Graphite Machining

Graphite is one of the strongest minerals in the world, with many applications in industrial production, from #2 pencils to EDM machinery. Because of its strength and durability, graphite has become one of the most common industrial materials in factories and other heavy machinery, out-performing plain steel as well as other carbon hybrids. However, graphite in its raw form cannot be used in any industrial applications. In order to make use of graphite, it must be machined.

Graphite machining is a process by which the graphite material is cut or shaped to suit a variety of applications and purposes. The graphite itself is almost impossible to cut and will dull most metals, so it's important to make sure that only diamond and carbide tools are used. However, because of this strength, using graphite has a number of benefits. The material won't rust or break down, is extremely strong, and can serve as a natural lubricant for bearings and other machine parts. This cuts down on the costs of other oils and lubricants.

Quick links to Graphite Machining Information

History of Graphite

The first uses of graphite were for pencil leads, and the first examples of graphite machining were in the sixteenth century when a particularly solid form of graphite was cut into sticks and used to draw or mark objects with. This solid deposit of graphite was discovered in England, but graphite is a common mineral and was soon discovered elsewhere. Today, the largest producers of natural graphite are India and China, while the United States is a leader in the production of synthetic graphite.

The first person to utilize graphite in the modern age was Joseph Dixon, who went on to form the Dixon-Ticonderoga pencil company. Dixon discovered that graphite could be used as a lubricant, both in foundries and other machines requiring bearings, and to realize it could be used as a brake liner. His graphite crucibles were used primarily to make metal for guns and arms during the civil war, and the pencils he created gained prominence on civil war battlefields when people needed more portable ways to write and communicate than the pens of the day, which came with heavy, cumbersome inkwells.

The first graphite processes Dixon and early manufacturers used focused mainly on shaping the graphite through heat and pressure, like in the compression molding technique. When Dixon first discovered graphite deposits, crucibles were in biggest demand, since the Civil war was increasing the country's demand for bullets. Once that conflict was over, the uses for graphite expanded, as did the need for better machining processes. In the past, with more solid sections of graphite, like the one mentioned in the section above, the mineral could be cut with saws and shaped that way. However, nowadays, machining services use more techniques to get more sophisticated shapes and types of graphite, and even to produce isostatic graphite or graphene through different physical or chemical processes. CNC milling means that hydraulics and other precision tools can be used to obtain the best possible graphite and graphene products.

How Graphite is Machined

To make graphite shapes and bricks, the main component is graphite itself. There are often additives, like aluminum and carbon fiber added to the graphite as it is molded or extruded, to add durability or lower electrical and thermal conductivity thresholds. These enhanced graphite products are often used in EDM or electrical discharge machining processes. EDM graphite can be used in electrodes. Some machining shops also have the capability to make wire EDM, in order to fully protect an electrical machine from discharge. In manufacturing, EDM can be used to prevent electrical overloads, which is especially important in CNC milling and machining. Another specialty graphite, pyrolytic graphite, has a unique kind of thermal conductivity - if heat goes across the width of the graphite sheet more quickly than it goes through.

Graphite is used in industrial applications like CNC machining and EDM processes because of its strength. It is the most stable iteration of carbon ever found in the known world. It's made of individual layers or a product called graphene, which can be isolated and used in other processes. Graphene is actually stronger than graphite and is a wonderful conductor of both heat and electricity. Graphene layers can be isolated and used by a process called exfoliation, in which they can be pulled off of the graphite solid itself one layer at a time, by using a strong adhesive. This conductivity is enhanced through the addition of other metals, as mentioned above.

Graphite is machined in order to produce the powder that is mined into usable products. Because of graphite's thermal conductivity and electrical discharge machining uses, graphite by itself, as well as carbon graphite are in very high demand in certain industries. A machining center can use state-of-the-art equipment and a variety of precision machining processes to turn graphite powder into the parts that are so important in industry.

Graphite takes two separate processes to machine it into industrial and consumer products. First, the raw graphite needs to be transformed into graphite powder, which can then be machined into the final product. Machining raw graphite includes breaking the graphite down from its natural flakes that appear in nature - or from the molded shapes humans can achieve in a lab. This can be done in several different ways, but the most common is simply to crush the flakes of graphite into a fine powder. Once the graphite has been milled into a fine powder, the machining process to transform it into the final product can begin.

