Speed Reducers

Speed reducers are mechanical devices that govern the output speed. They do not have a single purpose. Rather, they typically have two functions: the first is to reduce the input speed at the power source to preferred output speeds. The second is to increase the output torque, a measure of the angular force acted on an object to rotate it. With the use of speed reducers, the output torque is increased multiple times as compared to the input power source, making the output usable for various works.

Quick links to Speed Reducers Information

The History of Speed Reducers

- Speed Reducers Before the 20th Century

- The earliest account of a speed reducer-esque mechanism was given in the works of Ismail al-Jazari, a Muslim polymath. He made mention of gearbox-like arrangements in his book, The Book of Knowledge of Ingenious Mechanical Devices, written around 1206 AD. The knowledge he imparted, however, was not widely acted upon. Rather, modern speed reducers weren’t developed until the 19th and 20th centuries.

- In 1817, Watt & Boulton Engine, an early British engineering and manufacturing company, came out with a version of the gearbox that used two gears and a governor to maintain rotational speed. In 1881, a French company called de Dion-Bouton began producing gearboxes for steam cars.

- The first gear and drive shaft assembly, used to power manual transmission, was invented in 1898 by French inventors Louis-Rene Panhard and Emile Levassor. In 1904, the Sturtevant brothers in Boston, Massachusetts, invented the “horseless carriage gearbox." Unfortunately, manufacturers of the time did not have access to the same metallurgy we do today, and so, these gears were given to abrupt shifts that lead to transmission failure. Four years later, Henry Ford came out with the Model T, with gears that functioned using a planetary gearbox.

- Throughout the twentieth century, engineers and manufacturers continued to revise, perfect and diversify the speed reducer. In 1928, for example, Cadillac introduced a power transmission system that significantly reduced gear grinding and made shifting smoother.

- Speed Reducers in the 21st Century

- Now, in the 21st century, modern engineering has led to innovations that allow these mechanisms to be very compact and much smaller than they used to be. Precision machining during the manufacturing process for the gears and shafts ensures a close fit for the gear teeth. This maintains high levels of energy with minimal energy loss; many speed reducers are able to achieve efficiencies above 90%. Newer devices also require less electricity or fuel to operate, which helps increase efficiency. Reduction ratios continue to improve and reach new levels that were not possible in the past. Complex designs and assemblies such as those found in planetary gearboxes are able to routinely perform in repetitive or heavy duty situations. Even innovations as seemingly simple as flanged output shafts can help facilitate the assembly of a gearbox in a confined or hard to reach space. Speed reducer manufacturers are continually striving to reach higher operational reliability and increased power kw capacities with fewer parts.

Advantages of Speed Reducers

Speed reducers are important mechanisms with many advantages. First, they optimize speed, improve performance and increase equipment longevity. Second, they do not require auxiliary components. This reduces the likelihood of system malfunction, and makes them simpler and easier to maintain. Finally, they are reliable.

Speed Reducers Design

- Production Process

- Speeds reducers, which contain a set of gears and input and output shafts, are made through a series of steps. First, you need the gears and gear shafts. Gears are made through various processes, including: hobbing, broaching, form milling and blanking, while shafts are made through processes such as: casting, extrusion, forging, etc. Second, you need your gear housings. Housings are made mostly through die casting, using precision CNC die cast machines. Third, you need your gear motor, which manufacturers construct from carefully machined components, including either AC or DC power. Once they assemble all of these parts, manufacturers typically protect the exterior using a heat cured dry powder coating.

- Material Design

- Manufacturers machine speed reducers from strong durable metals like steel or hardened steel. When cost or weight is a concern, they may use plastic instead. Plastic is lightweight, dirt tolerant, with low speed meshing. Regardless, it’s important that any material they use is also corrosion and abrasion resistant, as the speed reducers will be subject to a lot of friction and heat. To help with this, they also add lubrication right there at the factory.

- Equipment Operation

- During equipment operation, the motor transmits power to the input shaft of the reducer. The speed reducer then converts this power into lower output speed, which the reducer transmits to the connected load through the output shaft. The gearbox and gear motor can together deliver the same amount of torque or more torque if needed, and speed operations up or down.

