Bolts

Industrial bolts are a type of high strength hardware, used for fastening two or more workpieces together. They are threaded, meaning that they have ridges that wrap around the outside of their shaft in a helical pattern. They use nuts to secure them to surfaces.

Note: There is another type of threaded fastener called a screw, which has a construction similar to industrial bolts. The similarity leads to confusion, and thus, many people use both of these terms interchangeably.

Quick links to Bolt Information

Applications of a Bolt

The purpose of bolts is to hold two or more surfaces or components together. Because of their nature, industrial bolts are one of those components that can be found in almost all types of machinery.

Some of the many industries that use them include: military, construction, automotive, aerospace, construction, civil engineering, petrochemical, or architectural industry.

The History of Bolts

Around 200 BCE, Archimedes invented a large bolt or screw pump, making use of the screw principle. The pump consisted of a screw with helical threads engraved on a shaft, fitted inside a tube. It revolutionized irrigation, allowing water to be raised from low-lying water bodies. While Archimedes is credited with this invention, historical evidence suggests that he actually borrowed the idea from the Egyptians, who he saw using wooden screw pumps for irrigation. Other historians give credit for the threaded screw to another Greek great, Archytas of Tarentum. According to them, he came up with the idea of threaded bolts 200 years before Archimedes.

Either way, modern bolts came into existence much later, in the 15th century. This happened when a German publisher, named Johann Gutenberg, used bolts to fasten his printing presses. Bolts were then gradually used in other equipment, including armor and clocks. With the increasing need of screws or bolts, engineers of the time also used bolt-cutting machines.

Despite the use of bolt-cutting machines, bolts were still made and used on a small scale until the advent of the Industrial Revolution. Once the Industrial Revolution hit, industrial bolts became an important component in the engineering world.

In the 18th century, engineers designed the first thread cutting machines, clearing the way for the mass production of screws. Because different companies had their own standards for manufacturing industrial bolt threads, the market was flooded with an array of different sized screw threads. Rather than offering versatility, this just made things in the industry confusing and difficult.

To solve this problem, in 1841, Joseph Whitworth, an English engineer, came up with the idea of standardizing the size of the screw threads in industrial bolts. He recommended a standardized angle of the thread flanks and numbers of threads per inch. His efforts brought change in the industrial bolts industry in Britain. Concurrently, across the Atlantic Ocean, American and Canadian engineers made similar efforts, making bolt threads standardized for specific diameters.

World War II forced Americans, British, and Canadian manufacturing companies to streamline their bolt standards, so that they could support one another with vehicles and weapons that could be used and fixed in all of their countries. They agreed on a standard in which all countries used imperial measurements. The unified standard stated that the flank angle should be 60 degrees, the crests should be flat, and the bolts would have rounded roots, which improved fatigue performance.

Since World War II, the powers that be have fine-tuned bolt standards with updated ISO standards, metric property classes and more. Also, engineers have developed fasteners for extremely high temperature situations, using nickel-based alloys. In the last twenty years or so, they have also spent a lot of time perfecting bolts made from materials like titanium, magnesium and aluminum.

Advantages of Bolts

There are many advantages to these kinds of fasteners. First, bolts have very low production costs. Second, bolts and nuts are both easier to install and easier to replace than other assemblies, like welded fasteners. Third, it’s easier to inspect bolts that are fastened in with nuts, rather than bolts that are welded in. The latter sometimes requires time consuming and costly inspection with an x-ray machine, whereas the former can usually be inspected with the naked eye. Finally, bolts and nuts create consistent bonds.

Bolt Design

- Production Process

- The manufacturing process used to create standard metal bolts takes many steps. First, manufacturers heat a wire rod in a furnace for 30 hours, then bathe it in sulfuric acid to remove any rust particles. Then they usually coat it with phosphate for rust resistance and lubrication. This concludes the pre-treating process.

- After this, manufacturers form the rods via cold forming. During this process, they use high pressure and long, round dies to shape the rod at room temperature. After the rod comes out of the dies, manufacturers cut it into shorter pieces and feed the pieces into another die; this die shapes their heads.

- The last step is threading. To thread the bolts, manufacturers send them through high pressure rollers that press in the thread pattern.

- Material Design

- The materials used to manufacture industrial bolts include aluminum, brass, copper alloys, plastics, steel, stainless steel, and titanium.

