Machine Vision

Machine vision systems are technical systems designed to mimic human vision. In industrial settings, machine vision (MV) refers to the computer "vision" used to control automated manufacturing equipment. In systems engineering, machine vision is separate from computer vision, which they instead see as a type of computer science.

Quick links to Machine Vision Information

The History of Machine Vision Systems

The history of machine vision systems begins in the 1950s. At that time, American psychologist James J. Gibson developed the concept of optical flow. Based on this, Gibson developed two-dimensional imaging technology for use with statistical pattern recognition. In 1960, Larry Roberts wrote a PhD thesis at MIT on the extracting 3D geometric information from 2D images. His work spurred the curiosity of researchers around the globe and from that research, we eventually gained 3D machine imaging.

In the 1970s, MIT once again became involved when their Artificial Intelligence Lab opened a machine vision course, during which they worked on practical vision tasks, like edge detection. Their labor bore fruit in 1978, when David Marr created a new approach to understanding images through the eyes of computer vision. Marr’s process called for operators to begin with a 2D sketch and build on it using computer technology to get a 3D interpretation.

By the 1980s, machine vision had begun migrating from the research labs to the manufacturing plant. There, vision systems were used to read numbers, letters, symbols and codes. Also in the 1980s, researchers developed the first smart cameras. Developers introduced smart cameras using digital signal processing (DSP) in the 1990s. This and other improvements of machine vision technology diversified the systems, and they soon became less expensive and more accessible.

Today, machine vision system use is extremely widespread and its future is bright. Analysts believe that, by 2022, the global machine vision market will reach a value of $15.46 billion. The market is spread across the globe, with Asia Pacific cornering 30% of the market, followed by the European continent, then North America.

Benefits of Machine Vision Systems

Machine vision systems offer their users many advantages. First, they eliminate the variables associated with human error. Likewise, they catch defects and details easy to miss by the human eye. They also sort products more efficiently than humans ever could. In addition, machine vision systems are versatile, as there are so many ways that they can gather and interpret information. Machine vision systems also provide a fast and convenient way to quantify image information and transfer it into a computer system.

How Machine Vision Works

Computer vision relies on digital cameras and pattern recognition software. Although machine vision has improved significantly in the past few years, computers are still incapable of the same kind of adaptable vision as humans. For this reason, machine vision software systems are usually programmed to fulfill those assignments that require consistent repetition of the same task.

Machine vision systems perform image processing using a number of different methods. These include: thresholding, stitching, pixel counting, filtering, color analysis, segmentation, blob detection and extraction, edge detection, pattern recognition, barcode reading, neural net/deep learning, optical character recognition and metrology/gauging. They may use one or more of these in sequence to achieve image processing.

- Thresholding

- A process that uses a set gray value to separate image sections. Sometimes, thresholding also involves changing each image section into while or back based on its position above or below the set grayscale value.

- Stitching

- Also known as registration, is the practice of combining adjacent 2D or 3D images.

- Pixel Counting

- A process during which system counts the number of dark or light pixels. Pixels are the smallest usable points in displays that use points to build an image. Every pixel is a tiny sample of the original image.

- Morphological Filtering

- Filtering, or morphological filtering, uses lattice theory to analyse and process digital images. Lattices are abstract structures consisting of a partially ordered set, where every two elements feature a different supremum and infimum.

- Color Analysis

- A process during which the software uses color to isolate features, determine quality, and identify items, products and parts.

- Segmentation Process

- A process during which the visioning system separates a digital image into several different segments. Doing so makes the images simpler and easier to analyze.

- Blob Detection

- And extraction is a process during which the vision system inspects the image for regions that differ from the rest, such as a black hole in a gray object. These regions, known as image landmarks, are actually blobs of connected pixels different from the rest.

- Edge Detection

- An image process method in which the system finds and defines object edges. Using this method, operators can attain a sort of outline or sketch of the image in question.

- Pattern Recognition

- Software can match, count or generally recognize chosen patterns within an image. This includes patterns that are partially blocked by another object, patterns that are rotated and patterns that vary in size.

- Barcode Reading

- A process during which the machine vision scans the barcode and compares it against stored target values. This way, it verifies the code, allowing the transaction to proceed, or it signals to stop or try again.

