Sandblast Equipment

The term “sandblast equipment,” or blaster/machinery, applies to a wide variety of tools and equipment designed to use sand (or a similar material) to clean or resurface industrial products and components. To do this work, sandblasters participate in the process of sandblasting, also known as blast cleaning.

Sandblasting is an abrasive blasting process that propels materials at a high pressure and high speed to smooth out rough surfaces. Note: Sandblasting has become the blanket term for all media blasting processes, though it technically refers only to media blast processes that use sandblasters and silica blasting media.

Quick Links to Sandblast Equipment Information

The History of Sandblast Equipment

The earliest abrasive blast equipment was invented in 1870 by a man named Benjamin Tilghman. He developed the blaster so that he could blast away paint and rust from old parts before repurposing them.

In 1893, air processors were invented, and abrasive blast equipment got a boost in 1904, when Thomas Pangborn added compressed air and sand to the blast equation. As the years went on, people began to discover that sandblast inhalation could cause a lung disease called silicosis. So, in 1918, to improve safety, engineers began building enclosures. These shielded workers from the abrasive blast media, while allowing them to still see it via a viewing screen. Later, they began adding in components such as protective clothing, air filters, dust collectors, etc.

Starting in 1939, manufacturers have tested all sorts of alternative abrasive blast media, ranging from crushed walnut shells to glass beads. To this day, they continue to search for ways to improve the safety and sustainability of blast equipment and media.

Advantages and Benefits of Sandblasting

There are many benefits to using the various types of sandblasting equipment out there. Let’s quickly go over them.

- Sustainability

- Advances in residual blast media collection allow for recycling and reuse of used particles, saving materials expenses and mitigating environmental degradation simultaneously.

- Other provisions for project sustainability are available as well. Use of organic blast media like crushed walnut shells, ground corn cobs and baking soda reduce risks to air quality, pollution caused by residual blast media and contamination of water sources in the weeks and months following an outdoor blasting project.

- Speed and Efficiency

- Because sandblast equipment is so simple, yet so powerful, sandblasting can be completed very quickly and very efficiently.

- Cost-Effectiveness

- Because, once again, blast equipment is so simple, it is fairly inexpensive. Plus, the materials required to make sandblasting work are generally easy to come by and inexpensive. Paired with the fact that blast media can often be recycled, the process is affordable all around.

- Versatility

- Use sandblast equipment for a variety of surface treatment tasks, including: coating removal, smoothing or roughening, etching, carving, degreasing, deburring, deflashing and descaling.

How Sandblasting Works

Sandblasting equipment works via the combination of high pressure, abrasive media and, sometimes, water. Basically, it scrubs parts clean, or scrubs parts smooth. Here’s another way of looking at it: It’s like erosion.

Sandblasters create this scrubbing action when the materials propel the abrasive blast onto the substrate surface. The blasting material, also known as media, can range from being highly abrasive (ex. fine glass beads) or mildly abrasive (ex. sand). All sandblasters send out abrasive media using either compressed air or pressurized water, typically via a nozzle gun.

Sandblaster Images, Diagrams and Visual Concepts

Sandblasting equipment includes systems or machinery, and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface.

Sandblasting equipment includes systems or machinery, and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface.

An example of manual blast cabinet.

An example of manual blast cabinet.

An example of a blast gun tool.

An example of a blast gun tool.