- Each offers something different. Aluminum, for example, is used for making light industrial bolts that are electrically conductive and resistant to corrosion and thermal energy. Brass, on the other hand, makes bolts with low magnetic permeability and oxidation resistance. Copper offers good wear resistance. Plastic offers excellent water resistance with light loads, while stainless steel fastener types are chemical and corrosion resistant.

- Design Aspects

- When designing bolts, bolt manufacturers think about a variety of different design aspects. These include: the major diameter of the external thread, pitch measurement (distance from one ridge, or crest, of one thread to another crest), helix angle (the slope of the thread) and thread angle (V-shaped angle between the crest, formed by threads).

- Customization

- For your unique task, bolt manufacturers can create any number of custom fastener designs. They can vary them in many ways, including: material, head type, head mark, screw grade, and characteristics like tensile strength. They can also fabricate them with fine or coarse threads; coarse thread bolts are most common for general applications. For added durability, manufacturers can coat bolts with corrosion resistant layers.

Parts of a Bolt

- Head of a Bolt

- The head acts as a mount where tools, based on the operation, either apply or resist torque. It also functions as a bearing surface that holds the substrate from one side.

- Different industrial bolts have different types of heads, including, square shouldered head, indented hexagonal head, hexagonal washer head, trimmed hexagon head, and flanged hexagonal head.

- A square-shouldered head has a truss head on a square shank that is especially designed to resist the motion. Indented hexagon heads are designed in conjunction with standard wrench dimensions and have a depression on the head. As the name implies, a hexagonal washer head has a built-in washer, which protects the assembly from disfigurement during installation. Trimmed hexagon heads are found in a standard bolt; it has clean and sharp corners.

