Baler Machines

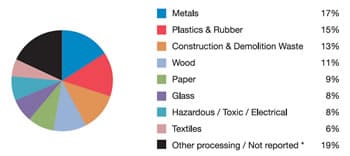

Keeping used materials out of landfills by repurposing them for new uses is one of the best ways to reduce our environmental impact and conserve scarce resources. An efficient recycling process creates a way for residential, commercial, and industrial locations to dispose of, sort, and reuse materials like: Ferrous & Non-Ferrous Metal, Ferrous & Non-Ferrous Metal,Plastic & Rubber, Construction & Demolition Waste, Wood, Paper & Cardboard, Glass, and Textiles.

Keeping used materials out of landfills by repurposing them for new uses is one of the best ways to reduce our environmental impact and conserve scarce resources. An efficient recycling process creates a way for residential, commercial, and industrial locations to dispose of, sort, and reuse materials like: Ferrous & Non-Ferrous Metal, Ferrous & Non-Ferrous Metal,Plastic & Rubber, Construction & Demolition Waste, Wood, Paper & Cardboard, Glass, and Textiles.

The recycling process begins with the collection of materials. A waste management company collects the recyclables with trucks from people‘s homes, from dumpsters at commercial facilities like office buildings and warehouses, or from industrial facilities. These recyclables are then taken to a recovery center for further processing.

The recycling process begins with the collection of materials. A waste management company collects the recyclables with trucks from people‘s homes, from dumpsters at commercial facilities like office buildings and warehouses, or from industrial facilities. These recyclables are then taken to a recovery center for further processing.

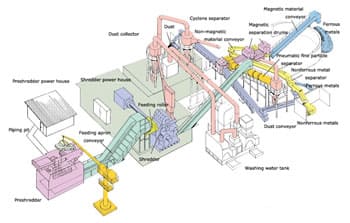

For larger recyclables, shredders, pulverizers, granulators, and other size reduction machines are necessary to break down materials into a smaller and more manageable size. Additionally, in some areas, recyclables have to be pre-sorted, but to encourage recycling many areas are now accepting unsorted materials. For this reason, many types of separation technologies have been developed to assist in efficient and accurate material sorting. Vibratory feeders, for example, can separate items based on weight to remove heavier objects like metals and glass. Other separators, like magnetic separators and screens, can also be used to methodically sort out each type of material into its own group.

After the materials have been separated, other processing may have to occur based on the type of material to prepare them for reuse. The materials are then put through a baling machine that compresses them into manageable bales or blocks. These bales can then be loaded on a truck and shipped to factories where the materials are reused in new products. For example, a bale of crushed metal cans could be shipped to a facility where the metal is melted down and then molded back into brand new cans.

After the materials have been separated, other processing may have to occur based on the type of material to prepare them for reuse. The materials are then put through a baling machine that compresses them into manageable bales or blocks. These bales can then be loaded on a truck and shipped to factories where the materials are reused in new products. For example, a bale of crushed metal cans could be shipped to a facility where the metal is melted down and then molded back into brand new cans.

If the material is taken to a mixed waste center, the waste has to be separated from the recoverable material. Most facilities are able to recover about 30% of the material during this separation, but the goal is always to raise that number.

When recycling industry experts talk about the "recovery rate", they are referring to the percentage of materials that they are able to recycle and keep out of a landfill. Obviously, there will always be some waste that is not reusable, but continuing to raise our recovery rate is key to preserving the environment and conserving our resources. Many people do not realize that plastic is a limited resource, even though so many things are made from it. That‘s exactly why it is so important to recycle as much as possible.

When recycling industry experts talk about the "recovery rate", they are referring to the percentage of materials that they are able to recycle and keep out of a landfill. Obviously, there will always be some waste that is not reusable, but continuing to raise our recovery rate is key to preserving the environment and conserving our resources. Many people do not realize that plastic is a limited resource, even though so many things are made from it. That‘s exactly why it is so important to recycle as much as possible.

It also takes far less energy to create a product from recycled material than it does to make it from raw materials. For example, it takes 88% less energy to make a plastic water bottle from recycled plastic than it does using a complete process with new plastic. The statistics are almost as drastic for cardboard, wood and glass products as well. Reusing materials is an easy way to improve efficiency and reduce our emissions of greenhouse gasses.

In a single stream recycling system, materials such as cardboard, glass and plastic are all able to be picked up together. This method is popular in residential recycling programs, since it allows residents to mix their recyclables and avoid having to sort material. The difficulty is that these mixed materials have to be sorted at the recycling facility. Because everything is mixed up, it‘s impossible to sort efficient and recovery a maximum amount of material. It has been shown that a single stream system harms the environment by failing to capitalize on the efficiency of sorted recyclable material. Products that could be recycled end up going to waste because the single waste stream is just too complex to sort in its entirety.