- Neural Net

- And deep learning are two systems that learn to recognize certain things and make multi-variable decisions over time, as they are fed new data and examples. They are designed to work somewhat like the animal brain, which develops new connections in the neural network as it learns new things. Deep learning systems can be supervised, partially supervised or completely unsupervised.

- Optical Character Recognition

- A system of automated text reading. This type of image recognition system reads texts like serial numbers.

- Metrology or Gauging

- The measurement of object dimensions, whether that be millimeters, inches, pixels or something else.

Machine Vision Images, Diagrams and Visual Concepts

Machine vision systems are assemblies of integrated electronic components, computer hardware, and software algorithms that process and analyze the images captured from the environment.

Machine vision systems are assemblies of integrated electronic components, computer hardware, and software algorithms that process and analyze the images captured from the environment.

The lens captures images and relays to a image sensor inside the camera.

The lens captures images and relays to a image sensor inside the camera.

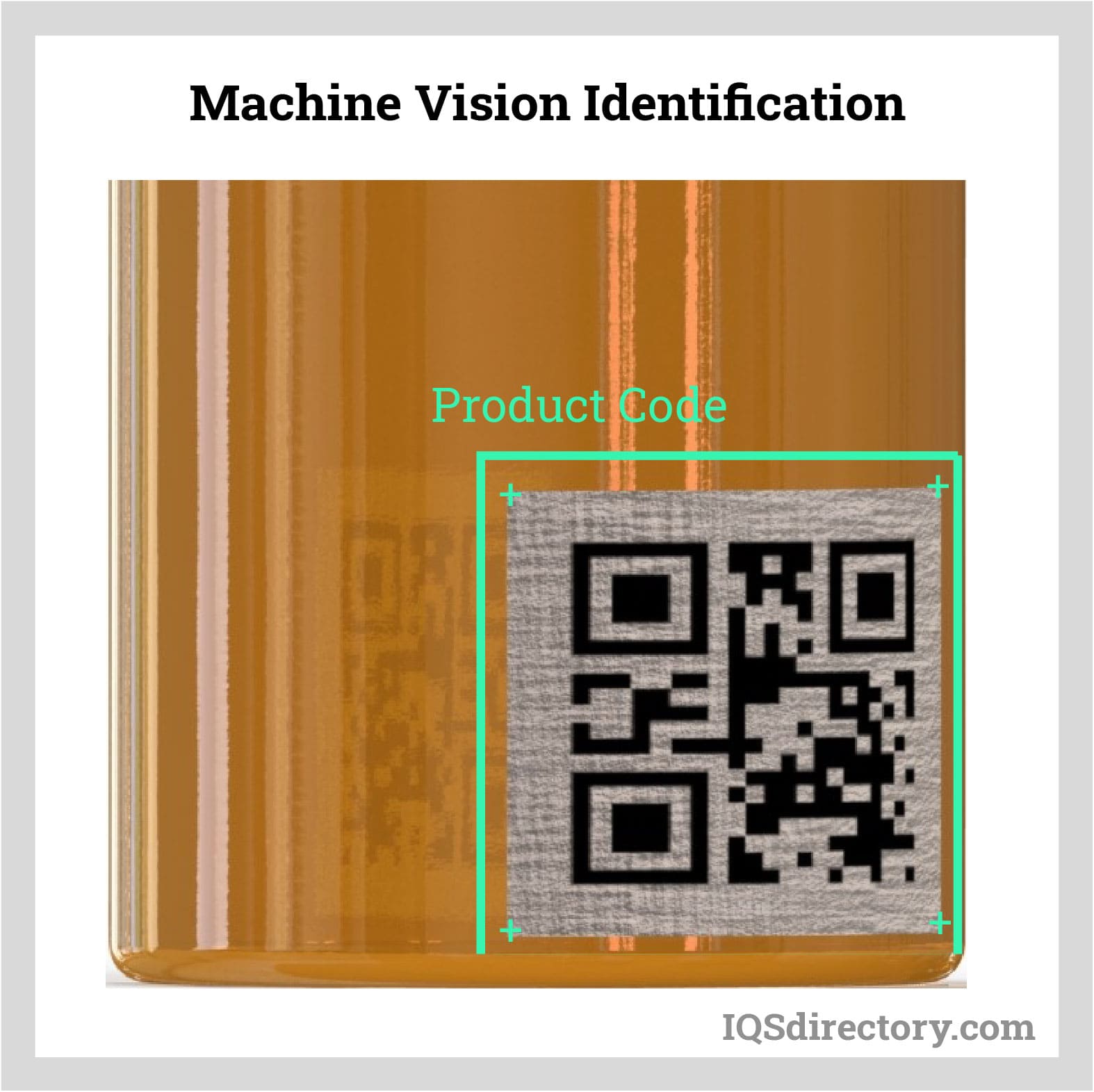

Machine vision identification scans and reads barcodes, 2D codes, direct part marks, and characters printed to improving traceability.

Machine vision identification scans and reads barcodes, 2D codes, direct part marks, and characters printed to improving traceability.

