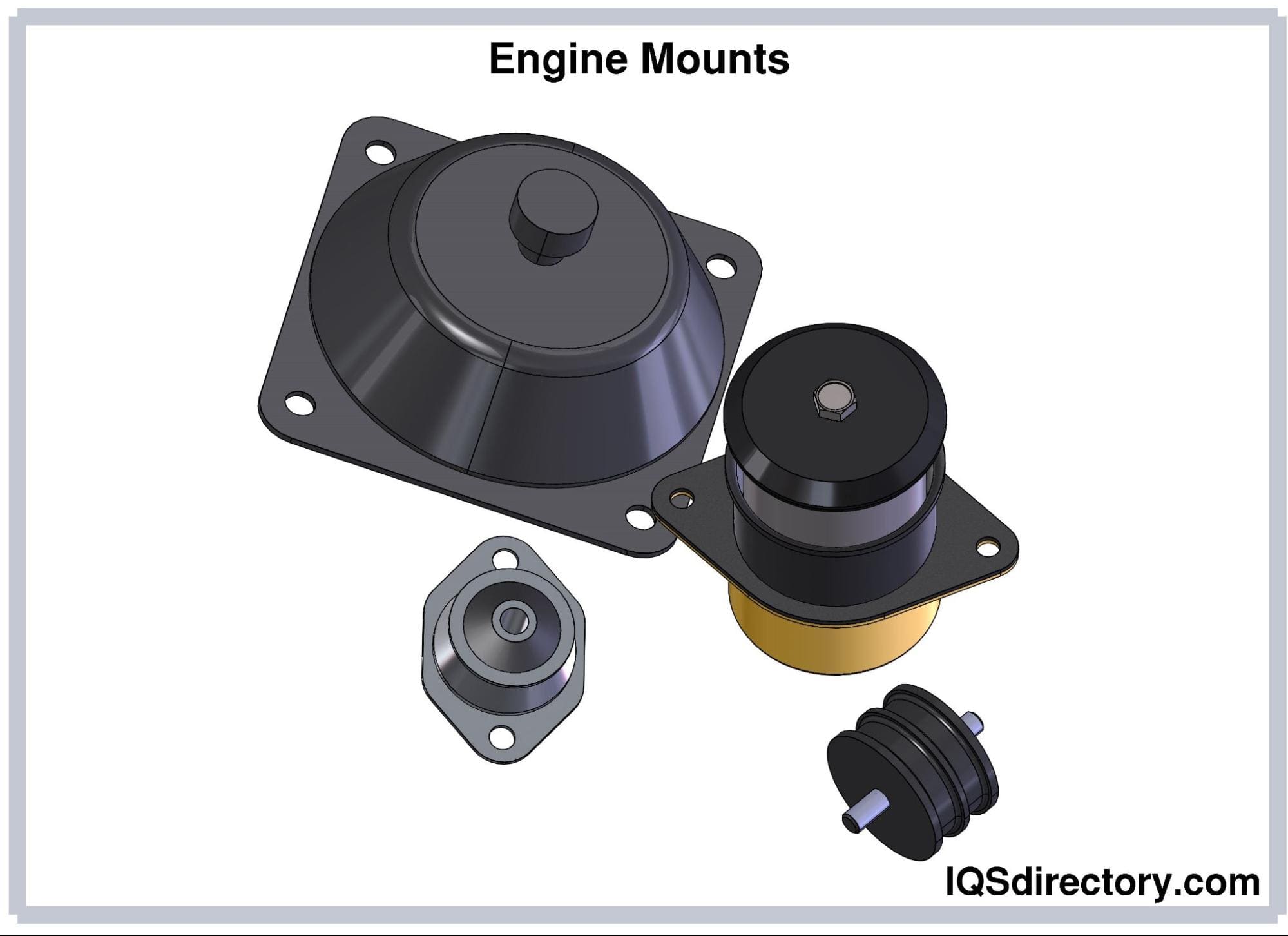

Engine Mounts

An engine mount is one of the most crucial components of a car or piece of industrial machinery. They can be found in tractors, trucks, buses, tractors, trains, boats, airplanes, and any other vehicle with an engine or motor. Any moving machine's correct operation depends on these tiny components. Depending on their use and quantity of energy they must absorb, engine mounts can take many different shapes or forms. However, most engine mounts are relatively modest and just big enough to dampen and absorb the energy without taking up too much room.