To solve this problem, many regions and facilities are turning to a dual stream process. Dual stream recycling means that fibre components like paper and cardboard are kept separate from the rest of the recyclable materials.

The greatest advancements in manufacturing and industrial operations are the provisions set aside for recycling equipment. As concern for the environment grows, more and more producers are purchasing recycling equipment or consulting recycling equipment manufacturers. All industrial operations are taking steps to improve their environmental footprint by developing processes and techniques that ensure the proper disposal of any waste materials.

The fast growing recycling industry is constantly perfecting and engineering new and more efficient processes for disposing of the millions of tons of waste left from manufacturing and commercial operations. All of the various methods are designed to take large amounts of waste and reduce it to a workable size capable for repurposing and reprocessing.

The first concern regarding waste matter is reducing it using specialized equipment. The reduction of waste is accomplished by shredders, pulverizers, compactors, granulators, and balers that use hydraulic force to crunch the waste and remove air. This assembly of devices can take a mountain of trash, garbage, and refuse and transform it into small chunks and bits.

The goal of all recycling processes is to mine waste matter to extract materials that can be transformed into raw materials for manufacturing. To accomplish this task, the various aspects of recycling equipment work together to break down waste, separate reusable materials, and package them to be shipped for use in producing new products. As simple as this description may seem, a great deal of engineering design and know-how is required at each step of the process.

The beginnings of recycling, as everybody knows, begins at the location where the waste materials are produced. For many people, the disposal of waste begins by taking a trash container to the curb. Though this is a vital part of waste management, it is only a portion of the process. The many forms of waste include computers, machinery, cars, appliances, clothing, paper, and aluminum cans.

Certain forms of waste are easy to distinguish since they are separated at the point of disposal. These types include plastic bottles that are shredded at stores, aluminum cans, clothing, and paper. Each of these types have been the concern of the general public for many years and have been consistently separated and reprocessed for manufacturing.

Though the awareness of the public regarding the volume of waste has been recently growing, manufacturers and producers have had to adjust their processes due to governmental requirements and regulations. The majority of industries have installed compactors that crush refuse prior to it being collected. In the case of some companies, they have their waste picked up every day to increase efficiency.

Once waste matter is collected, it has to be separated. Depending on the size and type of material, it can go immediately on to a vibrating conveyor line, which can be the first step in the separating process. For larger and more complex materials, they are pulverized, crushed, granulated, and sheared before being placed in the separation process.

One of the easiest forms of materials to separate are ferrous metals, which are heavier than other recyclable waste. To remove ferrous metals from huge and enormous piles of waste material, waste management engineers have designed massive magnets that hover over the vibrating conveyor feeder and pull out ferrous metals, which are baled, organized, and sent on for further processing.

The work of the recycling industry will continue to grow as new products replace old ones and the amount of waste increases. In the years since industrial leaders have become more aware of the need to recycle and its benefits, there have been gigantic technological advancements in the design and engineering of recycling methods. It can be assumed that those improvements will continue.

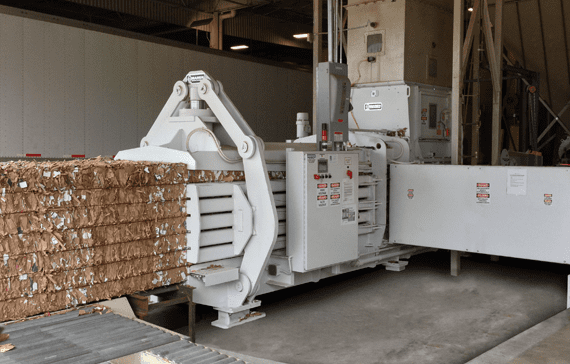

Balers are used to push materials together and compact them so that they can be formed into bales, or block-like shapes, that are easy to stack and transport. In recycling facilities, recovered materials are put into a baling machine after being sorted. This way, entire bales of plastic or metal can be shipped to manufacturers to be melted down and reused for brand new products.

Some baling machines even come with the added feature of moisture extraction to remove residue that may be leftover. Cardboard, plastics and even metals may have been used as containers for liquids that leave traces on the material when it is going through the recycling center. Moisture extraction ensures that the bales are dry when they leave the facility.

To begin creating a bale, a high volume of material is loaded into the input area of the machine. From this area, the material is led into a compression chamber where it is crushed and formed into a cube. Most balers are powered by electricity, but they use hydraulic power to compact and push material because this allows for a strong and consistent compressive force. After compaction, wire or strong plastic ties are then bound around the bale to hold it together while it is moved. Some balers can even be adjusted to create custom-sized bales. Since the bales are so heavy, a forklift is used to lift them and stack them or drive them directly onto a truck for shipping.

For manufacturers in industries that use recycled materials to create new products, compact bales are very convenient. They can be stored for processing at a later time, and easily moved around a factory using a forklift. Most factories are at maximum efficiency during high production, so it is optimal to have large amounts of material that can be melted all at once. Learn more about balers.