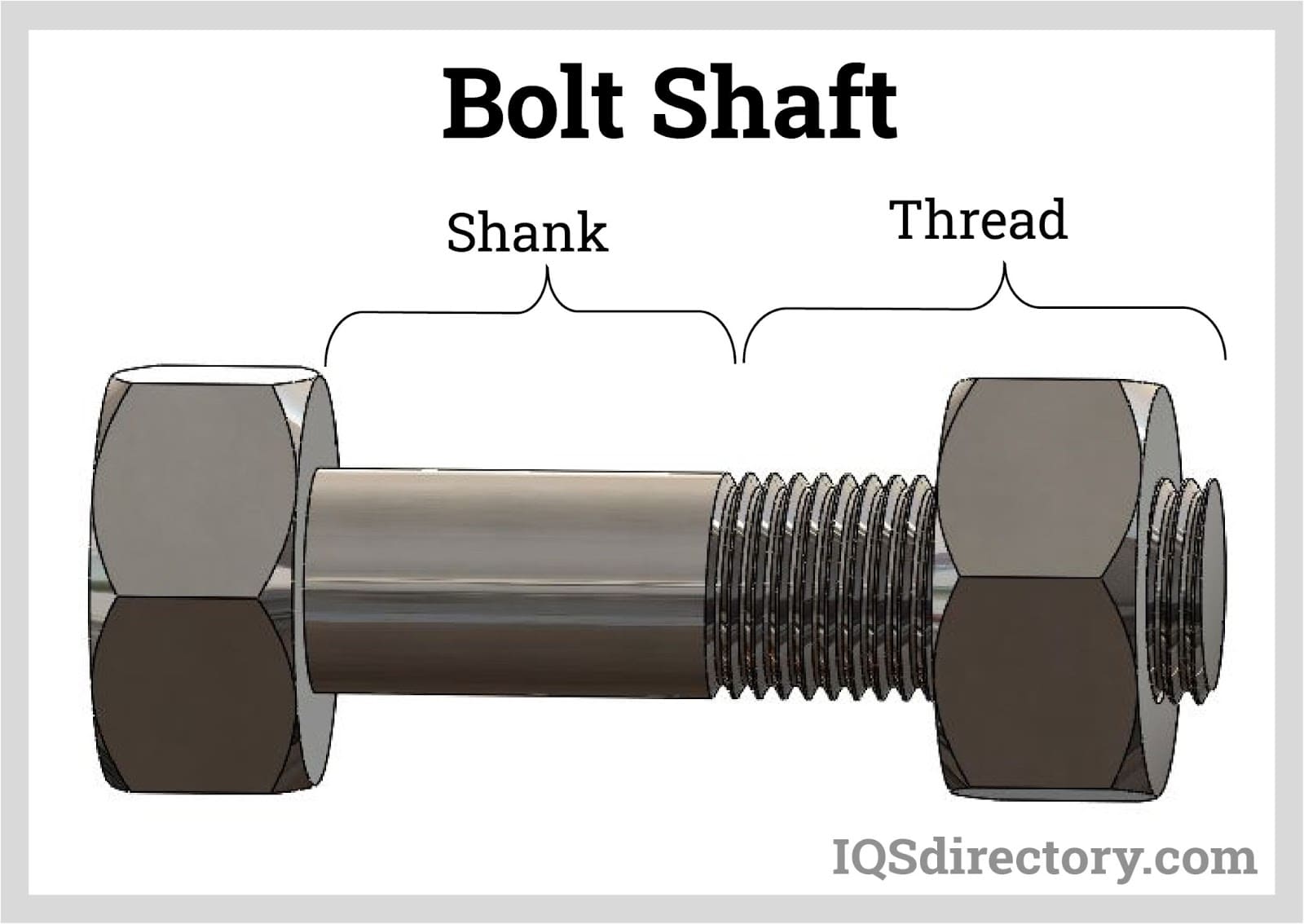

- Bolt Shank

- The shank is the shaft of the bolt on which helical threads are made externally. It is the longest part of a bolt and aligns the components when they are fastened.

- Bolt Chamfer

- The chamfer is the end of a bolt where the nut is fastened. The chamfer is slightly beveled, so that insertion of the bolt into the hole of the nut is easier.

Bolts Images, Diagrams and Visual Concepts

Bolts are used to fasten and secure the faces of assemblies using a nut and connects aligned unthreaded holes by being placed through the aligned holes which is secured with the a nut.

Bolts are used to fasten and secure the faces of assemblies using a nut and connects aligned unthreaded holes by being placed through the aligned holes which is secured with the a nut.

The shaft, a cylindrical member that bears the shear forces acting on the bolt and prevents the radial movement of the parts.

The shaft, a cylindrical member that bears the shear forces acting on the bolt and prevents the radial movement of the parts.