Once it is powdered, graphite can be machined in five different ways. Each starts with the same raw material. Graphite can be molded by compression, where the graphite is exposed to heat until it expands, according to thermodynamics, and then left to expand to the shape of a sealed mold. The next method, isostatic molding first makes the graphite isotropic, by compacting the graphite into a rubber bag to press it into a certain shape. This method changes the nature of the graphite powder itself, making it into isostatic graphite. Isostatic graphite is especially fine-grained, as well as unusually dense. This makes it a high demand component of some industrial products, especially ones in which every aspect of manufacturing must be kept constant. The fine grains of isostatic graphite keep the product consistent. Another method, vibration, is accomplished by shaking the containers at high speeds until the graphite powder compresses. Hydraulic compression is used with vibration at times, to create a more stable product. Graphite can be die-molded, where the graphite is compressed to extreme thinness, then shapes are punched out of the powder. The last method, extrusion, also uses dies, but pushes the graphite through the opening in a die, instead of using a die to punch the graphite out.

To start machining graphite manufacturers, you need instructions. The specifications for the part that the customer needs are published in a modeling software, like CAD. If there needs to be a certain type of graphite used - like isostatic, this will be expressed in the specifications, so that the machinists know what process to use. The machinists will then use one of the molding processes above to produce your components.