A vertical baler is a baling machine which utilizes a vertically oriented ram to compact recycled materials. Materials can be loaded in a variety of different ways, but most vertical balers are loaded through a large compartment on the front of the machine, which is then closed during operation.

A vertical baler is a baling machine which utilizes a vertically oriented ram to compact recycled materials. Materials can be loaded in a variety of different ways, but most vertical balers are loaded through a large compartment on the front of the machine, which is then closed during operation.

Since they are vertically oriented, they usually take up far less floor space than other baling options.

They are usually less expensive as well. Vertical balers are most commonly associated with cardboard baling, but they are capable of baling many different types of recycled materials and can be customized to fit specific requirements. Learn more about vertical balers.

Horizontal balers are balers equipped with a horizontally acting compression ram. This kind of baler is usually much larger than a vertical baler but has the added benefit of handling larger quantities of materials at one time and can even operate continuously. Horizontal balers can be fed manually or can be equipped with automated systems like conveyors and feeders to continuously feed materials into the compression chamber. Applications which handle high volume recyclables usually take advantage of horizontal balers as they provide greater material handling efficiency. These balers can also be designed to handle practically any recycled material, from paper to metals.

Learn more about horizontal balers.

Horizontal balers are balers equipped with a horizontally acting compression ram. This kind of baler is usually much larger than a vertical baler but has the added benefit of handling larger quantities of materials at one time and can even operate continuously. Horizontal balers can be fed manually or can be equipped with automated systems like conveyors and feeders to continuously feed materials into the compression chamber. Applications which handle high volume recyclables usually take advantage of horizontal balers as they provide greater material handling efficiency. These balers can also be designed to handle practically any recycled material, from paper to metals.

Learn more about horizontal balers.

A two ram baler is a style of horizontal baler which uses two horizontally oriented rams instead of just one. These balers are typically fitted with larger hoppers and feeding mechanisms, so that they can more quickly feed material into the compression chamber. With two rams, the baler can effectively compress bulkier materials and larger quantities of materials. In some cases, a two ram baler can eliminate the need for shredding, pulverizing, and other conditioning processes. In general, two ram balers allow recyclers to process more material, faster. However, since they are using two rams, they do require more room and more power.

A two ram baler is a style of horizontal baler which uses two horizontally oriented rams instead of just one. These balers are typically fitted with larger hoppers and feeding mechanisms, so that they can more quickly feed material into the compression chamber. With two rams, the baler can effectively compress bulkier materials and larger quantities of materials. In some cases, a two ram baler can eliminate the need for shredding, pulverizing, and other conditioning processes. In general, two ram balers allow recyclers to process more material, faster. However, since they are using two rams, they do require more room and more power.

View a full list of Baler Manufacturers

and industry specific information

Compactors are designed to compress waste materials and scrap products for easier transportation, handling and better space efficiency. Industries such as food processing, manufacturing facilities, retail and consumer businesses and automotive factories all benefit in terms of environmentally and economically from compacting trash. Reducing the bulk volume of trash reduces the money and effort required to dispose of it.

Compactors are designed to compress waste materials and scrap products for easier transportation, handling and better space efficiency. Industries such as food processing, manufacturing facilities, retail and consumer businesses and automotive factories all benefit in terms of environmentally and economically from compacting trash. Reducing the bulk volume of trash reduces the money and effort required to dispose of it.

Compactors are similar to industrial balers in that they reduce waste, but are typically used for non-recyclable materials in order to save space in landfills and other trash disposal locations. Compactors tend to be smaller than balers and result in more compact bundles of waste at the end of the process. Specific types of compacters include trash compactors for residential, commercial or industrial purposes, compactors fitted into the back of garbage trucks to conserve space and compactors that are designed for specific materials. Most waste materials such as textiles, food products, containers, metals, plastics and fibrous materials can be processed with compactors, however hazardous materials such as aerosol cans, batteries and chemicals should be disposed with an approved method. Recycling is an important way for manufacturers to reduce the carbon footprint of industrial activity, and compactors remain an integral part of this.

A large chamber, an electric motor and a hydraulic or pneumatic press are the three main components of a compactor. Industrial compactors can have manual or automated loading functions from a large input area which is able to handle large volumes of waste material. The input area feeds the waste material into the chamber where it is pounded and compacted under great pressure from the press. Using a hydraulic press minimizes the energy lost in the process and reduces the heat produced by the machine. Industrial compactors usually produce bales of compressed materials, while commercial or residential compactors are more likely to use bags or bins to store compressed waste until disposal. The compressed material is then ready for transport to a permanent disposal location, or to a recycling facility to be reused. Factories, hotels, schools, medical centers and manufacturing facilities typically have a compactor on the premises for ease of access and minimal transport costs. While the initial expense of purchasing a compactor may seem high, there are many advantages to using compactors onsite. For example, they help to minimize odor and vermin problems, reduce the frequency of required waste removal, eliminate spillage and leaks from overflowing waste containers and improve standards of housekeeping around a facility. Learn more about compactors.

