Industrial Shredders

Two of the biggest problems in our modern society are data security and pollution. As weird as it sounds, one industry addresses both problems. Shredding is an environmentally sound process that helps recycle materials and can also eliminate sensitive information. This earth friendly process saves energy and eliminates cumbersome refuse.

One of the best ways to dispose of waste products is shredding. There is a unit for almost every type of waste. Large industrial strength units are an ecological way to eliminate everything from metal to biological wastes.

Industrial shredders are composed of a feed area with blades or gears for crushing or slicing material and a chute that passes the material into a receptacle or conveyor for further handling. Industrial shredders are often located in large, commercial shredding plants, inside the home or office or in a truck called a mobile shredder.

Quick links to Industrial Shredders Information

The History of Shredding Services

Before shredders were a viable option for large wastes it had to be perfected throughout history. The heavy duty shredders that we see today had a humble beginning. It is no surprise that this process is almost as old as paper itself. Sometime around 4000 BC, the Egyptians created the first known paper called papyrus. When a mistake was made people would tear the paper up with their hands. This is the earliest occasion of document destruction.

It wasn't until 1908 that a specialized paper shredding unit was created. Abbot Augustus Low was a prolific inventor that was second only to Thomas Edison in official United States patents. In August of 1909 Low was awarded a patent for the Waste Paper Receptacle. This was the first mechanical paper shredder known to history. Unfortunately, Low never got around to manufacturing this product and most of his work was ignored and lost.

In 1935, a German man named Adolf Ehinger created the first machine-run shredder. He based the invention off of a hand crank pasta maker. It is said that he created it so that he could shred anti-government propaganda in 1930's Germany. He later replaced the hand crank mechanism with an electric motor and marketed it to government agencies. It is worth noting that Ehinger's company, EBA Maschinenfabrik, created the first cross-cut paper shredder in 1959.

The cold war saw an increased need to destroy sensitive documents. During the 1950's through the 1980's, these units were used almost exclusively by government agencies to destroy confidential government information.

The rise of the digital age ushered in a new era for information safeguarding. Hard drive destruction has become vital for almost every industry. Medical records, bank account information, and other identifying information must be destroyed in order to prevent criminals from exploiting them. Similarly, large amounts of industrial, biological, and medical wastes need to be eliminated in an efficient and economical manner.

Industrial units were born out of this chain of events. Improved technology and an increased desire for environmental accountability led to the development of units that can handle larger and more diverse wastes.

Benefits of Industrial Shredders

Shred companies use this professional machinery to efficiently eliminate a large variety of materials. The high powered tools dispose of virtually any waste products. Many of these industrial units make it easier to recycle waste as well. Shredders may be small and hand-fed or large and able to shred thousands of pounds of material per hour.

These units are vital to almost every business, from healthcare to paper production for recycling, because it is an efficient way to safely eliminate sensitive information as well as hazards to humans and the environment. It allows a company's employees to focus on their job without the worry of discarding waste. Businesses in almost every industry can benefit from industrial shredders but many people aren't aware of how much a quality industrial unit can dispose of.

Various units can dispose of wood, plastic, textiles, and biomass. If you have something that you need to get rid of, there is probably a unit that can reduce and package your waste for easy removal and recycling.

How Industrial Shredders Work

Large industrial units work in much the same way that the small, household units do. Refuse is loaded into a dedicated area and it is processed through a cutting mechanism. Then it is packaged in a manner that allows for transportation and disposal. There are many different types of industrial units. They are capable of destroying various types of waste, including:

- Tires and Chassis

- Metal

- Wood

- Plastic

- Garbage

Shredders Images, Diagrams and Visual Concepts

Equipment designed for shredding dense and light materials for recycling or destruction of unusable products.

Equipment designed for shredding dense and light materials for recycling or destruction of unusable products.