Graphite Machining Images, Diagrams and Visual Concepts

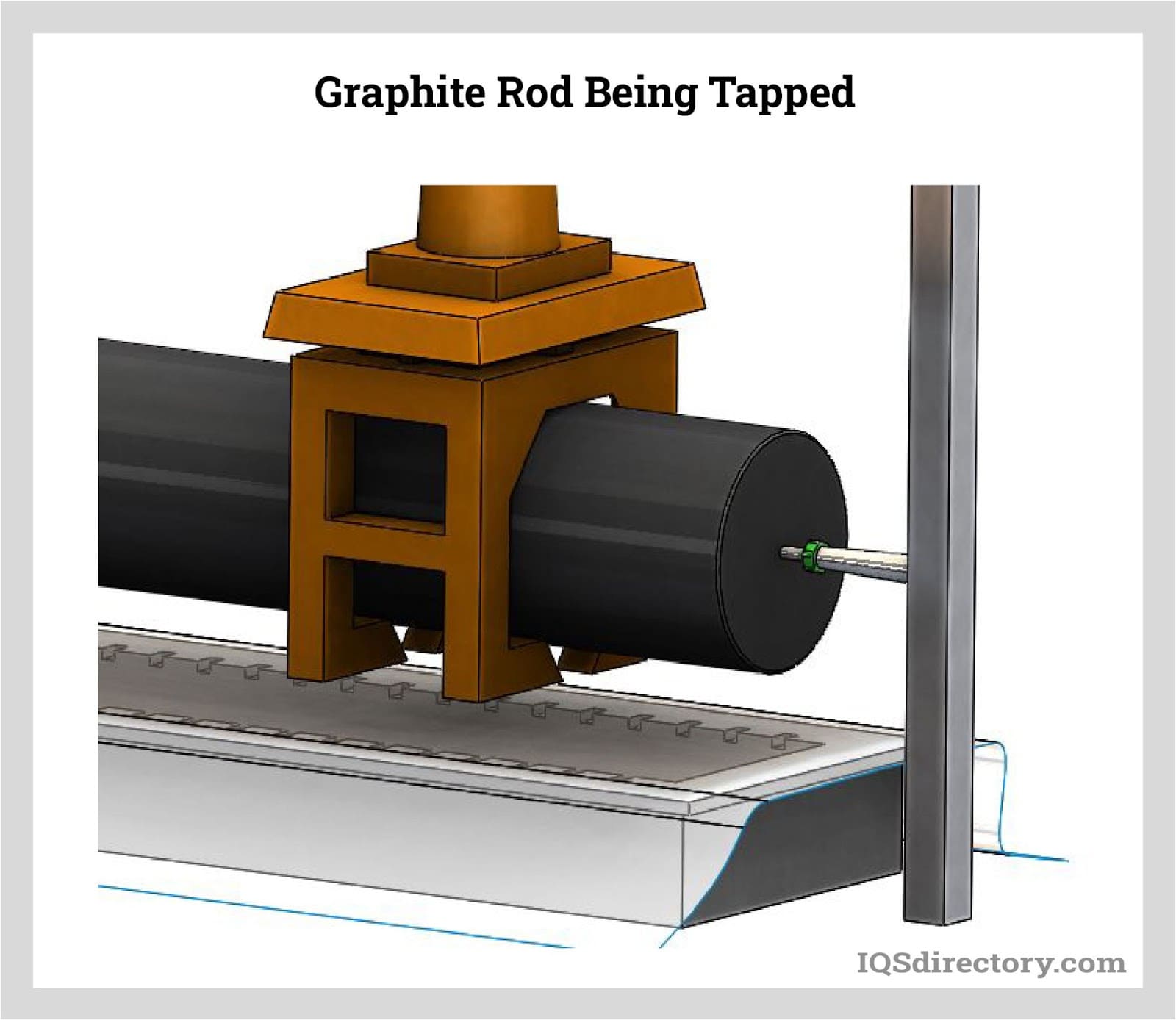

Graphite machining, a method for shaping, forming, configuring, and cutting graphite material to produce parts and components.

Graphite machining, a method for shaping, forming, configuring, and cutting graphite material to produce parts and components.

