Linear Bearings

Linear bearings, also known as linear-motion bearings, linear slides or linear actuators, are mechanisms designed to provide motion to a wide range of machine components. Typically, linear bearings move objects along a straight line only.

The object being moved on the linear bearings generally only needs to be moved in one direction, which makes the function and design of these linear bearings simple. The movement is produced with a high amount of repetition and fluidity.

Quick links to Linear Bearings Information

The History of Linear Bearings

- Beginning History of Linear Bearings

- Bearings have been around, in the form of the rolling bearing, since ancient times, perhaps since before the wheel. The oldest roller bearings were wooden. While the oldest roller artifacts we have are from the wreckage of a Roman ship, dated around 40 BC, archaeologists have also found evidence of roller slide use on Egyptian hieroglyphs and tomb drawings. The various drawings suggest the use of bearings in the form of tree trunks under sleds, sledges with liquid-lubricated, plain bearing-esque runners, and bearings used with hand drills.

- Around 1500 AD, Leonardo da Vinci incorporated drawings of ball bearings into his helicopter design. This was the first recording of proposed linear bearing use with an aerospace application. Later, the Italian engineer Agostino Ramelli published the first sketches of roller and thrust bearings. Then, in the 17th century, Galileo improved upon his model by proposing caging balls or rollers inside an enclosure to reduce friction.

- These drawings and propositions were acted upon in the mid-1740s by John Harrison, who used caged-roller bearings for his H3 marine timekeeper.

- The first of what we would consider "modern" linear bearings were patented in 1794 by British inventor Philip Vaughan. His ball bearing design had the ball running along a groove in axle assembly. Around this same period of time, the Industrial Revolution came into its height, and linear bearings were an important part of it. They assisted in applications such as the smooth running of wheel and axle assemblies, watchmaking (producing more precise timekeeping) and water mills.

- Later History of Linear Bearings

- In the late 1800s, we saw the development of new linear bearing styles, such as the radial style ball bearing, which was patented by a Parisian bicycle mechanic in 1869, and the tapered roller bearing, patented by Henry Timken in 1898. Also, in 1883, Friedrich Fischer developed a method for milling and grinding bearing balls of consistent size and shape. This opened the door for the creation of a full bearing industry.

- At the turn of the 20th century, in 1907, we saw the development of the self-aligning linear ball bearing. The bearing industry again showed innovation around WWII, with the invention of the wire race bearing in 1934. This innovation continued after WWII, from the ‘60s through the ‘80s, with the development of v-groove bearing guide wheels, bi-material plain bearings, and bearings made from Teflon-based material.

- Today, the linear bearing industry features linear bearings useful in all sorts of high tech applications, from high speed bearings in dental drills, to aerospace bearings in the Mars Rover, to flexure bearings in optical alignment systems. Linear bearings have become much more popular in recent years, largely due to industry advancements in robotic automation.

Advantages of Linear Bearings

Linear bearings are incredibly useful and advantageous for many applications. Their most obvious advantage is also their function: bearings allow a component to move freely back and forth and left to right or vice versa. In addition to this, linear bearings are easy to install and are typically low cost. Plus, they require very little energy to run. Finally, they are highly customizable.

Linear Bearings Design

To make linear bearings do their job, manufacturers have a few different choices of motion mechanisms. All of these fall under the "rolling" or "plain" categories; most are "rolling." These include balls, slides and rails. Each element offers something different, and is assembled a different way.

- Rolling Elements

- Manufacturers make bearings with roller elements with an assembly of a sleeve-like ring and a row of balls systematically assembled in cages. The cages, as well as the balls, are made of hard metal to ensure durability and strength. Technically, the cage is a rail and the balls are rollers. The surfaces of rails and rollers have a smooth finish to ensure smoother and noise-free operation. Sometimes, some lubricant is also used to reduce friction and enhance the movement of the component. Rolling element linear bearings have many advantages. The biggest one is superior strength and motion that is more reliable.

- Typically, these systems need manual interference to carry out the movement. However, there are also computerized, intelligent linear bearings that can be controlled with the help of a remote control or control panel. Such sliding systems are fueled by electricity or batteries.

- Plain Elements

- Apart from these, plain bearings are also available that have no provisioning for balls or rollers. These linear bearings have limited uses in industrial operations.

- Typically, linear bearings are made from strong materials like cast iron, hard-coat aluminum or stainless steel. They can also be made of more flexible materials like bronze, plastic, PTFE or acetal.

- Manufacturers produce many different types of linear bearings used in conjunction with larger automated systems, such as positioning tables and robotic assisted assembly lines. Because there are so many linear slide (ls) manufacturers, standardization is not common. Instead, manufacturers give special consideration to determine custom specifications such as: roller diameter, width, stud length, inside diameter and load capacity needs to be for the specific application. Linear bearings are typically available with a variety of lower control limits (lcl). They’re also available as high load (hl) models and some of the linear bearings styles are self-cleaning and lubricating, while others need to be cleaned and lubricated with regularity to ensure successful utility.

Linear Bearings Images, Diagrams and Visual Concepts

Linear bearings supports the load of the carriage during its single-axis linear movement and provide a low friction sliding surface for the guide rails.

Linear bearings supports the load of the carriage during its single-axis linear movement and provide a low friction sliding surface for the guide rails.

