Liquid Filters

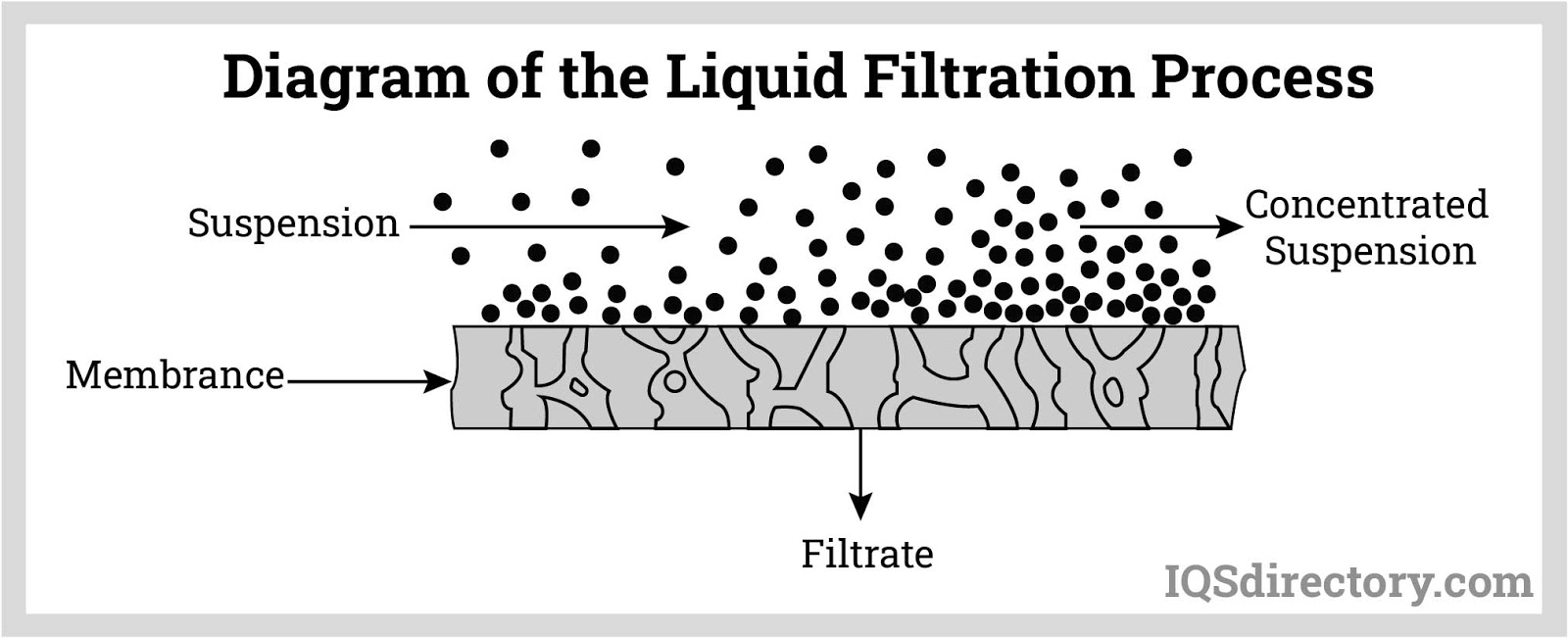

Liquid filters clean or purify liquids that run through them. All liquid filters operate by passing a liquid through a semi-permeable or porous substance, which allows the liquid molecules to pass through, but blocks large particulates and chemicals.

Note: The word "filter" actually refers to the housing or holding mechanism of a filtration system. "Filter media" refers to the porous barrier, chemical or mat that clarifies the liquid.

Quick links to Liquid Filters Information

The History of Liquid Filters

- Beginning of Liquid Filters

- Water is vital for life, thus, since antiquity, many people have been inventing ingenious ways to filter water for human consumption. The earliest written evidence regarding liquid filtering comes from Egyptian and Indian civilizations. There are Sanskrit writings that offer use of charcoal, sand, and boiling, as effective ways to clean the water supply. Egyptian inscriptions give insights into their use as a liquid filter; they used alum to coagulate contaminants, which they could then remove, in order to make water drinkable.

- Around 500 BCE, a Greek physician, Hippocrates, discovered water could be sieved to capture sediments mixed in water; the liquid filters he made are known as "Hippocratic Sleeve." After Hippocrates, virtually no developments were made in liquid filter technology for about 1,000 years. Around the 17th century, experiments focusing on filtration systems started to emerge, and one of the most noted experiments involved desalination of water, which used a sand liquid filtration system. The experiment failed but opened the door to further experimentation with water filtration.

