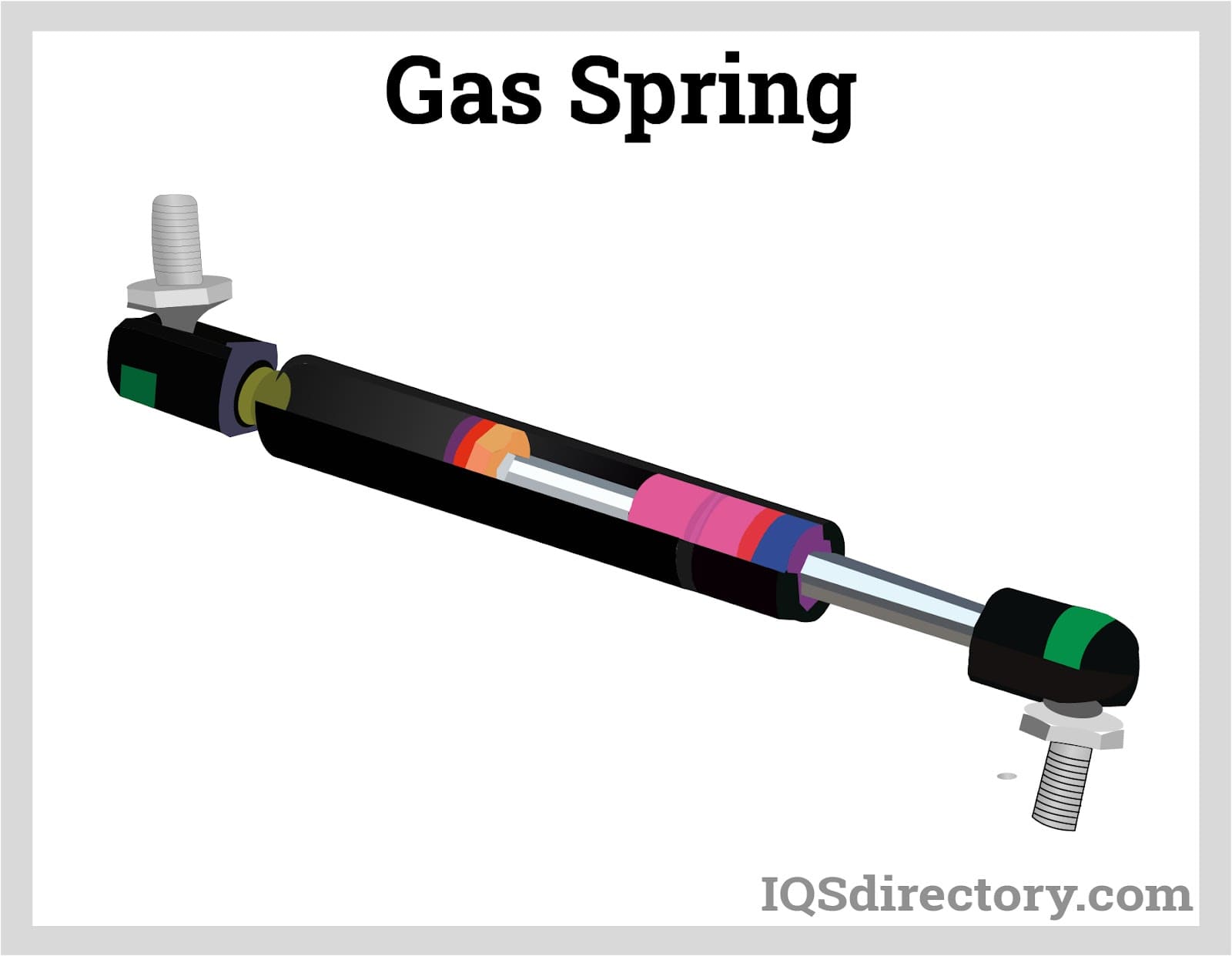

Gas spring, a hydro-pneumatic element that stores potential energy by compressing gas contained in an enclosed cylinder sealed by a sliding piston.

Gas spring, a hydro-pneumatic element that stores potential energy by compressing gas contained in an enclosed cylinder sealed by a sliding piston.

