Marking Machinery

The term "marking machinery" encompasses a wide range of machinery and equipment that is used to create markings for and on a variety of products and parts. Once these markings have been designed and fabricated, they are then put onto packages by labeling machinery.

Quick links to Marking Machinery Information

The History of Marking Machinery

- The Early History of Marking

- The practice of marking goes back thousands of years. The earliest evidence of engraving we have right now is a chiseled shell that dates back between 540,000 and 430,000 years. It was found in Trinil, Java, Indonesia, the same place where the first homo erectus was found. The second oldest engraving examples that we have discovered date back to the Middle Stone Age, around 60,000 BC. These are hatched ostrich shells decorated with banding, found in South Africa in the Diepkloof Rock Shelter, likely used as water containers. Next, there are many examples around the world of engraved bone and ivory from the Upper Paleolithic period, and engraved petroglyphs from prehistoric cultures.

- During antiquity, after the beginning of the 1st Millennium BC, metal engraving was conducted using chasing or a combination of lost-wax casting and chasing. It could only achieve shallow grooves on metal jewelry. The artisans of antiquity also loved to engrave gemstones. This artform remained popular until the 19th century AD.

- As early as the 1st century AD, people began engraving glass, usually with a wheel. They did so to cut decorative figures or scenes into glass vessels. Decorations over the centuries included those related to Greek mythology, hunting, entertainment and the Old and New Testament. The practice of glass engraving, which was popular in large cities like Rome, seems to have died out sometime during the 5th century. They also used this method to cut and attach embellishments, like gold leaves, to wares to make them appear more expensive.

- Middle Ages and Marking

- During the Middle Ages, goldsmiths in Europe began using engraving to inscribe and decorate their metalwork products. Around this time, they also began using print impressions so they could repeat their designs. Out of this grew the practice of using printing plates. The Germans started this trend around 1430, and the Italians quickly followed suit. Some of the most famous and successful engravers of the day (1470 to 1530) were Albrecht Dürer, Lucas van Leiden and Martin Schongauer.

- The golden age of engraving was ended by the rise of etching, which began in Europe during the late 1400s. Note: across the pond in present-day Arizona, we also have evidence that, prior to 1100 AD, the Hohokam culture was using acid etching to decorate marine shells.

- In 15th century Germany, artisans practiced etching with iron plates. They used this technique to decorate metal items like cups, plates, armor and guns. The invention of etching for printmaking is attributed to Daniel Hopfer, a craftsman who lived in Augsburg, Germany between around 1470 and 1536. A shield he decorated and a sword he decorated are now housed in the Real Armeria of Madrid and the Germanisches Nationalmuseum of Nuremberg, respectively. The decline of engraving really began in earnest with the advent of the copper plate. The biggest advantage of etching was that it was much easier and less complicated.

- During the mid-Renaissance, Jacques Callot, of Nancy, Lorraine, in modern day France, developed the échoppe, a type of etching-needle. The échoppe had a slanted oval section at the end, which allowed etching artisans to create the same swelling line as engravers. Etching continued in art for hundreds of years.

- Modern Marking Systems

- Today, engraving and etching are still performed, but mainly using CNC controlled machinery. Modern mark systems are used primarily for artisan, industrial, electrical and printing applications. They offer speed, efficiency, precision, repeatability and versatility.

Benefits of Marking Machinery

While older methods of marking, like hand stamping, are cheaper than marking machinery, they are vastly inferior. For example, they are both labor intensive and inconsistent. Marking machinery offers the benefits of programmability, precision, repeatable results, speed and efficiency and easy adjustments. Also, because there are so many different types of marking machinery out there and so many designs manufacturers can use, there’s bound to be something for you.

Marking Machinery Design

When picking out marking machinery for a customer, manufacturers think about a number of different factors. These include: the type of material being marked, the lifespan of the material being marked, application volume/machine capacity, the intended use of the material being marked, the amount of detail required and environmental friendliness.

In aerospace and medical equipment processing, for example, marking equipment must apply enough pressure to alter an object’s surface, but it must also do so with extreme precision. Parts and machinery fabricated for these fields must be accurate to design and cannot be compromised. Other applications that use durable material that is not so delicate may require much more heavy duty or rugged marking methods, like embossing or engraving.