- Design Considerations and Customization

- Speed reducers are available with a variety of modifications to suit the right purpose. When constructing them, manufacturers consider application relevant concerns such as: load capacities, torque capacities, gear pitch and output. Considerations like these help determine speed reducer features like: size, number of gears and reduction ratio(s) (the ratios of the input speed to the output speed).

- Manufacturers can customize the features mentioned above. Another way they can customize your gearbox is to make it work in conjunction with one or more additional components meant to regulate motor speed, such as: sprockets, v-belts, chain drives or sheaves.

Speed Reducer Images, Diagrams and Visual Concepts

Speed reducers are gear train between the motor and the machinery used to slow down the transmission.

Speed reducers are gear train between the motor and the machinery used to slow down the transmission.

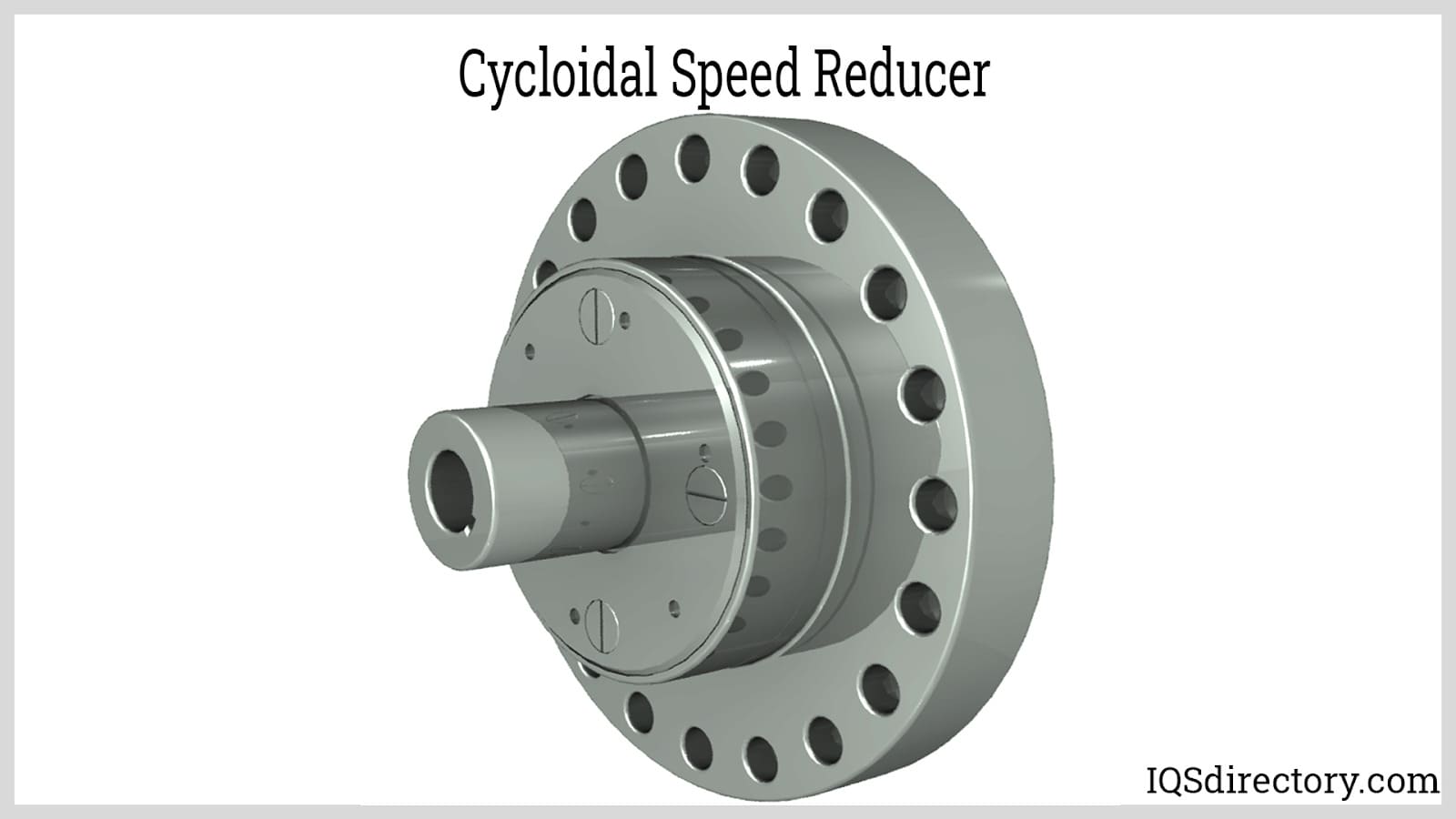

A cycloidal speed reducer, a device that reduces the speed of the input shaft which offers high ratios in a small package with little backlash.

A cycloidal speed reducer, a device that reduces the speed of the input shaft which offers high ratios in a small package with little backlash.

