Machine Guarding

Moving machine parts can result in serious occupational injuries like amputations, crushed fingers or hands, burns, or blindness. Costly injuries can raise workers' compensation insurance costs, including amputations, lacerations, and abrasions. There are mechanical and non-mechanical risks associated with every piece of machinery. The first line of protection against machine operator injuries is machine guards. In addition, each machine must have sufficient safety measures to protect operators and workers from dangers like revolving parts, sparks, and flying debris. Any component, operation, or procedure that could lead to harm must be protected.

Mechanical Hazards

There are three regions of the machine most likely to cause injuries. Firstly, the point of operation. This is where the machine cuts, shapes, bores, or molds material. The power transmission apparatus can also be dangerous. This mechanical system transfers energy to the machine's working components. Operators should be careful around flywheels, pulleys, belts, connecting rods, couplings, cams, spindles, chains, cranks, and gears. Finally, any other moving part of the machine may cause injuries. These include the machine's feed mechanisms, auxiliary components, and reciprocating, rotating, and transverse moving parts.

Types of machine guards

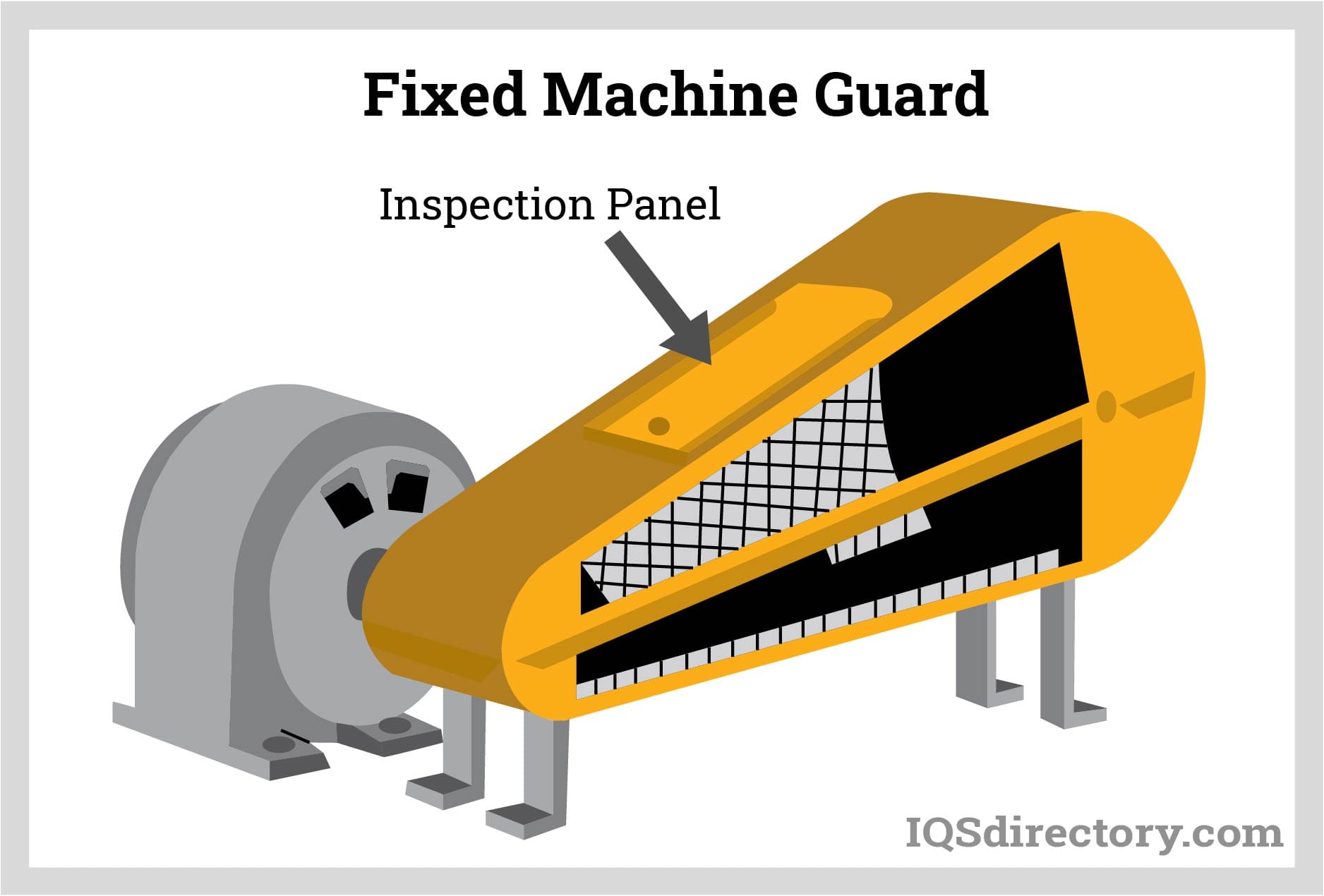

Fixed machine guard

A fixed machine guard ensures protection by acting as a physical barrier. It works regardless of the machine’s parts. It could be made of plastic, sheet metal, screen, wire cloth, bars, or any other material strong enough to resist repeated use. Physical access to the machine is challenging with fixed guards. A fixed machine guard is preferred over all others due to its relative simplicity.

Advantages and Limitations of a Fixed Machine Guard

Fixed machine guards can be suitable for repetitive operations in high-production systems. They’re adaptable to specific applications and require minimal maintenance. Some manufacturers design their own fixed machine guards, and they can provide the best protection.

However, a fixed machine guard may interfere with visibility. Manufacturers may have to remove them frequently for machine maintenance.