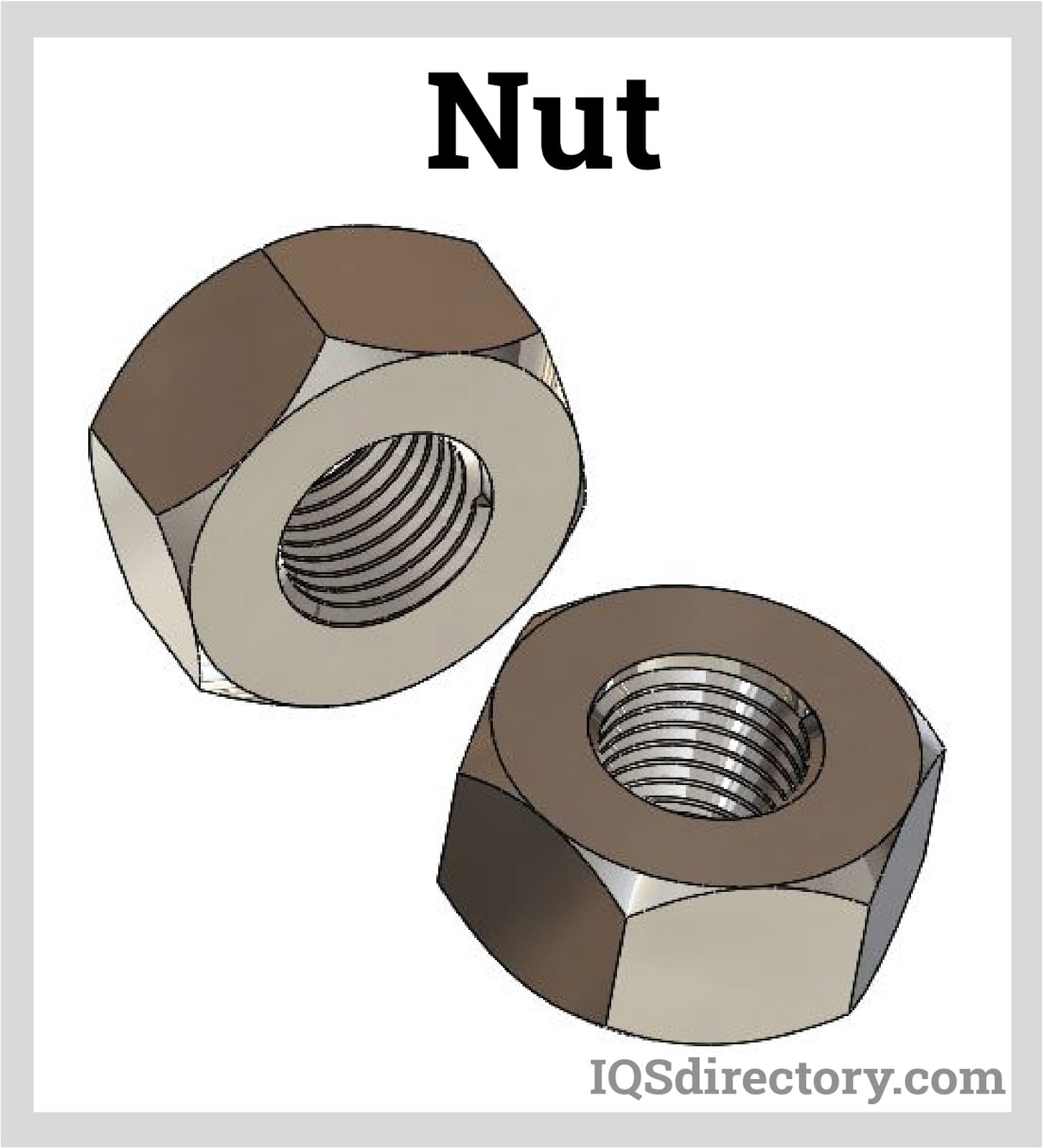

The nut is the female member of a bolted joint that contains a threaded hole providing clamping force and prevents axial movement.

The nut is the female member of a bolted joint that contains a threaded hole providing clamping force and prevents axial movement.

A washer, a thin plate with a concentric hole at its center placed under the bolt head and the nut to distribute the load of the threaded fastener over a larger area.

A washer, a thin plate with a concentric hole at its center placed under the bolt head and the nut to distribute the load of the threaded fastener over a larger area.