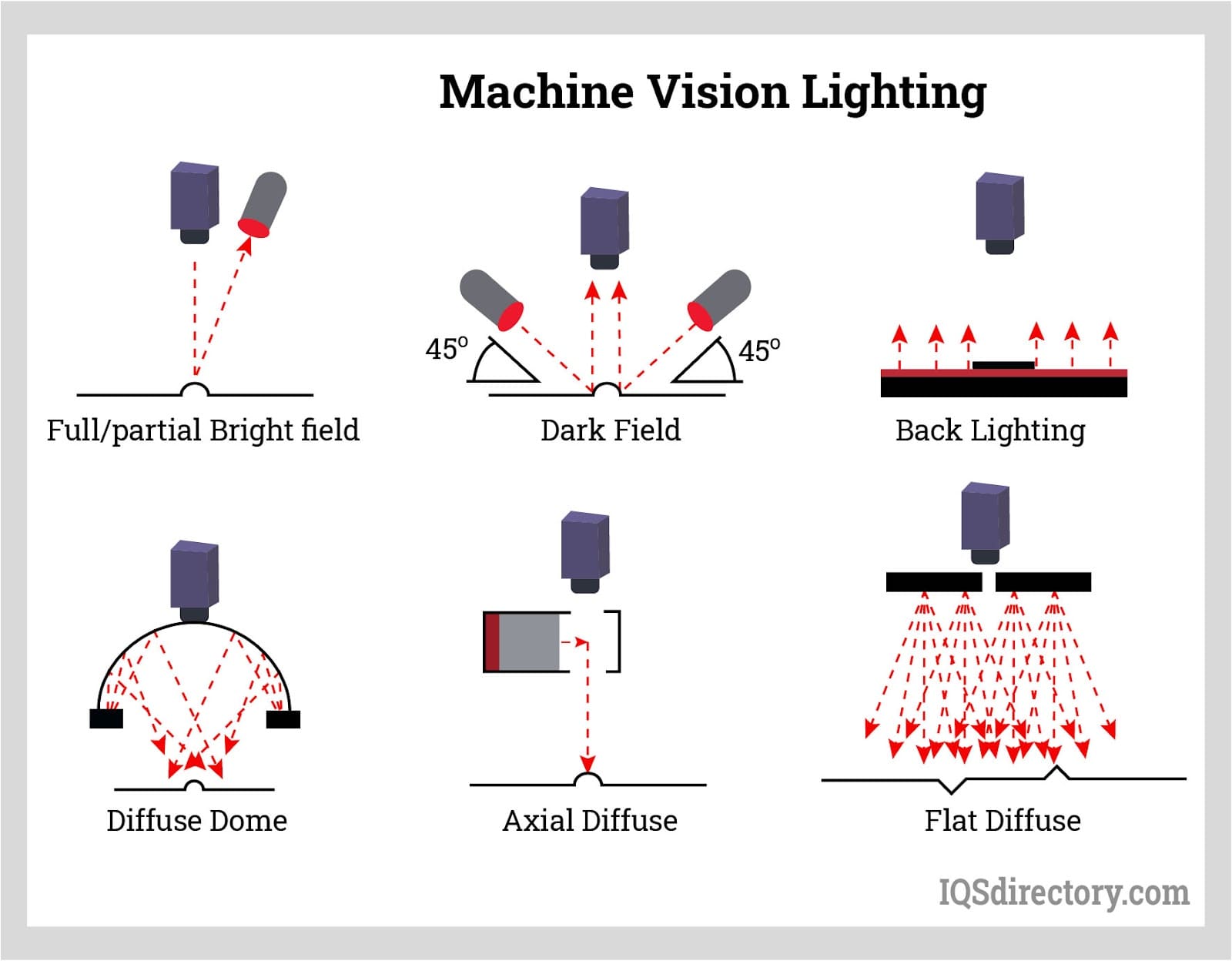

The lighting is responsible for illuminating the object and highlighting its distinct features to be viewed by the camera.

The lighting is responsible for illuminating the object and highlighting its distinct features to be viewed by the camera.