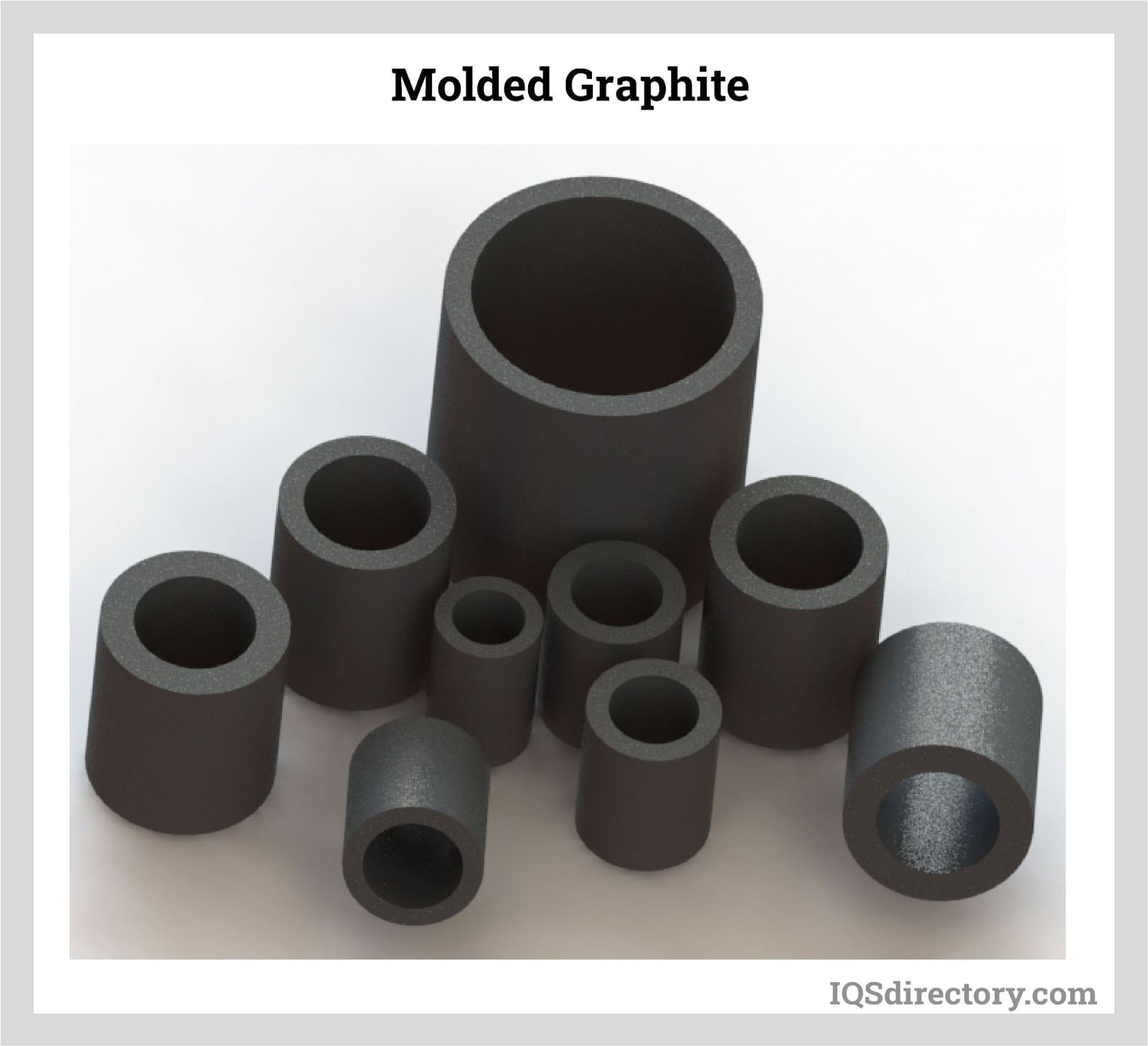

Molding process for graphite machining produces components with similar properties made by isostatic pressing.

Molding process for graphite machining produces components with similar properties made by isostatic pressing.