How Marking Machines Work

Different marking machines work differently. However, in general, we can say that marking machines work by removing areas of a material in order to create some sort of mark. They do this using a mark tool that makes direct contact, a laser beam that makes indirect contact, or strong chemicals (ex. acid bath) eat away at material.

For large projects, marking machinery manufacturers can program the depth, size and location of the desired marking pattern into a computer. They can also take a digital image and upload onto an automated CNC system and let it program the machine to create that image.

Marking Machinery Images, Diagrams and Visual Concepts

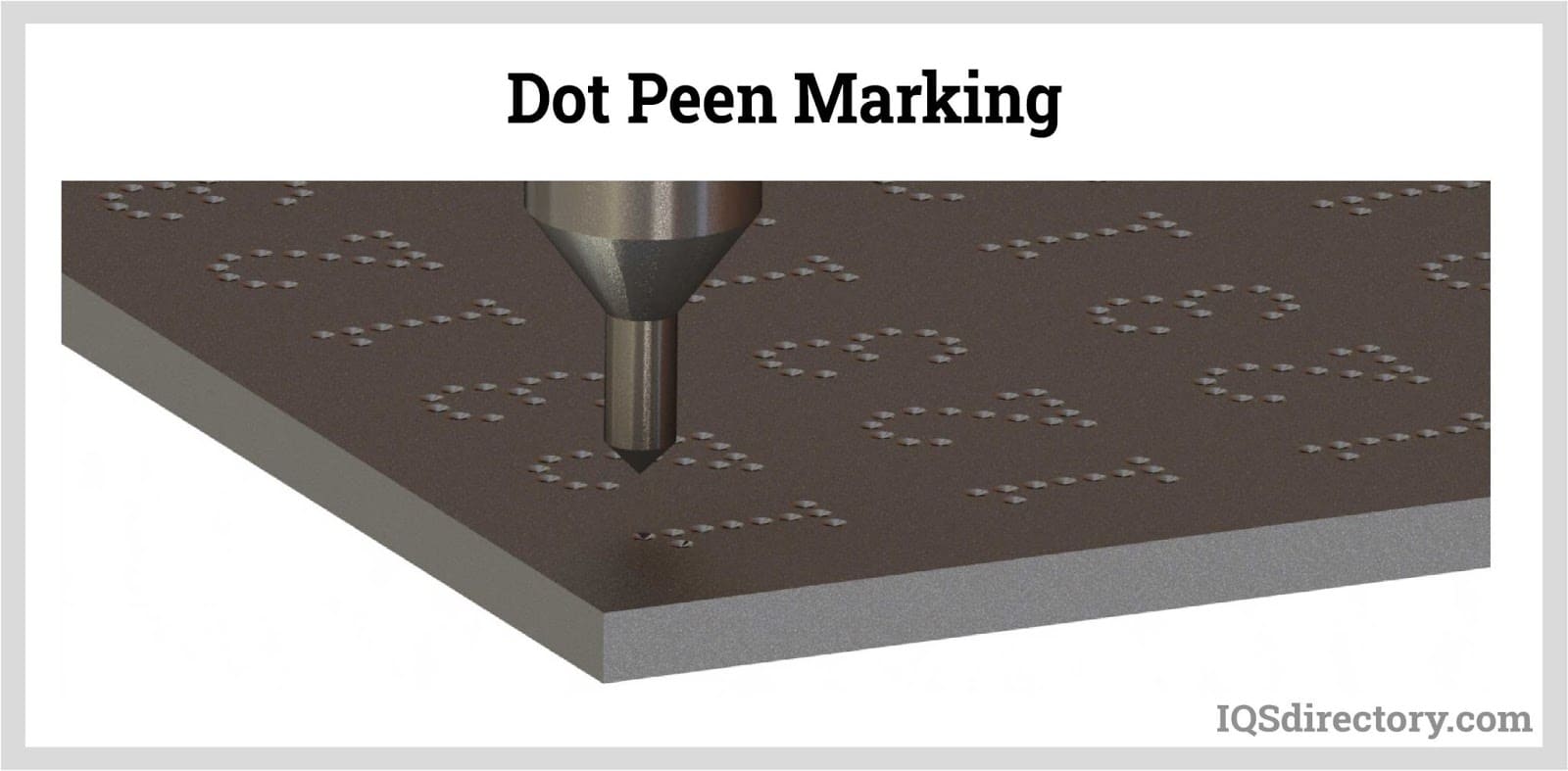

Dot peen marking machine uses a marking pin made of rigid material to engrave a series of small dots closely spaced to one another to form straight or curved lines.

