Labeling Machinery

Labels are used and even required in many applications, to provide variable information about the objects to which they are adhered. Independent and government bodies such as the Food and Drug Administration (FDA), often dictate what information must be recorded on individual object labels to ensure standard identification as well as protect the health and safety of consumers. Nutritional facts and product warnings are commonly found on food and beverage labels, which also include brand name labels and decorative embellishments, as do most other retail items. Commercial merchants use barcode and pricing labels to provide both the consumer and clerk with pricing information and viability. Additionally, many companies include important information for product care. Far from limited, labels can also be used as signage and organizational tools in addition to product components.

Labeling products and packages are a vital part of industry. As one labeling expert said "...the label is perhaps the single most important marketing element on a package." Thus, it is crucial to have a basic understanding of the machinery and systems in this $15 billion a year industry.

Quick links to Labeling Machinery Information

History of Labeling Machinery

The labeling industry evolved over the last 300 years. The foundation for labels began even earlier with the invention of paper-making in the 12th century in southern Europe and the invention of the printing press in 1440. Labeling began in Europe in the 1500s as people started to attach labels to books that were given to a library or university. These labels served as a method to identify the donor, recognizing and honoring such a costly gift. Another early use of labels was to identify goods being transported in casks or bottles. As glass bottles became more common in the late 1600s, the practice of labeling wine sold by the bottle became necessary. The law only allowed labeled wine to be sold in bottles, since there was no way to insure uniform size of the hand-made bottles. If the vineyards labeled privately issued bottles for wealthy patrons they were allowed to use bottles for the wine. This was the beginning of the first bottle labeler.

Labeling expanded greatly during the Industrial Revolution with several key developments spurring that growth. These advances included the invention of the continuous paper-making machine, development of the lithographic printing process, color printing, the bottle labeler, and gummed paper. This growth of labeling continued through the 20th century with the invention of self-adhesive label material, automatic labeling machines, pressure sensitive labelers, seal machines, shrink labels, fill machines, dispensers and applicators.

Benefits of Labeling Machinery

There are many benefits of a well-designed fully integrated labeling system that fits seamlessly with a business’s production plan. It allows the business to efficiently manage inventory and shipping as appropriate labels allow for tracking of packages. Since so much of labeling is required by federal regulation, a well planned labeling-system keeps the production level of the factory operating at full speed. No product can be shipped until it has the correct labeling, so a labeling-system can either be a production bottleneck or it can facilitate the movement of the product to market.

There are many reasons businesses use labeling machinery. It helps a business comply with governmental regulations. The Competition and Consumer Act of 2010 mandates the labeling of products for several reasons. First, labels are needed to provide mandatory consumer product information. Second, industry-specific regulations must be included on a product’s label. Finally, imported products must have certain information on labels to meet customs laws.

Also, labeling systems help meet the consumer's need for information. Labels are necessary to provide consumers with important information about the product such as a list of ingredients, date of manufacture, expiration date, instructions for use, warnings, and environmental advice.

In addition, there are logistical benefits in using labeling machinery. Labels also include barcodes and UPC symbols that facilitate the purchase transaction at the point of sale, allows producers to track lot numbers for important recalls, and enables companies to track its inventory supply.

Finally, businesses invest in labeling machinery for marketing benefits. Researchers have found that 35% of purchases are because of eye-catching packaging and 70% of purchasing decisions are made in the store. This is why businesses spend billions of dollars in the labeling market annually.

Parts of a Labeling System

Labeling machinery accomplishes two basic jobs: creating labels and fastening them to the product container. These tasks often require the coordination of more than one type of machine. A labeling system may include label makers, dispensers, and applicators arranged to work together through sophisticated computer software. Sometimes the individual labeling machines may operate separately. The following is an overview of the individual labeling machines.

- Label Makers

- The modern labeller is a computerized label printing machine that comes in three sizes: hand-held, bench-top, or floor-mounted models. The machine prints the label designed with label-making software onto the label material. The label printer may use a variety of stock such as paper, plaster, foil, and even metal. The machine will also have a mechanism attached to it that feeds the label stock into the printer. The stock will normally be wound on a roll or in fanfold sheets. While there are many different methods of printing used by industrial label-makers, the most common types are thermal printers. There are two types of thermal printers: digital and thermal transfer. Digital printers create a label by using special heat-sensitive paper printed on with a heated print head. These printers have the advantage of requiring no expensive ink, but the labels will fade after several months. Thermal transfer printers use a heated printer head to transfer ink from a ribbon to create type on the label stock. Though they require expensive ink ribbons, the labels last much longer.