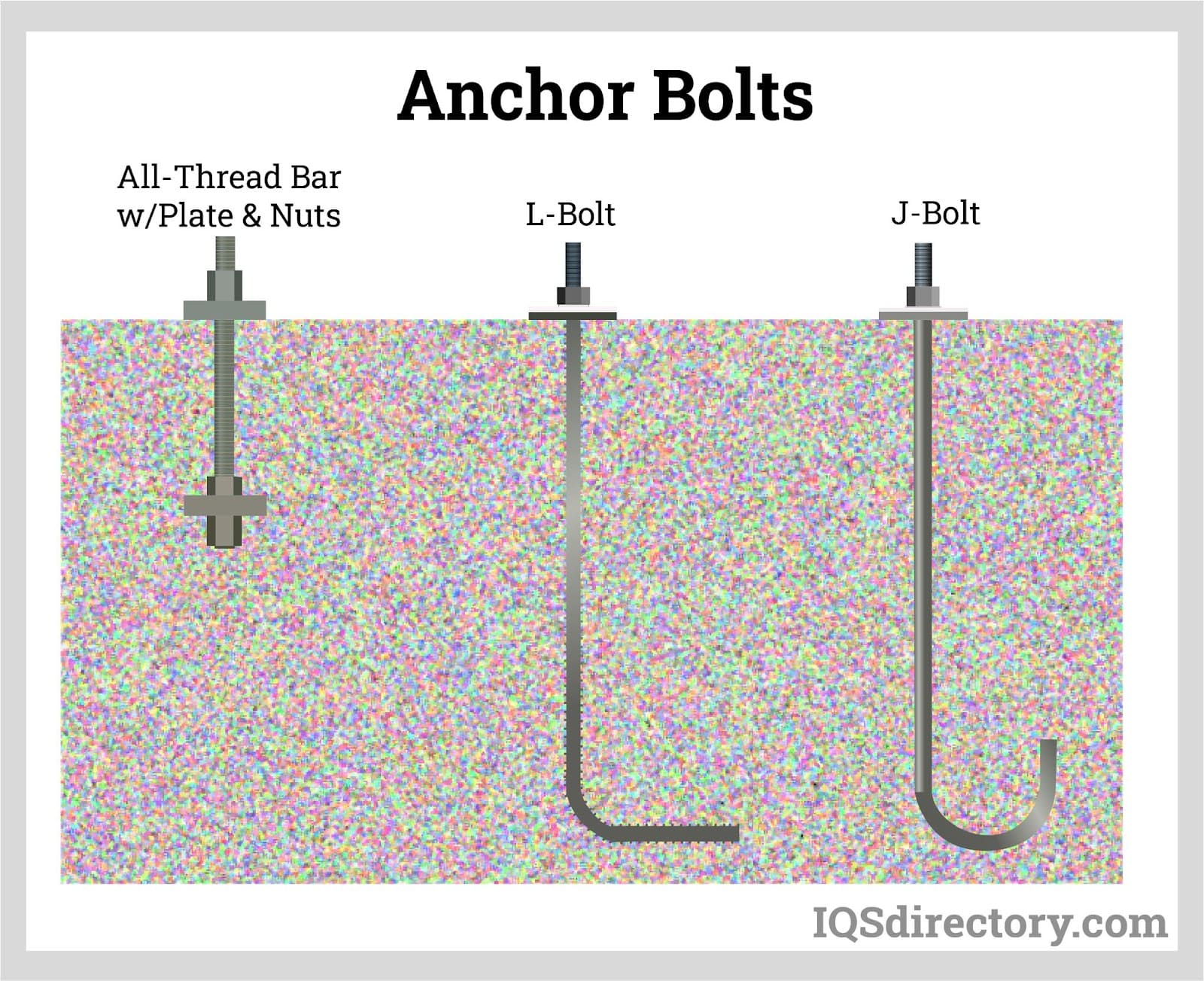

Anchor bolts are designed to join components into concrete surfaces.

Anchor bolts are designed to join components into concrete surfaces.

Serrated flange bolts are almost similar to standard flange bolts in construction, except the circular flange under their heads for a firmly grip.

Serrated flange bolts are almost similar to standard flange bolts in construction, except the circular flange under their heads for a firmly grip.