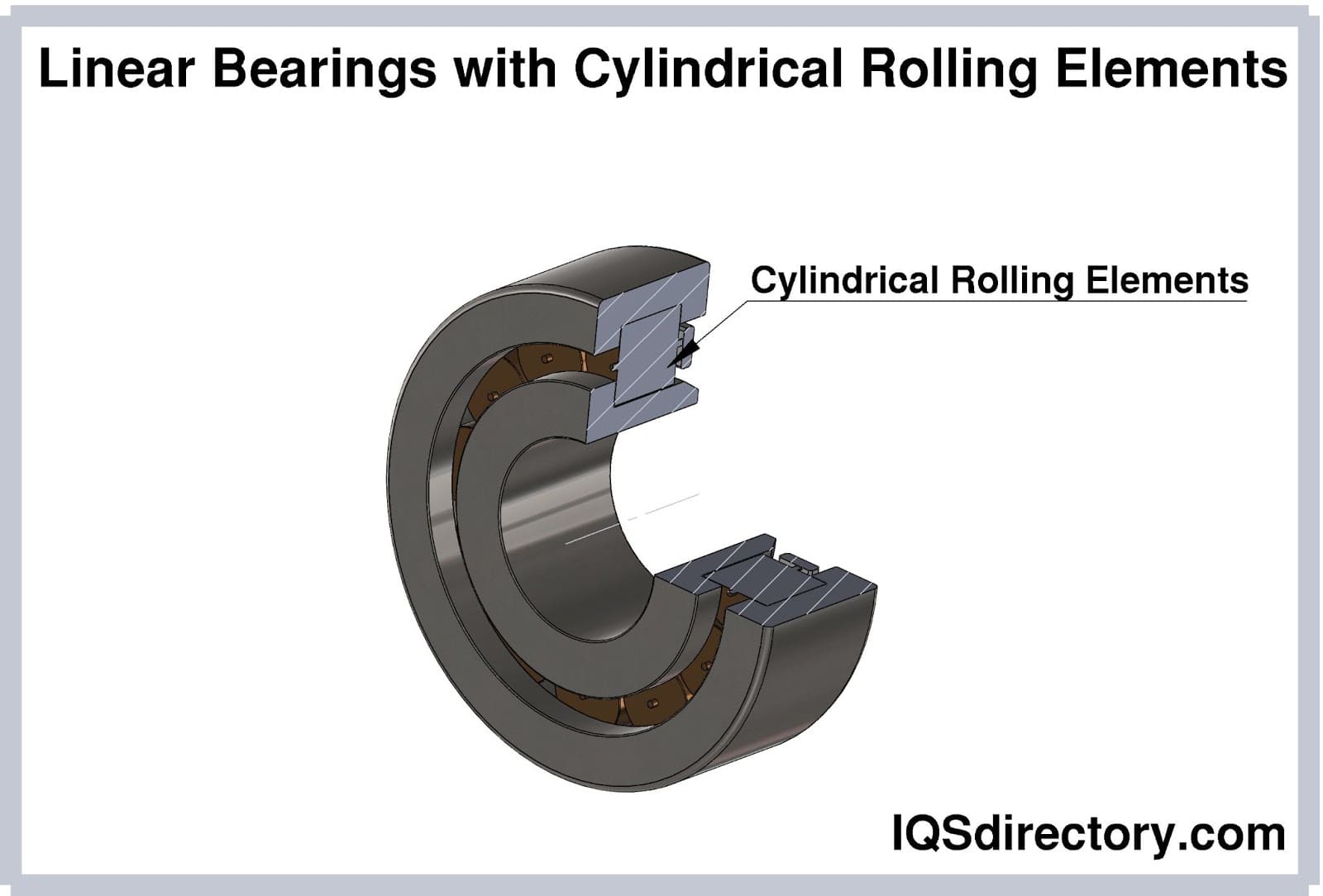

Linear bearings that have cylindrically shaped rolling elements, they have higher load capacity, rigidity, and impact resistance than ball bearings.

Linear bearings that have cylindrically shaped rolling elements, they have higher load capacity, rigidity, and impact resistance than ball bearings.

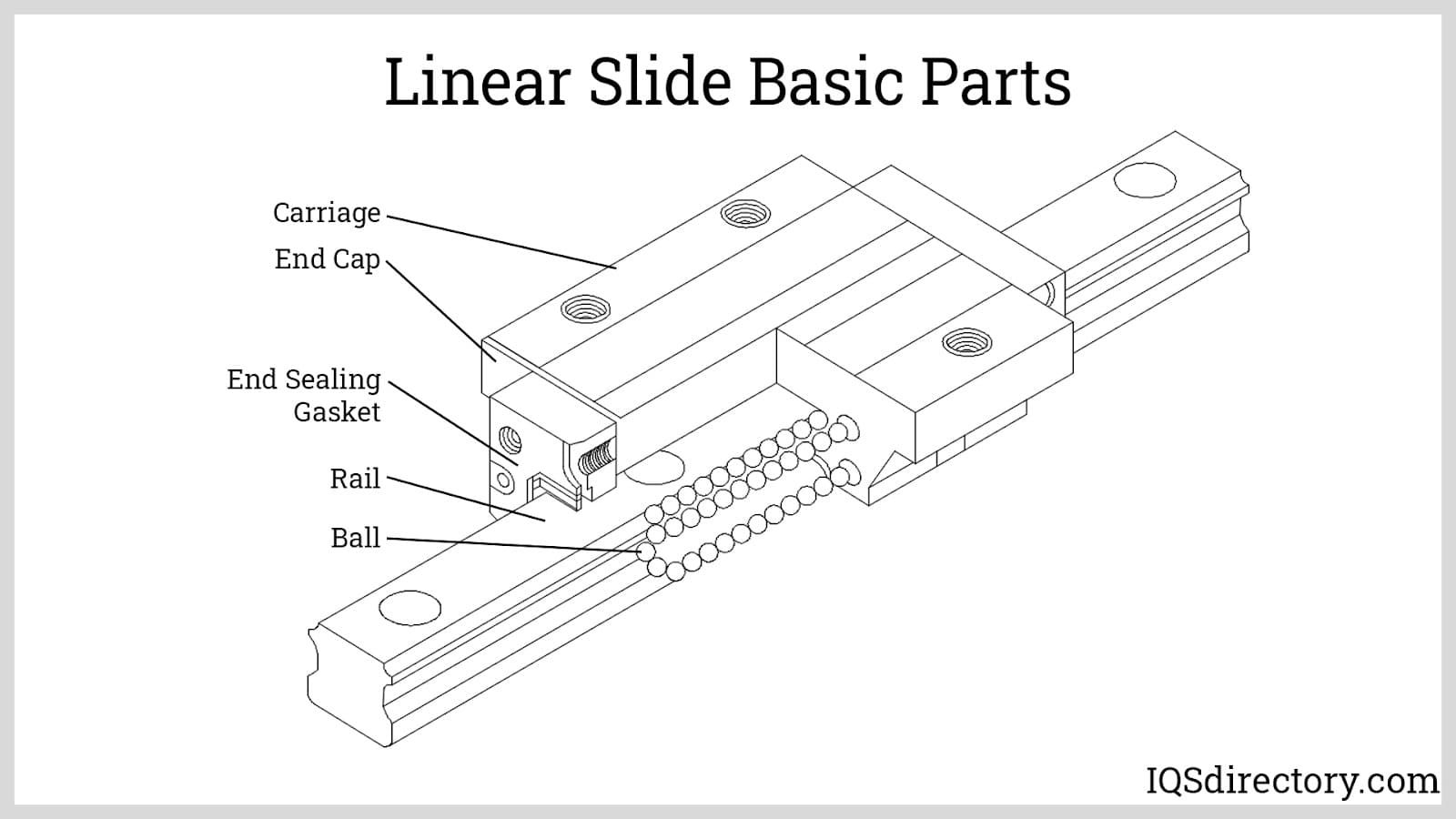

The basic parts for a linear slider.