- Label Dispensers

- The manual label dispenser was developed in the 1920s to remove the label from its backing paper and feed it through a backing plate to a worker who then attached the label to the container. In the 1970s electric "gun" label dispensers became available. These were first used in the bulk mailing industry and greatly increased worker efficiency. A worker who could label 500 pieces of mail a day using a manual dispenser now was able to label 2000 pieces.

- The dispenser moves the label and its stock forward through a feed-roller assembly. Sensors and limit switches control the movement of the material through the dispenser. The label and stock are advanced to a peeler plate where they are separated and prepared for the next machine in the system which is the applicator.

- Applicators in the Labeling Process

- Applicators advanced the labeling process one step further by attaching the dispensed label to a product container. These machines are positioned beside the moving containers on a production line. The printer applicator dispenses the label partially and as the package moves past it the label is attached to it. They are capable of pressure sensitive labeling or heat sensitive labeling.

- The applicator receives the label from the dispenser as the used backing stock is discarded onto a take-up spool. The front edge of the label (called a "flag") is positioned by the applicator for attachment to the package sent to it by an automatic feeding line. Sensors ensure that the package and label are properly oriented to each other so the label application is accurate. The applicator may use pressure or heat to complete the attachment of the label to the container. After the label is applied to the product the applicator sends it down the packaging line.

Using Labeling Machinery

In a large industrial setting, more than one machine is required to accomplish the labeling of products. This system is often constructed of stainless steel, very durable, and consists of a few main sections. First, the heart of the system is the label maker. It is a printer controlled by a computer to produce the specifically designed label. A feeder attachment advances the blank label stock into the printer. The stock is usually wound on a spool or in fanfold sheets. The label maker prints the label on the stock and then forwards the finished label to the next machine in the system which is the dispenser.

The substrates to which labels are applied are numerous. The surface material and form is one of the most important considerations when selecting labeling machinery. While some machines are compatible only with flat or squared surfaces, others are specifically designed to label edges, curves, bottles and other three dimensional objects. Medical labelers, for example, often provide tamper proof seals that must move along the edge of the vial or container. Labeling machines not suited to this or other irregularities such as round or tapered surfaces will not provide accurate printing or application. Common options for printing include vertical or horizontal wrap labeling, which are used when labels must circumnavigate the entirety of the container or package. Flat labels can be top, bottom, front, back or any combination. No matter the placement, it is essential that the label material, adhering mechanism and surface material be compatible. Corrugated cardboard, papers, plastics, fibrous materials, foils, films and metals are all commonly labeled. Hot glue, pressure sensitive, thermal transfer, stamping and even simple ink transfer may all be used by label applicators or print and apply labelers. These materials may be part of the label material or backing, but may also be applied to the reverse side of the stamp or sticker just before application.

Labeling System Images, Diagrams and Visual Concepts

Labeling machinery refers to any equipment involved printing and attaching labels to the products and categorized based on the function.

Labeling machinery refers to any equipment involved printing and attaching labels to the products and categorized based on the function.

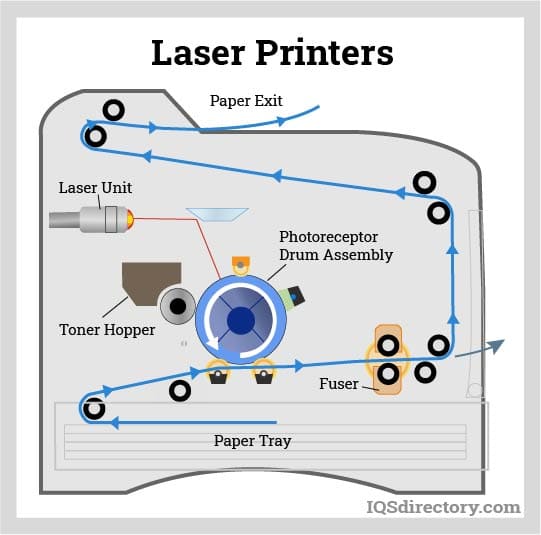

Laser printers can create multi-colored images, texts, and graphics quickly which can withstand UV light exposure, heat, and rubbing.