Dot peen marking machine uses a marking pin made of rigid material to engrave a series of small dots closely spaced to one another to form straight or curved lines.

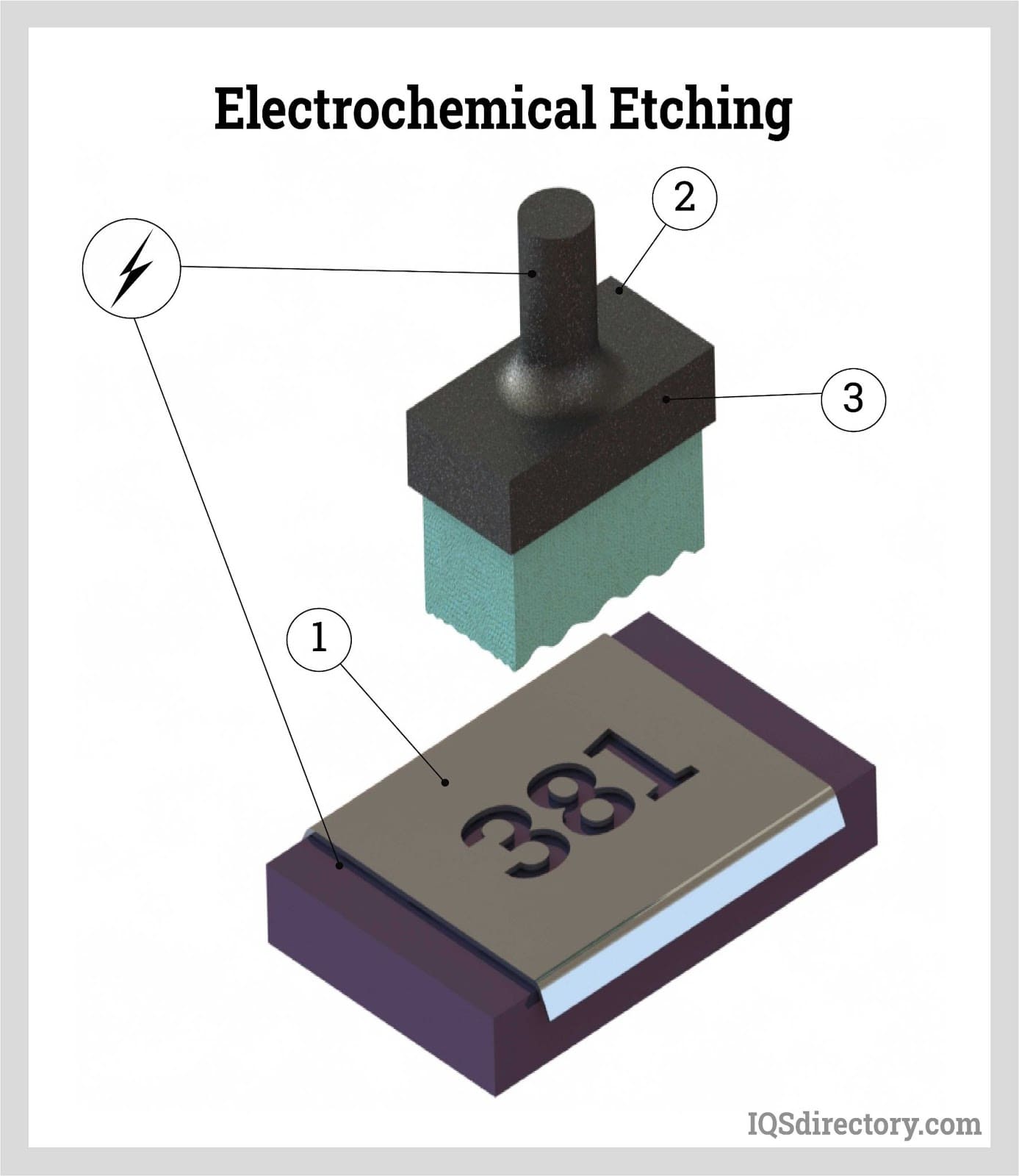

Electrochemical etching, the process of transferring a marking pattern from a stencil to an electrically conductive substrate through an electrolytic reaction.

Electrochemical etching, the process of transferring a marking pattern from a stencil to an electrically conductive substrate through an electrolytic reaction.