The basic parts for a linear slider.

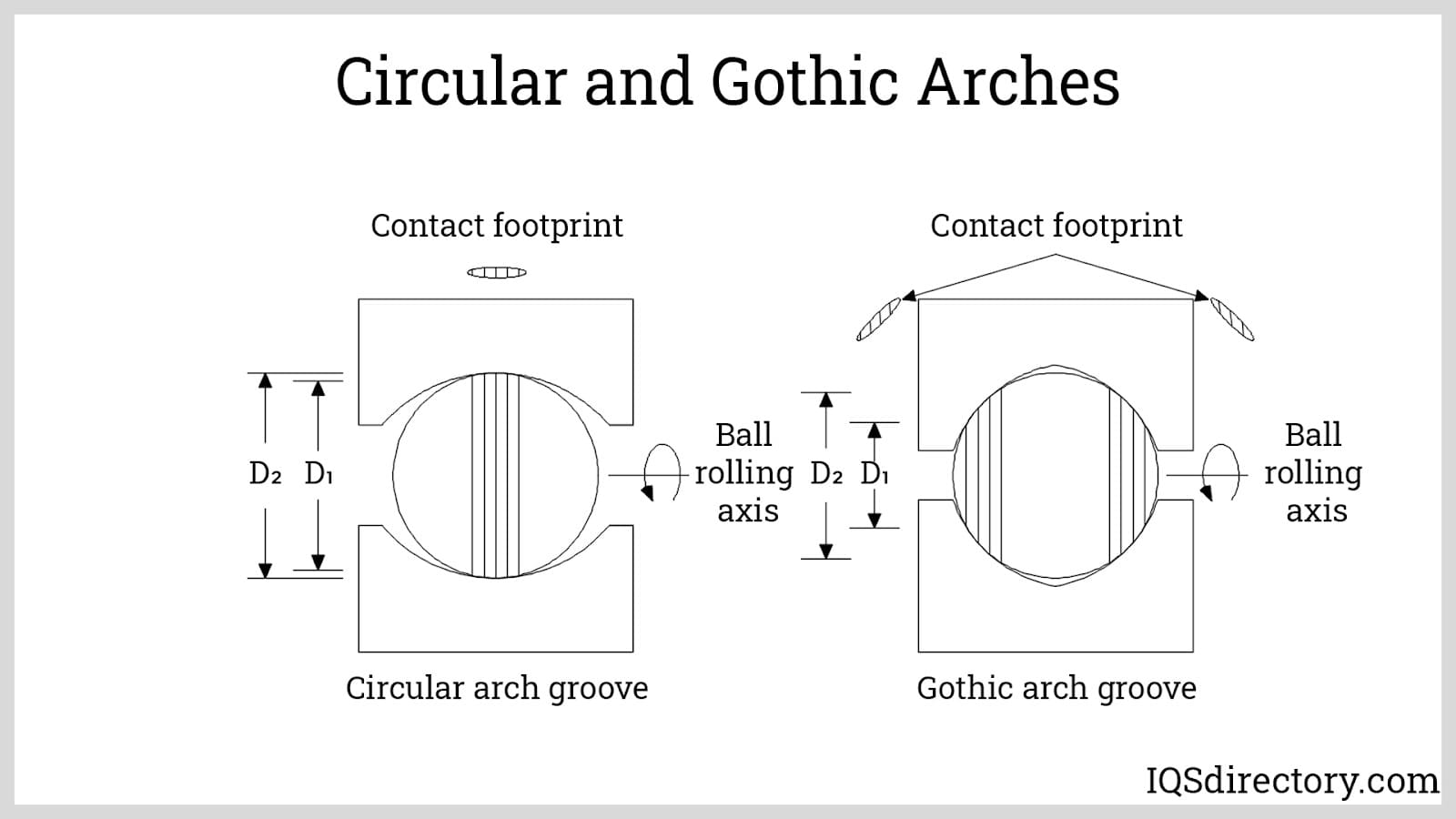

The circular arch creates less friction, while gothic arches have a higher load capacity.

The circular arch creates less friction, while gothic arches have a higher load capacity.