Granulators are machines that are designed to granulate a substance into a grain. What differentiates granulators from other size reduction machinery such as shredders or grinders is that granulators make large components and make them significantly smaller then what a grinder could do. Granulators generally have an open rotor configuration which means that air can easily move around the rotor while cooling the product however there are also closed rotor granulators which operate with high speeds. The components are typically ground down to the consistency of corn meal and sometimes even smaller. These grains range from 0.2 and 4.0mm.

There are two types of granulation which are wet granulation and dry granulation. Wet granulation causes the granules to be formed when the granulation liquid is pour onto a powder bed and is mixed together through a impeller, screws, or air. The agitation of these two substances creates the wet granules.The most common liquids included are water, ethanol, and isopropanol. Aqueous based solutions are generally much safer to handle than solvent based solutions.

Dry granulation is when the granules are formed without the use of a liquid. This process is prefered in situations where the products may be sensitive to moisture and heat. To create these granules without the utilization of moisture will require the use of a compactor. Granulators are very important for various applications involved in the recycling industry. These products are ideal for lighter materials like plastics and rubber as these substances do not grind well.

Learn more about granulators.

In many recycling and recovery plants, scrap and waste materials are often stored in large piles to be processed at a later time. For these kinds of facilities, the use of a grappler is often the most effective method for introducing these piled materials into the recycling and recovery process. Grapplers can pick up large quantities of scrap material from these storage piles and place or feed the material into processing equipment, like material separators, shredders, and balers.

In many recycling and recovery plants, scrap and waste materials are often stored in large piles to be processed at a later time. For these kinds of facilities, the use of a grappler is often the most effective method for introducing these piled materials into the recycling and recovery process. Grapplers can pick up large quantities of scrap material from these storage piles and place or feed the material into processing equipment, like material separators, shredders, and balers.

A grappler is a piece of material handling equipment which can take on many shapes; however, all grapplers serve the same purpose of picking up and maneuvering large quantities of scrap materials. This kind of equipment is generally attached to the long boom or arm of a piece mobile heavy machinery, much like a backhoe. One of the most common types of grapplers is the claw grappler. The aptly named claw grappler has a series of curved metal arms that look like claws. This machine is controlled by an operator who can open and close the claw to lift and release loose material. For recycling plants where metal is being handled, it‘s quite common to use a scrap handling magnet, in place of a claw grappler, since this can easily pick up scrap metal using magnetic force.

Grapplers typically use either hydraulic or electric force to open and close their lifting mechanisms. These lifting arms need to be very strong in order to clench heavy materials and safely lift heavy objects that could be found among the debris. A grappler can typically be purchased and added as an attachment to a backhoe or a similar piece of heavy equipment. This versatility keeps equipment costs low while still giving recycling facilities the implements they need to handle high volumes of recycled material. On the other hand, they can also be purchased as part of a complete material handling vehicle. Many material handling equipment manufacturers design and supply grappling vehicles specifically constructed for use in recycling facilities. These types of equipment are equipped with stabilizers to keep the vehicle from tipping over when lifting heavy materials. Learn more about grapplers.

Industrial metal shears are used to cut large pieces of metal, particularly sheet metal. The shearing machine cuts the metal into thin strips as it is fed into the machine, turning it into dozens of smaller pieces that can easily be transported, melted down, and used again for another product.

Industrial metal shears are used to cut large pieces of metal, particularly sheet metal. The shearing machine cuts the metal into thin strips as it is fed into the machine, turning it into dozens of smaller pieces that can easily be transported, melted down, and used again for another product.

Some shearing machines are very simple and they cut the metal simply by using the energy transferred when the operator presses down on the foot pedal, while others are hydraulically or mechanically powered. Within the machine itself, there are sectional knives or sliding blades that have the ability to cut cleanly through the sheet metal when they are forced down on it. Cutting isn‘t always designed to take place on a perfect 90 degree angle since it actually requires less force to cut diagonally through the material. For this reason, many metal shears have angled blades.

Metal is inserted into the shearing machine from the shear table, a work table upon which the machine rests. This table supports the metal as an operator slowly slides it into the machine for cutting. Some metal shears are mobile so that they can be moved around a scrap yard or large recycling facility, while others are built to be stationary and compliment a complete recovery process.

Some metal fabrication shops receive large pieces of sheet metal directly from suppliers who have reclaimed it from other facilities or who no longer need it themselves. The workers in the fabrication shop can use metal shearing machines to straighten the edges of the metal or cut it down to a size that matches a set of specifications for a project they are working on. This is a much more cost-effective way to manufacture metal products than if the fabricators were to purchase 100% of their metal brand new.