- Early filtration efforts were largely undertaken to filter visible contaminants and enhance the taste of water, rather than purify water. The relationship between diseases and contaminated water was not discovered until the 17th century, by a Dutch scientist named Antonie van Leeuwenhoek. While studying water under a microscope that he made, he found microscopic bodies suspended in water that looked clean with the naked eye. However, even then, no direct relationship could be ascertained at that time. It took a couple more centuries for scientists to figure out how water carried disease-causing microbes and had caused large-scale casualties.

- After this stimulus, liquid filters started to evolve, and various types of liquid filters came into existence. The most common liquid filters were charcoal, wool, and sponge based, which cleaned water by trapping even small contaminants.

- Liquid Filters in the 19th and 20th Centuries

- In the mid-19th century, scientists discovered that Cholera is a waterborne disease. To combat this, inventors experimented with large-scale water treatment systems, designed to provide water to cities just like the Roman aqueducts did. Builders constructed many water treatment plants, eventually settling on rapid sand filtration and the use of chlorine for water disinfection.

- The next big development in the liquid filter technology came out in 1865, when Swiss scientist Jacques-Louis Soret determined the formula for ozone, a molecule with the chemical formula O3. Once determined, scientists found they were able to use the molecule to treat water through a process known as ozonation. This discovery was well-timed, as, at the same time, scientists and the general population had discovered the ill effects of chlorine liquid filters. They quickly began creating new and improved home water filtration units. Over the next 200 years, different liquid filtration systems emerged, like cartridge based filters, reverse osmosis water filters, and gas filters.

- The next steps in liquid filtration came in the 20th century, with various desalination techniques. In the beginning of the 20th century, a scientist developed a desalination technique involving ion exchangers; they removed salt particles from water by exchanging them with sodium ions and other related cations. Then, in the 1950s, American researchers began investigating the use of semipermeable membranes during desalination. However, the technique remained economically impossible for the next 30 years. In the 1970s, municipalities in the coastal region embraced the technique, making it viable for the public.

Advantages of Liquid Filters

Water and liquid filtration is necessary in virtually every manufacturing plant, as well as commercial buildings. Liquid filters provide healthy and clean water, but they do much more than that. With a liquid filter, manufacturers can create better products, free of contaminants and weakening particles. Plus, their workers, hydrated by good drinking water, will be healthier, happier and more productive. In residential settings, a small-scale reverse osmosis water filter offers clean and clear drinking water at a low cost, with a side of energy efficiency. Finally, liquid filter products are versatile, customizable and affordable.

Liquid Filter Design

- Filter Housing Material

- Multifilament mesh, micro-fiber and spun materials are examples of the most popular media configurations. They are often made of durable materials such as steel, stainless steel, aluminum and thermoplastics. These include cartridges, holders and frames among other designs.

- Filter Media Material

- The media is the most important filter element. Examples of the many filter media types include: sands and gravels, activated alumina, activated carbon and copper-zinc alloy, activated charcoal, membranes, cotton, polyester, nylon.

- Types of membranes include: thin film composite membrane (bacteria and heat resistant, able to filter nitrates, but vulnerable to chlorine), cellulose triacetate membrane (narrow pH range, little to no resistance to bacteria in water, vulnerable to temperature change, does not reject nitrates, but has excellent resistance against chlorines), and polyethersulfone membrane (superior flow rate, excellent downstream cleanliness).

- Design and Customization

- When designing liquid filters, manufacturers are able to create both generic and application specific systems. One of the biggest factors they consider is the size of the particles to be removed. Likewise, they consider the level of filtration required. Next, they must also consider the nature of the particles to be filtered. For example, are they acidic? Oily? Dusty? Finally, they consider the pressure bar drop, continuous versus batch operation, size, porosity, absorption, ply, stream composition and temperature, load capacity and the efficiency or accuracy of a given liquid filter.

- Using these design considerations, liquid filters manufacturers create systems capable of grabbing particulates as small as 0.001 µm and particulates well above than 0.1 µm. They can also form housing materials into any custom or modified standard shape or size you need.

Features of Liquid Filters

All liquid filters work like strainers, but there are a number of ways in which they achieve this. Methods include: mechanical filtration, distillation, adsorption, ion exchange, reverse osmosis, and ozonation.