Laser printers can create multi-colored images, texts, and graphics quickly which can withstand UV light exposure, heat, and rubbing.

Label applicators, are labeling machines that attach pre-printed labels on films with pressure-sensitive adhesive on their backside, to products, containers, cases, and packages

Label applicators, are labeling machines that attach pre-printed labels on films with pressure-sensitive adhesive on their backside, to products, containers, cases, and packages

Vial labeling system, a wrap-around labeling system dedicated to attaching labels to vials.

Vial labeling system, a wrap-around labeling system dedicated to attaching labels to vials.

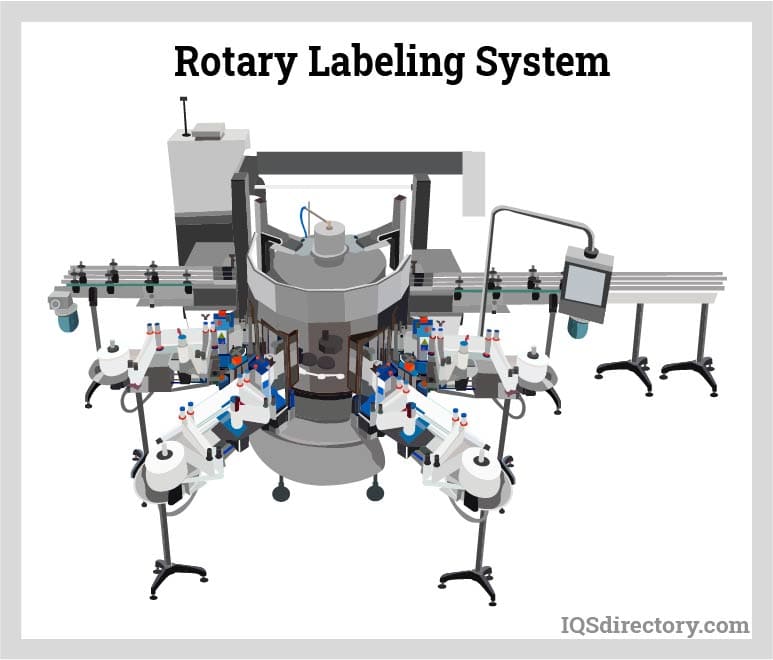

Rotary labeling systems, the products are transported from a linear direction to around a continuously rotating circular base

Rotary labeling systems, the products are transported from a linear direction to around a continuously rotating circular base

Types of Labeling Systems

There are three main types of labeling systems.

- Handheld Label Makers

- The advantage of this type is its portability. Certain applications need this feature, especially in the construction and warehouse fields. These are relatively inexpensive.

- Bench-Top Label Makers

- These are more versatile than the hand-held models and can produce labels in a high quantity quickly. They are also flexible in the type of labels they can produce such as barcodes, text and graphics, tags, wire markers. Some also are capable of printing labels on a variety of stock: paper, heat shrink sleeves and more.

- Large Label-Makers

- Floor-mounted and part of an integrated labeling system. These are best for large-scale operations where a high volume of labels need to be produced quickly and continuously. They will have the greatest flexibility and capability to meet the many labeling needs of a factory.

Types of Labeling Machinery

- Automatic Applicators

- Used for high volumes of labeling to label containers and other products. As the conveyor moves the product or container into position, a photo eye senses it and activates the application of the label.

- Barcode Labeling

- Entails the production and application of concise encoded tags which allow manufacturers to acquire vast amounts of information about a specific product or container without the use of large or cumbersome labels.

- Bottle Labelers

- Make up a large portion of all labeling machines as they are utilized in several industrial and commercial applications for both informative and brand labeling of bottles, jars and vials of varying shapes and sizes.

- Label Applicators

- Machines that automatically apply printed labels to products.

- Label Dispensers

- Used in conjunction with label printers and applicators to facilitate the easy removal of the tags, tickets and stickers from the protective backing on which they are printed.