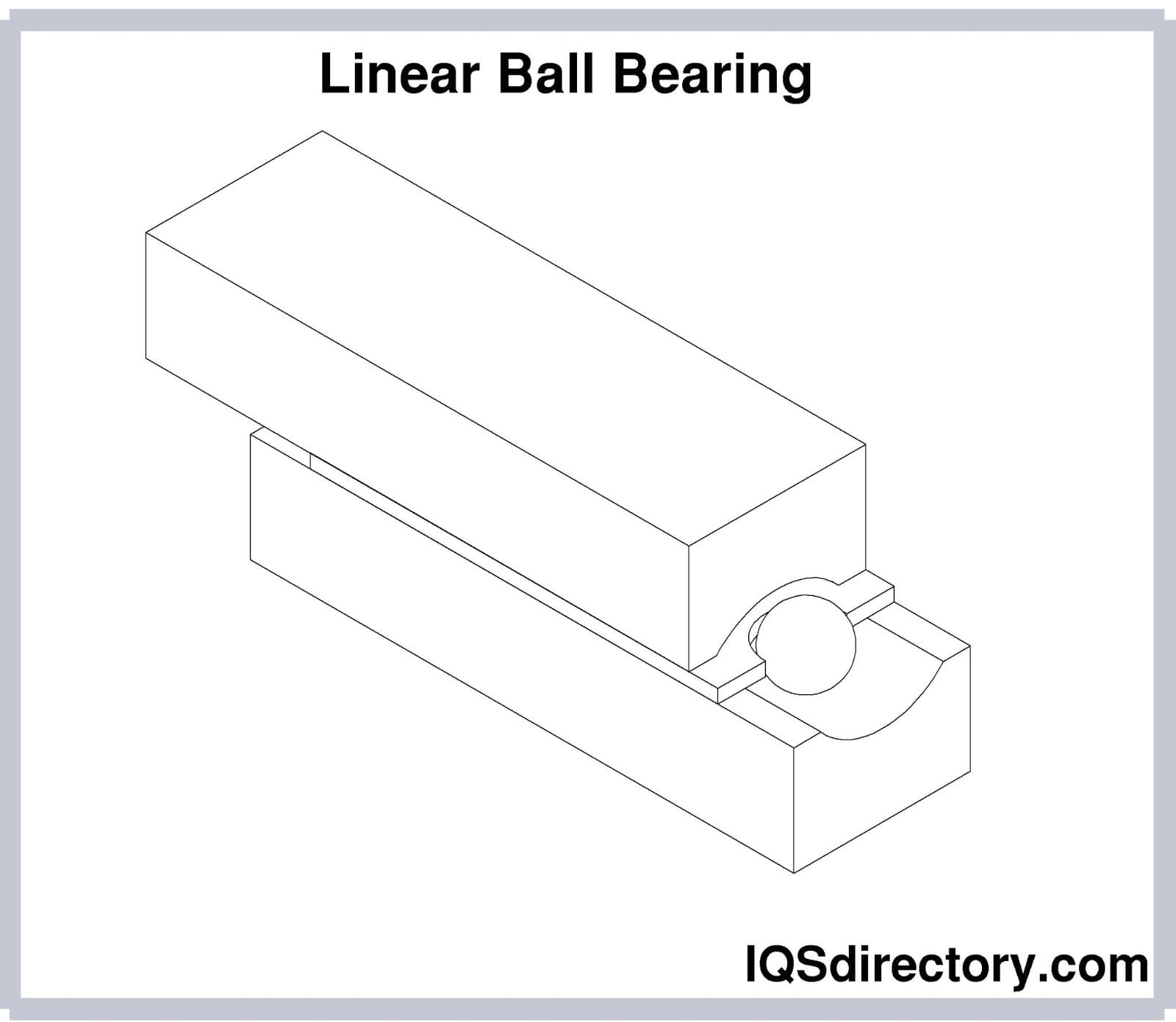

Non-recirculating linear ball bearings have metal balls fixed on the cage, the mating grooves of the bearing and the guide rail.

Non-recirculating linear ball bearings have metal balls fixed on the cage, the mating grooves of the bearing and the guide rail.

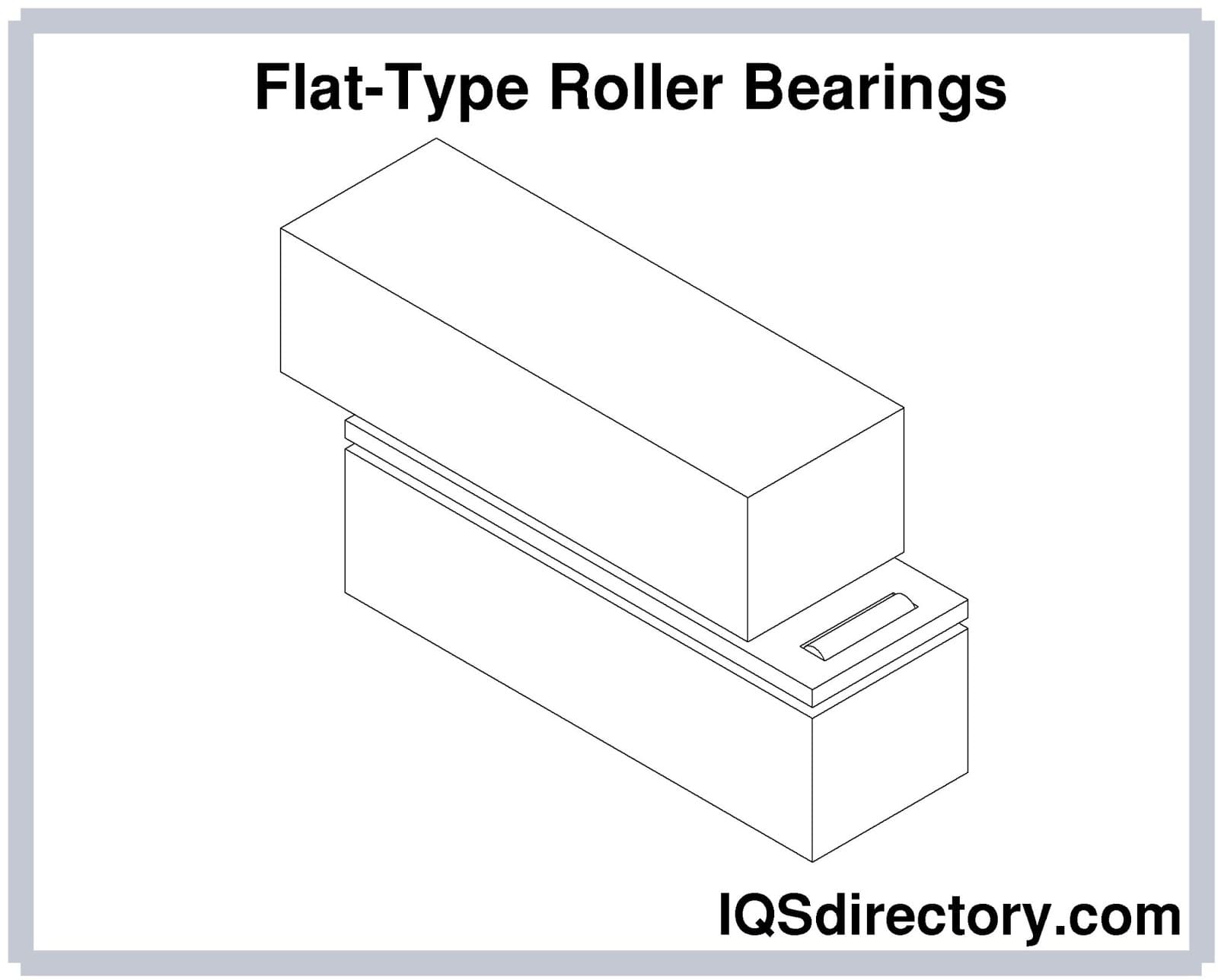

lat-type roller bearings have cylindrical lying on their horizontal axis in the cage.

lat-type roller bearings have cylindrical lying on their horizontal axis in the cage.