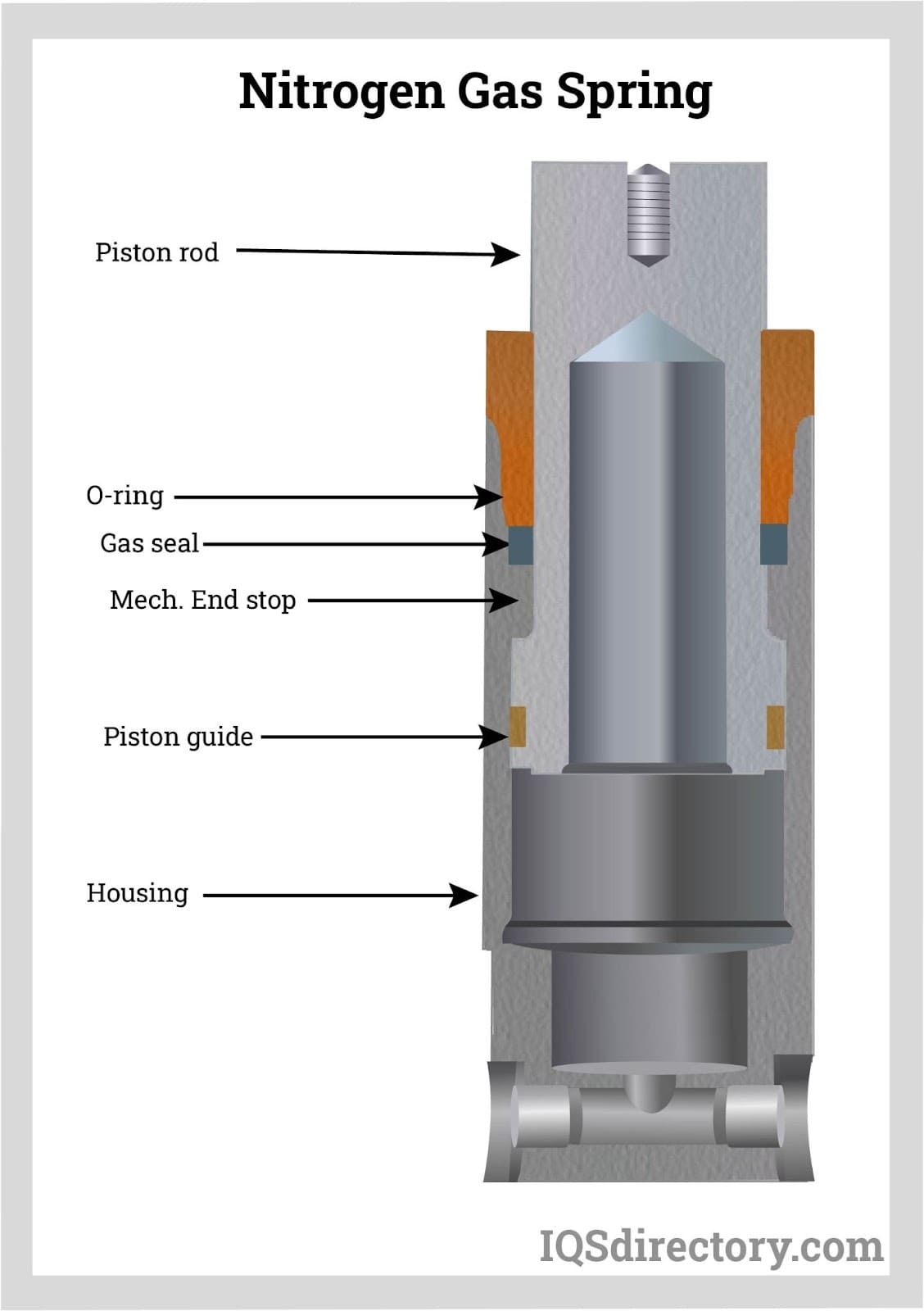

Nitrogen gas springs refers to gas springs because Nitrogen is the gas typically used inside the gas springs because it is inert and non flammable.