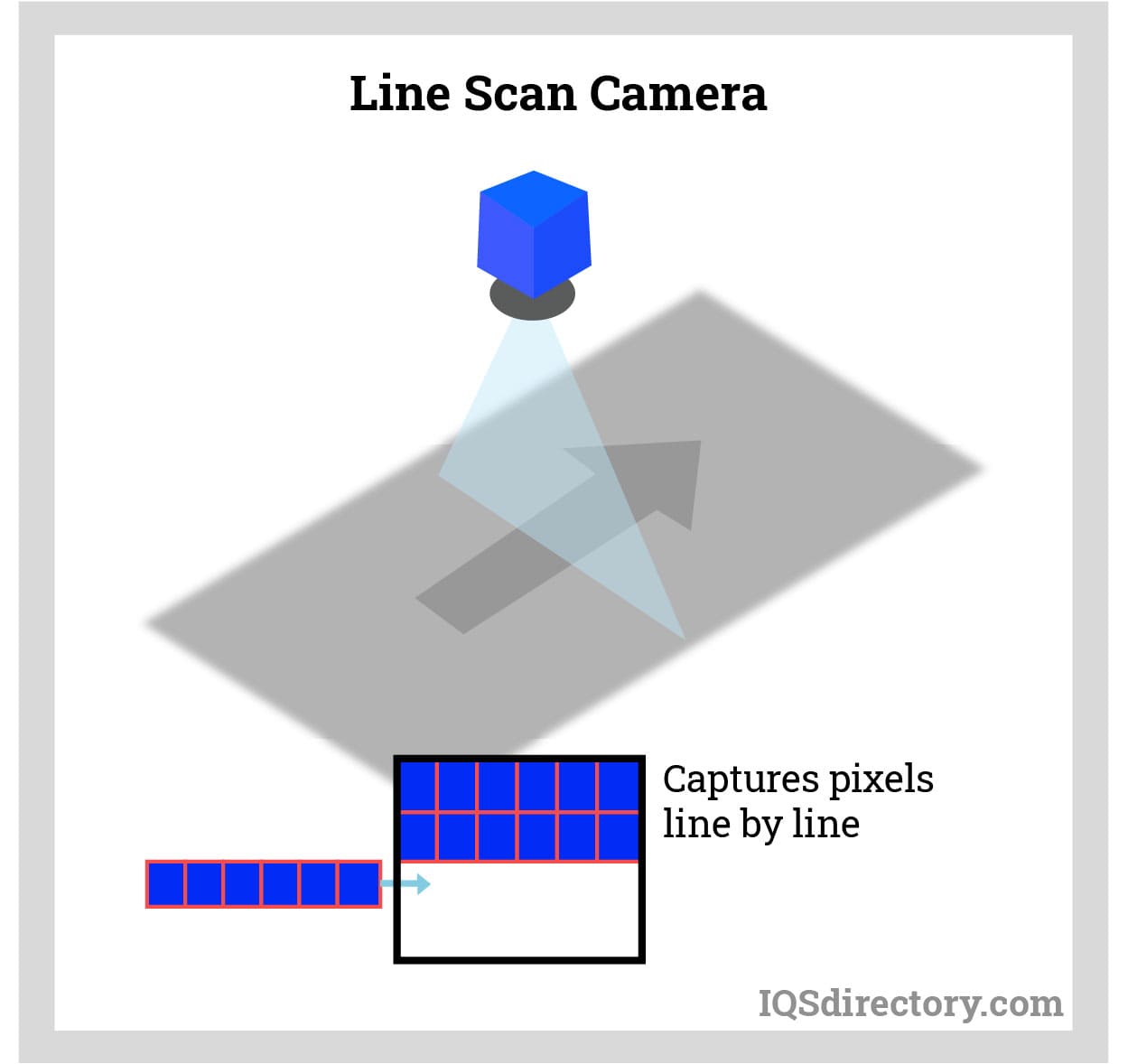

Line-scan cameras captures digital images one line at a time, then the complete image is constructed pixel line by pixel line.

Line-scan cameras captures digital images one line at a time, then the complete image is constructed pixel line by pixel line.