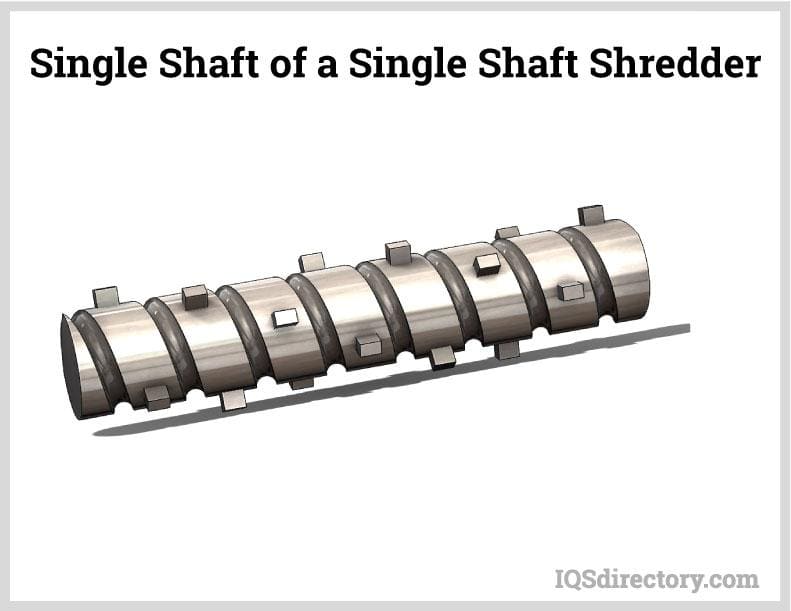

A single shaft rotates at a low RPM rate and shreds materials to one or two inches.

A single shaft rotates at a low RPM rate and shreds materials to one or two inches.

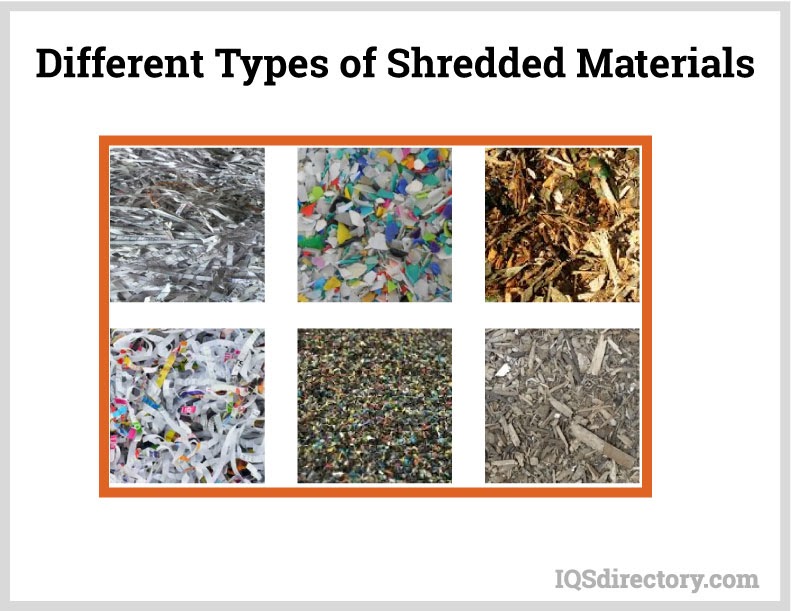

The different type of materials that can be shredded.

The different type of materials that can be shredded.