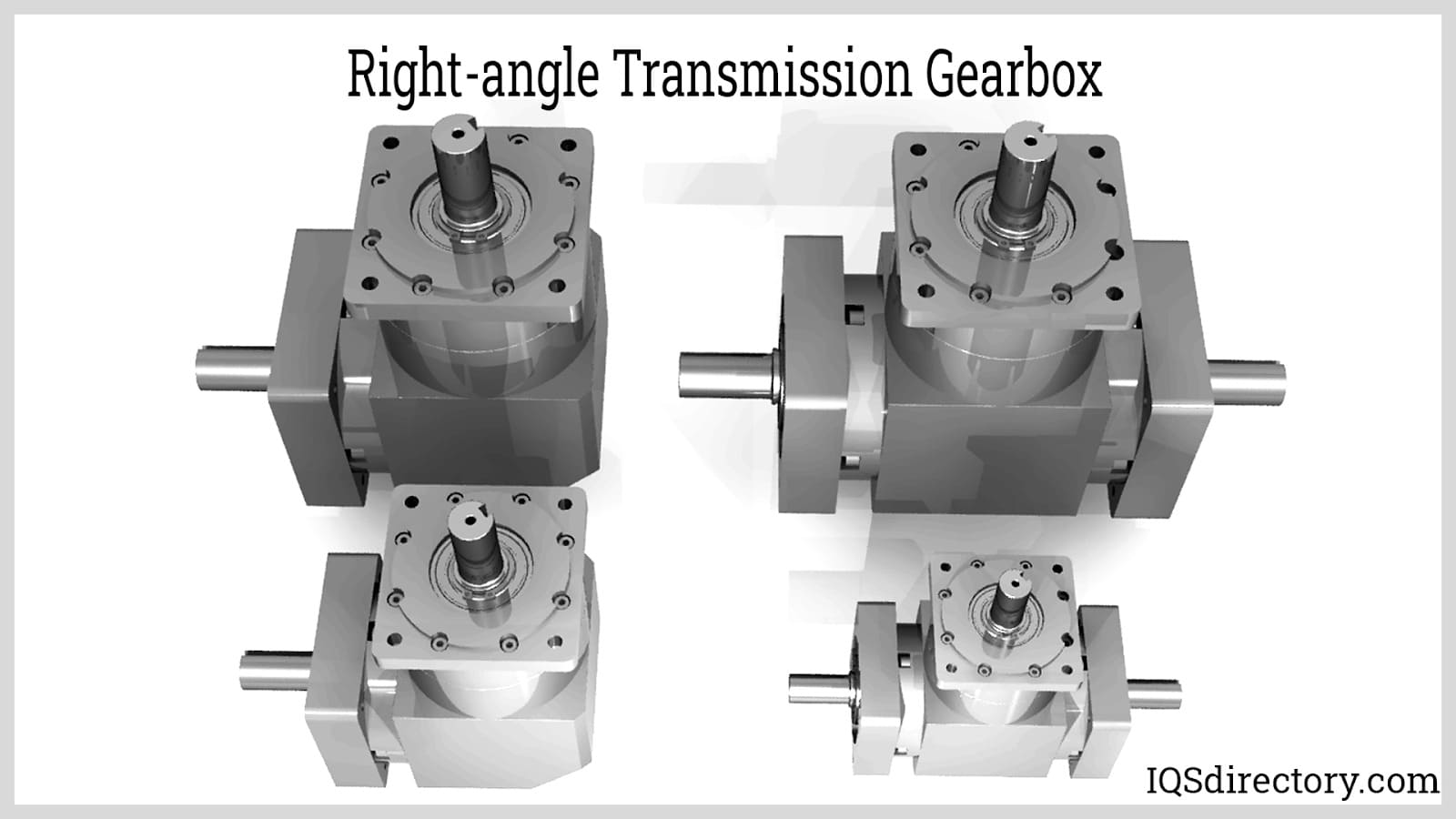

Right-angle gear drives are power transmission systems which use gears that transfers shaft power at a 90° angle.

Right-angle gear drives are power transmission systems which use gears that transfers shaft power at a 90° angle.