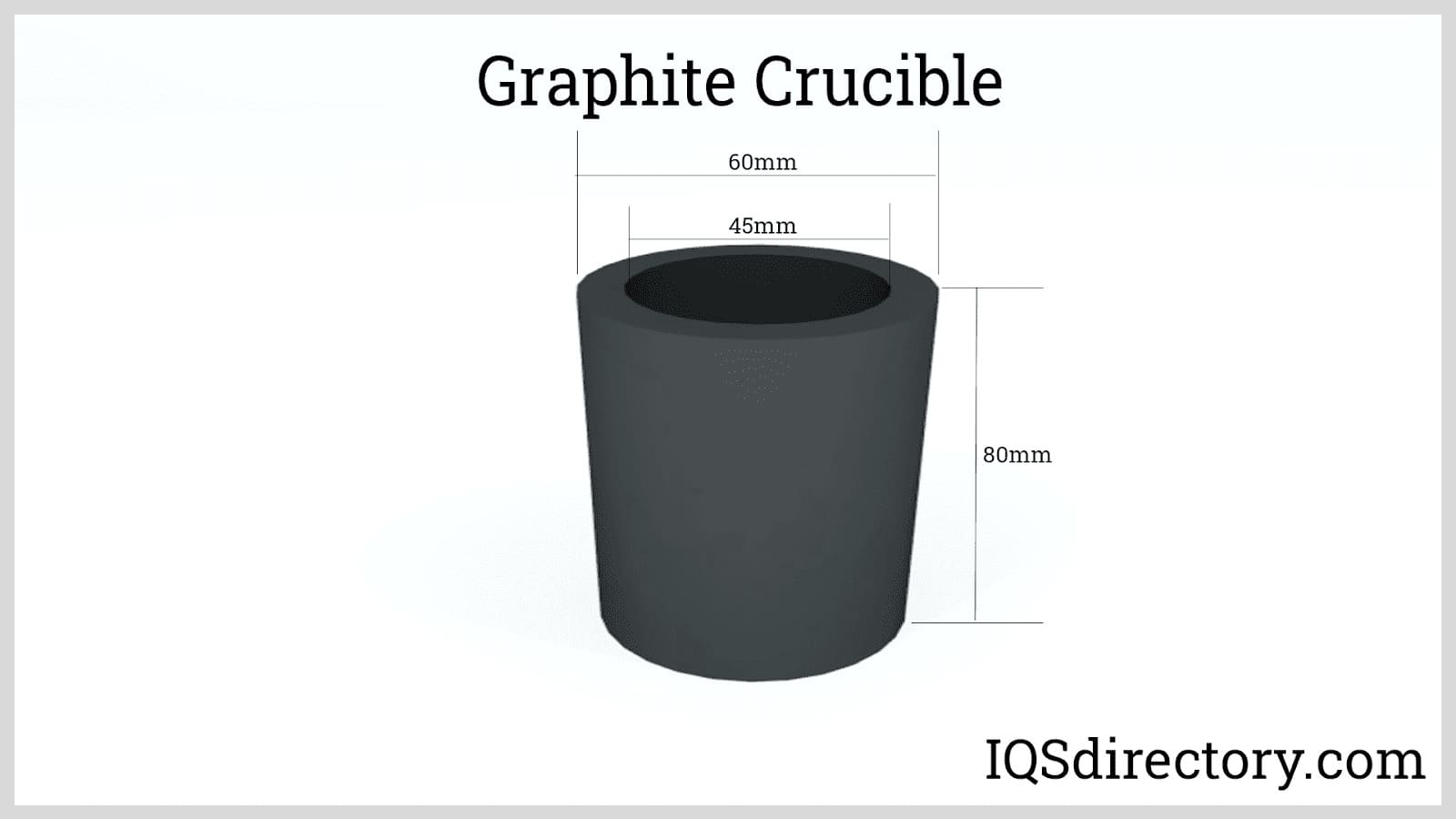

A graphite crucible, a container used for melting and casting non-ferrous non-iron metals.

A graphite crucible, a container used for melting and casting non-ferrous non-iron metals.

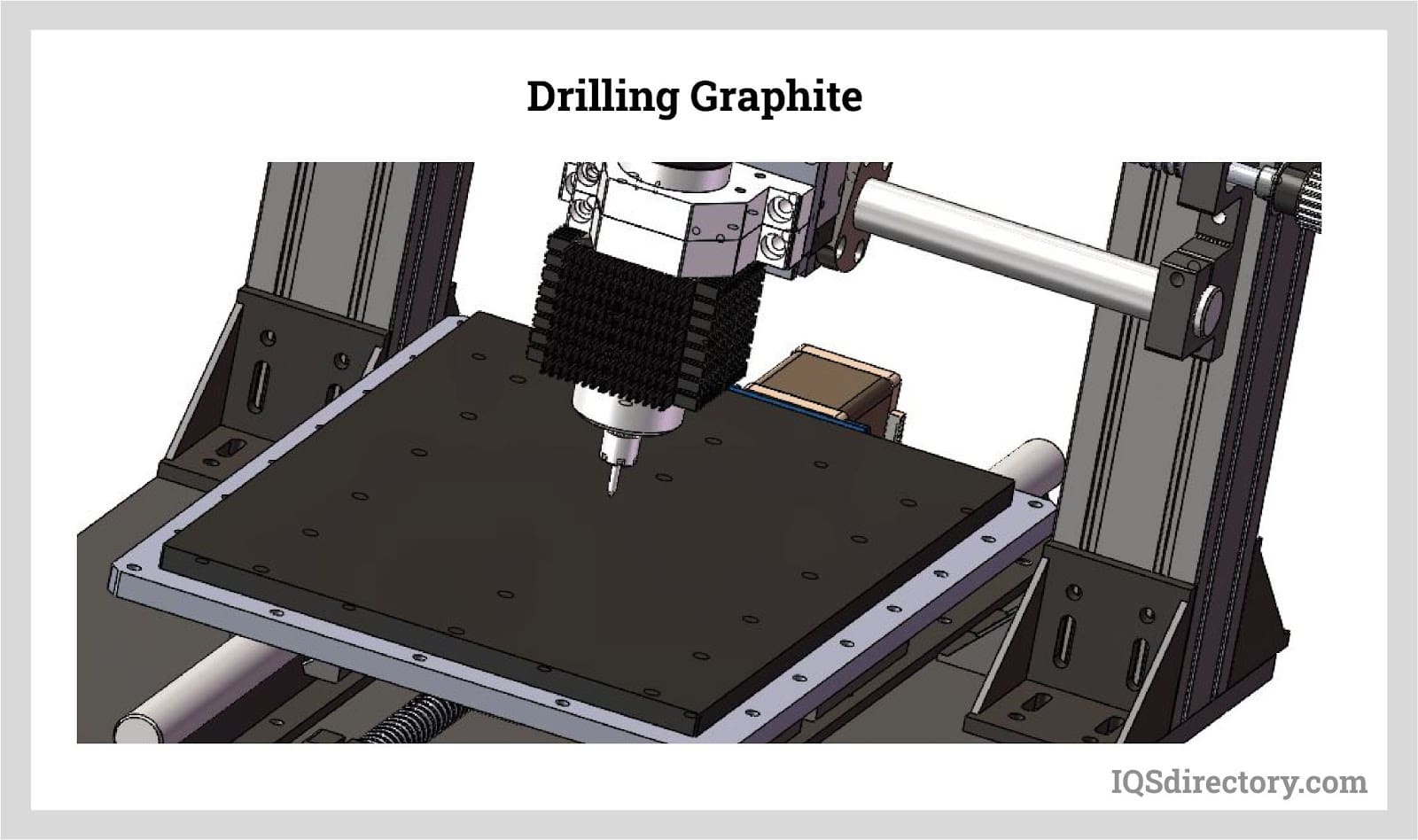

Drilling into graphite requires a higher spindle speed and a diamond coated drill bit with no limitations on hole size.