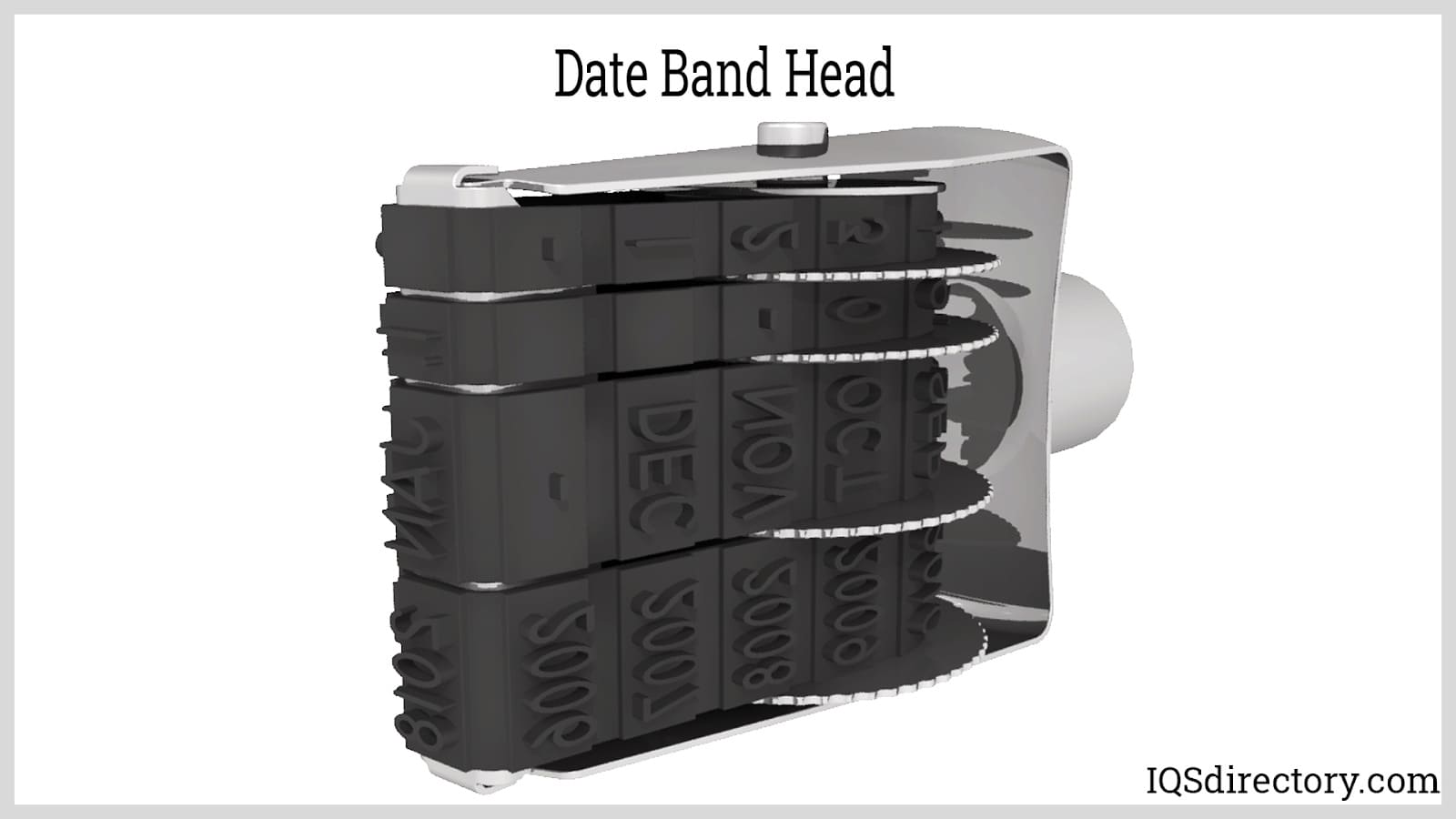

An example of the ink-based die marking which is usually made of rubber, making it ideal for marking brittle substrates.

An example of the ink-based die marking which is usually made of rubber, making it ideal for marking brittle substrates.