Some metal fabrication shops receive large pieces of sheet metal directly from suppliers who have reclaimed it from other facilities or who no longer need it themselves. The workers in the fabrication shop can use metal shearing machines to straighten the edges of the metal or cut it down to a size that matches a set of specifications for a project they are working on. This is a much more cost-effective way to manufacture metal products than if the fabricators were to purchase 100% of their metal brand new.

Some metal shear machines are built into large industrial balers, so that metals can be continuously sheared and baled in a large scale operation. Shearing in an operation like this creates metals in a more consistent size, which is perfect for baling since the idea is to have uniformly shaped and sized units for shipping. Learn more about metal shears.

Pulverizers are used to reduce the size of materials through grinding and crushing.

Size reduction is an important part of a wide variety of industrial processes. Pulverizer manufacturers provide pulverizers that can be used on many different material types, including brick, shale, coal, concrete, limestone, wood, and even plastic materials. Because there are so many uses of pulverizers, and because they are used to process such a wide range of materials, an equally wide range of pulverizer configurations is necessary to accommodate them.

Learn more about pulverizers.

Pulverizers are used to reduce the size of materials through grinding and crushing.

Size reduction is an important part of a wide variety of industrial processes. Pulverizer manufacturers provide pulverizers that can be used on many different material types, including brick, shale, coal, concrete, limestone, wood, and even plastic materials. Because there are so many uses of pulverizers, and because they are used to process such a wide range of materials, an equally wide range of pulverizer configurations is necessary to accommodate them.

Learn more about pulverizers.

Material separation is an important first step in the recycling process. Recovering products from the waste stream and making sure that they end up in the right category to be recycled is difficult but essential to efficient recycling practices. Recycling plants are always trying to raise their recovery rate to keep as much material as possible out of landfills and lower energy consumption by making new products out of these used materials. The right separation equipment properly tuned for a specific application will always play a serious role in creating a greater rate of recovery. Workers can separate some materials manually, but separation is always more effective with the aid of a machine, particularly when dealing with high volumes of material.

Material separation is an important first step in the recycling process. Recovering products from the waste stream and making sure that they end up in the right category to be recycled is difficult but essential to efficient recycling practices. Recycling plants are always trying to raise their recovery rate to keep as much material as possible out of landfills and lower energy consumption by making new products out of these used materials. The right separation equipment properly tuned for a specific application will always play a serious role in creating a greater rate of recovery. Workers can separate some materials manually, but separation is always more effective with the aid of a machine, particularly when dealing with high volumes of material.

As technology improves and more and more recovery centers do everything they can to raise their recovery rate, more materials are able to be eliminated from the waste stream and repurposed for new uses. The result is a reduced impact on landfills and a healthier approach to environmental care. Material separation equipment plays a key role in helping to maximize the efficiency and effectiveness of this process.

Magnetic separators assist in separating ferrous materials from non-ferrous materials. This is accomplished by exposing the unsorted material to a powerful magnet that is mounted over a conveyor belt or in a chamber. The magnetic force pulls out the ferrous metals, and leaves the rest. Magnetic separating equipment is very convenient in metal recycling facilities because it keeps material moving in scrap yards and other high volume facilities. Learn more about magnetic separators.

An air separation unit can be used to remove light debris and low value materials from a stream of potentially recyclable waste. In most cases, high pressure air is blown over the drop off point of a conveyor, allowing the heavier material to fall away to the next conveyor while the light material is blown into a bin or some other depository. Other air separators may use vacuum or cyclone technology to suck lightweight, non-metallic materials from the waste stream instead.

Learn more about metal shears.

An air separation unit can be used to remove light debris and low value materials from a stream of potentially recyclable waste. In most cases, high pressure air is blown over the drop off point of a conveyor, allowing the heavier material to fall away to the next conveyor while the light material is blown into a bin or some other depository. Other air separators may use vacuum or cyclone technology to suck lightweight, non-metallic materials from the waste stream instead.

Learn more about metal shears.

An eddy current separator is an advanced piece of material separating equipment that has the ability to separate non-ferrous metals like aluminum and copper out of a waste stream. An eddy current separator uses a powerful magnetic field to separate non-ferrous metals. However, unlike a magnetic separator which pulls out ferrous materials by attracting them, an eddy current separator actually causes an opposing magnetic field to form within the non-ferrous metals and thus repels these materials. For this reason, the separator is typically placed at the end of a conveyor where the non-ferrous materials are thrown forward into their own bin while other materials simply fall off the conveyor into a separate bin. It is important to note that all ferrous metals should be removed from the waste stream before the eddy current separator is used, as these materials can cause problems with the separator.