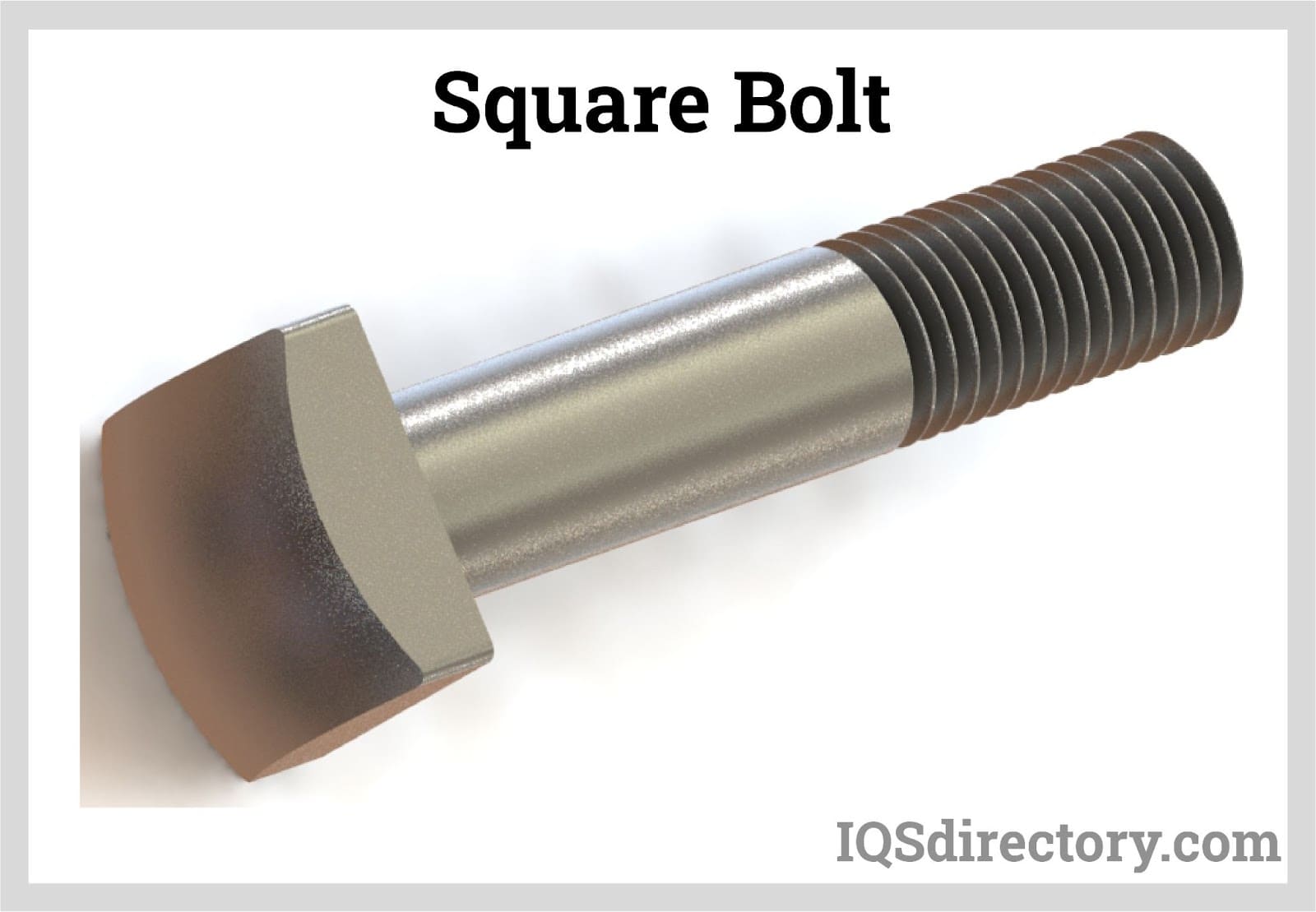

Square bolts are machine bolts that feature a square bolt head that offers a large bearing area for positive gripping.

Square bolts are machine bolts that feature a square bolt head that offers a large bearing area for positive gripping.

Types of Bolts

Bolts come in many different sizes, shapes, grades and materials.

- Oven Head Bolt

- Also known as a stove head bolt, oval binding head bolt or truss head bolt. It is designed for work with large diameter clearance holes in sheet metal.

- Square Head Bolt

- Named after the shape of their head, were once the industry standard. Now, they’re primarily used for aesthetics, to create a rustic look on buildings.

- Anchor Bolt

- Used heavily in building and construction. Most often, anchor bolts are found embedded in concrete and 1) anchoring columns and supports to a foundation, or 2) securing traffic signal poles.

- U-Bolt

- Named for their shape-they are bent bolts with threads at both ends. They may be round, square or semi-round and used when suspended items need to be attached to the surface of something. U bolts are common in the construction and automotive industries.

- Eye Bolt

- Threaded at one end and have a circular eye at the other, instead of a head. The eye is used to guide a cable, rope or chain for lifting purposes. Eye bolts are common in aircraft construction.

- J Bolt

- Also named for their shape, a letter J, or half of a U bolt. They are used as cast-in-place anchor bolts and often made of steel or titanium.

- Stud Bolt

- Round metal bars with screw threads either at the ends or on the whole thing.

- Expansion Bolt

- Consist of a taper-headed bolt, lead sleeve, metal cone and a nut. They are used to secure theatre, auditorium, stadium and classroom seating to the floor. They have attachments that expand as the bolt is driven into a surface.

- Lag Bolt

- Heavy wood screws that have a hexagonal or square head. Usually, users drive them into wooden beams or posts using a wrench.

- Hex Bolt

- Named for the six sides on their head, these fasteners are very common. Made of metal, they have a hexagon head, a shank threaded throughout the length and a washer. They come in many varieties, such as the heavy hex bolt and the hex cap screw. To fasten a hex bolt, use a hex nut.

- Shoulder Bolt

- Pivot mounting shafts that are not threaded all the way up. The threading instead stops before reaching the head, leaving a smooth-sided shaft that is usually a little wider than the threaded part. They can be square or round and are generally made out of stainless steel.

- Carriage Bolt

- Have a rounded head, but the collar is square, which fits in a hole and prevents twisting when it is being installed. They are primarily used for joining wood.

- Elevator Bolt

- These bolts have a flat head with a square collar, which keeps them in place when it is tightened. Mostly, they are used with conveyor systems.

- Flange Bolt

- These bolts have an integral washer, which helps distribute bearing weight and eliminate the disfigurement of material being bolted.

- Metric Bolt

- Industrial bolts that use the metric system as their measuring system. They are used by the international community.