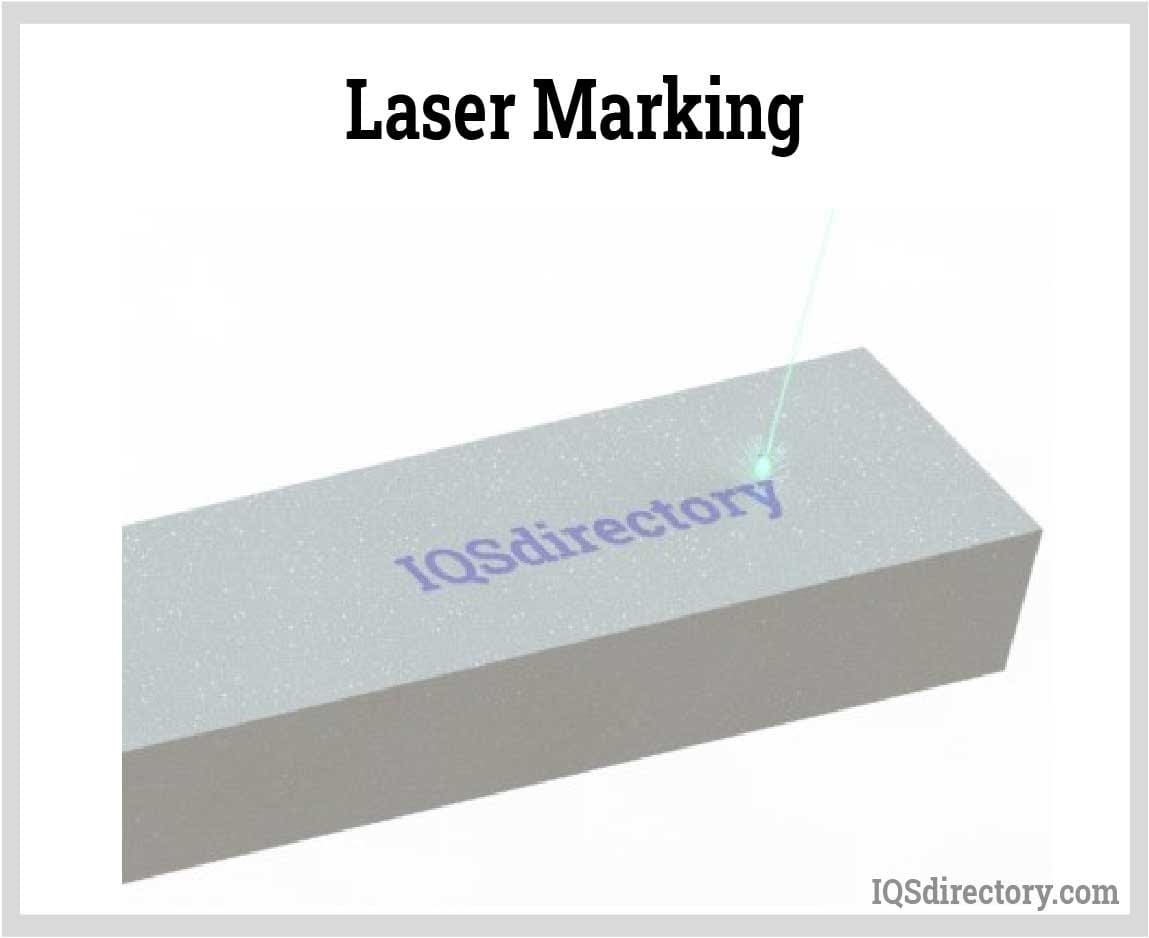

Laser marking, a marking process that incorporates laser technology to mark workpieces.

Laser marking, a marking process that incorporates laser technology to mark workpieces.

Scribe marking machine uses a stylus made from a hard material to produce a mark by piercing the substrate and is dragged along the surface to create lines or curves.

Scribe marking machine uses a stylus made from a hard material to produce a mark by piercing the substrate and is dragged along the surface to create lines or curves.

Hot stamping, the process of transferring ink from a carrier foil by pressing a heated die onto the surface.

Hot stamping, the process of transferring ink from a carrier foil by pressing a heated die onto the surface.

Laser marking machines make use of focused, high-energy laser beams that strike the surface of the material to print the marking pattern.

Laser marking machines make use of focused, high-energy laser beams that strike the surface of the material to print the marking pattern.

Types of Marking Machinery

Marking systems are made up of tools and machines that stamp, print, etch and/or emboss many different types of surfaces.