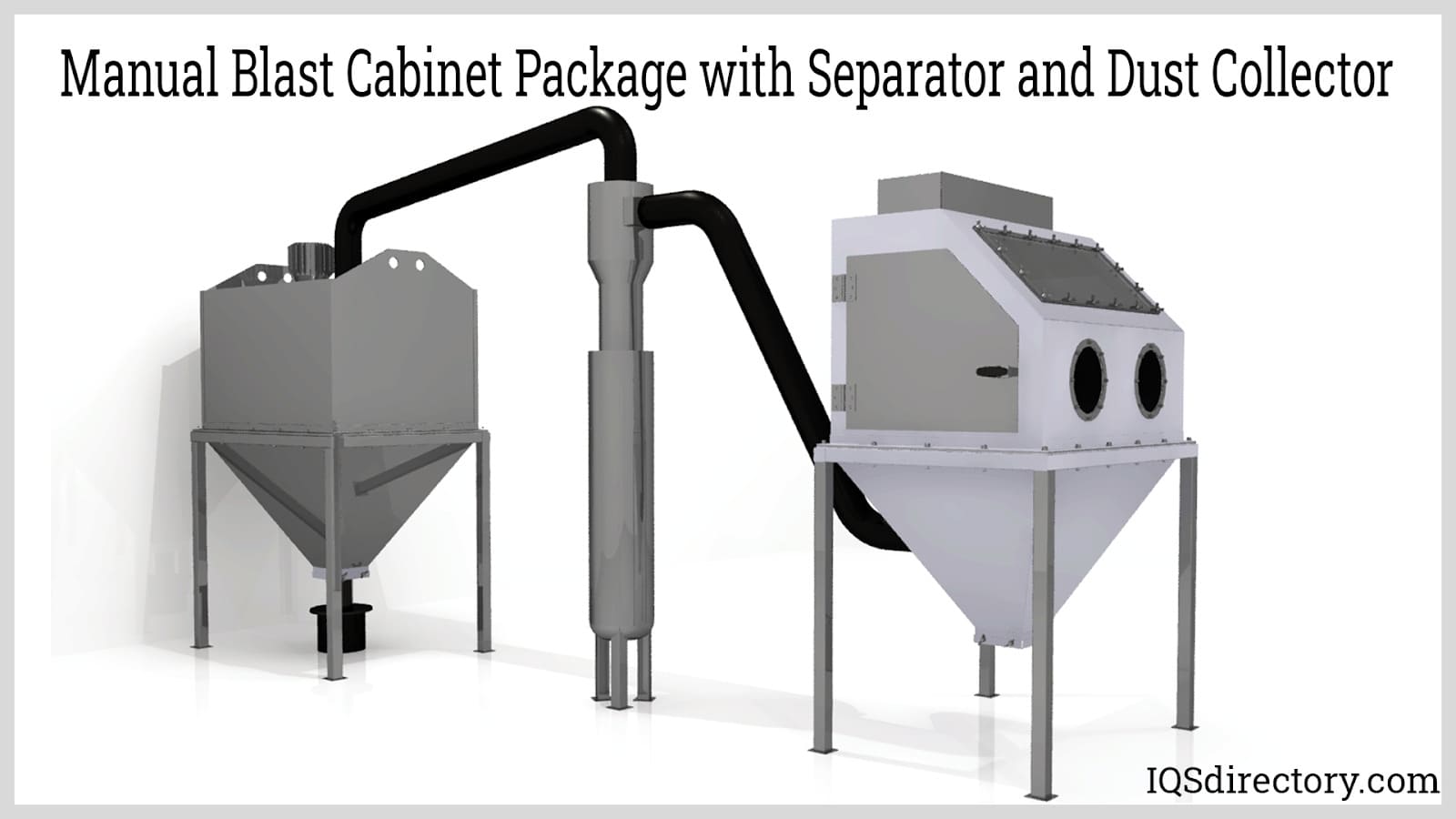

An example of manual blast cabinet package, which includes a a blast cabinet, separator, and dust collector.

An example of manual blast cabinet package, which includes a a blast cabinet, separator, and dust collector.

An example of a blast room equipment.

An example of a blast room equipment.