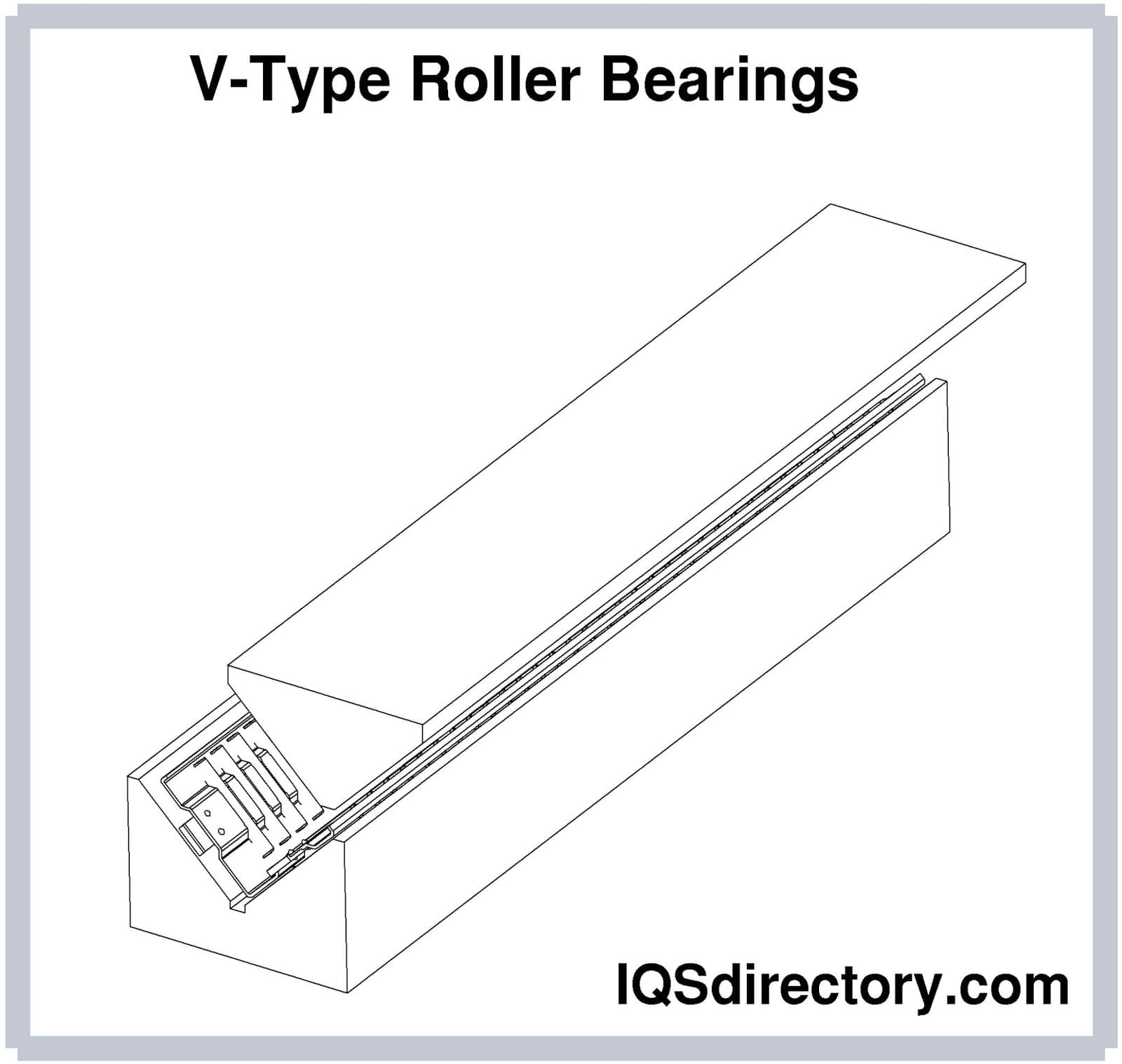

V-type roller bearings have a V-shaped pathway, forming a 90° angle.

V-type roller bearings have a V-shaped pathway, forming a 90° angle.