Nitrogen gas springs refers to gas springs because Nitrogen is the gas typically used inside the gas springs because it is inert and non flammable.

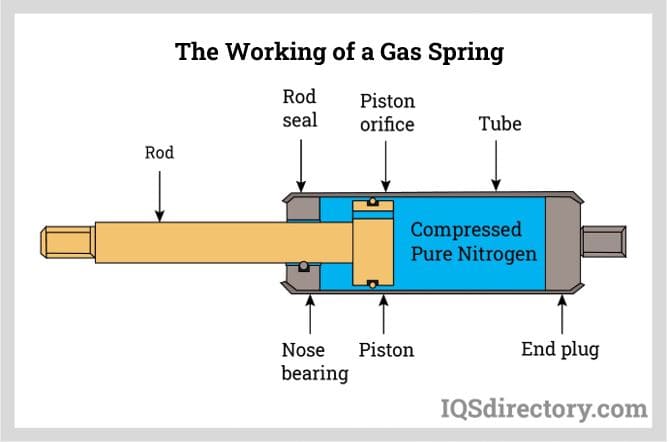

Gas spring’s working principle is based on the use of nitrogen gas with transformer oil 50% and turbine oil 50%, for the sealing, lubrication, and transmission of pressure.

Gas spring’s working principle is based on the use of nitrogen gas with transformer oil 50% and turbine oil 50%, for the sealing, lubrication, and transmission of pressure.

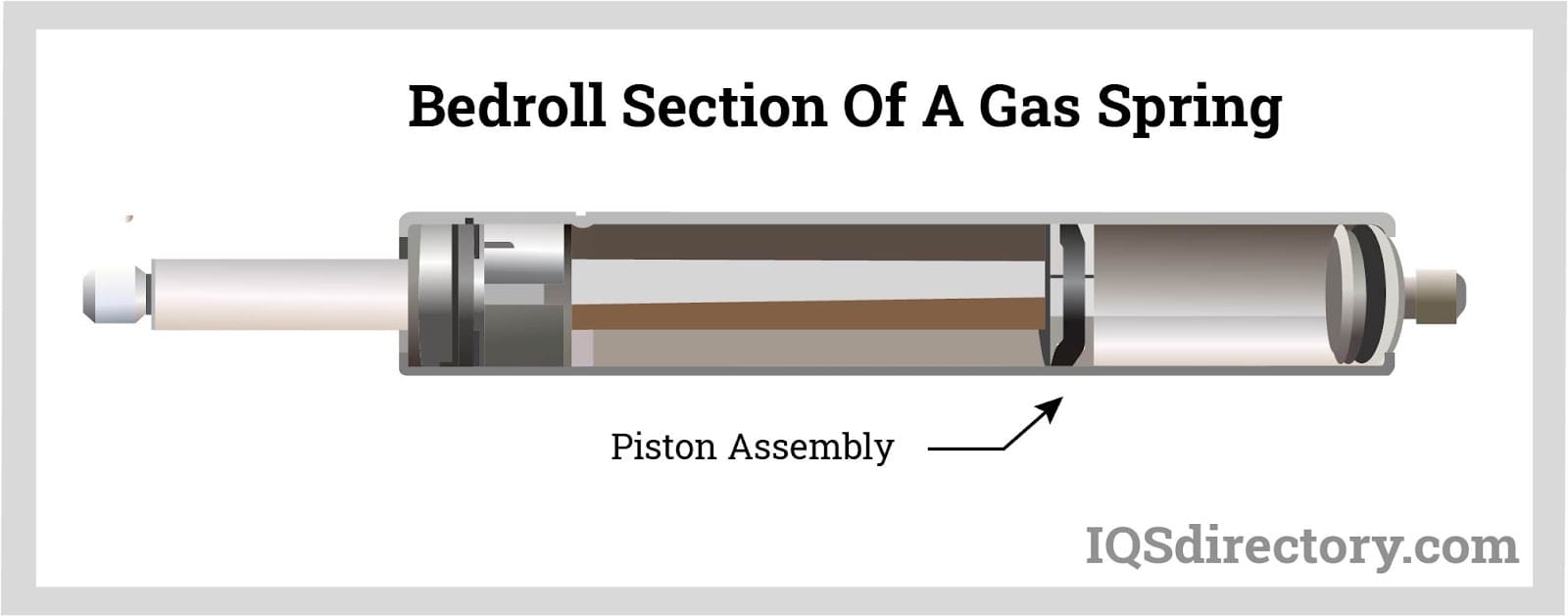

Beadroll Section, the section of grooved tube that functions to retain the guide and seal the package to prevent the damage to the seal package by the extending piston.

