Broaching

Metal production includes operations that are designed to change the shape of metals to conform to the needs of a product. One of the essential parts of these metal forming methods is cutting, which is far more complex than simply slicing a piece of metal to a specific size.

The classification of metal cutting involves a wide array of operations with the basic purpose of removing unnecessary material from a workpiece to make it comply to design specifications. The various forms of cutting involve a variety of machines that have been engineered to perform the process efficiently and accurately.

The types of processes that perform cutting include broaching, CNC machine cutting, expanded metal process, laser cutting, stamping, etching, and perforation. These methods for metal cutting stress and shape metals to conform to the needs of an application and are designed to accomplish each operation efficiently and precisely.

Broaching is an efficient method of removing unwanted material through use of a sharp toothed broach. The two types of broaching are linear and rotary, where linear moves in a line against the surface to be changed while rotary involves a rotated broach. The types of products produced using broaching include gears, fasteners, threading, pulleys, sprockets, and bushings. There is little restriction on the types of materials that can be broached, which include plastics and copper as well as various grades of steel.

The CNC process is used to achieve a wide assortment of manufacturing functions, which includes cutting. There are several advantages to CNC programming since instructions can be directly fed into the machine, which performs cutting operations quickly and efficiently regardless of the type of cutting.

The expanded metal process is a unique and unusual method for cutting metals. Solid sheets of metal and coils are expanded to form a mesh that is cut by a knife to create a design in the mesh. The expanding process involves stretching and cutting the metal simultaneously to produce the desired design.

Laser cutting is normally included in a CNC process since cuts made by a laser are extremely precise and accurate with exacting tolerances. The term laser is an acronym for light amplification by stimulation emission radiation. The beam of the laser is a highly focused radiation wavelength. CNC programming enhances the precision of laser cuts making them nearly flawless.

Metal etching is one of the more artistic methods of cutting since it cuts the surface of a metal to create a design, shape, or pattern by cutting grooves and fine lines. There are many varieties of metal etching, some of which include chemicals and acids as well as stamping, photofabrication, water jet cutting, and lasers, to name a few. When completed by a trained craftsman, etchings have exceptionally close tolerances as well as a smooth finish.

The term metal fabrication covers a wide array of processes used to shape, configure, transform, and manipulate metals. Cutting is one of the assortments of processes used by metal fabrication but plays a major role in sizing and shaping pieces to be fabricated.

Much like etching, stamping changes the surface of metals to form a design or pattern. While etching cuts into the metal, stamping uses a variety of processes to achieve its goals aside from cutting, which include bending, drawing, and blanking. Each of the different processes requires a different tool or die. A major benefit of stamping is its ability to quickly and efficiently produce finished products.

Perforating is a process that is somewhat similar to expanding but does not stretch metals to create a pattern. Metal that is perforated can serve several functions from being a decorative piece to being a protective covering for machines. The process takes metal sheet and punches it with force to create uniquely shaped holes.

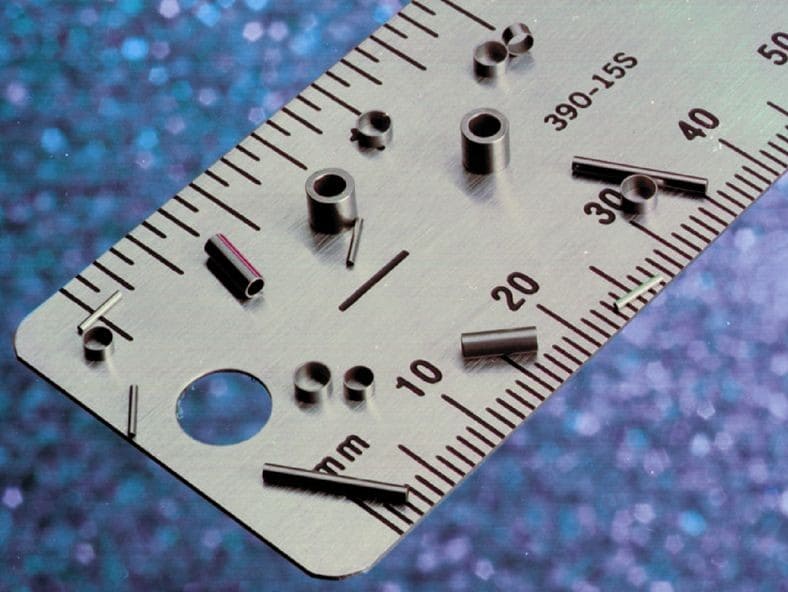

A very exciting and useful machining process is the use of a Swiss screw machine, which is a method removing excess material from a part by turning it through a cutting tool. This method of cutting is one of the most precise operations available and has become a staple for metal production.