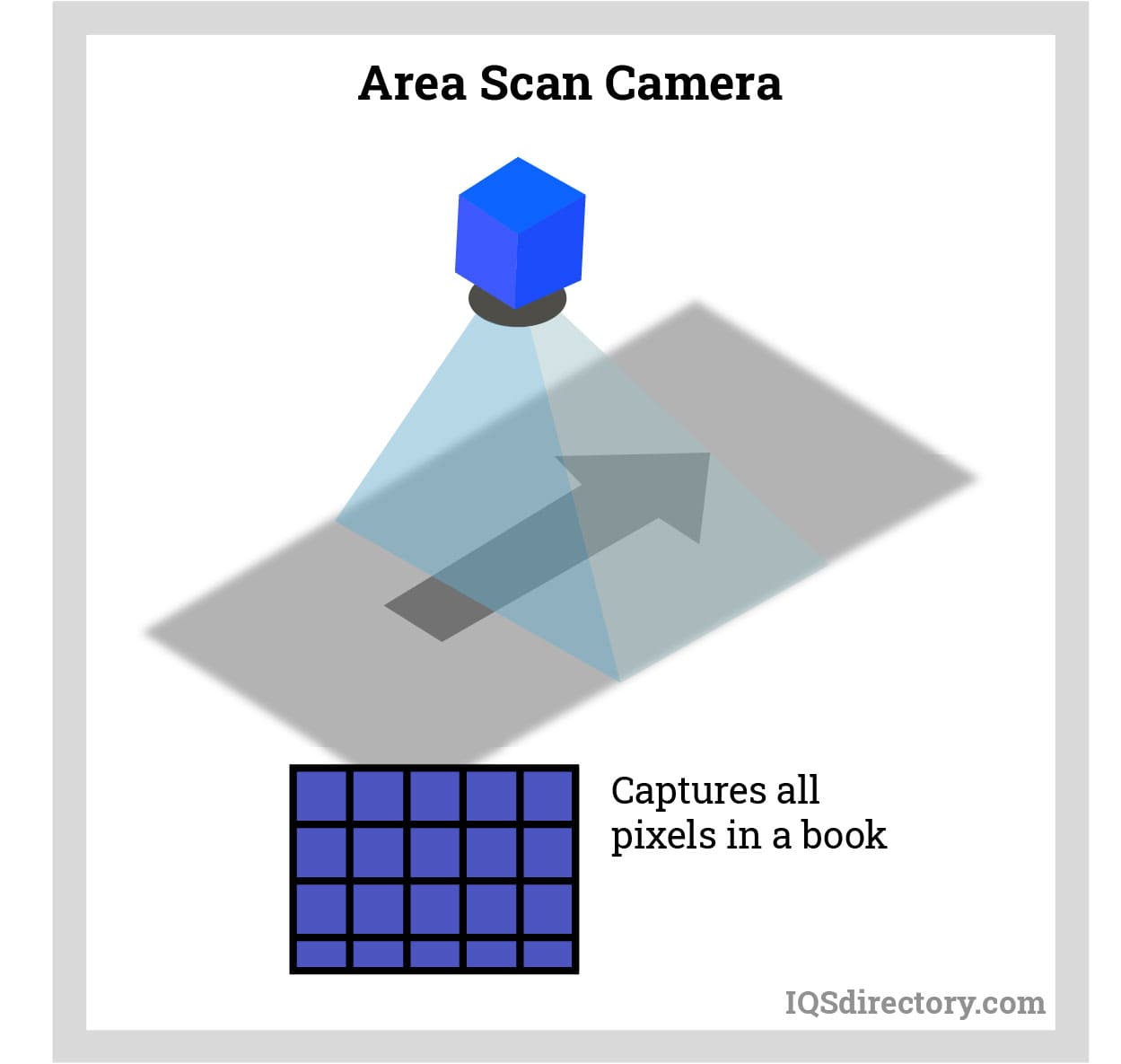

Area scan cameras use rectangular-shaped image sensors to capture images in a single frame, resulting in a digital image that has a height and width based on the number of pixels.

Area scan cameras use rectangular-shaped image sensors to capture images in a single frame, resulting in a digital image that has a height and width based on the number of pixels.