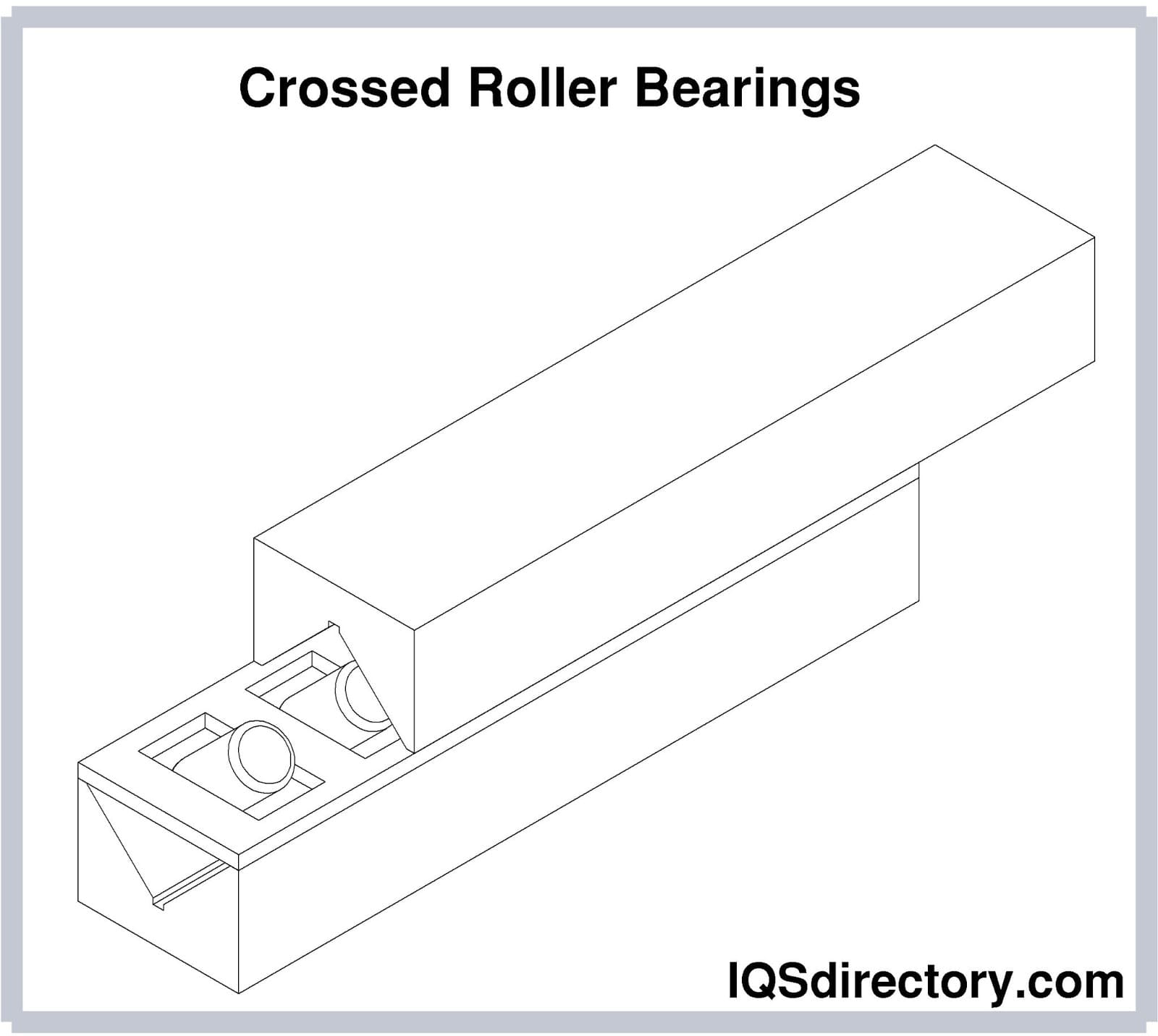

Crossed roller bearings have cylindrical rollers which forms a 90° angle with its cylinders, which forms a crisscross pattern among the rollers.

Crossed roller bearings have cylindrical rollers which forms a 90° angle with its cylinders, which forms a crisscross pattern among the rollers.

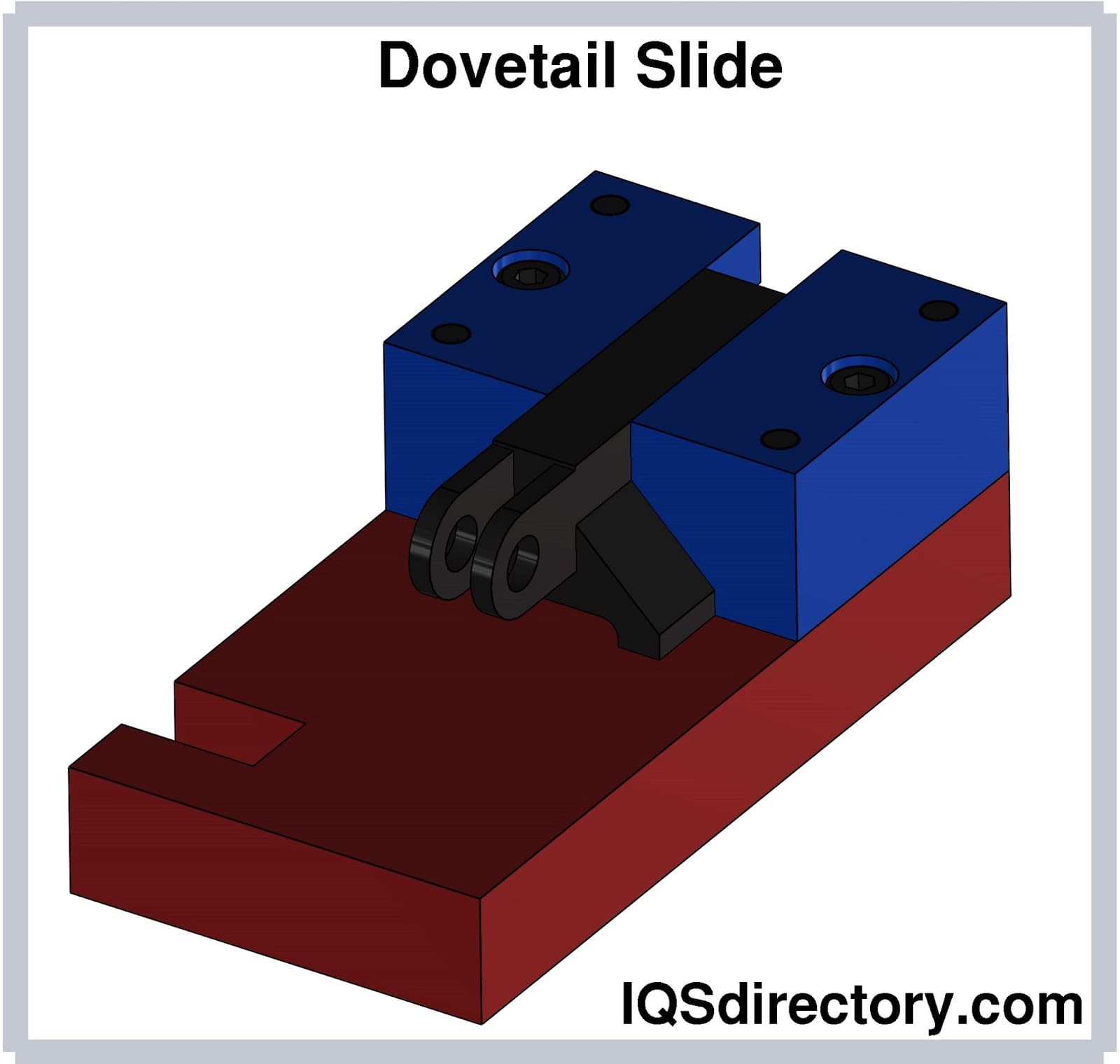

Dovetail slide, a linear bearing with a protruding V-shaped tongue and a mating saddle with a full contact with each other.

Dovetail slide, a linear bearing with a protruding V-shaped tongue and a mating saddle with a full contact with each other.