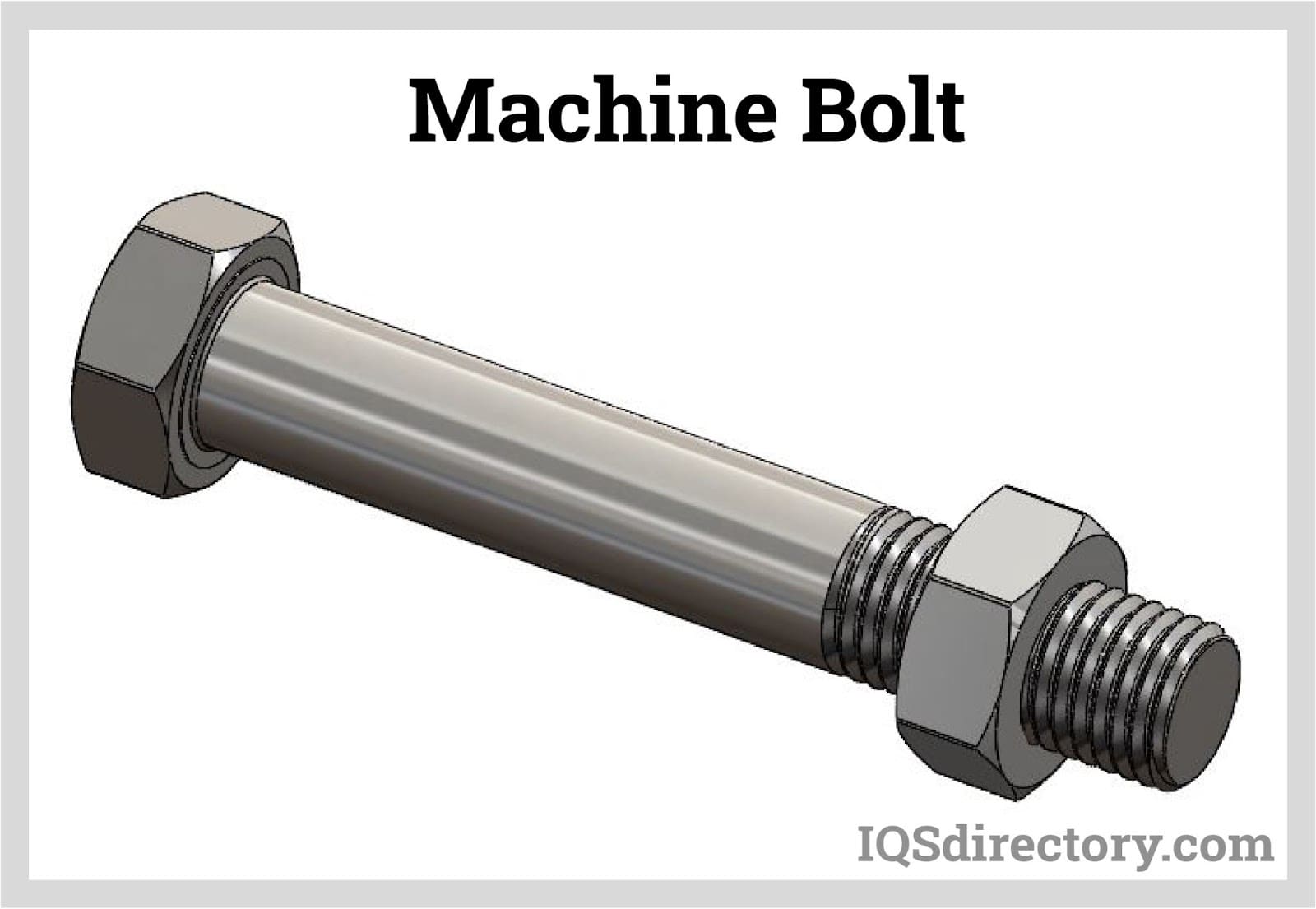

- Machine Bolt

- An industrial bolt with a square or hexagonal head. Machine bolts usually range in diameter between ¼ inch and 3 inches.

- Thru Bolt

- Can be defined as bolts that pass completely through a layer, and bind by way of a nut on the layer’s other side. Thru-bolts are the strongest and most reliable of all types of bolts, making them the bolt of choice for the most heavy-duty of applications. They are able to withstand a large amount of weight, and alleviate any safety concerns an application may have. Applications in which thru-bolts are utilized span a multitude of industries, and include rolling shutters, security grills, sun awnings, and garage doors.

Installation of a Bolt

To install industrial bolts, you need a nut and a tool like a screwdriver, high pressure drill or allen wrench. Nuts, which attach to the end of the shank, retain components on the bolt axis. Bolt the nut using angular force produced by your tool as you hold your bolt or place, or apply force to the bolt head as you hold the nut in place. Once the bolt is secured, the internal threads of the nut go over the external thread of the bolt. In the process, in order to accommodate one another, the bolt stretches slightly and the components slightly deform.