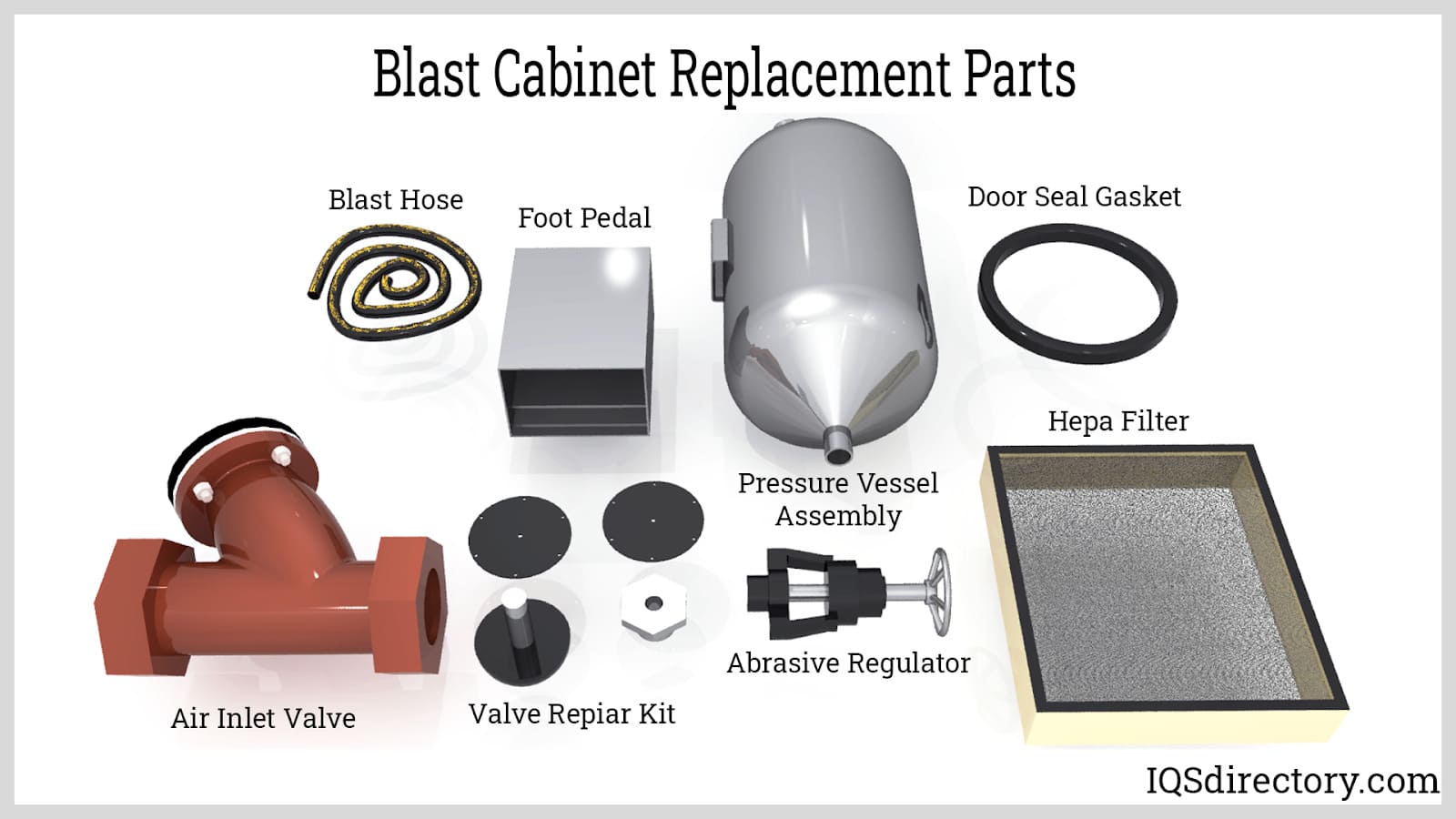

These parts are the most common parts in a blast cabinet that need to be replaced.

These parts are the most common parts in a blast cabinet that need to be replaced.

Types of Sandblasters

To accommodate the wide range of parts and products that rely on sandblasting, manufacturers create an equally wide range of blasting equipment. Examples include: automated blasting systems, sandblast cabinets, blast rooms, portable sandblasters, gravity fed sandblasters, siphon sandblasters, pressure sandblasters, wet sandblasters, dry sandblasters, bead blasters, wheel blast machines, air blast machines, and grit blasters.

- Automated Blasting Machines

- Allow for the large scale treatment of small parts and products. Consider how one of these could be used to benefit your company. Automated blasting systems remove contaminants, coatings and debris from parts in a manner similar to batch processing, conveyor-type systems.

- Bead Blasters

- Utilize high pressured streams of spherical abrasives to clean or otherwise resurface parts and components in industrial, commercial and domestic settings.

- Sandblast Cabinets

- In similar fashion to automated blasting machines, allow you to do large scale treatment of small parts. Sandblast cabinets are enclosures in which items are placed to be abraded. Blast cabinets are useful in containing the blasting operation and preventing exposure of the blasting media to surrounding workers.