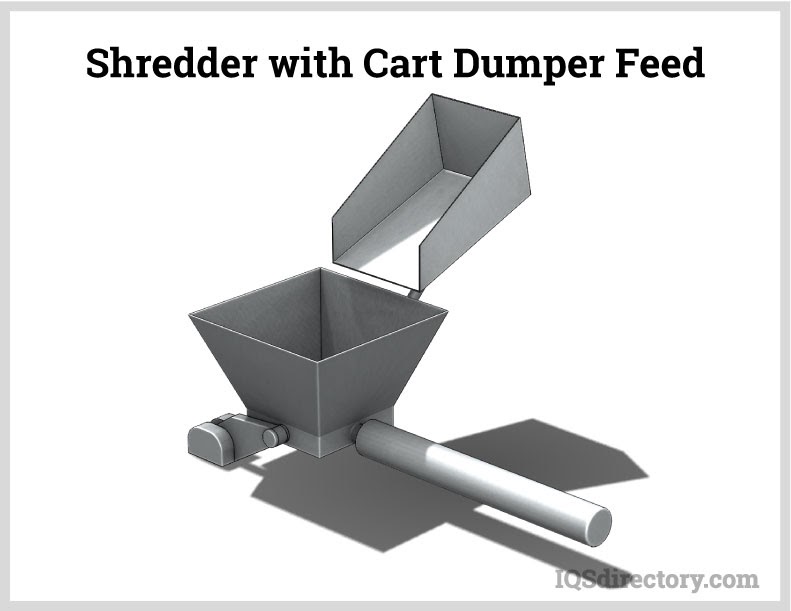

Fed into the shredder to allow processing.

Fed into the shredder to allow processing.

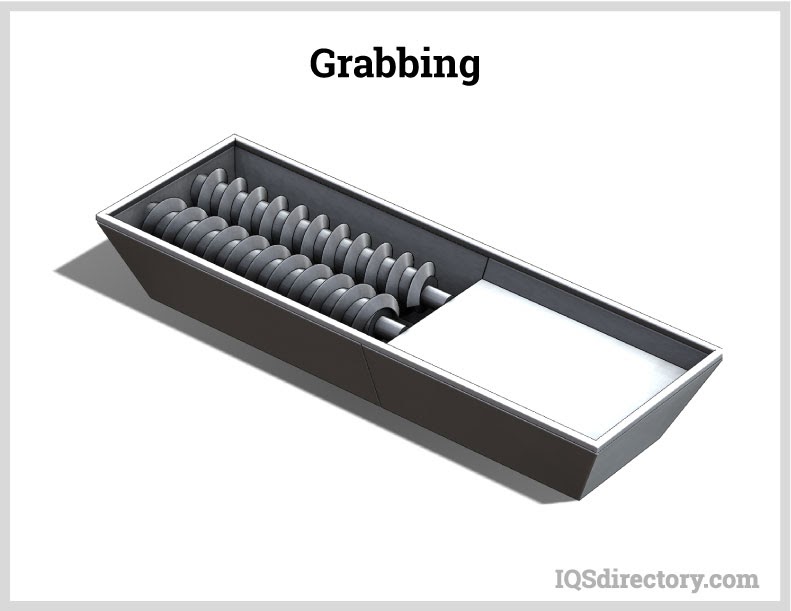

The material is grabbed by the cutting mechanism and is pushed through the rotating blades into smaller pieces.

The material is grabbed by the cutting mechanism and is pushed through the rotating blades into smaller pieces.