Beadroll Section, the section of grooved tube that functions to retain the guide and seal the package to prevent the damage to the seal package by the extending piston.

A gas spring consists of several parts, each being integral for the safe and successful operation of the component.

A gas spring consists of several parts, each being integral for the safe and successful operation of the component.

Tension and traction gas springs apply some force or maintain the tension to provides tension on the belt drive and mechanical assemblies.

Tension and traction gas springs apply some force or maintain the tension to provides tension on the belt drive and mechanical assemblies.

Types of Gas Springs

There are several distinct overall gas spring types or designs that work better for different applications. Several of the more common types are as follows:

- Extension Gas Springs

- The counterpart to the most commonly used type of gas spring (the compression gas spring). Compression provides dampening when a force is applied that shortens the stroke, or pushes the piston further into the main cylinder. On the other hand, extension gas springs provide isolation when the rod is fully extended either partially or fully due to high pressure within the chamber.

- Nitrogen Gas Springs

- Pneumatic energy storage devices designed for the damping and isolation of movements through the use of compressed air. Gas springs are a popular alternative to mechanical leaf or coil springs as they offer increased product longevity and precision operation.

- Locking Gas Springs

- Contain mechanisms that lock the rod in place once it has reached a full extension. These types of gas springs are useful for equipment that must be carefully handled, such as medical equipment.

- Adjustable Gas Springs

- Similar to normal locking gas springs; however, they are able to stop a moving rod at any point during its movement (not simply at full extension). These types of springs can be found in hospital "seating" (e.g. beds, emergency trolleys) that require an extra degree of controlled movement.

- Reducible Gas Springs

- Can have their force altered by having gas intentionally removed from them during the course of operations.

- Tension Gas Springs

- An "opposite" type of gas spring. Rather than primarily providing a pushing, output force, they are designed to hold tension and/or perform controlled pulling operations. These types of gas springs can be found in various pieces of household furniture, such as cabinets.

- Air Shocks

- A particular type of gas spring designed for damping and vibration isolation. Also known as shock absorbers, these devices are commonly installed on a variety of vibratory or oscillating industrial equipment such as conveyors and mixers, but are usually associated with vehicle suspension systems and jet or plane landing gears.

- Tool and Die Gas Springs

- Certain types of industrial gas springs (e.g. tool and die gas springs) typically use shorter stroke lengths than normal gas springs and produce higher forces. However, they accomplish this without the use of any damping agents.

- Dampers

- Sometimes gas springs are colloquially referred to as dampers. This is not a very accurate reference, since dampers are really strut-like devices designed to control motion without providing any force. In a rough sense, dampers can be considered as gas springs without any gas.

Applications of Gas Springs

As alluded to before, gas springs are used for a wide range of application types. Fundamentally, gas springs are used to make the movement of objects easier. A gas spring’s ability to pneumatically store potential energy (during compression) and also to pneumatically release that energy (during extension) enable users to (respectively) perform lowering and lifting actions that would be very difficult otherwise. One of the most common examples of gas springs’ usefulness is opening the trunk of a car. When a car trunk is unlocked, the energy stored during the previous compression stroke (i.e. the closing of the trunk) is released through the net output force and assists in the raising of the trunk. Gas springs can also be used to stabilize objects in a static position.

Gas springs can be found in virtually every industry. Furniture, medical and rehabilitation, aerospace, office supply, agriculture, marine, pharmaceutical, food processing, machine engineering, and transportation are just a few of the many industries that make use of gas springs in regular operations. Specific examples from other industries include the use of gas springs in tanning beds, awning extension, conveyors and landing gear for planes and jets.