- Portable Sand Blaster

- Can be taken from one worksite to another, making single treatments of large surfaces possible. Portable sandblasters are mobile machines of varying size and design that utilize high pressured streams of abrasive materials to clean or otherwise resurface parts and components.

- Blast Room

- A larger version of a sandblast cabinet. A typical blast room consists of three main components: a containment structure, an abrasive blast system, and dust collector. If additional dust cleanup is needed, you can check out the systems for dust removal IQS lists here. Also, it’s quite common for a blast room to have one or more recycling systems.

- Gravity-fed Sandblaster

- Use gravity to remove the discoloration or dirt from parts’ surfaces. When paired with this type of blaster, media is directed into the barrel of the gun from the top. Located at the top is a hopper, which holds the supply of media as you work. When you press the device, air, together with the media, blasts out of the nozzle at a very high speed. Gravity-fed systems use gravity to direct abrasives into the compressed air stream.

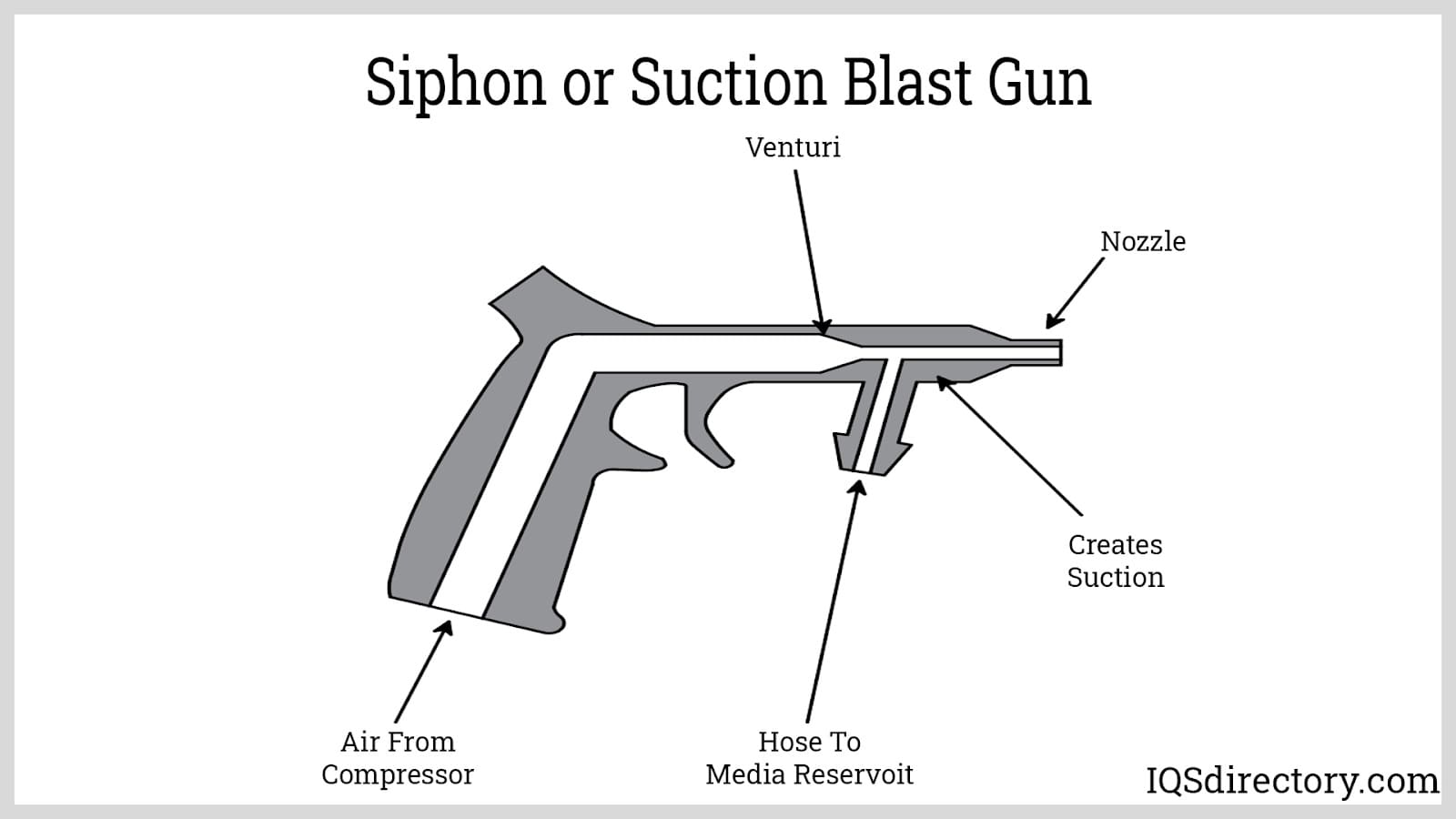

- Siphon Sandblaster

- Similar to gravity-fed sandblasters, but there is a small difference in the design of the container, which holds the media: It is placed below the nozzle instead of above. Siphon systems function using suction, or by passing the compressed air stream next to the unpressurized abrasive store. The change in pressure siphons abrasive into the stream of compressed air. This type of operation is relatively cost-effective, as sand can be recollected again into the reservoir.

- Pressure Sandblaster

- Use canisters, or vessels, to which a gun is hooked up. Out of this gun, or hose, wet sand is blasted. The pressure pot system is identical to the siphon system except that its abrasive store is negatively pressurized to allow for a more efficient combination of air and abrasive. Note: Pressure blasters are easy to use compared to the other types. The treatment of metallic parts requires one of two types of blasting machines; wet sandblasters and dry sandblasters.

- Wet Sandblaster

- Driven by pressurized water while a dry sandblaster uses the power of compressed air. It provides a water-driven wet blast that is best for the surface treatment of those parts that require cooling during the blasting. This reduces surface deterioration of the parts and maintains the aesthetic value of the material.

- Dry Sandblaster

- Release sand with high velocity on the surface to smoothen it. This method accounts for most of the surface treatment of a wide variety of materials, parts and products.