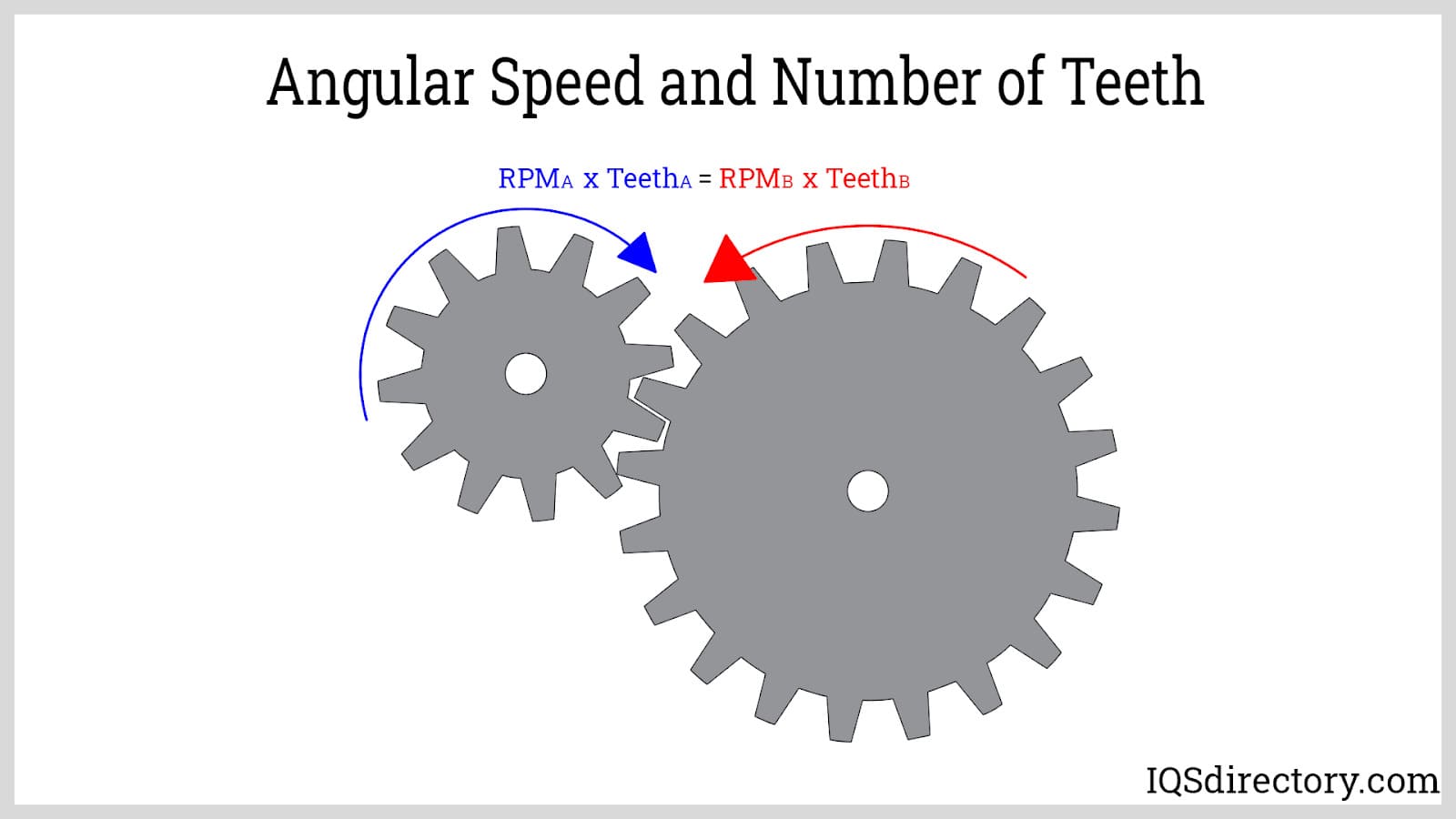

Gear drives can increase or decrease the speed of the driven shaft relative to the driver by using gears with different pitch diameters or numbers of teeth.

Gear drives can increase or decrease the speed of the driven shaft relative to the driver by using gears with different pitch diameters or numbers of teeth.

Worm gear drives have two main components: the screw and the wheel, rotating the screw by 360° turning the wheel by the number of worm threads.

Worm gear drives have two main components: the screw and the wheel, rotating the screw by 360° turning the wheel by the number of worm threads.

Regular maintenance improves efficiency of the speed reducers.

Regular maintenance improves efficiency of the speed reducers.

Speed Reducer Types

"Speed reducer" is an umbrella term that encompasses many equipment, including gear motors, gearbox, gear drives, and gear reducers. It’s important to know that the terminology used to describe them is quite unclear, and many terms are used interchangeably. Nevertheless, we will try to differentiate a few types for you below.

There are three main types of speed reducers, based on their mounting methods. These are: inline gear reducers, right angle speed reducers and shaft mounted speed reducers.

- Inline Gear Reducer

- Also known as an inline speed reducer, features an input shaft that is aligned with the output shaft. Inline gear reducers are used in a system with other components in order to decrease the incoming speed and power so that the parts that follow are able to handle the power and operate effectively. Components include different types of gearing, such as: planetary gears, cycloidal gear systems, and helical and spur gears.

- Parallel Gearbox

- Or parallel gear shaft speed reducer, contain both input and output shafts. While they work as well as inline gear reducers and offer better flexibility, they are more expensive than them.

- Right Angle Gearbox