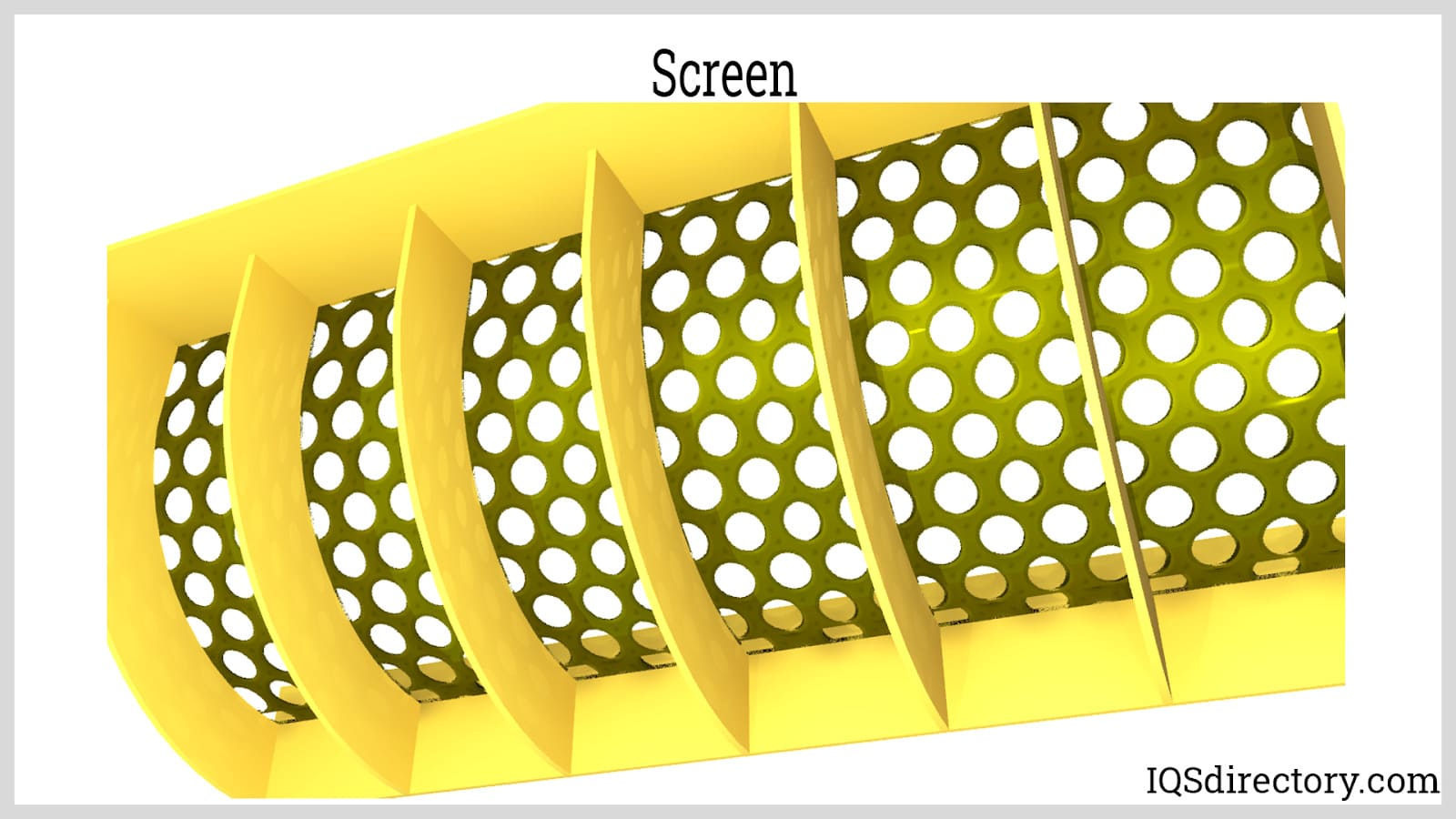

Screens are designed to fit the type of material allowing contaminants to be processed out.

Screens are designed to fit the type of material allowing contaminants to be processed out.

Types of Shredders

If your needs are limited to paper a standard unit will do. Large manufacturing facilities often have a much bigger need. It is advisable for a large manufacturer to purchase their own unit to deal with large quantities of waste. Many units are versatile enough to handle larger than normal waste disposal needs. Some applications require specialized units.

Even municipal solid waste can be shredded with specialized equipment. The process condenses solid waste and converts it so that it is more manageable for transport.

These units use the same principle but they are tweaked for their specific purpose. There are multiple modern designs that most industrial units use. They differ in the design of their cutting components. The different designs include:

- Horizontal Hammermills

- Vertical Hammermills

- Slow Speed Shears

- Single, Dual, Triple, and Quad Shafts

- Cracker Mills

- Refining Mills

- Automobile Shredders

- Hammermill-type shredders that are big enough to shred entire cars and compact them into small squares for recycling.