Drilling into graphite requires a higher spindle speed and a diamond coated drill bit with no limitations on hole size.

One of the specialized tools with diamond edges to machine the material.

One of the specialized tools with diamond edges to machine the material.

Graphite Machining Types

- Carbon Graphite

- Mechanical applications due to its strength and hardness. Carbon graphite has a lower level of heat resistance and conductivity than graphite.

- Extruded Graphite

- Has relatively fine grain size, and has good mechanical, electrical and thermal properties, with a preferential grain orientation and low ash content. Density, mechanical strength and oxidation resistance can be improved by means of further impregnation.

- EDM Graphite

- An important component of electrical discharge machines. The use of graphite causes less wear and tear on the EDM electrodes and removes metal quickly and efficiently.

- Graphite Bearings

- Often used in load capacity systems along with graphite bushings.

- Graphite Composites

- Are beneficial because they are lightweight, yet strong and durable. Graphite composites are used in the automotive, airplane, and aerospace industries to provide structural support and reinforcement.

- Graphite Crucibles

- Are used to store materials and samples during fusion and other mixing processes.

- Graphite Design

- Produces many products from machined graphite.

- Graphite Electrodes

- Used in ladle furnaces and electric arc furnaces. Graphite electrodes are advantageous for their high conductivity and performance under high temperatures.

- Graphite Fixtures

- Consist of packaging fixtures and sealing fixtures. Graphite fixtures are used in the automation and semiconductor industries.

- Graphite Machining

- The process that produces parts out of synthetic graphite materials.

- Graphite Rods

- Used in the fiber optics and semiconductor industries to produce a wide variety of machine components, including dies, spindles, and chucks.

- Graphite Tubes

- Used in furnaces because of graphite’s low heat sensitivity. Graphite is also used in the production of fluxing tubes used in the metal manufacturing industry; other industries using graphite tubes include chemical and scientific industries.

- Isostatically Pressed Graphite

- An especially fine grain, dense, isotropic graphite, which can be produced in large dimensions.

Physical Composition of Graphite

There are both synthetic and natural graphite’s. Natural graphite is derived from ore deposits and can be found in deposits in flakes, plates, or lumps. Both flake and plate graphite can be extracted by either underground extraction or by pit mining. Lump graphite can only be extracted in underground mining. The type of graphite in a particular ore has to do with how the deposit itself was formed, but it usually results from the same process coal is made from.

Humans have managed to find a way to make graphite in labs, instead of having to extract it from the ground. Synthetic graphite is derived from petroleum, and can be combined with carbon to produce other variations of the mineral that conduct heat and electricity more efficiently.

Production Utilizations for Graphite

Graphite can be used in many different industries and applications. Some of the many applications for machined graphite include degassing graphite tubes, cathodic protection anodes, boards, packing graphite rings, thrust washers, brazing fixtures and pillow blocks. Graphite machining is so popular because of the nature of graphite itself. Graphite can be reused many different times, lending a longer lifespan to an already exceptionally durable material. Credit must also be given to the graphite production industry. The industry's dedication to recycling and reusing what materials they can, means that the production of graphite is eco friendly, a boon for business in this day and age.

Once the machining process is done, graphite products, as well as graphite and carbon compounds are used in a variety of applications and industries. Some of the more popular uses are in the metallurgical industry, especially with smelting, where graphite is used to make crucibles. Another common use in the metallurgical industry is graphite tubes for fluxing. Graphite can be used in heating in some chemical industries. While it can be used in commercial heating and industrial furnaces, graphite plays a large role in chemical processing plants as well.