Bolt Standards and Specifications

Because industrial bolts are used in so many critical applications, various industries and organizations have come out with standard requirements for them. The military and aircraft industries, for example, have specific bolt standards that require special anti-corrosive coatings and materials. To make sure bolts are compliant, manufacturers put them through rigorous testing. Always make sure that the bolts you purchase have been tested for whatever industry standards you require.

In addition, while in the United States, most bolts are measured by the American Measuring System, Europe and Asia use the Metric System. To make sure your parts are compatible with products from other countries, we recommend you purchase metric bolts. Recently, metric bolts have become more popular in the U.S. for this very reason.

Other common standards for bolts include those laid out by ASTM and ISO, respectively. ASTM divided steel bolts into grades. ASTM grade designations indicate levels of proof and tensile strength, while ISO designations indicate all sorts of things, such as dimensions and tolerances. It’s always a good idea to get fasteners with certifications from ASTM or ISO.

Things to Consider When Purchasing Bolts

For the best bolt products, we recommend you work with an industrial bolt professional. For your convenience, we’ve listed a number of reputable suppliers near the top of this page. Browse their respective websites and, when you’re ready, reach out to three or four who you believe will work best for you. When you talk to them, make sure that they are willing to work within your budget, timeframe and specifications. As with anything, customer service is key. Compare and contrast the manufacturers with whom you speak, then make your choice!

Proper Care for Bolts

The biggest danger to bolts is rust and corrosion. To prolong bolt life, you can start by having them coated with anti-corrosion layers before you install them. From there, if you can, keep them out of the elements and away from prolonged moisture exposure as much as possible.

To remove dust, you can sand bolts (then lubricate to make them usable again), apply hydrogen peroxide (followed by fastener removal and scouring), repaint, or use rust cleaner. If you use rust cleaner, you need to make sure that it is manufacturer approved.

When all else fails, replace your bolts. It’s better to spend a little extra money in the short run, instead of face system failure or bodily injury from an unexpected system accident.

Industrial Bolt Accessories

Examples of industrial bolt accessories include thread pitch gauges, nuts, installation tools (drills, allen wrenches, etc.) and clamping kits. Check with your supplier to find out what accessories may serve you.

Bolt Terms

- Angle Controlled Tightening

- A tightening method in which the surfaces are pulled together by tightening the fastener with a pre-selected (snug) torque. The nut is given an extra measured rotation, further tightening the fastener, often beyond its yield point to ensure the achievement of a precise preload.

- Anti-Friction (AF) Coating

- Dry lubricants that are suspensions of solid lubricants of small particle size, such as graphite or PTFE.

- Anti-Seize Compound

- A compound that is applied to the threads of fasteners and whose purpose depends on the application. Anti-seize compounds can prevent galling or mating surfaces, improve corrosion resistance or provide a barrier to water penetration by sealing the threads.

- Bearing Stress

- The surface pressure acting on a joint face, resulting from the clamping force applied by a fastener.

- Black

- A term that refers to the comparatively wider tolerances employed in the manufacturing of nuts and bolts, not necessarily the color of the surface finish.

- Clamping Force

- The compressive force exerted on a joint by a fastener.

- Class of Fit

- The measure of the degree of fit between mating external and internal threads. There are three main Classes of Fit for metric screw threads: fine, medium and coarse.

- Creep

- The permanent deformation of a bolt or other fastener resulting from the application of stress and heat.

- Cut Threading

- Forming threads on a fastener by cutting away and actually removing the unneeded metal.

- Eccentricity

- The degree of difference between the centers of the surface of a bolt at different points.

- Fatigue Strength

- The fracture resistance of bolts during subjection to stress variations.

- Grip

- The thickness of all materials that a bolt is designed to secure.

- Head

- The top portion of a bolt. A head also refers to the portion of a fastener that forms its largest diameter.

- Joint

- The material(s) that the fastener (bolt) connects together.

- Nut

- A small metal piece with a hole in the center that fits over a bolt or over the end of a bolt. Nuts are often hexagonal (6-sided) in shape.

- Pull-Out

- The amount of force required to pull the fastener out of the base material.

- Shank

- The portion of a headed fastener that lies between the head and the point.

- Tensile Strength

- The amount of longitudinal load/elongation a fastener can withstand without failure of the fastener or joint.

- Thread

- A raised helical pattern going around the shank of a bolt. The thread is measured by pitch, which is the distance from one peak of the thread to the next, expressed in mm or threads per inch.

- Ultimate Torque

- The amount of force at which a threaded fastener, an insert or nut begins to strip or otherwise fail in a joint.