- Bead Blaster

- Remove paint or surface deposits by propelling a stream of fine glass beads at high pressure. This kind of blasting is not recommended for small parts. Rather, it is widely used for surface treatment of the bodies of automobiles. It is also popular for cleaning calcium deposits and embedded fungus on pool tiles or any such surfaces.

- Shot Blaster

- Use coarser metals as media for cleaning or polishing metal surfaces. Shot blasting releases sparks or light, called shot blasts, on impact. A shot blast may be composed of many different colors, depending on the selected media. Shot blasting uses two technologies: wheel blasting and air blasting. Shot blasters are machines that heave shot at a high speed toward an intended surface in order to remove paint, debris and buildup from the surface.

- Wheel Blast Machines

- Converts electrical energy into kinetic energy for propelling abrasives onto a coarse surface. This is ideal for surface treatment of big machines or parts that have a large surface area.

- Air Blast Machines

- Are powered by compressed air and projects metals through nozzles onto the component.

- Grit Blaster

- Grit blasting uses various particles like soft walnut shells, sand, silicon carbide, alumina, or emery particles based on the application. These particles are propelled by the power of compressed air, pressurized water, or steam.

- Grit blasters are machines of varying size and design that utilize high pressured streams of abrasive materials and slurries to clean or otherwise resurface industrial parts, products and components.

- Grit blasters are used to remove sand and scale in castings, and for stampings and billets. Before welding, metallic surfaces are prepared by grit blasting, which improves the adhesion of coating and gives a smooth finish.

- Media Blasting

- A process that removes coatings from metal, wood, fiberglass, and other substrates using pressurized streams of abrasive materials.

- Micro-Blasting

- Or micro-jet machines are specialized machines for applications needing selective surface preparation, material removal and finishing.

- Sandblast Media

- The variable abrasive materials used in sandblasting equipment to remove coatings and unwanted debris from the surface of metal, wood, plastic and glass industrial components.

- Shot Peening Equipment

- Used to mechanically and cosmetically modify the surface layer of metals.

- Soda Blaster

- A kind of grit blaster that uses baking soda. A soda blast is a healthy alternative to something like a silica blast, which, unlike the soda blast, can have harmful side effects on people when ingested.