- Dot Peen Machine

- Also known as pin mark machines, stamp, or peen, workpieces with a pneumatically driven marking pin. They make straight or curved lines made up of a series of small, closely spaced dots. Independent X and Y marking axes make sure dot placement is precise and legible. Dot peening is fast and accurate, and does not put undue stress on surfaces. Use the dot peen mark machinery you can find from producers on IQS Directory for producing text, logos and 2D data matrix codes.

- Embossing Machine

- Works with ductile materials, such as leather and plastic. By applying heat and pressure, they create permanent deformations that manifest as 3D images. Embossing machines are popular for use in credit card production, where they mark the cards with upraised letters and numbers.

- Engraving Machine

- When an application calls for the marking of a harder material, such as stainless steel, manufacturers will likely select engraving machines. Engrave machine technology is similar to embossing technology, but it can cut grooves into much harder materials. This type of marking machinery is popular in jewelry processing applications. There are many types of engraving machinery, including, most notably, laser engrave machines.

- Laser Engrave Machine

- This type of laser equipment removes material from objects using laser radiation. During this exchange, the laser mark machine does not actually touch the object. Only the highly focused laser beam touches it. This is advantageous for extra sensitive materials, such as glass. Laser engrave machines usually use a fiber laser because it is simpler and cheaper than others such as the CO2 laser. Choose laser engraving for direct photopolymer laser imaging, direct flexographic plate and cylinder engraving, subsurface laser engraving and fine engraving of jewelry.

- Laser Cut Machine

- Similar to laser engrave machines are laser cut machines, which also usually use fiber lasers as their laser source. The main difference between the two laser mark machines are the machine laser lens. The laser cut machine lens has a longer focal point that the laser engrave machine lens. The longer focal point results in less taper in the cut edge. This mark system makes the most difference with thicker materials, when less taper translates to reduced slope edge angles. Laser cutting is best for jewelry.

- Pad Printing Machine

- Prints 2D marks onto 3D products. It uses silicone pads to transfer images to a product surface from the printing plate. Pad printing machines are commonly used to mark products such as toys, electronics and medical equipment.

- Plasma Etch Machine

- Uses either gases or vacuum pressure to leave marks, is the most effective marking technique for surface modification. At the same time, plasma etching can only be performed in batches, which takes longer and can, if it takes too long, cause deterioration of the moldings.

- Chemical Etching Machine

- Another example is chemical etching. The advantage of chemical etching is that it is inexpensive, while its disadvantage is that it yields inconsistent results and so is limited in use to applications that do not require precise results.

- Steel Stamp Press

- If a manufacturer wishes to mark products at a low volume, he or she may select steel stamps. These create markings by pressing or hitting a marked stamp into a material with enough force to leave an indentation. Types of steel stamps include stamp marking kits, hand stamps and press stamps.

- Numbering Machine

- For legal documentation purposes, customers may purchase numbering machines, which print numbers onto pages consecutively.

- Press Marker

- Very fast and can leave permanent marks, but they are time consuming to assemble, cannot be used on fragile parts or hard parts, are not very flexible and can be dangerous to use.

- Etching Machines

- The process of using acids, bases or other chemically abrasive substances on a material for the purposes of engraving or marking a part or material. Also known as chemical milling, etching can be used to create master prints or dyes out of metal pieces to be used to create numerous imprints of a design or image.

- Other types of marking machinery include: roll mark devices, stylus marking devices, hot stamping machine and nameplate markers.

Marking Machinery Applications

Marking machinery makes marks such as: identification codes, images, designs, labels, logos and more. Customers use marking machinery to achieve a wide variety of ends, such as: increased customer recognition, retail product pricing, increased ease of product return, counterfeit deterrence and parts and product tracking.

Marking machines work on a wide variety of materials, including fabric, glass, leather, paper, plastic, textiles and wood. Marks from marking machines are adhered onto parts and products including: cables and wiring, consumer parts, credit cards, debit cards, greeting cards, glass sculptures, electronic parts, jewelry, packaging, storage boxes, wood trim and writing utensils.

Some of the many industries that employ metal mark machine services include: electronics, finance, shipping, fine arts, textiles and crafts, communications, quality control and furniture.

Marking Equipment Components

Marking machinery generally consists of specialized marking tools or secondary equipment. Specialized marking tools include scribers, which are thinly shaped components of any machine that ingrain a mark on a material, printing plates, laser markers, and steel stamps. Examples of secondary equipment include industrial inkjet printers and printing machines, which are used to ink mark flat surfaces. These machines are completed by their power source and programming.