Graphite is greatly desired for its durability, but the material has another draw - it's great ability to conduct electricity, and graphite electrodes are often used to stop build-up in machines. As technology has become more sophisticated, other industrial uses have become apparent. Electrodes made from graphite and carbon are popular in a variety of machine shops for their ability to discharge electricity, especially in industries that use a lot of CNC machining processes. Graphite can be formed into rods or rings, which can be used in heaters. Graphite can be used in pharmaceutical processes. Along with these more advanced uses, one of the original uses of graphite is still in use. Graphite has been formed into crucibles and solid plates of material, since the civil war.

The graphite products produced before the 1900s were mainly graphite crucibles used to hold metal that was in the smelting or forming process. This product became less popular once bricks and graphite shapes became more prominent in the industry in the last twentieth century. Nowadays, the graphite shape is the most common product, with bricks and crucibles far behind.

Graphite is one of the components of batteries, especially lithium-ion batteries. The increase of mobile devices has made lithium batteries more popular, and the rise of electric cars has made these kinds of batteries - and therefore graphite - more popular. Graphite can be used to make steel, as it's one of the carbon additives that can be included in the final part of the smelting process. Since carbon raising can be a competitive industry, this is one of the main uses for synthetic graphite dust. In the automotive industry Graphite is a part of brakes, used to lubricate molds in foundries (as graphite powder), and of course, makes up the tips of lead pencils.

How to Choose the Right Graphite Machining Manufacturer for You

When choosing a manufacturer there are several factors to consider. The first is which graphite process you'll need your manufacturer to be able to fulfill for you. It's important to make sure that the design and specification software you use is compatible with your manufacturer's preferred software. While there are many efficient and capable manufacturers that can successfully machine graphite, it's important to choose one that you feel comfortable working with, and that you can collaborate with easily.

Since graphite machining has five different processes to achieve a final consumer process, not every company will have the necessary machines to accomplish every process. This is why it's important to make sure that if you have specific needs in the machining process, (isostatic molding, etc.) that you choose a manufacturer that will be able to accommodate those needs.

Graphite Machining Terms

- Angstrofine

- The most advanced type of EDM graphite. Angrostofine is used when fine detail and a smooth finish is required.

- Billet

- An uncut block of graphite produced by the manufacturer that ranges from two to seven square inches. A billet is commonly used for longer projects.

- Breakthrough

- The exit end of a through-hole cavity which occurs at the moment of completion.

- Carbon

- An abundant element of natural occurrence, often used instead of the word graphite. Graphite is a type of the element carbon.

- Coke

- A processed form of coal. Processed coke burns more steadily and is stronger than metallurgical coke.

- Composite

- Two or more materials combined. An example is copper graphite, which is a metallic/carbon composite.

- EDM

- Electrical Discharge Machining; a process in which metal is removed through burning or erosion instead of through cutting.

- Electrode

- A tool used in EDM which mirrors the desired shape. The electrode must be made out of materials that can carry an electric current.

- Filler

- The carbonaceous particles in manufactured graphite comprising the base aggregate in an unbaked green-mix formula.

- Flash

- Thin fin or web of metal extending beyond the confines of the casting, usually along the joint line as a result of poor contact between cope and drag molds.

- Grain

- Referring to a region in a carbon or graphite body that is identifiable as being derived from a particle of filler.

- Horn Gate

- Curved gate in the shape of a horn arranged to allow entry of molten metal at the bottom of the casting cavity.

- Isotropic

- Having uniform properties in all directions. The measured properties of an isotropic material are independent of the axis of testing.

- Machined

- To shape, cut or finish a product by the use of a machine.

- Premium Graphite

- A material with a particle size of five microns or less.

- Transducer

- Changes one form of energy into another; in EDM it is used to change electromagnetic force into mechanical force for the machining of graphite. Although there is sound produced when machining graphite, it is too high pitched for most human hearing.

- Trim Die

- Die used for shearing or trimming a workpiece.

- Workpiece

- Material that is being machined. The material will continue to be operated on until it is a replica of the original.

- Graphite Molds

- Used for a number of different applications across a wide range of industries, specifically when dealing with processes which utilize permanent molds in a product manufacturing process. The reason why graphite molds are utilized in this form of manufacturing is due to the fact that graphite as a material has a rather high melting point of 4200 K or around 6,422 degrees Fahrenheit.