A few components go into making a rubber engine mount. The molded rubber bushing or mount, which serves as a vibration dampener, is one of these. Normally, this component will be directly connected to the engine. Additionally, a bolt that runs the entire length of the motor mount will be present and utilized to fasten it. Ensuring a rubber break between the two mating surfaces is the goal. Some motor mounts feature a metal cover over the rubber portion to increase stability.

Discovering the Proper Mounting Technique

Analyzing the ideal mounting method is crucial before developing an engine mount. As a starting point, consider the following data:

- objects' combined weights

- engine kind

- mass inertia moments

- operating and idle speeds

- maximum torque output

Customers may occasionally possess records including all of this information already. However, these forms are available from suppliers to utilize rather than having to fill out the data. Then, this information should be matched to a manufacturer's system analysis program to study the proper model nonlinear mount properties, static and dynamic loads, and single- and multiple-body systems. After a model is developed, two different analyses will occur.

Static analysis: to determine whether the mount can support the load given the engine's weight and torque.

Dynamic analysis: to look for engine disturbances and natural frequencies that may impact how the engine mount functions.

Rubber Engine Mount Types

Engine mounts come in a few different varieties. Many are well suited for particular tools and purposes. Three of the most typical types of engine mounts are listed below.

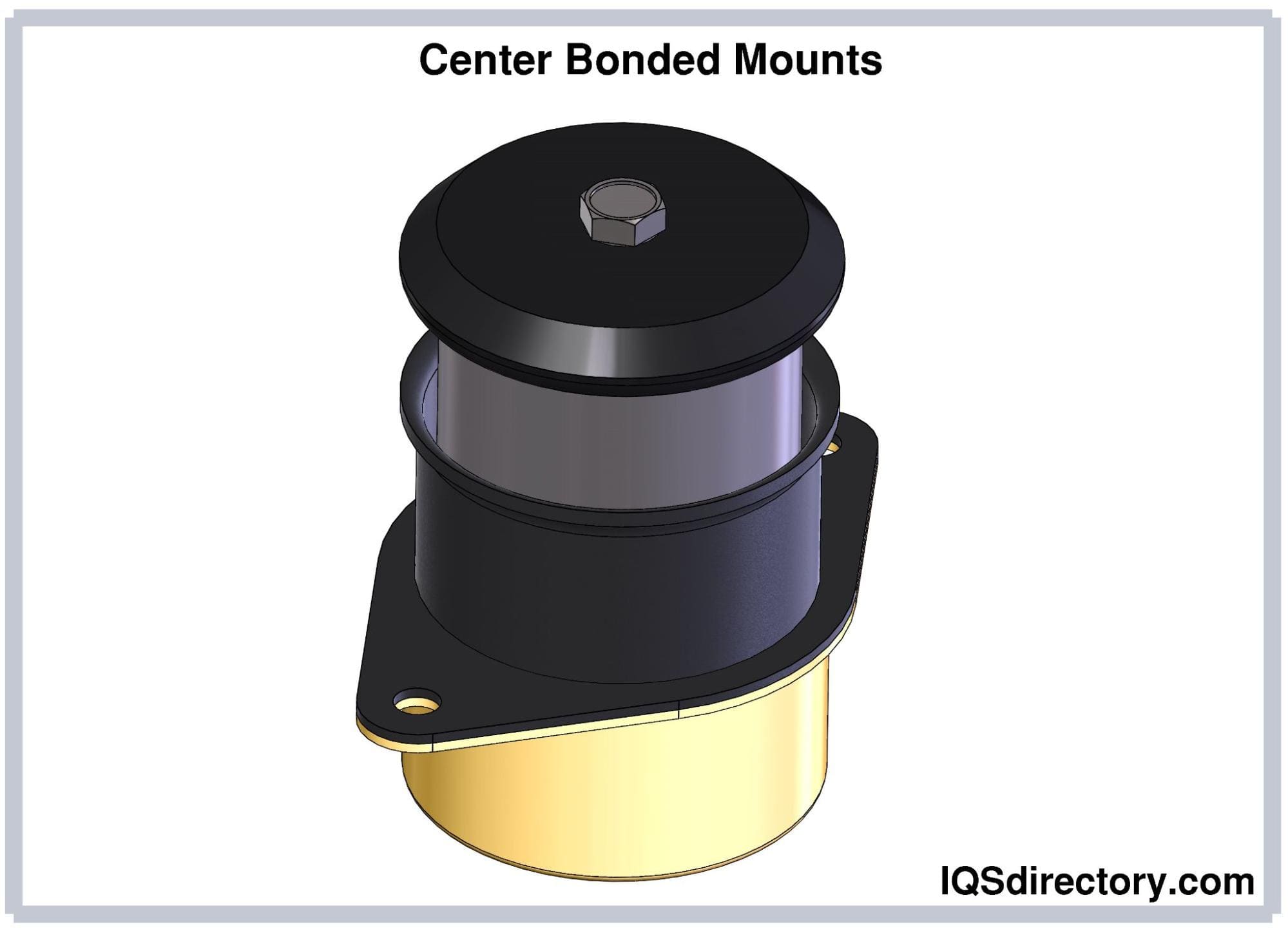

Center-Bonded Mounts

These motor mounts work to reduce noise, vibration, and shock. They have a very simple design, making installation simple and easy. They are adaptable for uses that call for isolation in a single major direction. Heavy shock loads can be supported by center-bonded mounts, providing comfort for the operator and reducing wear and tear on the equipment. These engine mounts are utilized in many applications, such as mobile and transport-mounted machinery, cars, and portable equipment. Vehicles and equipment used in the industrial, automotive, railroad, and maritime sectors frequently have center-bonded mounts. They are a great option because the installation process is quick, simple, and reasonably priced.

Double-Piece Mounts

One of the most widely used engine mounts is this one. The key distinction from center-bonded mounts is that they can tolerate vibration inputs from both directions (rebound loading), which makes them perfect for off-road or tough applications. This mount is made to concentrate the stresses on its two sides rather than all around it. Their straightforward construction allows for a great degree of flexibility in function and application and can be manufactured from several energy-absorbing elastomers. These mounts are ideal for construction, industrial, on- and off-road, and machinery. The most comfortable engine mounts in shock and vibration absorption are two-piece designs.