One of the classic forms of metal fabrication is the shaping and manufacturing of tubes into a wide variety of diameters, sizes, and lengths. Tube fabrication involves bending, enlarging, and cutting tubes from a variety of metals to produce parts, components, and products.

Water jet or hydro cutting is a process of using water under high pressure to remove excess material from metals. Though water is the medium for supplying the cutting, it is enhanced with various types of abrasives that complete the cutting process. Water jet cutting is very popular for its accuracy and precision.

Broaching is a cost-effective, precision metal removal service that can cut almost any material, though broaching technicians most often use softer metals.

The purpose of broaching is to cut the external (flat, round or contoured) surface or internal part of a shape or form, like an internal spline, a gear, a sprocket, a keyway, a slot or surface serrations. Broaching is performed in a broaching job shop.

Broaching is a cost-effective, precision metal removal service that can cut almost any material, though broaching technicians most often use softer metals.

The purpose of broaching is to cut the external (flat, round or contoured) surface or internal part of a shape or form, like an internal spline, a gear, a sprocket, a keyway, a slot or surface serrations. Broaching is performed in a broaching job shop.

Most products made through broaching are intended for use within the industrial sector. Examples include: gears, fastener threading, fastener heads, pulleys, sprockets, wrenches and bushings. As noted, a variety of materials may be broached. The common list consists of copper, aluminum and brass, with some steel grades, plastic and wood. Learn more about broaching.

CNC machining is a manufacturing process that utilizes specialized computer programs to instruct the automated design and production of high precision parts for a number of industries.

CNC machining is a manufacturing process that utilizes specialized computer programs to instruct the automated design and production of high precision parts for a number of industries.

An acronym, CNC stands for computer numerical control. This refers to a broad range of CNC manufacturing processes utilized throughout the production process to create small or large volumes of identical precision parts quickly and efficiently. Learn more about cnc machining.

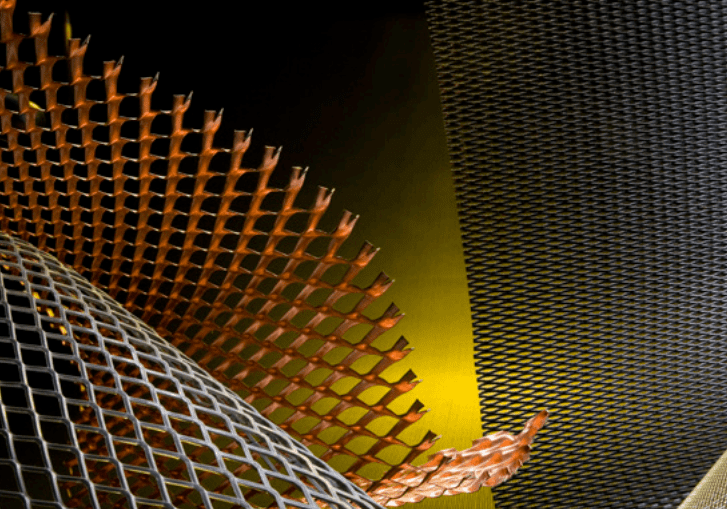

Expanded metal includes all metallic elements or alloys that have undergone a specific machining process in which a sheet or coil is simultaneously cut and drawn to provide an open grid like pattern.

Expanded metal includes all metallic elements or alloys that have undergone a specific machining process in which a sheet or coil is simultaneously cut and drawn to provide an open grid like pattern.

An economic alternative to perforated metals, the production of expanded metal sheets results in no waste material as it is slit rather than punched. Fewer raw materials are needed as well because each component can be stretched to as much as ten times its original length. Learn more about expanded metals.

Laser cutting is a low-distortion hot cutting process that most commonly uses a CO2 laser for the cutting of material, which is usually metal. "Laser" is an acronym for Light Amplification by Stimulated Emission of Radiation. The beam of the laser is an extremely focused radiation of a wavelength, meaning the beam will not dissipate like conventional light beams.