An eddy current separator is an advanced piece of material separating equipment that has the ability to separate non-ferrous metals like aluminum and copper out of a waste stream. An eddy current separator uses a powerful magnetic field to separate non-ferrous metals. However, unlike a magnetic separator which pulls out ferrous materials by attracting them, an eddy current separator actually causes an opposing magnetic field to form within the non-ferrous metals and thus repels these materials. For this reason, the separator is typically placed at the end of a conveyor where the non-ferrous materials are thrown forward into their own bin while other materials simply fall off the conveyor into a separate bin. It is important to note that all ferrous metals should be removed from the waste stream before the eddy current separator is used, as these materials can cause problems with the separator.

A scrap handling magnet is very similar to a grappler but uses electromagnetic forces to attract and hold objects instead of mechanical force. Scrap handling magnets consist of an electromagnet connected to a chain on the end of a hydraulic arm that can raise and lower it. Scrap handling magnets come in a variety of sizes, but they are usually round and the top portion is encased in a strong metal body to protect the magnet and hold it firmly in place during use. The magnets used to lift scrap metal can be powerful enough to pick up thousands of pounds at a time, and they are frequently used in facilities that specialize in metal recovery.

A scrap handling magnet is very similar to a grappler but uses electromagnetic forces to attract and hold objects instead of mechanical force. Scrap handling magnets consist of an electromagnet connected to a chain on the end of a hydraulic arm that can raise and lower it. Scrap handling magnets come in a variety of sizes, but they are usually round and the top portion is encased in a strong metal body to protect the magnet and hold it firmly in place during use. The magnets used to lift scrap metal can be powerful enough to pick up thousands of pounds at a time, and they are frequently used in facilities that specialize in metal recovery.

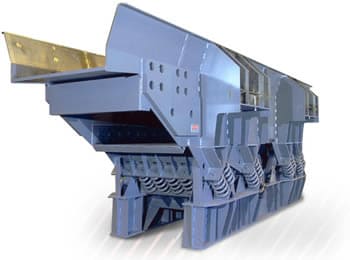

The meticulous task of sorting mixed recyclables can also be accomplished by screeners. Screeners are another type of material separation equipment, which, as their name suggests, separate materials through the use of different types of screens. Screeners utilize a more mechanical approach to separation than the separators listed above, but they also come in a huge variety of styles and sizes to meet the requirements of different applications and to specialize them for particular materials. Below are several types of screeners used for recycling applications:

One very common screening machine is a vibratory screener. Recyclable materials are fed into the vibratory screener and across a screen. The machine constantly generates vibrations in the screen which causes the recyclables to jostle around. This movement dislodges smaller components from the general bulk of recyclables, and these smaller components can then fall through the screen into their own bin or continue on in the recycling process. These screeners are very valuable for separating materials by size, and since larger materials generally require more processing, this type of separation can save time and energy by pulling out smaller pieces that do not need the extra processing. Learn more about vibratory separators.

Rod deck recycling screens are a specially designed version of a vibratory screener. Instead of a normal grid screen, the rod deck consists of several rows of rods. Much like a vibratory screen, as material is fed into the rod deck, the machine generates vibrations which cause the material to jostle and bounce, loosening smaller bits from the bulky materials. Though their operation is essentially the same, rod decks are better equipped to separate wet, abrasive, heavy, and difficult to handle materials. The flexibility and reduced surface area of the rods keeps materials from sticking and blinding, making this kind of separation equipment a huge asset in many recycling applications.

A disc screener is made by creating a series of discs that rotate around a rod and then lining the rods up side by side so that materials can be pulled over them and smaller materials fall through the space between the discs. The rotation turns objects over during motion, so that after a few feet any smaller bits of material have fallen through the discs. In a recycling plant, a disc screener can improve recovery rates when the disc sizes are designed with particular materials in mind.

A disc screener is made by creating a series of discs that rotate around a rod and then lining the rods up side by side so that materials can be pulled over them and smaller materials fall through the space between the discs. The rotation turns objects over during motion, so that after a few feet any smaller bits of material have fallen through the discs. In a recycling plant, a disc screener can improve recovery rates when the disc sizes are designed with particular materials in mind.

A star screener is similar to a disc screener, except star shaped implements are used instead of discs to screen material. These horizontally mounted star shaped pieces pull in fractured material and help to recover damp and cohesive material by separating it. The speed of the screen‘s rotation can be adjusted based on the type of material being processed in the recycling facility.

Shredding equipment is critical to the recycling process because it breaks down tough materials into smaller, more manageable parts before they are baled or made into a more convenient form for reuse. Different types of shredders are used for almost every kind of material that you can imagine; from rubber to plastic to metal and beyond. Because they are needed for so many different applications, shredders are manufactured in a wide variety of sizes and styles. Document destruction, for example, is much less heavy duty than metal shredding, so manufacturers create machines that meet the needs of each industry. One application that has seen a significant increase in shredding over the years is electronic scrap processing. Because there are now so many old electronic devices on the market, it is necessary to find ways to break them down and reuse their components.