- Dispensers only partially remove the backing which is then fully removed by hand or other automated device.

- Label Machines

- Can dispense, print, or apply labels to packages.

- Label Makers

- Refer to stand alone labeling systems that simplify the production of tags, tickets, stickers and seals for ease of use and customization in many home and office environments. Although the term is more often applied to small hand-held devices, larger labeling machinery may also be referred to as such.

- Label Printers

- Specially designed machines used to print labels or adhesive stamps on such variable materials as tape, ribbon, paper, metal, plastic, film, ceramics or fabric.

- Labeler

- A term that can be applied to any number of labeling machinery, or machinery designed to create or apply tags, tickets or stickers which provide information or decoration for the products and materials to which they are applied. A labeler might include a complete labeling system or individual parts such as printer, dispenser or applicator.

- Labeling Equipment

- Includes the machines used to print and apply labels.

- Labeling Machines

- Dispense, print, and apply labels to products.

- Labeling Systems

- Used in the packaging process and can print and apply labels to final products.

- Print and Apply Labelers

- Print labels when needed and apply them. An operator positions the product and activates the unit for label application by depressing a foot switch or a proximity switch, palm button or hot eyes; the operator then removes the product and continues the sequence again.

Applications for Industrial Printers

Industrial labeling systems have many applications. First, they produce and attach the marketing label to the product container. Second, the labeling system can be used to place barcodes on the product which can be used to store product information. Labeling systems also are used to place important consumer information on products.

Therefore, label printers are a vital part of nearly every industry. Electronics, cosmetics, construction, mail, pharmaceuticals, agriculture, food and beverage, chemical, and medical industries all depend on labeling as an important step in their production. There is hardly a field of industry that does not require some type of labeling process. If you're looking for label printers, you can find them on IQS Directory.

Customization of Labeling Systems

Few items truly are "one size fits all" products. This is especially true of labeling machinery. The best labeling systems are designed with the specific customer’s needs. Since these needs will vary from the type of label stock needed to the type of container to which it will be attached, it is important that a labeling system be tailored for its unique application.

A few important steps are required for the successful manufacture of a customized labeling system. First, the business should assign a project manager that will oversee all parts of the business that will have input on the design and purchase of a labeling system. Second, a team needs to be chosen from every department that will be involved in the process, especially with members of the package development sector and members from the engineering department. Third, prepare a requirements document that clearly states all the demands the labeling system needs to meet and any unique features it must possess. Fourth, choose a short list of companies who have the necessary capability to design the labeling system. This should be a list of three to six companies. Send each of them a request for a quote. Finally, conduct a vendor evaluation analysis for each quote received. This will objectively measure each vendor’s quote and enable the business to choose the best company to design the labeling system.

Installation of Labeling Machinery

There are no special considerations for installation of hand-held or bench-top label machinery. There are several factors to consider in the installation of large multi-machine labeling systems which require expertise and experience. Improper installation can negate many of the benefits a business hopes to achieve from its labeling department. For these reasons it is prudent to seek the services of a packaging engineer to oversee installation.

Standards and Specifications for Labeling Machinery

Since labels carry important information for consumers, federal law regulates that labeling machinery produces labels that meet certain compliance standards. These were first published in 1978 by the American National Standards Institute and the Underwriters Laboratories in the document "Standards for Safety of Marking and Labeling Systems." This document specifies two important standards labels should meet. First, the label produced must be able to endure the environment to which it will be exposed. Another important compliance feature is durability of marking. The labeling system must produce labels that withstand smudging when exposed to certain chemicals or normal wear and tear.

Things to Consider When Purchasing Labeling Machinery

Several design aspects need to be considered when choosing labeling machinery. First, look for labeling equipment that can be connected into systems that measure overall equipment effectiveness (OEE). This will enable the business to evaluate the productivity and performance of the labeling system and understand how to increase efficiency.

- Flexible Equipment

- Second, seek equipment that is flexible. As labeling regulations increase, new overseas markets open up, or changes occur, the labeling needs of a business may expand or change. Purchasing labeling machinery that offers a wide range of capability will be very cost-effective in the future.