- Cardboard Shredders

- Another common type of industrial shredder. Because cardboard is such a widely used packaging material, the efficient minimizing, removal and recycling of cardboard is an industry necessity. Cardboard shredders process used cardboard packaging.

- Chipper Shredders

- Cut wood or other materials in small chips. Chippers are often used to handle wood products and materials such as branches, cardboard boxes, crates and particle boards are often shredded for recycling or conversion into other products. Chipper shredders cut wood into chip form, which reduces their bulk for easier disposal. Wood chips are also often used outdoors as walkways, in playgrounds and in landscaping or gardening.

- Document Shredders

- Used to carefully destroy sensitive documents.

- Granulation Machines

- Used for shredding small materials such as plastic bottles.

- Hammermills

- High-speed rotor equipped machines with large hammers for crushing material into reduced sizes with up to 6,000 horsepower of force. Hammermills come in various sizes and material reducing capabilities.

- Hard Drive Shredders

- Specialized hard drive destroyers ensure that no one will be able to steal data from old hard drives. Protect confidential and private information by physically demolishing platters of hard discs so their contents may never be recovered and fall into the wrong hands. These shredders do what deleting, overriding and cutting holes in disc drives can't. Hard disc shredders are often offered by companies that shred paper or microfilm via saw tooth hook cutters.

- Hydraulic Drive Shredders

- Have a pump, which powers the motor and is connected to an electric motor or diesel engine. These shredders can reverse away from the load and resume forward rotation in less than three seconds.

- Industrial Grinders

- Use attrition and compression to crush material into small pieces. They are often used to chip pieces of a larger piece of something. These small pieces are readily recyclable and used to make a new part.

- Industrial Shredders

- Equipment designed to destroy things in advance of disposal or reprocessing.

- Medium-Speed Shredders

- Round and drum-like with multiple cutter inserts that work against a fixed bed knife. They are commonly used for reducing materials like plastics, electronic scrap, wood waste and nonferrous metals.

- Metal Shredders

- Heavy-duty shredders that shred metal scrap for recycling purposes. Metal Shredding units will help you deal with difficult to manage metal waste. Specialized units handle the disposal of almost all types of metal waste.Metal scrap shredders are the strongest variety of shredder. They take products such as steel drums, cable, tubing, sheet metal or old cars, separate their metal parts from non-metal parts, put them through a heavy-duty shredder, and then compress them into dense blocks. Steel is often recycled through shredders, as half of stainless steel is produced from scrap metal.

- Mobile Shredders

- Shredding equipment that can be moved from place to place.

- Paper Shredders

- One of the most common types of material shredders known. They can vary greatly in size and capacity and are standard fixtures in environments such as offices and paper mills.

- Plastic Shredders

- Designed to cut discarded plastic into manageable pieces in advance of reprocessing.

- Shear Type Shredders

- High torque, low speed shredders with two or more counter rotating shafts. The shafts have hooked knives capable of reducing a wide variety of materials such as tires, paper and baled metals such as aluminum.

- Tire Shredders

- Used both in junkyards and other rubber recycling centers. They are slow speed, high torque machines, capable of handling the dense rubber used in tires and tubing.

- Tube Grinders

- Used primarily for wood and organic material. They have a hammermill that rips and tears large pieces of material into smaller pieces, pulling them below the tub floor and forcing them through openings in grates below the mill.

Shredding Location

- Off Site Shredding

- The shredding industry provides service to its customers in several ways. The most common way, off-site shredding, is widely used by recycling plants for tires, wood, organic materials, old automobiles, scrap metals, plastics and cardboard. In this method, the materials are transported to a shredding facility. Remote document shredding is a service where a driver picks up the materials to be shredded and transports them to the facility where they are shredded in the same day. Some facilities offer mobile shredding, which is a service that brings large shredders on a truck to different businesses for the on-site shredding of documents. The trucks are often modified box trucks with industrial-sized shredders inside that can shred up to 8,000 pounds of material in an hour. This service is for businesses such as medical practices or government agencies that need industrial shredding but are required by privacy laws such as the Health Insurance Portability and Accountability Act to witness the shredding of their documents. This is not only convenient but it eliminates a step in which information can be lost or stolen. This, however, is not feasible for the elimination of large industrial waste.