Shredding equipment is critical to the recycling process because it breaks down tough materials into smaller, more manageable parts before they are baled or made into a more convenient form for reuse. Different types of shredders are used for almost every kind of material that you can imagine; from rubber to plastic to metal and beyond. Because they are needed for so many different applications, shredders are manufactured in a wide variety of sizes and styles. Document destruction, for example, is much less heavy duty than metal shredding, so manufacturers create machines that meet the needs of each industry. One application that has seen a significant increase in shredding over the years is electronic scrap processing. Because there are now so many old electronic devices on the market, it is necessary to find ways to break them down and reuse their components.

So, how do shredders work? Well, even though they are all a little different, the basic principle is the same across the board. There is a series of interlocking metal shafts with metal discs fitted along the entire length of the shaft at regular intervals. Theses shafts are usually located at the bottom of a hopper/feeding area and a motor powers their rotation. The discs on the shafts have sharp teeth that protrude at different points. These teeth are what grab onto objects being fed into the shredder and pull them in between the shafts where they separate into many tiny pieces. After the materials have been pulled through the shafts and broken up, they exit out of the bottom of the shredder into a bin or directly onto the floor of the facility where they are packaged or cleaned up.

Shredders can be built with only one shaft for smaller materials and light duty shredding tasks, or they can be built with up to four shafts for heavy duty applications and processing of bulk items. For instance, a shredder with two to four shafts would be used to shred tires since they are large and bulky until they are broken down. Having the ability to do this increases the speed of recycling and saves money. Without shredders it would be almost impossible to process and reuse much of the material that we are able to recycle today. Learn more about industrial shredders.

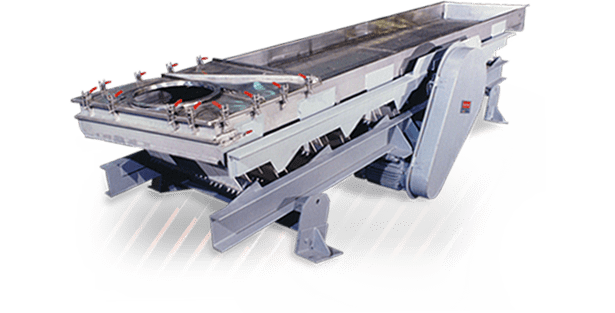

A vibratory feeder, also known as a vibratory conveyor, is a type of equipment that uses vibrations to transport bulk material through stages of a particular process, like packaging, recycling, or finishing. Vibratory conveying differs from standard belt, screw, and pneumatic conveying in that it can handle sticky or delicate materials without damaging them or causing them to liquefy. Vibratory feeders are ideal machines to use for material handling as they are low-maintenance, and the only moving part it contains is a vibrating drive located underneath the feeder pan and out of the way of any materials. The other parts of a vibratory feeder are inexpensive and easy to replace. Vibratory feeders can be powered either electromagnetically or electromechanically, the latter of which is driven by a motor supported by eccentric weights or an eccentric crank.

A vibratory feeder, also known as a vibratory conveyor, is a type of equipment that uses vibrations to transport bulk material through stages of a particular process, like packaging, recycling, or finishing. Vibratory conveying differs from standard belt, screw, and pneumatic conveying in that it can handle sticky or delicate materials without damaging them or causing them to liquefy. Vibratory feeders are ideal machines to use for material handling as they are low-maintenance, and the only moving part it contains is a vibrating drive located underneath the feeder pan and out of the way of any materials. The other parts of a vibratory feeder are inexpensive and easy to replace. Vibratory feeders can be powered either electromagnetically or electromechanically, the latter of which is driven by a motor supported by eccentric weights or an eccentric crank.

There are several main types of vibratory feeders. The first, vibratory bowl feeders, are also referred to as centrifugal feeders or vibratory bowls. These feeders are used by parts manufacturers to align finished or semi-finished parts to prepare them for packaging. The second, vibratory conveyors, covers a broader range of troughs, trommel screens, and vibrating screens that are made for the purpose of conveying and sorting bulk materials. The third, rotary feeders, are also referred to as rotary valves or rotary airlocks. They transfer airtight bulk material to vibratory or screw conveyors. The fourth and final category is linear feeders, or inline feeders, which are commonly used to transport parts from bowl feeders in a vibratory linear motion for short or relatively long distances.

There are several main types of vibratory feeders. The first, vibratory bowl feeders, are also referred to as centrifugal feeders or vibratory bowls. These feeders are used by parts manufacturers to align finished or semi-finished parts to prepare them for packaging. The second, vibratory conveyors, covers a broader range of troughs, trommel screens, and vibrating screens that are made for the purpose of conveying and sorting bulk materials. The third, rotary feeders, are also referred to as rotary valves or rotary airlocks. They transfer airtight bulk material to vibratory or screw conveyors. The fourth and final category is linear feeders, or inline feeders, which are commonly used to transport parts from bowl feeders in a vibratory linear motion for short or relatively long distances.