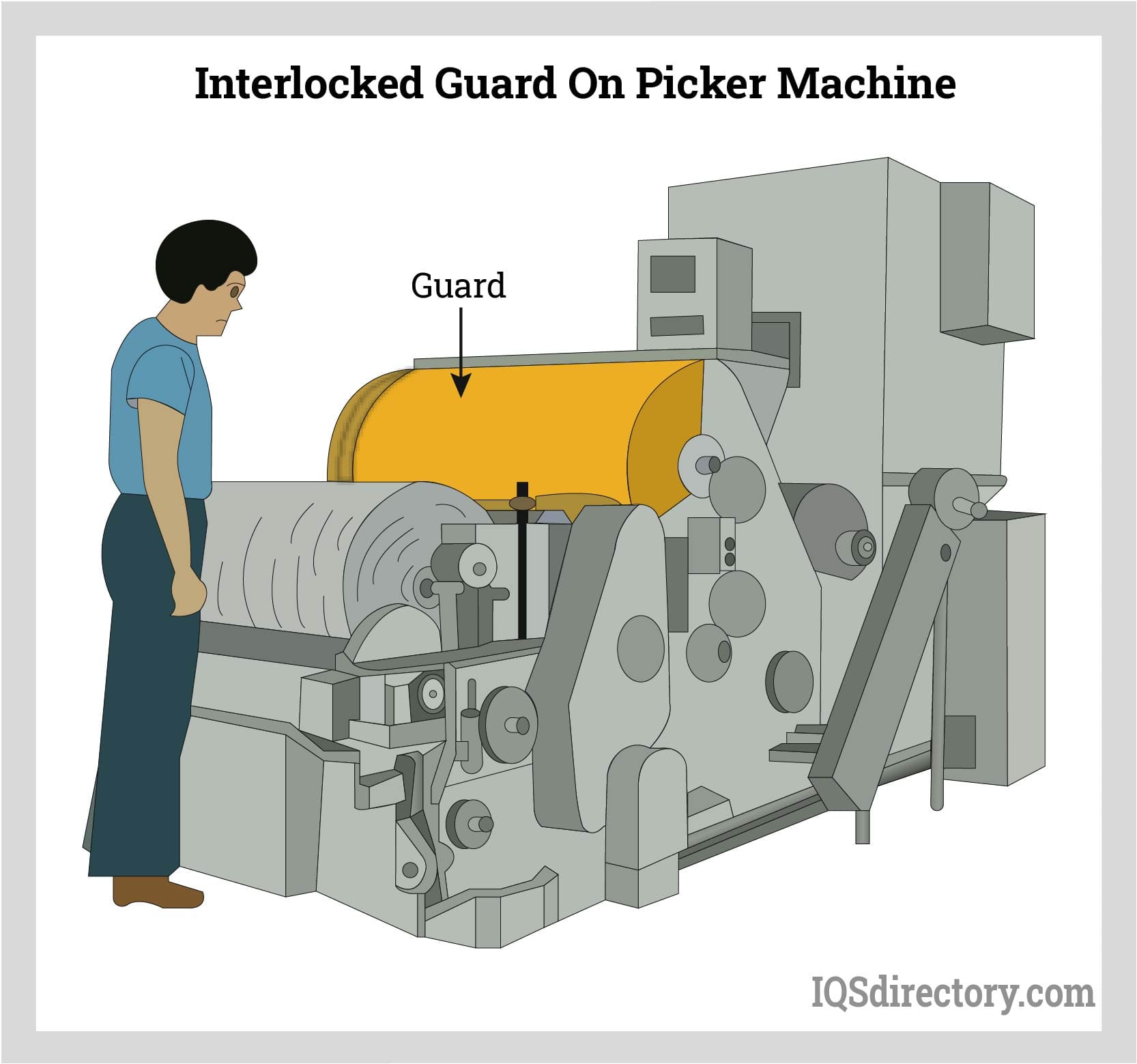

Interlocked Machine Guard

When an interlocked machine guard is opened or removed, the machine's tripping mechanism, power, and moving parts will automatically disengage. The machine can be started when the guard is back in place. An interlocking guard may be electrical, mechanical, hydraulic, pneumatic, or a combination. The machine shouldn't automatically restart after the guard is changed. To effectively prevent workplace risks, all removable guards must be linked.

Advantages & Disadvantages of Interlocked Machine Guard

An interlocked machine guard can enable jam removal from the machine without removing the fixed guards. They are adjustable to different requirements; however, they require careful maintenance.

Self-adjusting Machine Guard

A self-adjusting machine guard is a barrier with openings determined by how the stock moves. The guard is pushed aside as the operator pushes the stock into the danger zone, creating an opening that is just big enough to let the stock through. The guard resumes its resting position after the stock has been taken out. This guard shields operators from harm by creating a barrier between the operator and the danger region. Self-adjusting machine guards could be metal, plastic, or other sturdy materials.

Advantages Of Self-Adjusting

Although off-the-shelf guards are commercially available, they may not offer a high level of security. They require frequent maintenance and adjustment and can interfere with the operator’s visibility.

Applications Of Machine Guarding

Machine guarding is often used for drilling, milling machines, saws, assembly lines, compact presses, and grinding machines.

Choosing the Right Machine Guarding Supplier

To make sure you have the most positive outcome when purchasing Machine Guarding from a Machine Guarding Supplier, it is important to compare at least 4 Companies using our list of Machine Guarding manufacturers. Each Machine Guarding Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Machine Guarding company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Machine Guarding businesses with the same quote.