Laser cutting is a low-distortion hot cutting process that most commonly uses a CO2 laser for the cutting of material, which is usually metal. "Laser" is an acronym for Light Amplification by Stimulated Emission of Radiation. The beam of the laser is an extremely focused radiation of a wavelength, meaning the beam will not dissipate like conventional light beams.

Laser cutters are frequently controlled through precision programs. These precision programs, which direct the laser cutting process with minimal human intervention, get the information they need from CNC systems that use CAD designs to input machining details.

In addition, technicians may partner an "assist gas," like nitrogen or carbon dioxide, with laser cutting, in order to ready newly cut surfaces for painting or corrosion resistance coating. CO2 laser cutting, for example, is a gas assist laser cutting technique, and it is considered the most powerful wave laser in the world today. Learn more about laser cutting.

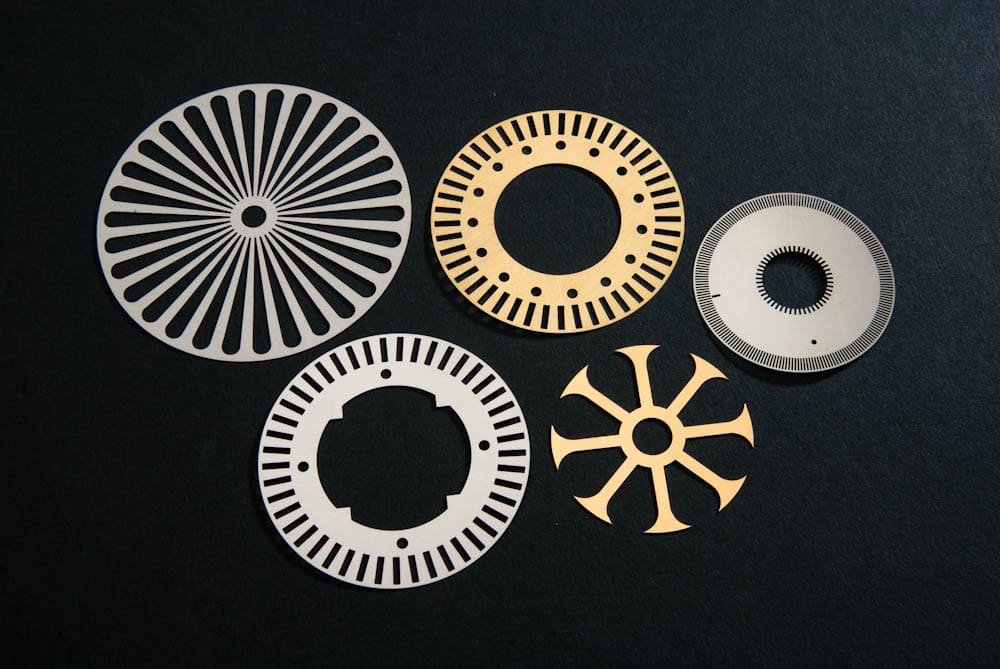

Metal etching, also referred to as metal engraving, is the process of creating grooves, fine lines or impressed designs on metal parts or sheets. There are a number of different methods with which to achieve the desired pattern or finish on a metal part; the most common of these methods are mechanical or chemical machining or acid etching.

Metal etching, also referred to as metal engraving, is the process of creating grooves, fine lines or impressed designs on metal parts or sheets. There are a number of different methods with which to achieve the desired pattern or finish on a metal part; the most common of these methods are mechanical or chemical machining or acid etching.

Today, metal etchings are most commonly done using chemical or mechanical machining or acid etching. Other techniques include photo etching, also called photofabrication, stamping, water-jet cutting, laser engraving, electro discharge machining (EDM) and mechanical milling. Laser etching, or engraving, is favored for its ability to create very fine, clean lines on surfaces with little need touchups. EDM achieves exceptionally close tolerances by exposing the metal part to streams of corrosive electromagnetic discharge. After etching, manufacturers can smooth or polish away any imperfections, burrs or marks. Learn more about metal etching.