Small parts manufacturers use vibratory bowl feeders extensively for the purpose of efficiently orienting products for distribution or further finishing. Bowl feeders were originally designed by pharmaceutical companies to sort, count, and organize pills. Nowadays, they are also built to work with items such as toothpaste caps, molded rubber parts, o-rings, ammunition, and fasteners.

Many industries-such as food processing, agricultural, and pharmaceutical-use vibratory conveyors, screens, and trommels for bulk and powder material handling. Vibratory conveyors are used frequently in recycling industries to sort and convey numerous materials such as metals, crushed cement, wood, and plastic. Mining, pulp, sand and gravel, and fertilizer companies use vibrating screens and trommel screens to sort, sift, and convey their materials. A grizzly screen is a powerful type of vibrating screen which is most frequently used in the mining industry. Vibratory conveyor systems usually work together with rotary airlock feeders when they must convey powder bulk solids. In the processes of reclamation or collecting dust, rotary feeders and dust collecting systems are used together.

Bowl feeders are similar to vibratory finishing bowls, and are made of plastic, silicone, or metal. These machines are equipped with a vibrating drive that is mounted to the bowl‘s base. A ramped ridge-which is typically designed for a specific part-leads to the outfeed area, and runs up along the bowl‘s edge in a spiral. The bowl, which vibrates in a circular motion, moves the parts up the spiral ridge. As it reaches the output area, it narrows and forces the parts to form a single-file line. Small parts such as coins, legos, o-rings, and washers can easily be aligned for packaging and counting when they are dumped into the bowl feeder‘s center.

Bowl feeders are similar to vibratory finishing bowls, and are made of plastic, silicone, or metal. These machines are equipped with a vibrating drive that is mounted to the bowl‘s base. A ramped ridge-which is typically designed for a specific part-leads to the outfeed area, and runs up along the bowl‘s edge in a spiral. The bowl, which vibrates in a circular motion, moves the parts up the spiral ridge. As it reaches the output area, it narrows and forces the parts to form a single-file line. Small parts such as coins, legos, o-rings, and washers can easily be aligned for packaging and counting when they are dumped into the bowl feeder‘s center.

Vibratory conveyors vibrate in one direction, and they move heterogenous mixtures or powder bulk solids from one piece of equipment to the next. Some varieties of these vibratory conveyors have ultra-low vibrations for the purpose of handling solids such as lettuce or gummy bears which are sticky, delicate, or prone to liquefy. Trommels, or trommel screens, are vibrating screens which separate small and large particles. Rotary trommels are used in recycling and the processing of gravel. Trommel magnets help sort ferrous from non-ferrous materials, and are frequently used alongside metal recycling rotary trommels. Continuous flatbed trommels usually have filtering devices or screens that help in sorting particles of varying sizes. Larger particles are conveyed either to be further processed or contained.

The incorporation of vibratory feeders into various industrial processes has many benefits. Feeders are highly cost-effective in comparison to manual labor, and therefore can save a company more time and money in labor costs. Instead of one operator per machine, a number of automated machines can be overseen by one operator. Bowl feeders can process small parts more accurately, quickly, and effectively than a worker can do by hand. In addition to saving time and money, it also spares workers strenuous and tedious tasks. Vibratory conveyors are an alternative solution for machines such as belt, screw, or pneumatic conveying, as vibratory conveyors are more capable of handling sticky or friable materials that would otherwise be more likely to agglomerate or cake. Trommel screens and rotary trommels are more capable of efficiently sorting recyclable materials by reducing the labor required to carry out the process.

Learn more about vibratory feeders.

The incorporation of vibratory feeders into various industrial processes has many benefits. Feeders are highly cost-effective in comparison to manual labor, and therefore can save a company more time and money in labor costs. Instead of one operator per machine, a number of automated machines can be overseen by one operator. Bowl feeders can process small parts more accurately, quickly, and effectively than a worker can do by hand. In addition to saving time and money, it also spares workers strenuous and tedious tasks. Vibratory conveyors are an alternative solution for machines such as belt, screw, or pneumatic conveying, as vibratory conveyors are more capable of handling sticky or friable materials that would otherwise be more likely to agglomerate or cake. Trommel screens and rotary trommels are more capable of efficiently sorting recyclable materials by reducing the labor required to carry out the process.

Learn more about vibratory feeders.

One very common screening machine is a vibratory screener. Recyclable materials are fed into the vibratory screener and across a screen. The machine constantly generates vibrations in the screen which causes the recyclables to jostle around. This movement dislodges smaller components from the general bulk of recyclables, and these smaller components can then fall through the screen into their own bin or continue on in the recycling process. These screeners are very valuable for separating materials by size, and since larger materials generally require more processing, this type of separation can save time and energy by pulling out smaller pieces that do not need the extra processing.