- Mechanical Liquid Filtration

- In this process, suspended contaminants are separated mechanically from water, using a variety of filter media. Mechanical filtration is obtained either in a tank or in a cartridge.

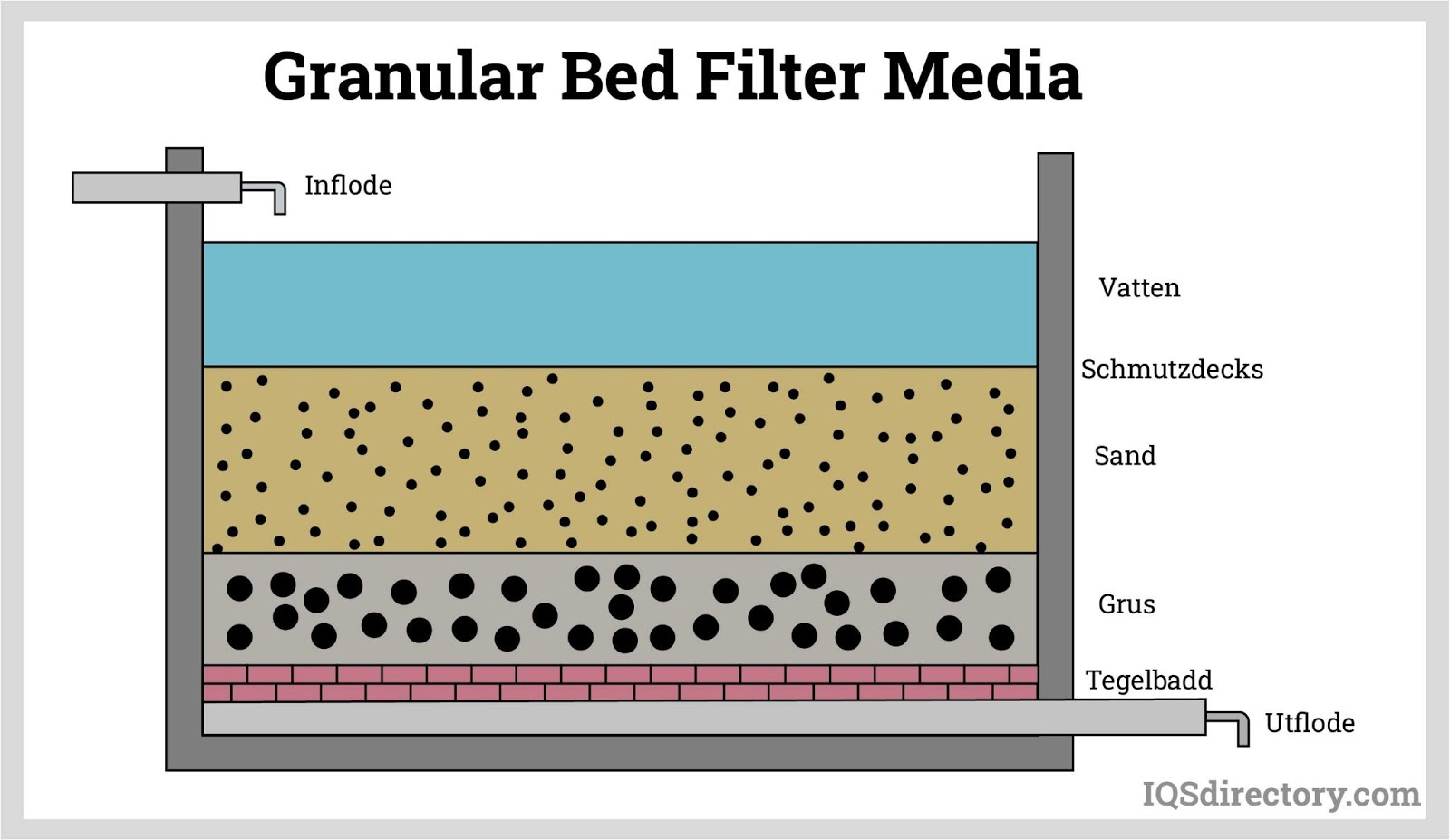

- Tank-type mechanical liquid filters have multiple layers of different media, including sands and gravels, activated alumina, activated carbon and copper-zinc alloy. These media physically block contaminants, successively. Once the media reaches its service life, the media is disposed of.