- Reduced Downtime

- Third, search for labeling equipment that is manufactured to reduce downtime. Manufacturers of labeling machinery understand that labeling downtime is costly to a business, so many are striving to eliminate time-consuming adjustments when the type of label must be changed in the system.

- Speed of Production Line

- Fourth, be sure to choose a system that is calibrated to the speed of the rest of the production line. Two important speed considerations need to be remembered. First, the labeling machinery should have high speed to keep up with daily production targets. Second, the system needs to be sized so that it can run 15% to 20% lower than its maximum capacity. This will reduce the wear on the machinery and extend its life.

- Production Needs

- Fifth, be sure to communicate fully with the machinery supplier the production needs of the business. The supplier needs to know all the details of the customer’s operation-even the small details. These small details can sometimes make a major design difference in the system. The customer also needs to communicate directly with the actual engineers and technicians who will design the labeling system. Finally, the supplier should have a layout graphic that indicates exactly how the customer wants the labeling system to fit into the production line. This can mean the difference between a right-handed or left-handed machine.

- Factory Acceptance Test

- Finally, request a factory acceptance test from the supplier when you request a quote for a labeling system. This is a dry run once the final system is installed on the factory floor. The request should be very detailed and include a test of the expected failures that normally occur with daily operation of a normal labeling system. Though the customer may have to pay for such a test, it will be money well spent as it will insure the customized system can deliver what the business needs.

- Package labeling has become an important part of every aspect of life, from the food people eat to the cars they drive. Such an important component deserves the time and attention to better understand it and employ it efficiently in industrial settings.

- To find labeling equipment that will suit your needs, try connecting with the list of manufacturers at the top of this page.

Labeling Machinery Terms

- Acrylic Adhesive

- Utilized with laser labels that are sensitive to pressure derived from high-strength acrylic polymers.

- Adhesion

- A bond created when two surfaces come in contact; usually needs at least twenty four hours for ultimate adhesion.

- Applicator

- An apparatus that automatically runs labels through and applies them to products.

- Barcode

- A binary coding system in optical reading utilizing bars of differing thickness or position in the encoded field; theses codes are printed by machines.

- Coated Paper

- Paper with a coating on the surface that results in a smooth finish; these surfaces range from eggshell to glossy.

- Cold Temperature Adhesive

- an adhesive that bonds to frozen or refrigerated typically colder than thirty five degrees or less.

- Debossing

- A procedure that presses an image down into the paper surface; varies from embossing, which produces a raised image.

- Face Cut Label

- square cut or die cut label that does not have waste or matrix between labels removed.

- Fan-Folded Labels

- labels on continual backing that are pressure sensitive and have alternating folds along perforations resulting in a type of flat pack.

- High Temperature Adhesive

- The purpose of this adhesive is for labeling in environments where the heat exposure is to temperatures exceeding four hundred fifty degrees.

- Label

- the practical side of a pressure sensitive assembly, consisting of a face and adhesive; consists of a variety of shapes.

- Lift Tab

- A label edge not covered with adhesive for ease of removal; the coating of the adhesive used is known as patterned gum.

- Machine Readable

- the ability of a label to be read through scanning barcode with a laser scanner or similar apparatus; also known as Scannability.

- Pattern Gummed Adhesive

- adhesive coating that varies bands of non-adhesive going parallel with the direction of the machine with bands of adhesive; frequently utilized with a lift tab.

- Permanent Adhesive

- typified with a high ultimate adhesion since the label cannot be removed whole, or needs a lot of effort to remove.

- Pressure Sensitive Adhesive

- This adhesive is constantly tacky and adheres to a wide range of surfaces it meets in conjunction with hand pressure; the adhesion value determines whether it is removable or permanent as well as the particular surface it bonds to.

- Release

- The process of removing a pressure sensitive label from the carrier or liner; this is interrelated to the degree of tension required to release the label.

- Removability

- the pressure or state that pressure sensitive labels can be detached from a surface.

- Static Cling Labels

- this label sticks to a substrate through static electricity without adhesive.

- Tacky

- The pressure sensitive label’s preliminary bonding to a surface with the least amount of pressure and contact time; also a description of the sticky feeling from physically contact with adhesive.

- Web

- A continual roll of label stock that differs from sheets that are run through printing presses.