- Contain input shafts that are aligned at a right angle to the speed source (positioned perpendicularly to the output shafts). This design uses worm gearing or bevel gearing, based on the requirement. Some designs also use hybrid drives. Among these designs, a worm gear system is considered the cost effective solution. However, its efficiency goes down as the ratios go higher, whereas bevel gear type reducers have an upper limit, around a ratio of 6:1.

- Because of its use of worm gearing, some people call this type a worm gear reducer, worm gear speed reducer, worm speed reducer, worm type reducer or worm gearbox. Worm gear reducers are used in applications involving low horsepower. Worm gear reducers maintain high gear ratios, high shock tolerance, and compact design.

- Shaft Mounted Speed Reducer

- Compact in size. They eliminate the need for a foundation and coupling because they are mounted directly on the drive shaft.

- Now that we’ve covered those major types, let’s talk about some other variations.

- Variable Speed Reducer

- Devices that control the rotational speed of an alternating current (AC) or direct current (DC) electric motor. They may be mechanical, electromechanical, hydraulic or electronic depending on the demand and are compatible with alternating current (AC) or direct current (DC) motors, though the vast majority are for AC motors only. Process control and energy conservation are two benefits gained by using a variable speed drive.

- Gear Reducer (Reducer Gear)

- Used to minimize power size and total machine size and handle heavy shock loads. This term is often used interchangeably with gear drives, mechanisms used to provide a variable output speed from a constant speed power source or to increase torque for a variable speed power source.

- Gearbox Speed Reducer

- Or speed reducer gearbox, lowers motor speed by decreasing output speed and increasing torque. When speed reducer gear boxes are mounted directly onto a motor instead of just a shaft, they are referred to as gear heads.

- Gear Motor Unit

- When speed reducers or gear boxes are coupled with a standard C-frame motor, the unit is known as a gear motor unit. In an alternative arrangement, a frame motor and a speed reducer are joined together by a component called coupler, which joins the reducer input shaft and the motor shaft. In other arrangements, a belt is used to transmit the motor speed of the reducer.