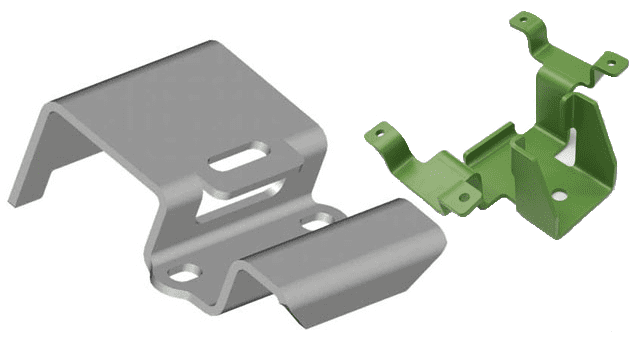

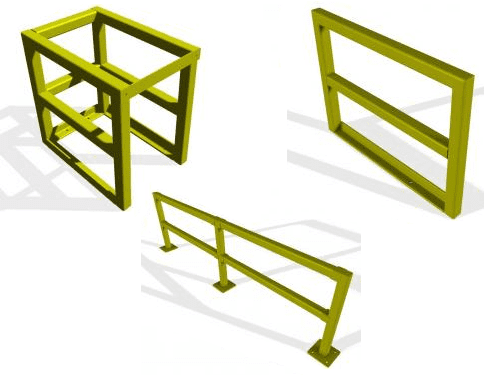

Metal fabricators are companies that process metals into usable products. Fabrication is a blanket term used in reference to a wide range of metalworking processes. Some of the most common fabrication processes include metal bending, metal welding, stamping, punching and many other metal forming processes.

Metal fabricators are companies that process metals into usable products. Fabrication is a blanket term used in reference to a wide range of metalworking processes. Some of the most common fabrication processes include metal bending, metal welding, stamping, punching and many other metal forming processes.

Fabricated metal parts are almost never made from freshly mined, unprocessed metals. Rather, they are usually fabricated from metal materials that were processed in some fashion. The standard metal raw materials used by metal fabricators include plate metal, tube stock, formed and expanded metal, welding wire/welding rod, and casting.

Virtually any metal or metal alloy can be used to create a part or product, but some, like steel, stainless steel or aluminum, are more likely to be used than others. Some of the other metals commonly used in fabrication processes include bronze, brass, and titanium. Learn more about metal fabrication.

Metal stamping is a method of metal forming which utilizes a press to force sheet metal into a tool or die.

Metal stamping is a method of metal forming which utilizes a press to force sheet metal into a tool or die.

Many other metal forming processes like bending, drawing, blanking, and cutting can be incorporated into metal stamping. With a variety of different tools and dies, metal stamping can produce a very diverse range of metal products. The metal stamping process is perfect for quickly and efficiently manufacturing large quantities of products at a low cost, and metal stamped parts are repeatable and can attain precision tolerances. Learn more about metal stampings.

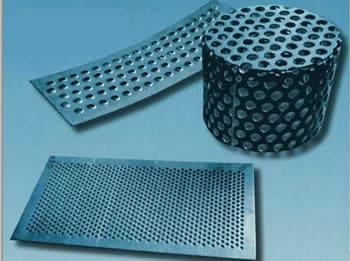

Perforated metals are created in a metal stamping process in which a pattern of holes is blanked out of sheet metal.

Perforated metals are created in a metal stamping process in which a pattern of holes is blanked out of sheet metal.

Many different kinds of metals can be perforated including steel, aluminum, brass, and titanium, and these metals can serve a variety of purposes. They are commonly used in structural, design, and filtration applications. Lightweight perforated metals like aluminum can be used as decorations, while perforated steel is frequently used for architectural support. There are also many different kinds of perforation patterns like staggered and straight patterns, and the holes come in a variety of shapes and sizes as well. Learn more about perforated metals.