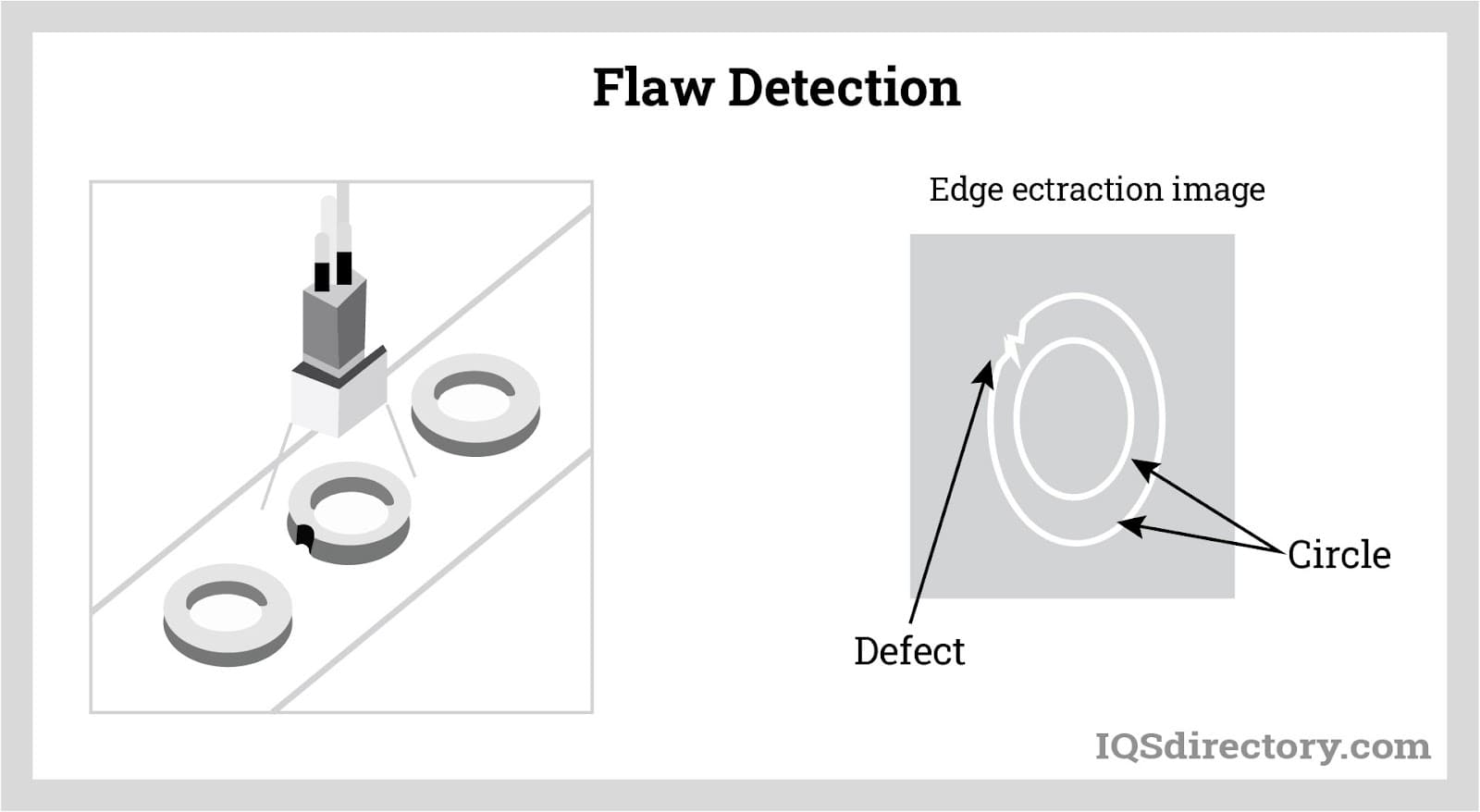

The machine vision searches for any irregularities present on the part's surface, which can affect the product functionality and reliability.

The machine vision searches for any irregularities present on the part's surface, which can affect the product functionality and reliability.

Machine Vision Types

- CCD Cameras

- Use charge coupled device (CCD) chips to gather information. The CCD chips convert photons into digital or electrical information that operators can upload onto an image file on a computer. This is useful because it means that they do not have to extract data from film.

- Laser Inspection Systems

- Use photoelectric sensors that work with the assistance of laser beams. They can be used for a number of vision applications, including: scanning barcodes or serial numbers, finding any and all microscopic product surface defects, and counting parts during service production. In addition, laser inspection systems can create 3D reproductions of a surface they’ve scanned.

- Optical Inspection Systems

- Inspect products using machine vision. Vision inspection systems such as these are common components of assembly lines, where they perform tasks such as: scanning serial numbers, counting products and checking for defects.

- Optical Sorting Systems

- Those systems designed to use machine vision specifically to sort products.

- Magnetic Imaging Systems

- Work with materials that have magnetic properties. Using these properties, along with an x-ray-esque sensor, they create visual representations of the product.

- Smart Cameras

- Machine vision cameras that use imaging software and processing circuitry in order to gather high quality images. While highly portable, they have a small storage capacity, so they are typically combined with or connected to the main system.

- Robotic Vision Systems

- Semi-autonomous machines, such as AGVs, that move around in industrial settings and use computer vision to see on a limited basis.

Machine Vision Applications

In general, the goal of machine vision is to provide image-based information of products, images or surfaces, so that operators can analyze them. In addition to generic image analysis, common machine vision solutions and applications such as: automation process control, quality control and screening, automatic inspection, robot guidance, integrated systems, hardware product manufacturing, software product manufacturing and assembly line.