Types of Linear Bearings

The three main types of linear bearings are linear ball bearings, linear roller bearings, including needle bearings, and slide bearings. Other types include crossed roller bearings, precision linear bearings, miniature linear bearings, linear rotary bearings, linear air bearings, pillow block linear bearings, dovetail slides, ball screws, rail bushing bearings, and profile rail bearings.

- Linear Ball Bearing

- An especially efficient type of rolling element ball bearing. They use a hard-rolling ball element to separate two moving parts along a straight line. They seek to provide smooth, low friction linear motion in rotary applications.

- There are linear ball slide types: radial ball bearings and thrust ball bearings. Radial ball bearings carry both radial and axial loads, while thrust ball bearings are solely designed for pure thrust loads. They are used for light to moderate loads, such as delicate instrumentation, robotic assembly, cleanroom environments and high-end appliances.

- The balls or rollers in this mechanism do not need any additional lubrication. They have a self-lubricating technique that helps enhance the smoothness of the motion, whenever necessary.

- Linear Roller Bearing

- Also belong to the subcategory of rolling element linear-motion bearings. However, unlike the other types, they are non-motorized. Instead, they are run by hand as they carry loads by placing round elements, usually cylinders, between two objects. They have more load capacity because the contact between the rollers and line spreads the load out. They are self-cleaning, inexpensive and simple to use.

- A favorite tool for businesses that have a small budget or have limited operations, the size and load bearing capacity of these systems can be chosen according to the need of the business. A customized non-electric roller bearing system can provide better and more controlled movement of components.

- Needle Bearing

- A type of roller bearing, have cylinder rollers that are much smaller in diameter and use a thinly shaped needle roller.

- Slide Bearing

- Use low friction metals like Teflon and graphite inside of metal backing plates for linear movement and weight bearing. They are used on heated pipelines on oil production modules, in steel fabrication, and in oil or water transportation.

- Crossed Roller Bearing

- Have a much larger load capacity than ball slides because of the contact line between each roller and the raceway.

- Precision Linear Bearing

- Used in machine-tool spindles and in other high-precision applications. They are considered high in quality and have a tight bearing tolerance.

- Miniature Linear Bearing

- Operate at low torque and provide high performance in applications where low noise, minimal run-out and long life are required.

- Linear Rotary Bearing

- Used when accurate linear movement of large objects is required. They use a cylinder roller that is able to divide and handle heavy loads and are self-lubricating. They are used in car axles, machine shafts, clock parts and grinders.

- Linear Air Bearing

- Crossed roller slide assemblies that are controlled by a pair of air cylinders. They are low friction because the materials being moved ride on a cushion of air. They are round or rectangular, come with or without a vacuum and magnetic preload, and are used often in the aerospace industry and machine tools. Linear air cylinders are often made of aluminum and are used for tensile testing and precision positioning.

- Pillow Block Bearing

- Housings that are mounted to provide load support for a rotating linear shaft. They are often made of iron and may be plain, which constrain, guide or minimize friction in rotary or linear applications, or ball, which produce smooth, low friction movement in rotary applications.

- Dovetail Slide

- A type of plain bearing. They are composed of a stationary linear base and a moving carriage. From the carriage protrudes a v-shaped, or dovetailed, channel that locks into a groove in the base. Once locked together, the carriage can move freely along the channel’s linear axis. If you so choose, you can attach a platform to the carriage and create a dovetail carriage.

- Ball Screw

- A type of linear actuator that convert rotational motion into linear motion. This actuator linear requires little friction to work, which makes it better for use with high thrust loads. In addition, because the ball screw is designed with close tolerances, it works well in settings that require high precision.

- Rail Bushing Bearing

- One of the most used motion bearing varieties. The key advantage of rail bushing ball motion bearing systems is they can efficiently handle torsional misalignment that happens due to variations in the movement.

- Profile Rail Bearing

- Employed in a large number of applications for their high accuracy, better strength, dynamic load capacity, and compact design. These systems offer higher load capacity than standard round rail systems with the help of ball channels that are located inside and outside.

- Flat Ball Cages

- A linear bearing design in which the balls are trapped in a frame that spaces them at equal distances.

- Flat Roller Cages

- Similar to a crossed roller bearing, but the axes to all the other rollers are parallel instead of crossed.

- Gonio Way Bearings

- Curved to mimic the arc of a pendulum.

- Linear Motion Bearings

- Used to bear loads and direct linear motion.

- Metric Linear Bearings

- Designed for settings in which an object must be moved in a straight line in one direction with high accuracy and are identified by metric units of measurement.

- Plastic Linear Bearings

- Allow objects to move smoothly along in a straight direction with a minimum of friction. Made solely from plastic, these bearings are able to withstand the same rigors that ceramic or steel bearings can while possessing certain advantages over the more traditional materials, like being corrosion resistant to chemicals and acids that would harm conventional bearings.

- Positioning Stages or Tables

- Composed of two basic components: a precision linear slide (ball or cross roller), which serves as a linear bearing and guide, and a drive mechanism, which accurately moves and positions the slide top along the linear axis.

- Flat Ball Cages

- A linear bearing design in which the balls are trapped in a frame that spaces them at equal distances.

- Flat Roller Cages

- Similar to a crossed roller bearing, but the axes to all the other rollers are parallel instead of crossed.

- Gonio Way Bearings

- Curved to mimic the arc of a pendulum.

- Linear Motion Bearings

- Used to bear loads and direct linear motion.

- Metric Linear Bearings

- Designed for settings in which an object must be moved in a straight line in one direction with high accuracy and are identified by metric units of measurement.

- Plastic Linear Bearings

- Allow objects to move smoothly along in a straight direction with a minimum of friction. Made solely from plastic, these bearings are able to withstand the same rigors that steel or ceramic bearings can while possessing certain advantages over the more traditional materials, like being corrosion resistant to chemicals and acids that would harm conventional bearings.

Linear Bearing Applications

Linear motion bearings are produced to provide a means for objects to slide or roll within an appliance, product or machine system. They are popular because they provide low friction, smooth, and precise movement.

There are many common uses for linear motion bearings. They are responsible for sliding parts of machines and various other products, such as furniture, automobiles, home appliances, drawers, workstation height adjustment mounts, etc. They are also quite frequently used as part of industrial motion control systems, along with devices such as linear actuators.