- Helical Gear Reducer

- Have teeth machined at an angle not parallel to the axis.

- Cyclo Reducer

- Mechanisms used for reducing the speed of an input shaft by a certain ratio through use of rolling elements. These reducers gain their effectiveness through use of a round disc that rotates off center, slowing the input speed.

- Planetary Gearbox

- Has a sun gear, planet gears and a ring gear. In planetary gearing, one or more of the central or outer gears revolve around the sun gear, just like the planets in planetary motion. This means that planetary gearboxes are able to produce many different reduction ratios. The planetary gear system, also known as epicyclic gearing, is as old as the second century; it was first used by Ptolemy to predict the motion of planets.

- Cycloidal Speed Reducer

- The same as the toothed gear you see in mechanical clocks. Unlike the standard involute gear, the movement of gears around each other is epicycloid and hypocycloid.

- Spur Gear

- The simplest type of gears. They have radial teeth that are aligned parallel to the axis of motion.

- Gear Drives

- Mechanisms designed to alter the speed, torque or direction of rotating shafts using gear ratios. They are used to provide a variable output speed from a constant speed power source or to increase torque for a variable speed power source.

- Reduction Gears

- Mechanisms that lower the speed or torque of a rotating input shaft through use of gears with varying circumferences. Speed reducers such as gearboxes rely on reduction gears to perform their function of decreasing the number of rotations per minute.

- Worm Gear Speed Reducers

- Right angle speed reducers used in applications involving low horsepower. Worm gear reducers maintain high gear ratios, high shock tolerance, and compact design.

Speed Reducer Applications

Customers use speed reducers to control output speed in their mechanisms and systems. Gear reducers are used to minimize power size and total machine size and handle heavy shock loads.

Speed reducers are utilized by a wide range of industries. Common industries in which speed reducers are found include: material handling, automation, automotive and transportation, aerospace, recreation, construction, food and beverage processing, oil and gas and textiles.

Speed reducers are used in a variety of applications, including automation equipment, conveyors, compressors, printing presses, pumps, compressors, generator and robotics applications and are widely used in metallurgy machinery, mine machinery, robotics, construction machinery and other industrial machines.

Speed Reducer Installation

There are things you need to consider while connecting the reducer and the input shaft. The main issue that emerges while connecting the reducer and the input shaft is the radial load, also called the overhang load. The radial load is the force or torque acted in the shaft bearing since it is connected to source with sprockets, pulleys, and belts. Shaft bearings are designed to accommodate radial loads, however, if it exceeds the limit for which the speed reducer is designed, the whole gear arrangement can fall apart. The load can be calculated by dividing the torque transmitted by the radius of the connecting device, which can be pulley or sprocket.

Standards and Specifications of Speed Reducers

Make sure the speed reducer system you purchase is properly certified and tested, using the standard guidelines recommended or required in your industry and region. Some of the most common ones include those put out by the International Standards Organization and the American Gear Manufacturers Association. Learn more by talking to your service provider.

Choosing the Right Speed Reducer Manufacturer

The secret to getting a good speed reducer system is having a high quality contract manufacturer in your corner. For your convenience, we’ve compiled a thorough list of speed reducer manufacturers and suppliers. Find it near the top of this page. Use our listing to examine and sort top speed reducer manufacturers. The company information includes website links, company profile, locations, phone, product videos and product information. Customer reviews are available and product specific news articles.

Learn even more about each by requesting a fast quote or calling them on the phone. All of the speed reducer companies we’ve listed can design, engineer, and manufacture speed reducers to meet your companies specific qualifications. However, only one of them is the right one for you. Find out which by reaching out to three or four and discussing your specifications, questions and concerns with each. Compare and contrast their answers, making special note of their price quotes, delivery system, lead times and attitude. Customer service is key! After making your choice, get started with your new partners.

Proper Care for Speed Reducers

Speed reducers manage large amounts of rotational speed and churns out functional speed and torque. They go through enormous pressure while doing so, and if they are not maintained properly, they can fall apart much before what the rating says. Keep reading for an outline of the most important aspects of speed reducer care.