Machine vision can be used for multiple purposes over the length of an assembly line. It can be used to measure, count, inspect goods, or to read serial numbers on items such as die casted products. Machine vision has replaced workers in many jobs where humans are likely to err as a result of distraction or fatigue. Machine vision is also installed in those automation applications in which a robot arm or AGV needs to be guided.

Machine Vision Equipment Components

Although machine vision systems differ by product, three key elements remain the same: machine vision lighting, an imager like a digital camera or vision sensor, and special image processing software.

- Imager Component

- If they use a digital camera, manufacturers may either separate it from the main machine vision unit, or they may combine it with the unit. If the former, manufacturers can connect the camera to the main unit in a few different ways. First, they may use a custom processing accessory called specialized intermediate hardware. Second, they may connect the two components with a frame grabber housed inside a computer. Alternatively, they can use digital cameras that connect to computers directly using interfaces like USB, FireWire or Gigabit Ethernet. Meanwhile, if the latter, they call the camera element a smart sensor or a smart camera. Vision sensors, like cameras, capture precision imagery.

- Image Processing Software

- Or vision software, is the programming that extracts and interprets the raw images collected by camera or sensor. It creates data based on the images that operators can understand and use. It can, for example, count, measure, inspect and/or sort the data on behalf of the users.

Standards and Specifications of Machine Vision

Machine vision systems are beholden to a few different industry standards, depending on where you are located. First are EMVA standards. EMVA, or European Machine Vision Association, creates standards related to reliable and exact measurement procedures and transparent data presentation. They also offer general programming that can be used with a wide variety of systems, making data sharing and application changes easier. EMVA partners with standard associations from North America (AIA), Japan (JIIA), Germany (VDMA) and China (CMVU).