Other more general uses for various types of linear bearings include optic alignment, disk certification, precision dispensing, vision inspection, wafer testing and handling, precision gauging and automated production equipment.

They are an essential part of industries such as automation, packaging, medical, machine manufacturing, metal fabrication, printing, automotive, and food processing.

Things to Consider When Purchasing Linear Bearings

It is important to have the correct size and capacity bearing for your application. Having an inadequate system would translate into increased involvement time and production cost. To that end, here a few tips on selecting the right type of linear motion bearing system for your application:

- Understand the Mechanism

- The first step in selecting the ideal system is to explain your exact application requirements to manufacturers so that they can suggest the best solution. They know about bearing type characteristics like: load capacity, accuracy, smoothness, ease of installation, self-alignment, speed, pre-loading availability, end support mount, drag capacity, etc.

- Consider the Type of Load

- The load that is put on the bearing can be vertical, horizontal, pitch roll, and yaw moment load. Sometimes, a single load can be a combination of all these loads. Additionally, loads may also vary in the magnitude and path. Make sure that there is a suitable load vector at every bearing. Typically, load vectors should be compatible with the linear load bearing system; it helps increase the life expectancy of the mechanism.

- Consider Your Required Accuracy

- The accuracy of load bearings should also be taken into consideration when selecting a load bearing system. The precision of linear bearing can be termed as the variation observed in the height while it travels through the length of the rail. Profile rail bearings can be a better solution when you need your application to run at high accuracy.

- Find the Right Manufacturer

- Perhaps most important of all, you need to find the right manufacturer. Without them, your efforts could very well be in vain. So, who is the right manufacturer and how do you find them? The right manufacturer is the manufacturer who is not only experienced and skilled, but who is also willing and able to meet all of your specifications. The manufacturer you choose should not only be able to provide you with quality bearing products, but also provide those products in a timely manner and at a price that works for you. The right manufacturer will care more about your application than their bottom line.

- Take steps to find this manufacturer by browsing those companies we have listed above. Each and every one of them is a proven reliable provider. Take a look at their sites, pick three or four that may work for you, and then reach out to all of them with your specifications. Compare and contrast their answers, and make your choice.

Proper Care for Linear Bearings

To avoid costly and time-consuming repairs like regrinding and scraping, we recommend you seek a linear bearing manufacturer with testing engineers that will work for you during linear guide design and development stages. They will do the following:

- Evaluate Load Distribution via Hertz Contact Theory

- Load distributions in linear bearings can be evaluated with the help of a measuring tool that is based on Hertz contact theory. Such tools can indicate and suggest how motion errors can be contained within the set limit of tolerance.

- Transfer Function Method

- Another method, which is referred to as the transfer function method, can also be considered for the easy calculation of motion errors. With this method, the calculation can be done using a hydrostatic feed table. The transfer function technique, which is also known as the reverse technique, helps determine the condition of rail-form errors using the data of the measured motion errors.

- Sometimes, this technique is employed to address the motion error in the linear motion bearing table and to reduce the motion error by making adjustments in the rail-form error. The motion error can be reduced to less than a micrometer, using the transfer function method. That is a negligible figure having no great impact on the performance of the linear motion bearing.

- Check for Straightness Error

- The rail-form error is an important piece of information for calculating motion error; however, finding the rail-form error is not a simple exercise in a linear motion bearing system. For that reason, many engineers consider using another technique that does not use rail-form errors for the calculation of motion errors. Instead, this method uses the straightness error of a building block to measure the motion error. A laser interferometer and a straight edge are used during the assembly of the linear bearing process for the calculation of straightness errors. Sometimes, a dial gauge is used in place of the laser interferometer with a straight edge to check the straightness error.

- Horizontal straightness errors are removed to decrease the impact of inaccuracies brought in by roll (or ball placement) errors. Parallelism errors often build up between the joining of two rails. Checking the parallelism errors is sometimes helpful in accurately measuring motion errors.

- However, the data calculation is different in both the processes. The calculation of straightness error is based on the Hertz contact theory, which also helps spot rail-form errors.

Linear Bearing Accessories

Accessories you might consider to make your linear guidance system complete include: lubricant, roller tables, mounts, stopper bolts, linear locks, clamps, height adjusting blocks, linear guideway block stopper plates, and slide guide mounting hole caps. To figure out if an accessory would benefit your system, talk to your manufacturer.

Linear Bearings Terms

- Axial Clearance

- The amount of play or movement displayed when a bearing’s inner ring is moved axially in relation to the outer ring.

- Basic Dynamic Load

- The load under which a bearing can operate while rotating.

- Bearing Analyzer

- A device used to measure a bearing’s performance, and for fault analysis after use.

- Bearing Cage

- A device used to separate the rolling elements of a bearing (also known as a retainer).

- Brinelled

- The result of rolling elements being forced onto inner or outer raceways, leaving indentations in the raceway which lead to premature bearing failure.

- Carrier

- Responsible for supporting and moving the load. Carriers are commonly attached to the linear slide with a bearing system.

- Gib

- A wedge-shaped piece of metal or wood designed to hold structural parts in place and/or provide a bearing surface.

- Graphitic Corrosion

- The deterioration of bearing housings in grey cast iron products.

- Grease Pocket

- A special design feature of a cage/retainer that allows grease to accumulate and then slowly be fed to the rolling elements.

- Load Rating

- The maximum amount of weight that a bearing can withstand.

- Lubricant

- A substance is used to lubricate the moving surface of a bearing, protect against corrosion, conduct and transfer heat and keep contaminants from entering.

- Pear Skin

- A term that refers to the "fuzzy" appearance of the load-bearing surface of a bearing, which is caused by contamination.

- Raceway

- The portion of the bearing in which the ball or other part slides. Raceways provide the track of confined movement for the bearing mechanism itself.

- Radial Clearance

- The space between the rolling elements and the races in an unmounted bearing, designed so that the bearing has the necessary net clearance to operate.

- Seal

- A device to stop the ingress of contamination and the escape of lubrication.

- Stay Rod

- The long fasteners used to hold the retainers together when riveted retainers are used in a maximum bearing capacity.

- Tensile Strength

- The ratio of a material's strength to its cross-section.

- Tribology

- The study of friction, lubrication and wear on two moving surfaces in contact.

- Weibull Distribution

- A statistical analysis tool that is used to study bearing life and calculate the probability of failure.