- Cartridge-type mechanical filters use surface filtration media and depth liquid filtration. In surface filtration, water is strained through the filter medium, which captures particles of a certain size and develops a layer. The layer helps with further filtration. However, the filters used in surface filtration are clogged frequently, thus, need frequent maintenance.

- Adsorption

- In this type of liquid filtration, the contaminants are adsorbed on the surface of an adsorbent media. The filtration involves physical and chemical forces. The contaminants adhere to the adsorbent surface because of physical adsorption, and the process is supplanted by chemical adsorption, as a chemical ionic process also takes place. The media used in adsorption is usually activated carbon.

- Reverse Osmosis

- Liquid filtration, water in a concentrated solution is forced towards a less concentrated solution through a semipermeable membrane, which selectively allows movement of materials. Reverse osmosis is not a natural phenomenon; thus, the water is pressured to move to a less concentrated solution. The water discharged after the process has less dissolved contaminants and deemed suitable for drinking and other purposes.

- Ozonation

- Liquid filtration, ozone, a molecule consisting of three oxygen atoms, is fed into water sources, which disinfects water and removes water quality issues, including odor and color. This is used as an alternative to the practice of using chlorine in water for disinfection purposes. The Ozone process leaves no traces of chemicals and makes water healthy for consumption unlike chlorine disinfection, which has led to many diseases.

- Distillation

- An old process to separate organic and inorganic material from water by evaporation. Distillation process effectively removes biological contaminants and inorganic minerals. The counter top distilling machines can produce up to five gallons of water per day, evidently the separation process is very slow. Moreover, distillers need regular maintenance for them to work efficiently. Due to the limitations, distilling filters has fallen out of favor.

- What Makes Liquid Filters Unique?

- Something that makes them stand out is their use of filter cakes, a resource used by many liquid filters, including some cartridge filters and bag filters. A filter cake is the solid material removed from a fluid. A cake is formed when large quantities of solute or particulate build up on the intake surface of the filter media. It is easily removed, washed and even sorted. Valuable materials, such as oil or metallic dust, are commonly obtained through liquid filtration and easily recycled or reincorporated into the production process to reduce waste and cut costs.

Liquid Filter Images, Diagrams and Visual Concepts

Liquid filters are equipment used to separate suspended solids from a fluid stream.

Liquid filters are equipment used to separate suspended solids from a fluid stream.

Granular beds are made from coarse and fine sediments such as sand, anthracite, and gravel.

Granular beds are made from coarse and fine sediments such as sand, anthracite, and gravel.

Liquid filtration, the process of removing solid particles, impurities, and contaminants that are suspended in a fluid stream.

Liquid filtration, the process of removing solid particles, impurities, and contaminants that are suspended in a fluid stream.

Synthetic fabrics made such materials as polyester, nylon, polypropylene, and fluoropolymers which are monofilament and multifilament.

Synthetic fabrics made such materials as polyester, nylon, polypropylene, and fluoropolymers which are monofilament and multifilament.

Filter aids are incompressible, insoluble, and inert solids used in pre-treatment to increases filtration efficiency.

Filter aids are incompressible, insoluble, and inert solids used in pre-treatment to increases filtration efficiency.

Cartridge filter, a medium that is encased inside a housing, allowing the flow from the outside to the insides of the cartridge.

Cartridge filter, a medium that is encased inside a housing, allowing the flow from the outside to the insides of the cartridge.