- New Application

- We advise that when you use speed reducers for new applications, you do not operate them under extra loads. For the first two weeks, operate them with new oil and under standard loads prescribed in the handbooks. With this procedure, the fine particles that usually are stuck in the gear system and other additional components come loose and can be removed easily. After the two-week period, we recommend you drain the oil with fine particles and add the oil in again. To make the whole operation cost effective, it is good practice to filter the oil repeatedly and use it again, as disposal of oil leads to rising operational costs.

- Preventive Maintenance

- When speed reducers work, the lubricant and oil oxidizes, leading to the formation of sludge and acids. Therefore, it is important that you perform preventive maintenance diligently. This involves lubricating the speed reducers with appropriate lubricants and changing the oil periodically. The period of changing lubricant and oil varies based on the design; however, changing lubricant after every 2500 hours of operation is a good practice. However, if speed reducers are exposed to heavy loads repeatedly, change the lubricant and oil more often.

- Reducer Lubrication

- Improper lubrication is the biggest culprit of gearbox failure. This is because lubrication reduces the friction created by the rolling and sliding of gears,and helps dissipate heat energy by acting as a film between components.

- Always sufficiently lubricate your gearboxes with approved speed reducer lubricants. Common examples include mineral based and synthetic polyalkylene glycols and hydrocarbon polyalphaolefins. The viscosity of the lubricant should complement the ambient temperature of the speed reducer. And as the reducer functions, the lubricant should maintain an elasto-hydrodynamic (EHD) film between the components to dissipate the heat energy.

- Reducer Oiling

- To ensure a long life and optimum performance, it is important that a speed reducer has a sufficient amount of oil. Find out what the proper oil level is from your manufacturer, and then always maintain that level. Do not go over or under this level. While inadequate oil will certainly cause your gearbox to fail, excessive oil can also take a toll on speed reducers. This is because, with more oil, more air gets trapped with churning, leading to a stunted ability to regulate heat, leading to overheating. Get an accurate reading when the speed reducer is not operating and has had enough cooling time after operation.

Accessories for Speed Reducers

Accessories you may want to consider include shift levers, paddle shifts, gear position display, oil pump, oil cooler, slip yoke and bell housings.

Speed Reducer Terms

- Actuator

- A device that creates automatic motion by converting various forms of energy to rotary or linear mechanical energy.

- Axial Movement

- Also referred to as "endplay." The movement of the end of a motor or gear shaft. Usually measured in thousandths of an inch.

- Backlash

- A condition in which a speed reducer’s output shaft moves, but the input shaft remains motionless.

- Cam

- A rotating disk shaped to convert circular into linear motion.

- Efficiency

- The measurement, stated as a percentage, of a speed reducer’s ability to perform adequate speed reduction. Efficiency represents the comparison of power input and power output.

- Endshield

- The part of a motor that houses the bearing supporting the rotor and acts as a protective guard to the internal parts of the motor; sometimes called the endbell, endplate or end bracket.

- Gear Ratio

- With regard to speed reducers, the ratio that represents the comparison between the input speed of the gearmotor and the output speed of the gear head.

- Horsepower

- Is a unit of work equal to 33,000 foot pounds per minute, 550 foot pounds per second, or 746 Watts.

- Hysteresis

- The difference in the output state of a mechanical system with respect to input history; a component of bi-directional repeatability.

- Input Horsepower

- The amount of input power generated by a motor that a speed reducer can accept.

- Lost Motion

- Motion lost because of mechanical hysteresis, backlash, or torsion related stiffness in a rotational control system.

- Mechanical Rating

- The amount of power that a speed reducer can safely manage before the occurrence of overload.

- Mounting Position

- The placement of a speed reducer input shaft and output shaft.

- Output Horsepower

- The power that a speed reducer releases from the output shaft, which depends on the speed reducer’s efficiency.

- Output Shaft

- The part of the speed reducer to which the driven equipment is connected. The output shaft is responsible for the power transmission to the driven equipment.

- Thermal Rating

- A rating measuring a speed reducer’s continuous transmission of power.