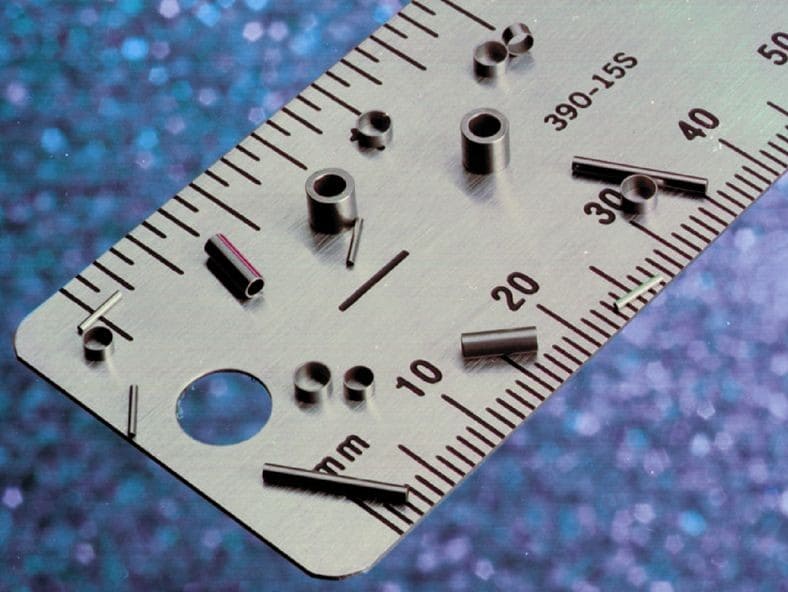

Although specialty screws and fasteners are a common product manufactured by screw machining, also known as Swiss screw machining, other types of turned parts have crucial applications as precision medical tools, automotive tools, laboratory tools, electronics components, appliance components, military parts and many others.

Although specialty screws and fasteners are a common product manufactured by screw machining, also known as Swiss screw machining, other types of turned parts have crucial applications as precision medical tools, automotive tools, laboratory tools, electronics components, appliance components, military parts and many others.

Precision turning and machining processes are often required for the construction of such products. Learn more about screw machine products.

Sheet metal is metal in the form of thin, broad sheets.

Sheet metal is metal in the form of thin, broad sheets.

Sheet metal itself is seldom a finished product; rather, it used to create many different products in the aerospace, automotive, communication, computer, construction, electronics, food processing and storage, military, and pharmaceutical worlds.

The process by which sheet metal is formed into usable parts and products is called sheet metal fabrication. It features a variety of fabrication processes, such as bending, drawing, flanging, punching, shearing, spinning, and stretching. All sheet metal fabrication processes seek to create high quality, long-lasting parts and products, while reducing material and labor costs. Learn more about sheet metal fabrication.

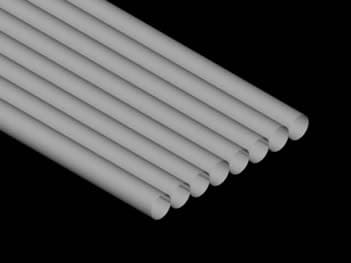

Tube fabrication, or pipe fabrication, uses a variety of techniques to shape, bend, enlarge and cut tubes of all sizes and metals into parts, components and consumer products. Tubes are used to serve many functions: containment, support, transportation, protection etc. While tube fabricators are not generally involved in forming raw metal materials into tubes, tube fabrication services are an essential part of the process of tube or pipe manufacturing.

Tube fabrication, or pipe fabrication, uses a variety of techniques to shape, bend, enlarge and cut tubes of all sizes and metals into parts, components and consumer products. Tubes are used to serve many functions: containment, support, transportation, protection etc. While tube fabricators are not generally involved in forming raw metal materials into tubes, tube fabrication services are an essential part of the process of tube or pipe manufacturing.

Equipment such as swaging machines, mold bending, hydraulic tube benders, and CNC mandrel bending machines are used extensively by trained engineers in the processes of tube cutting, flaring, swaging, and bending. Each of these processes are applied to ensure the fortitude of the tubing and the prevention of material diffusion. Learn more about tube fabrication.

Water jet cutting is a volume reduction process used to create new shapes and machine existing shapes. Hydro cutting offers manufacturers and fabricators an alternative to resource-intensive hot-cutting processes like laser and plasma cutting. Water jet cutters are capable of precisely cutting intricate shapes out of metal and plastics as well as some glass and ceramic materials.

Water jet cutting is a volume reduction process used to create new shapes and machine existing shapes. Hydro cutting offers manufacturers and fabricators an alternative to resource-intensive hot-cutting processes like laser and plasma cutting. Water jet cutters are capable of precisely cutting intricate shapes out of metal and plastics as well as some glass and ceramic materials.

Customers of waterjet cutting services and waterjet cut products include those in the aerospace, automotive, communications, food processing, and industrial equipment manufacturing industries, as well as lumberyard workers and artists. Waterjet cutting services are popular with these customers and others because, unlike conventional cutting processes like blade cutting, they do not create burrs or other imperfections. Also, because waterjet cutting does not use heat, but is rather a cold-cutting process, it does not put products at risk for warping from friction, discoloration, or other related damage. Learn more about water jet cutting.