Another popular standard is the GigE Vision standard, a global camera interface standard designed by AIA to ensure the creation and use of low-cost and gigabit ethernet communication. To find out more, talk to your suppliers and industry leaders.

Choosing the Right Machine Vision System Manufacturer

If you are looking for a machine vision product or system, you need to consult with an experienced professional who can match you with the best technology for your application. To find such a professional, check out the list of machine vision system manufacturers we have listed on this page. All of those listed on our page have excellent brand reputations and are proven reliable and worthy of your business. Before browsing their interactive profiles, we recommend you put together a comprehensive list of your specifications. That way, when you go to speak with one or more manufacturers, you’ll have all your ducks in a row and will be ready for a productive conversation. As you jot down your needs, make sure to include your: primary applications (barcode scanning, quality control, inspection, etc.), budget, timeline, standard requirements, delivery preferences and post-delivery support preferences. Once you’ve done that, take your list and compare and contrast the services and products of the manufacturers listed here to what you’ve written down. Pick out three or four suppliers in whom you are most interested, then reach out to them and discuss your application at length. Find out what custom vision solutions they can offer you. Finally, look at the services, products and capabilities of each supplier side to side, and choose the one with the best machine vision solutions for you.

Machine Vision Terms

- 3-D Imaging

- A technology that provides 3D images from a large quantity of 2D cross-sectional images. These images are assembled in a computer from pictures or scans taken of a desired piece.

- Acquisition

- The manner in which outside information is brought into an analysis system.

- Aperture

- The diameter of the lens, which controls the amount of light that reaches the photoconductive image sensor.

- Attenuation

- Reduction of signal strength.

- Chroma

- Quality of color, which includes both hue and saturation.

- Decompression

- The restoration of original information from compressed data.

- Depth of Focus

- The range of the distance from the sensor to the object at which the lens is focused.

- Digital Imaging

- Conversion of a video picture into pixels by means of an A/D converter, where the level of each pixel can be stored in a computer.

- Dichroic Filter

- A filter used to transmit light based on wavelength rather than on the plane of vibration. Dichroic filters will transmit one color while reflecting a second, when illuminated with white light.

- Fiber Optics

- Light source or optical image delivery via long, flexible fibers of transparent material, usually bundled together. Light is transmitted via internal reflection inside each fiber; coherent fiber optics are spatially organized so images can be relayed.

- Focal Plane

- The plane perpendicular to the lens axis at the point of focus, usually found at the image sensor.

- Frame Rate

- The amount of frames that are displayed per unit of time.

- Gauging

- The non-contact dimensional examination of an object.

- Gray Scale

- Variations of values from white through shades of gray to black in a digitized image with black assigned the value of zero and white the value of one.

- Halogen Lamp

- An incandescent lamp inside which is a gas similar to iodine that is constantly evaporated and then redeposited on the filament.

- Image Analysis

- The process of identifying objects and shapes in a photograph, drawing, video or other visual image. Image analysis is used for everything from colorizing classic motion pictures to piloting cruise missiles.

- Image Plane

- The plane surface of the imaging sensor, perpendicular to the viewing direction, at which the optics are focused.

- Infrared

- The region of the electromagnetic spectrum adjacent to the visible spectrum, just beyond red with longer wavelengths.

- Laser Technology

- Often used to create 3-D images of a recorded surface. Lasers produce high powered light with electrical properties.

- Machine Vision Products

- Encompass all systems and components designed and used for the application of computer vision in industrial and manufacturing proceedings.

- Pattern Recognition

- Classification of images into predetermined categories, usually using statistical methods.

- Pixel

- Acronym for picture element. Pixels are the individual elements in a digitized image array.

- Process Imaging

- The process of manufacturing at both the design and production stage. Process imaging is a generic term for quality control imaging.

- Sharpening

- An image processing operation that enhances edges. A non-sharp mask adds a low-pass, filtered image to the original, resulting in edge enhancement.

- Shutter

- An electrical or mechanical device used to control the amount of time the imaging surface is exposed to light. The shutter is often used to stop the blur created by moving objects.

- Spatial Filtering

- Enhancing an image by changing its spatial frequencies.

- Zoom Lens

- A compound lens that remains in focus as the image size is continuously varied. A zoom lens may be motorized or manually operated.