The importance of these devices is clearly seen in the automotive industry. As illustrated above, gas springs are a crucial component of car trunks. Additionally, the automobile industry alone uses gas springs for tailgates, hoods, supports for open doors, suspension, sunroofs, seat adjustment and steering dampening - among other applications.

Customizing Gas Springs

As previously stated, gas springs are typically designed with a high degree of precision. As a result, these devices are extremely customizable. The following examples illustrate how almost every aspect of a gas spring can be adjusted in some way:

Aluminum and stainless steel are common building materials for gas springs. However, manufacturers and suppliers often offer gas springs in a number of different materials. Highly customized gas springs can be fashioned from materials such as polyurethane, or EPDM synthetic rubber.

The composition of the air or gas that will be passing through a gas spring is a major factor in its operation. As alluded to before, nitrogen is commonly used because of its inert qualities. Carbon gas springs are a common alternative that also provides many beneficial qualities and is safe to use in most industrial applications.

The size of gas springs is highly variable. They may range from two inches to twenty inches or even several feet. Dynamometers (machines to test engine power) are examples of equipment requiring "oversized" gas springs.

Load capacity is an important consideration in initial gas spring design and directly related to its fluid flow and force exertion. The load capacity of gas springs is as variable as their size. It can range from less than one-hundred to over eighty-eight thousand pounds.

The specific needs and requirements for a gas spring depend largely on the industry-specific application for which it will be used. Like mechanical springs, there are several factors that must be carefully considered when deciding what features your gas spring should have for a given application. Some physical factors to take into account include cylinder diameter, maximum width, rod diameter and mounting style. Performance specifications to take into account include working temperatures, absorber stroke, compressed and extended lengths, maximum force and maximum cycles per minute.

It is important to identify the most relevant features of your given application and to customize your gas springs accordingly. For example, body material is largely important as it must endure not only the physical stresses, but also the chemical and environmental stresses of an application as well. If your application for a gas spring occurs in a highly corrosive environment (e.g. the food industry, a marine setting, a pharmaceutical plant), you should select gas springs composed of non-corrosive material. Stainless steel gas springs are commonly used for such scenarios. Other materials used include thermoplastic, aluminum and steel; sometimes, these are coated with black nitride or chrome plated for further protection.

Choosing a Gas Spring Manufacturer

Gas spring and industry specific professionals can provide helpful insight when selecting the proper gas spring for a given application in order to ensure safety and optimal performance. Besides competitive prices, some factors to consider when selecting a gas spring supplier are:

- Levels of Certification

- E.g. conformity to environmental friendly ISO standards.

- Level of Customer Support

- E.g. offering assistance with on-site installations.

- Ability Plus Willingness to Customize Products for Your Specific Applications.

Proper Care for Gas Springs

Gas springs are carefully calibrated to endure the rigorous application of variable pressures at inconsistent velocities. This is crucial since failure in any number of aforementioned industrial applications could be fatal. In addition to design, proper use of gas springs is integral to product safety and longevity (e.g. strictly using gas springs within their intended load capacities).

Along with longevity, the lack of need for regular maintenance is a main advantage of gas springs over traditional ones. Although they do not need to be regularly maintained, gas springs can and should be recycled once their usable life cycle is finally over (e.g. due to accidental damage). Once depressurized and drained, used-up gas springs are as recyclable as other forms of metal.

Gas Spring Terms

- Compressed Length

- Minimum length of the spring’s shock.

- Damping

- Is gained while regulating the flow of gas through the valve at the orifice of a gas damper piston, it creates a cushioning effect that slows the mechanism before it extends fully.

- End Fittings

- Are used to attach the gas spring to the item it will be controlling, mounting brackets may also be used. There are different options for multiple applications and purposes.

- Extended Length

- Maximum length of gas spring when it is fully extended.

- Force

- Measured 5mm from full extension of the gas spring, and it is a function of the pressure in the cylinder acting on the cross section of the rod. The larger the diameter of the rod, the lower the force.

- K-Factor

- Ratio of compressed force to extended force, compressed force being always larger than extended force.

- Piston

- A cylinder or disk that displaces fluids or moves under fluid pressure within a larger cylinder.