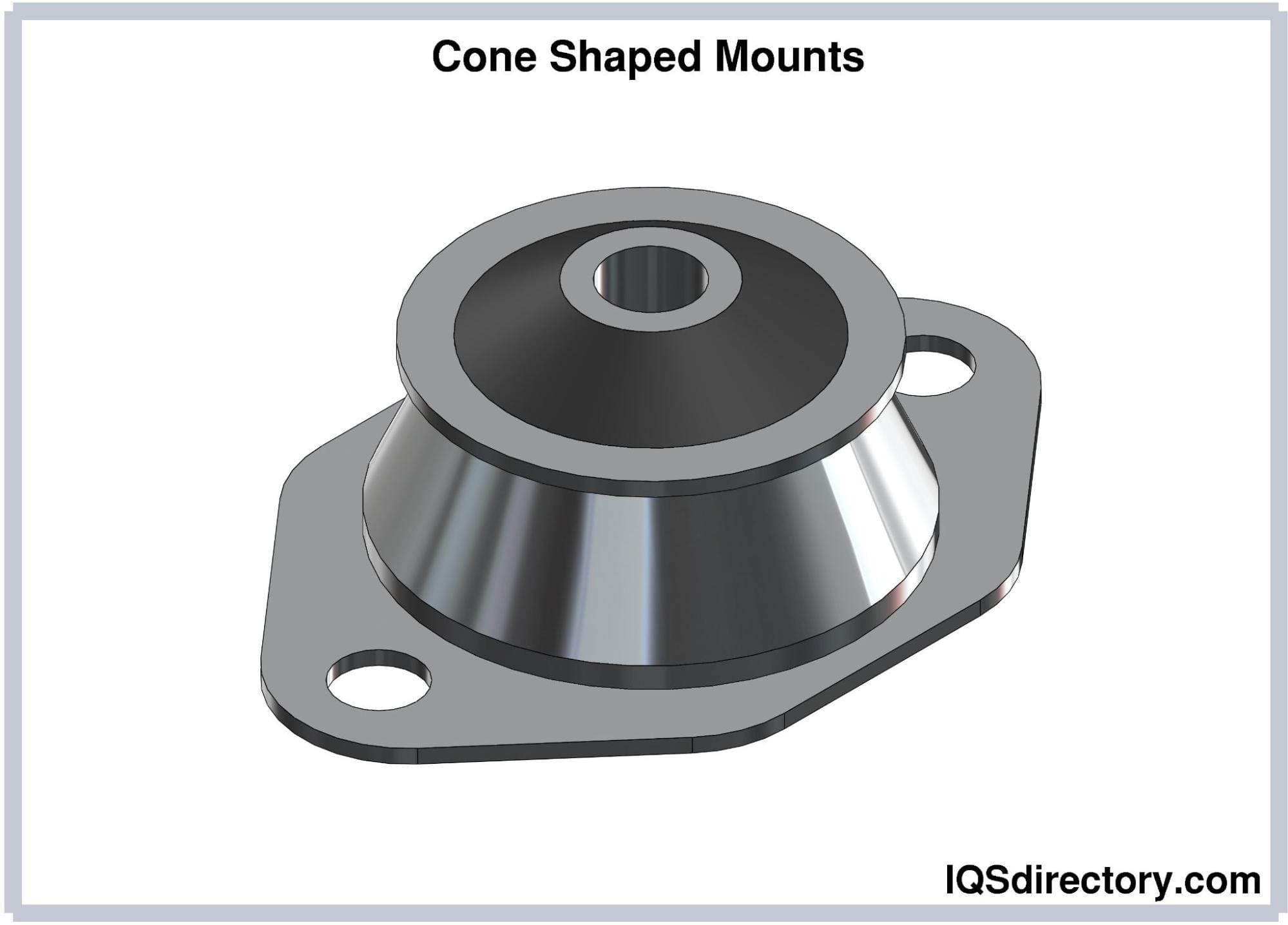

Cone-Shaped Mounts

One of the best engine mounts available is the conical mount. They offer excellent vibration damping and noise reduction and great load-bearing capacities. Conical mounts are a great option for both on- and off-road machines and vehicles. OEMs have a wide range of stiffness options with conical mounts, which will impact the vibration absorption capabilities. Conical mounts are durable and simple to install. Conical engine mounts give machine operators the peace of mind that they'll remain comfortable and in superb condition.

Advantages of Rubber Engine Mounts

- outstanding reduction of excessive noise and vibration

- They prevent engines from being damaged.

- They increase the lifespans of the engine and any linked sensor components.

- They prevent damage to the transmission.

- versatile in their arrangements and shapes to accommodate a wide range of applications

- They feature a long lifespan; when chosen properly, a rubber mount can outlive the engine it is meant to support.

- It balances the engine's stability and energy absorption, which are frequently at odds.

- resistant to ozone, water, oil, and other harmful fluids/elements, allowing them to function in demanding environments at a reasonable price

Considerations for Rubber Engine Mounts

Identifying the necessary engine mounts is one of the toughest issues in engine mount design. When selecting an engine mount, the following typical applications are taken into account:

- Will the mount be used for on-road versus off-road vehicles?

- Will the mount be used on vehicles used for smooth roads and on highways, such as those used in public transit?

- Will the mount be used with stationary equipment used internally, such as air compressors?

- Will the mount be used with transportable on-site equipment, such as power generators?

Choosing the Proper Engine Mount Company

To make sure you have the most beneficial outcome when purchasing engine mounts from an engine mount company, it is important to compare at least 4 to 5 companies using our engine mount directory. Each engine mount company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each engine mount company website using our patented website previewer to get an idea of what each company website specializes in, and then use our simple RFQ form to contact multiple engine mount companies with the same message.