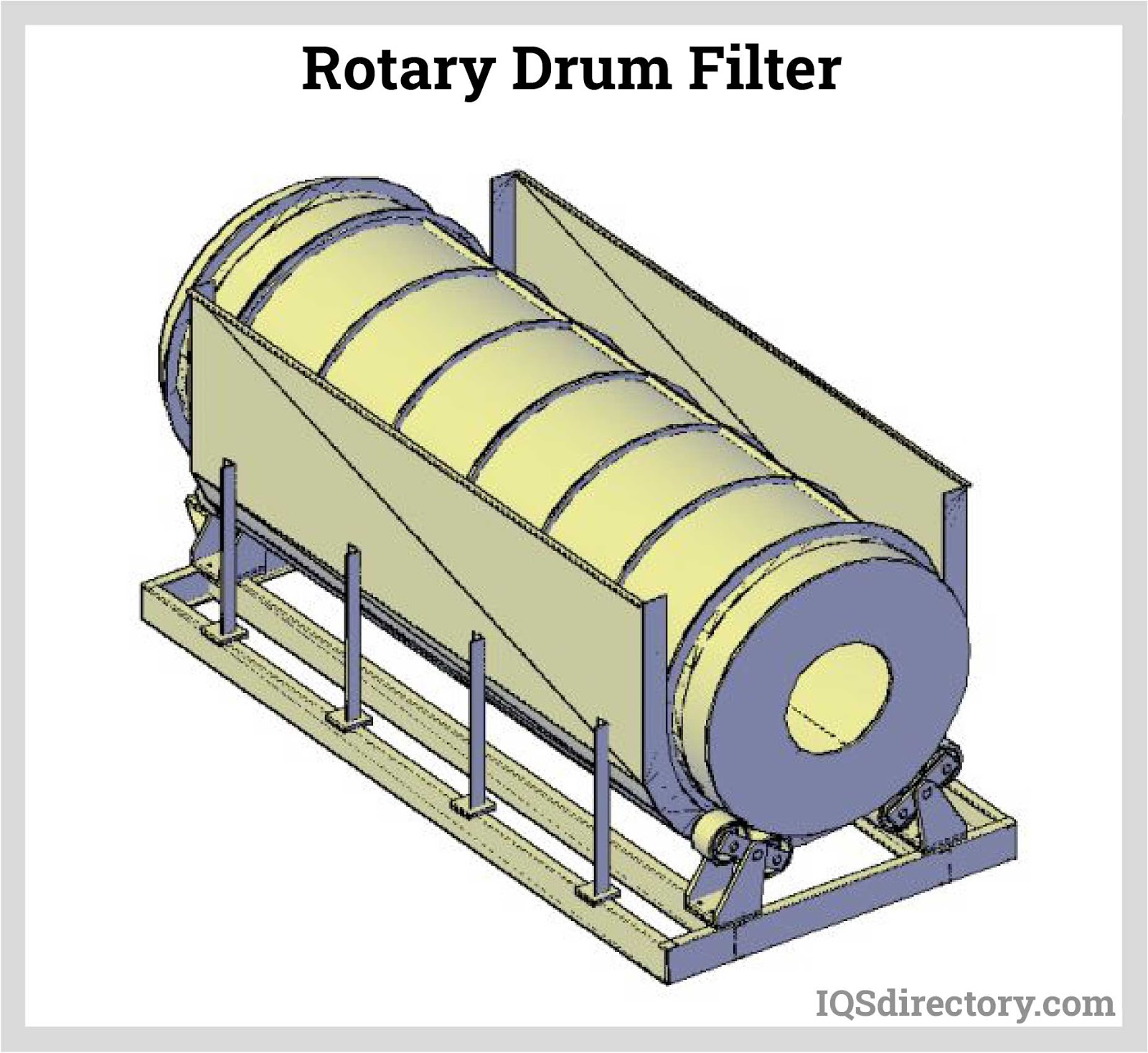

Rotary drum filters use a rotating drum to drawn the liquid to a vacuum and the solid material is retained on the surface of the drum.

Rotary drum filters use a rotating drum to drawn the liquid to a vacuum and the solid material is retained on the surface of the drum.

Filter presses processes slurry by pumping to plates containing the filter medium, then de-watered under high pressure.

Filter presses processes slurry by pumping to plates containing the filter medium, then de-watered under high pressure.

Types of Liquid Filters

- Biodiesel Filters

- Used to clean and clarify biodegradable and environmentally friendly fuel alternatives to petroleum diesel.

- Carbon Filters

- Filters that contain carbon in their solid state. They use absorption to remove unwanted soluble substances from water and can be found in many applications, including personal water filters and purifiers.

- Coolant Filtration

- The process of removing suspended debris or other unwanted impurities from a process stream composed of chemical compounds designed to cool machine and engine components.

- Filter Media

- The material through which liquid is passed to remove all particles and impurities.

- Fuel Filters

- Designed to filter sediments from fuel supplies because particulates are harmful to engines and can significantly decrease engine life.

- Gas Filters

- Remove excess or unwanted debris and solutes suspended in gasoline that would otherwise impede performance and harm valuable engine components.

- Hydraulic Filters

- Liquid filtration devices designed especially to remove and eliminate contaminants and impurities from hydraulic fluids. More than 70% of all hydraulic systems failures are caused by fluid contamination.

- Industrial Water Filters

- Remove impurities from water in industrial settings.