- Soda blasting equipment is a specific type of media blasting apparatus that uses pressurized streams of sodium bicarbonate to clean or otherwise resurface industrial parts, products and components.

Sandblaster Equipment Components

Different sandblasters have different components. Below are a few more common ones, including blasting media, air compressors, nozzles, blast hoses and pressurized water.

- Blasting Media

- In the sandblasting process, an abrasive media, such as sand, glass beads, or steel grit, is shot at high speed so that the surface of a hard material becomes smoother.

Some blasting media types include:

- Silica Sand or Silicon Dioxide

- Silicon dioxide is sand, which is a commonly used material for removing rust or dirt from surfaces. Sand is efficient in abrasive blasting, as the particles are sharp, making the process easier.

- Glass Bead

- If you wish to get a matte and satin finish, this medium is perfect. This grit has very fine particles that produce a much smoother and brighter finish of the object being sandblasted.

- Aluminum Oxide

- Media is much sharper than glass bead and stays sharper for a long time, and that is why it is used in paint removal and general cleaning.

- Air Compressors

- Dry machines use air compressors to generate a powerful stream that propels abrasives against surfaces.

- Pressurized Water

- Only a small minority of blasting projects use pressurized water. Mostly, it is used for the treatment of surfaces that need to be cooled during blasting.

- Nozzles

- Used to direct the blasting stream. The most common type of nozzle is the ceramic nozzle.

- Blast Hoses

- Used with a pressure blaster, where it conveys media from a pressure vessel (where it is stored) into the blast nozzle. Note: the vessel and the blast hose are pressurized to the same level.

- Dust Collector

- Many types of abrasive blast equipment include a dust collector in their system. This dust collector captures a large portion of the dust produced via sandblasting. A dust collector is especially important when you’re working with media that is hazardous to human health, such as silica sand. It’s also useful for media reusing and recycling.

How to Use a Sandblaster

To use your sandblaster, start by connecting the hose to the air tank, and the nozzle to the hose. Fill your vessel with the media of your choice. Make sure that all of your pressures are properly matched and calibrated. Once you’re ready, control the blast gun via your controls. Typically, this means pointing and pulling the trigger of the blast gun. Sometimes, this means signaling for the trigger to pull via a remote control. Either way, this is the part where your product gets blasted to a smooth polish or an even finish.

Applications of Sandblasting

Blast equipment is used to remove any number of imperfections from a metal, wood, glass, or plastic product surface. Most often, the equipment is used to remove: rust, paint, discoloration, corrosion, dirt, dust and the like. Often, manufacturers use it as a surface preparation prior to painting.

This is useful for a wide variety of industrial applications that include: industrial cleaning and processing, automotive manufacturing and repair, marine, construction, agriculture, aerospace, decorative design, woodworking, and glass working.

Within these industries, customers turn to sandblast equipment for the finishing of parts and products such as recently produced fasteners, engine components, tractors, watercraft, cars, aircraft, heat exchangers, bridges, building components and printed circuit boards.

Design and Customization of Sandblasting Equipment

When manufacturers are designing a sandblast system, they consider several factors.

One factor they look at is the size of the operation. For example, gravity-fed systems, especially when combined with portable blasters, work well for small projects, especially in portable blasters.

Another thing they look at is what media they’ll pair with the sandblast machine.

- Angular or Rounded Media

- They consider whether they’ll use angular media or rounded media. This depends on the application for which they are making the machine.

- Angular materials are used for deburring, descaling, paint and coating stripping, surface texturing and cleaning.

- Rounded media may be used for these applications as well, but they can also be used to confer compressibility onto a metal surface by repeated, intense collisions with shot; this stress strengthens the surface.

- Traditional or Organic Media

- They also need to consider whether they will use organic/plant based media, or whether they will use something more traditional, such as aluminum oxide. Plant-based media, like nut shells or fruit kernels, in addition to being eco-friendlier, can be less expensive, more reusable, and better for user health. IQS Directory provides a directory of corn cob media suppliers on this site. Several other types of media can also be found here on IQS Directory.

- Equipment Customization

- Using these considerations, among others, manufacturers can create a custom blaster for any application. Custom blaster features and accessories may include: an outer case, a blast hood, a moisture separator, custom nozzle material, remote control use, and custom hose configuration, among others.