- On Site Shredding

- An on-site industrial unit may fit your needs better if you deal with large amounts of cumbersome waste. Large facilities have an even greater need for waste disposal and recycling. These units may be manual feed or have a heavy duty method for loading objects.

- A good company will discuss your needs in depth and offer the most convenient, cost-effective option. These units mangle and package your waste for convenient disposal. Most companies provide convenient debris bags to collect and transport pre-shredded paper, or other pre-shredded waste.

Environmental Benefits

These units are one of the most important pieces of recycling equipment that your facility can have. They extend the lives of a host of different things. They reduce waste to a manageable package and allow for easy transport. From there, these 'packages' are sent to specialized facilities and used to make new products. These recycled goods are repurposed into a variety of different products. This is better for the environment and can save companies millions of dollars.

What is from recycled refuse?

- Paper Products

- Paper products are taken to a paper mill and condensed by shredders that strip cut, cross cut and particle cut paper into small shreds or pieces. They are then reduced to a raw pulp, which is used in the manufacturing of new paper that contains recycled fibers.Used cardboard boxes and cartons are often shredded by steel cutters or shears to produce packing material or cut down to a certain size.

- On a small scale, paper can be used for animal bedding, garden mulch, package protection, and a host of other creative applications.

- On a larger scale recycled paper has an almost infinite amount of uses. It can be made into a high quality substance that is used to make walls in houses and buildings. It is tough, relatively cheap, and easy to manufacture.

- Glass Bottles

- Glass is unique because it can be recycled over and over without a loss in quality. It is resilient and diverse in its applications. Glass can be used to make more glass products, of course, as well as making tiles, concrete, and asphalt.

- Plastic Products

- Plastic products such as drums, pipes, car bumpers and bottles are reduced into fine particles by granulators via a rotor with strong blades and high rotations per minute. The resulting material is then heat treated and converted into other plastic products.

- Rubber From Tires

- The rubber from old tires can be used to make new tires, asphalt, artificial reefs, and an expanding amount of other things.Old tires are often cleaned, separated from their steel rims and shredded to produce crumb rubber, which is made into new tires and is used in the manufacturing of road asphalt. Crumb rubber is also sometimes used as a surface material for sports complexes.

- Municipal Waste as a Fuel

- Municipal solid wastes offer a particularly encouraging possibility. They can be used to make refuse-derived fuel. Researchers are working to try to find a renewable alternative to fossil fuels. This can have a massive impact throughout the entire globe. It has the potential to change the way the world functions.

- The positive environmental impact that shredding offers cannot be overstated. Reusing these materials reduces the amount of garbage and saves energy.

Standards and Safety for Shredders

Improper use of equipment can lead to serious injuries or even death. Anyone that is present during the process must observe and adhere to the stringent safety guidelines. The safety regulations vary per unit but there are universal ones that should always be observed.

Use a mixture of techniques to find the best unit for your needs. Research the different types, collect information from customers, and try to find an opportunity to observe multiple units in action.

The industry has come a long way from manually tearing paper by hand. The modern world needs a way to destroy paper products and large wastes in bulk. But it does not stop there. Companies all over the world need to find convenient, cost effective, solutions for the disposal of a variety of wastes. Quality companies can offer you professional solutions to your waste disposal. On-site, industrial units allow larger companies to dispose of their refuse in an environmentally sound manner. It is your responsibility to deal with waste products efficiently and ethically.

These guidelines are applicable to units of all types. The list is by no means exhaustive. Consult the owner's manual or safety guide for safety tips from the manufacturer.