- Liquid Filtration

- The systematic removal of organic and synthetic impurities from a fluid process stream.

- Reverse Osmosis Water Filters

- Use pressure to force water through thin, microporous films or sheets in order to trap or retain unwanted particulate impurities and dissolved solids.

- Strainers

- Used in filtration systems to remove large particles.

- T-Type Filters

- Have both inlet and outlet ports situated at one end. The ports of their major axes are in a straight line with the axis of the filter element perpendicular to the line.

- Water Filter Systems

- Complete units that begin with a "dirty" water source and result in a purified end product. In the system, unpurified water is filtered and then acquired as a "clean" product.

Types of Filter Assemblies

- High Flow Filter

- Used for situations that have a high amount of particulate, water count or acid, while low-flow filtration systems are used for the opposite reasons.

- Vacuum Filter

- Vacuum dehydration systems use vacuums to move liquid through the liquid filters at a high flow rate.

- Bag Filter

- Also known as a liquid filter bag or baghouse, is normally used for air filtration. However, bag filters can be manufactured to process liquid as well. Bag filters are oval or cylindrical tubes, made of woven or felted materials like cotton or nylon. You can use bag filters with or without a bag filter housing, depending on the application. Bags range in size and material, to best serve the customer. They strain and clean liquids best in aquariums, pools and wastewater treatment plants.

- Pleated Filter

- Made up of a number of uniform folds, constructed from filter media. Usually, the filter is designed as a geometric shape, like a cone, cylinder or plate. Pleated filters are compatible with a variety of other configurations, such as cartridge filters. They can filter many different liquids, including: glycol, brines, flood water, machine coolants and disposal water.

- Cartridge Filter

- This water filtration system uses mechanical filtering in order to remove harmful solids and sediments from water. It is typically cylindrical, but it can also be flat, depending on its application. While cartridge filters are highly versatile, they are most often used as pool filters, fish aquarium filters and tap water purifiers. Also, you often find cartridge filters in housings and pipes.

- Depth Filter

- Use media with multiple layers. This makes them more effective at screening particles. Examples of the media they use include: pleated cellulose, pleated synthetic fabric, string wound fiber, and spun bonded polypropylene. Depth liquid filters are popular for their long working lives.

- Membrane Filter

- Used to purify liquid, such as wastewater or milk used for cheese production. They rely on the process of reverse-osmosis. During membrane filtering, liquid passes through a semipermeable membrane, which is made from polymer films and acts as a mechanical filter that screens most dissolved solids, including important salts and minerals. Membrane permeability is determined by membrane pore size; it blocks all particles larger than its pores. Membrane filters are popular in: the creation of bottled water, wastewater treatment, removal of toxic materials from artificial kidneys and recovery of organic vapors. The only drawback of membrane filters is the fact that they are prone to clogging.

- Chemical Filter

- Used when solute purification is needed; any equipment that is used to separate constituent materials in a flow of liquid can be referred to as a chemical filter.

- Wet Dry Filter

- Though less applicable in many industrial environments, are also used because they offer the unique ability to act as both a liquid and an air filter, providing enhanced filtration capabilities.

- Oil Filter

- Remove excess or unwanted debris and solutes suspended in gasoline that would otherwise impede performance and harm valuable engine components. Depending on the application, they may also be referred to as: gas filters, hydraulic filters, coolant filters, bearing filters and biodiesel fuels. They’re important for use in motor vehicles, naval vessels and light aircraft.

- Filter Press

- A piece of equipment that separates liquids and solids using pressure filtration. It uses a frame, filter plates, a manifold and filter cloth.

Liquid Filter Applications

While the overall purpose of filtration is by definition to remove particulates from a fluid process stream, there are three main goals of liquid filtration: Filters may be used to acquire the suspended materials, clarify the liquid or in many applications, both clean and clarify.

Liquid filters remove and separate solids, dusts, chemicals and even odors from a given liquid process stream. During an industrial application, they may filter contaminants as unique as: nitrates, minerals, pesticides, arsenic, sulfates, dirt, fluoride, and microscopic organisms.

They are popular for use in: textile mills, cosmetics, food and chemical processing, refrigeration, automotive, petroleum and oil, paper and pulp, marine, electronic, photographic, printing, medical, water purification and waste treatment and pharmaceutical industries.

Standards and Specifications for Liquid Filters

It’s incredibly important that all the parts of the liquid filter system you purchase are certified. Many different organizations, both independent and government affiliated, put out standard requirements and recommendations. Those organizations include: ASTM International, ANSI, SAE, the EPA and NSF International.