Standards and Specifications of Blasters

To keep workers safe while using a blaster, and to prevent future illness, manufacturers must adhere to many safety standards. In particular, it’s important that they operate sandblast equipment per the guidelines of OSHA.

Specifically, manufacturers should include safety accessories including: blast hoods or helmets, hearing protection, protective clothing, and adequate respiratory protection.

Simple changes to blaster workspaces, like the introduction of enclosed blasting cabinets, protective clothing, respirators and workspace ventilation, make operating silica blaster equipment much safer for workers.

Things to Consider When Purchasing Sandblasting Equipment

Selecting the right sandblast equipment is crucial to getting the desired surface treatment of materials.

Considering the following factors will assist you in choosing the suitable equipment:

- Type and thickness of material to be removed.

- The primary consideration for purchasing a sand blasting machine is the type and thickness of the abrasion that you intend to remove.

- Condition and age of the concrete base or metallic surface.

- Blasting sand with high velocity onto an abrasive surface may produce different results on old or crumbling surfaces and surfaces with high compressive strength.

- Nature and thickness of surface coating or painting.

- Surface treatment also depends on the thickness of coating or painting to be removed. Light profiling would be required for applying a thin coating while heavy texturing would be suitable for applying a thick coating on the surface.

- Other features of blasting equipment.

- You should also check other features and safety tips for the smooth functioning and getting the best results from the blasting equipment. Some machines come with restrictions on exhaust fumes, and there are waste disposal rules that need to be followed.

- Options for adding attachments.

- Check whether the machine has options to add attachments. A machine that can be fitted with a wide variety of attachments will make it easier to use in different kinds of situations.

You can look for a blasting equipment supplier on an online directory, such as ours. To assist you, we’ve listed some of the best sandblast equipment manufacturers and suppliers we know of, such as Empire Products. While investigating, always cross-check the quality of products and services. Also, try to find out whether the supplier can satisfy your requirements in a customized and budget-friendly way. In other words, find a supplier that puts your requirements first. This way, you will get the most satisfaction and the best value for your money.

Sandblast Equipment Terms

- Abrasives

- Media used for blasting, grinding or polishing. Abrasive materials are either in loose form or formed together into wheels, files or bricks or adhered to cloth or paper with resin or glue. Natural abrasives include sand, baking soda, garnet, emery, flint and corundum. Metallic shot, grit and plastic material are also used as abrasives in cleanings of castings and surface preparation.

- Abrasive Grains

- Tiny, individual particles of an abrasive mineral used in sandblasting.

- Abrasive Blasting Respirator

- A continually flowing air line respirator fabricated to cover the shoulders, head and neck of the wearer. Its purpose is to protect the worker from recoiling abrasives from the sandblasting equipment.

- Aluminum Oxide

- Hard mineral formed from the chemical reaction between oxygen and aluminum; the creation of aluminum oxide on the surface of a metal prevents future occurrences of oxidation. After the material has been sandblasted by the sandblasting equipment.

- Deburring

- Procedure involving the use of abrasives such as coated or bonded abrasives to remove burrs, jagged edges or protuberances on the surface of an object created during industrial applications.

- Dwell Time

- The amount of time that a blasting nozzle of sandblasting equipment remains fixed upon a particular area. Extended dwell times may cause excessive heat generation and damage the product.

- Emery

- A naturally-occurring abrasive containing aluminum oxide and iron oxide used in light applications rather than industrial processes because of its low hardness.

- Friability

- The extent to which abrasive grains break or split apart upon impact or under pressure; friable abrasives fracture relatively easily and possess a shorter lifespan.

- Shot Blasting

- A rapid, dust free process that leaves the substrate clean and dry. Shot blast machines hurl shots toward the intended surface at a high speed, removing debris, paint and buildup from the surface.

- Shot Peening

- A procedure used by sandblasting equipment that prepares a part or surface to withstand stress or fatigue breakdown.

- Slurry

- A pasty liquid mixture containing suspended solids.

- Superabrasives

- Category of hard mineral abrasives consisting of diamond and CBN; superabrasives maintain tremendous hardness.

- Zirconia Alumina

- Tough, artificial abrasive used in heavy sandblasting applications involving various forms of steel.