- Qualified Individuals

- Only qualified individuals should operate the unit. This is as true for small machines as it is for large machines. These units are manufactured with certain safety features but no feature is foolproof.

- Know the Safety Features

- Ensure that you are familiar with those safety features and their possible limitations. Always know where the emergency shut off is and how to use it.

- Don't put too much in at one time. This leads to jams that can make any unit dangerous and unpredictable.

- but only a licensed professional can diagnose and repair a unit.

- Consider Unit Size

- There is much to consider and your options are plentiful for waste management and disposal. You must decide if your needs are small enough to be handled by a mobile unit or if you require a massive industrial unit for your needs.

- It is important to remember that no two units are exactly alike. There are good manufacturers who dedicate themselves to quality and conversely there are ones who cut corners in the interest of profit. You must identify your options in order to make the best choice for your business. You must also remember that what is good for someone else may not be good for yours. Don't buy an industrial unit just because someone else is satisfied with its performance. The best unit on the market may not be right for your needs.

Shredder Terms

- Automotive Shredder Residue (ASR)

- Material left from an automobile that has been sent through an industrial shredder and all the ferrous metal has been taken out. Sometimes referred to as fluff.

- Balers

- Compress materials that have been shredded by industrial shredders into dense rectangular bales.

- Bales

- Compressed material that has been shredded by industrial shredders, which is bound, usually by wire.

- Banding

- The material, usually wire or nylon, wrapped around bales to secure them.

- Burden Depth

- The depth of the material is spread on a conveyor belt.

- Cross-Cut

- Cut in two directions by industrial shredders, resulting in smaller particles.

- Destruction Chamber

- The place in industrial shredders where material is torn, sliced, crushed or reduced.

- Downstream Separation

- The separation of material after it has gone through industrial shredders, usually from a conveyor belt. Magnets, eddy current separators, trommels and other downstream separation equipment is often used.

- Eddy Current Separator

- A device for separating nonferrous metals from nonmetallic material that uses a mechanically driven alternating magnetic field and a non-magnetic metallic particle. An eddy current is created and the particle is taken from the fixed field generator.

- Feed Width

- The width of the opening where material is inserted into the industrial shredder shredder.

- Ferrous

- Iron-based metals like steel.

- Grapplers

- A highly resourceful tool used in a variety of applications and is designed to pick up waste material, loose material, ferrous and non-ferrous metals, automotive salvage and much more.

- Granulator

- Shredding machinery for shredding small materials such as plastics.

- Hydraulic

- Involving, moved by or operated by a fluid under pressure.

- Material Burden

- Material on a conveyor belt that needs to be sorted.

- Metal Shears

- A procedure for straight-line cutting of flat stock metal. Performed by forcing an upper blade and lower blade past each other with a desired offset.

- Non-Ferrous

- Non-iron based metals such as aluminum and copper.

- Pallet Shredders

- A type of industrial shredder, a heavy-duty machine that can shred dense and strong materials like rubber tires, plastic containers and large volumes of cardboard and paper.

- Shredder Drive

- The motor of the industrial shredder, often configured a number of different ways including electric or hydraulic.

- Slurry

- A liquid based mixture or suspension of solids.

- Speed

- Denoted in "feet per minute." Determined by shredding continuous forms and materials and by calculating the length of paper shredded over a given time.

- Strip-Cut

- Shredded into thin strips. Generally the cut is the length of the material.

- Throat

- The opening where the paper or other materials are fed into the shredder. It needs to be large enough to accommodate the size of material.

- Unshreddables

- Materials that industrial shredders are unable to handle because they are too large or too thick to be shredded.

- Used Shredders

- Are a great option, not just because they are inherently more economical than new shredders, but also because they are competitively priced and sustainable.

- Waste Capacity

- Measured in gallons, the volume of paper or other products being shredded by industrial shredders that the waste bag or waste bin can hold.

- Waste Shredders

- Useful for industrial businesses, municipal service departments and waste disposal centers.