Find out which standards your filter must adhere to by consulting an industry leader and/or your supplier.

Things to Consider When Purchasing Liquid Filters

An array of liquid filters is available on the market, some promising to kill viruses, whereas others assure the removal of volatile organic compounds. The presence of different types of liquid filtration systems on the market puzzles many buyers, and they end up buying ones that do not serve the purpose or need maintenance more often than it works. It is important for buyers to weigh all the factors carefully before committing to a model, design, and liquid filter technology. Steps that can help you to make an informed decision are as follows:

- Identifying Contaminants

- The first step involves identifying the contaminants that are required to be removed, as impurities in water vary from region to region. To identify them, consider consulting a certified laboratory to carry out a water quality test. Alternatively, you can identify contaminants by looking at the consumer confidence report released by community treatment plants. However, the report discusses the quality of water at the plant, not at your faucet, and pipelines and distribution system, including your house's plumbing can alter characteristics of water.

- Researching for Requirements

- The next step is researching the liquid filters that complement your requirements. By the water quality test, you will know what are the primary contaminants in the water supply. This information will help you to single out the system that can give you clean water. The options that you will come across include mechanical filters, distillation units, adsorption based filtration system, ion exchange, and reverse osmosis systems.

- Once you decide which type of system can fulfill your requirement, you need to figure out:

- Filtration rate and size of the unit.

- Examine performance data.

- Cost of a liquid filter (combination of the initial purchasing cost and maintenance fees).

- Finding the Right Manufacturer

- Finally, you must find the right manufacturer. Because clean water is such an important application, we recommend you work with a seasoned supplier who respects your specifications and requirements. Find a supplier like this by scrolling to the top of this page, where we’ve compiled a list of our top liquid filter industry picks. Browse their respective websites, and then reach out to a few that you believe could work for you. Ask them questions about all the things we’ve outlined today. To make your choice, compare and contrast their answers and attitudes. Remember, it’s not just about price—it’s about high-quality products and service, too.

Liquid Filter Accessories

You can buy bulk filter media by itself or large quantities of filter housings by themselves. These options are preferred for applications that require custom or replaceable components. However, you can also buy both the filter media and filter housing together. These come fully assembled for easy installation, use, maintenance and replacement, making them especially popular in domestic environments as well as those that entail frequent replacement or maintenance. Most pre-assembled units are fully disposable.

Liquid Filters Terms

- Absolute Filtration Rating (AFR)

- The diameter of the largest spherical particle that is able to pass through a filter in certain testing conditions. The AFR indicates the biggest opening in any given filter element.

- Absorption

- A process by which a solid is employed in the removal of a soluble substance from water.

- Beta Ratio

- The number of similar-sized particles moving upstream through a filter in a ratio to the number of particles moving downstream.

- Bridging

- A condition in which particles fill and block the entire area between adjacent sections of a filter.

- Bubble Point

- The gas pressure at which a constant stream of gas bubbles is released from a wet filter element under specified testing conditions.

- Bypass (Relief) Valve

- A mechanism that ensures proper fluid flow when pre-selected flow levels are surpassed. The valve allows for part or all of the fluid to bypass the filter.

- Channeling

- The tendency of contaminating particles to pass through a low-density area of a poor filter around its seal points.

- Clarification

- The filtering of liquids that have only a small amount of solid particles.

- Collapse Pressure

- Maximum pressure a filter element can withstand without any permanent deformation(s).

- Cycle Length/Filter Life

- The amount of time that a filter is able to operate effectively before it needs to be cleaned or replaced.

- Differential Pressure

- Difference in pressure between any two positions of a component or system.

- Effective Area

- Area of the filter element that is exposed to fluid flow.

- Efficiency

- Ability of a filter element to remove a particular contaminant at a specified contaminant concentration. Efficiency is typically expressed as a percentage.

- Element (Medium)

- The porous material that performs the actual filtration process.

- Housing

- An enclosure that directs the fluid flow through the filter element.

- Mean Filtration Rating

- The average size of the pores of a given filter media.

- Media Migration

- The release into the flowing fluid of components that make up the filter media.

- Pore

- A small opening in a filter that allows fluid to pass.

- Rated Flow

- Optimal flow for which a certain filter is designed.

- System Silting

- Collection and settling of micro-sized particles inside a fluid system.