Standards and Specifications for Marking Machinery

Marking machinery must be maintained to extremely high-quality standards.

The main standard for marking machinery is the CE mark. The CE (French: "Conformite Europeenne") mark certifies that a product has been tested and meets health, safety and environmental requirements of the European Union. If you plan on using this equipment in Europe or if your marked products are bound for Europe, it’s important to make sure that the marking machinery you purchase bears CE production identification.

To ensure safety of machinery, those planning to use marking machinery also need to make sure that their mark equipment is OSHA compliant.

Things to Consider When Choosing Marking Machinery

The ins and outs of marking machinery may seem a bit confusing, but with the right manufacturer guiding you, finding the right equipment for you won't be so hard. A good marking machinery manufacturer will help you select the best machinery and tools for you based on factors such as: your product volume, product material and industrial application, as well as how your new machinery will fit into your existing system.

Find the manufacturer or supplier for you by checking out the comprehensive list that we’ve provided towards the top of this page. Those with whom we partner are vetted, experienced and reliable. Take a look at their respective information and websites, pick a few that you find most promising, and then reach out to each of them with your specifications and questions. Compare and contrast their responses, keeping an eye out for price points, delivery policies, available certifications, lead times and overall customer service. The supplier that hits all these points is the one for you.

Marking Machinery Terms

- Bar Code

- A code used in the identification of products through electronic scanning, consisting of a sequence of parallel lines that vary in width. The spacing between the individual bar lines also varies.

- Bevel

- The slant from the surface of an engraved character to the background is referred to as the first, or character, bevel. The second bevel is the clearance taper, or sighting angle, which is usually a 45-degree angle on each side of the hand stamp.

- Bottoming

- Impressing a stamp or die to the background of the characters or design. Bottoming also refers to the ironing out of metal displaced by a stamping die.

- Character

- In marking systems, the individual letter or number marked upon an object. Character faces and styles vary.

- Chase

- A frame of metal in a hot stamping press that holds the die in place during the stamping process.

- Chemical Etching

- A process in which a mark is burned onto a product through the application of a screen and an acid.

- Die

- In marking machines, a metal plate onto which a design or image is etched or engraved to be stamped, rolled or printed onto a product.

- Dot Marking

- Also called "dot peening," it is a type of micro-percussion marking system in which sequences of dots are used to mark an object according to design requirements.

- Etching

- A process in which a metal plate is coated with wax through which lines are cut. A corrosive acid is applied, which removes the metal under the lines.

- Foil

- In hot stamping, a thin, flexible material consisting of a coat of color that transfers to the stamped product during the stamping process.

- Hand Stamp

- A steel stamp that engraves a design onto an object by striking the stamp with a hammer. Hand stamps are useful when producing low volumes of products.

- Impregnation Printing

- The process of transferring a special ink based on a sublimating dye to the inside of molded parts. Impregnation printing is useful in applications requiring wear resistance.

- Ink Jet Marking

- Marking system in which a mist of ink is transferred to an object to mark the object according to design requirements.

- Insert

- A stamp or type placed with a piece of marking equipment, such as a die, to produce a particular design or image.

- Intaglio

- An image or design created by engraving the design onto a metal plate and filling the recessed design with ink. A damp piece of paper is then pressed against the plate in a roller press, producing a reverse image on the paper.

- Mortise

- A depression or cavity in a die into which an insert is placed.

- Numbering Head

- A device that marks products with multiple characters simultaneously for fast and consistent identification.

- Pad Printing

- The process of transferring ink to a molded part by filling ink in a plate in which characters are engraved hollow, moving it to a pad and pressing the pad on the face of the molded part; the ink is then cured by thermal treatment, ultraviolet treatment or other curing processes.

- Part Marking

- The process of engraving, etching, or otherwise marking a design, image, logo or identification code of a manufacturer on a product or part.

- Steel Branding Die

- A die that can be heated to a temperature sufficient for burning characters or designs into wood, leather and other materials.

- Steel Stamp

- A marking device that is pressed or hit into a material. Steel stamps include hand stamps, press stamps and stamp marking kits.

- UPC (Universal Product Code) Number

- A number code below the bar code that consists of 14 numbers, which provide product identification.

- VIN (Vehicle Identification Number)

- A unique combination of letters and numbers created by a vehicle manufacturer to accurately identify a vehicle.