Electronic Connectors

Electrical connectors compose a vast family of very different devices that possess the common denominator of somehow completing an electrical circuit. Connectors provide a convenient way to form electrical circuits that can be disassembled in the future should the need arise.

The most familiar connectors are found at the ends of power cords and in wall sockets; they are used to transmit electric power (usually AC) between a power source and a device that operates on electric power. Other connectors form electrical circuits between pieces of equipment themselves. Since connectors are largely used to create more flexibility in creating and maintaining circuits, many of them are designed to be temporary (in the case of various portable appliances). However, a connector can serve as a more permanent electrical link between two wires or machines (e.g. a television cable).

Quick Links to Electronic Connectors Information

Applications of Electrical Connectors

The commercial use of electricity is one of the defining marks of the modern world today. Naturally, then, electrical connectors are important utilities in consideration to a wide range of industrial, commercial and consumer products across a wide range of industries. By definition, the electronics industry and its products are inseparable from electronic connectors. Computers, mobile devices, audiovisual equipment, telecommunications equipment, and various types of electronic boards all require various types of connectors to function. One trend among connectors is a shrinking of size as electronic products continue to become more compact. Other industries that depend on connectors for their own versions of electronic products include the automotive industry, the medical industry, and the industrial industry.

Components of Electrical Connectors

The term connector is somewhat confusing because it can refer to two very dissimilar pieces of equipment. This confusion arises from the definition of a connector: an electromechanical piece of equipment that is responsible for completing an electrical circuit. An electrical circuit is completed when two conductive pieces (i.e. metal pieces) on different pieces of equipment form a connection. Generally speaking, there are two types of connectors, male connectors and female connectors, that exist by themselves but must work together to create such a connection. Male electrical connectors possess some form of metal extensions, or pins (e.g. power plug prongs) that create connections by fitting into matching receptacles, or sockets, that compose the female electrical connectors (e.g. walls sockets). The term pinout refers to the electrical contacts, or pins, of the male connection and varies widely with reference to the specific number and configuration of pins available. The pinout of an electrical connector is essential in its construction and use. Furthermore, the term connector is potentially confusing for a second reason: it is sometimes used to refer not only to a male or female connector in isolation, but also to a pair of such connectors working together as a unit. Generally speaking, the term connector in this article will use the term in the former sense.

Even though a fundamental theme among connectors is wide variety, they can usually be broken down into a few common parts. While the contacts or terminals are the components responsible for actually creating a connection, the housing is responsible for protecting the contacts from external elements. Contacts/terminals are overwhelmingly made of non-corrosive metals with high degrees of conductivity; however, any material able to conduct electricity (such as silicon or carbon) may theoretically be used. Beryllium copper and phosphor-bronze are two of the most widely used metals for electrical contacts; other metals used include brass and modified copper. The housing portion of a connector is typically made of plastic (although it can be composed of other insulating or dielectric materials); it can sometimes be further subdivided into insert and enclosure portions. Connectors are important but fragile pieces of equipment that are susceptible to mechanical or chemical threats. Thus, many connectors are equipped with strain relief features (to redirect undesirable mechanical forces acting on the connector) and various types of features to protect against chemical attacks. Some examples of the latter category include seals between the insert and enclosure (for protection from water, moisture, or oil) and shells that have been plated or anodized (to defend against corrosion).

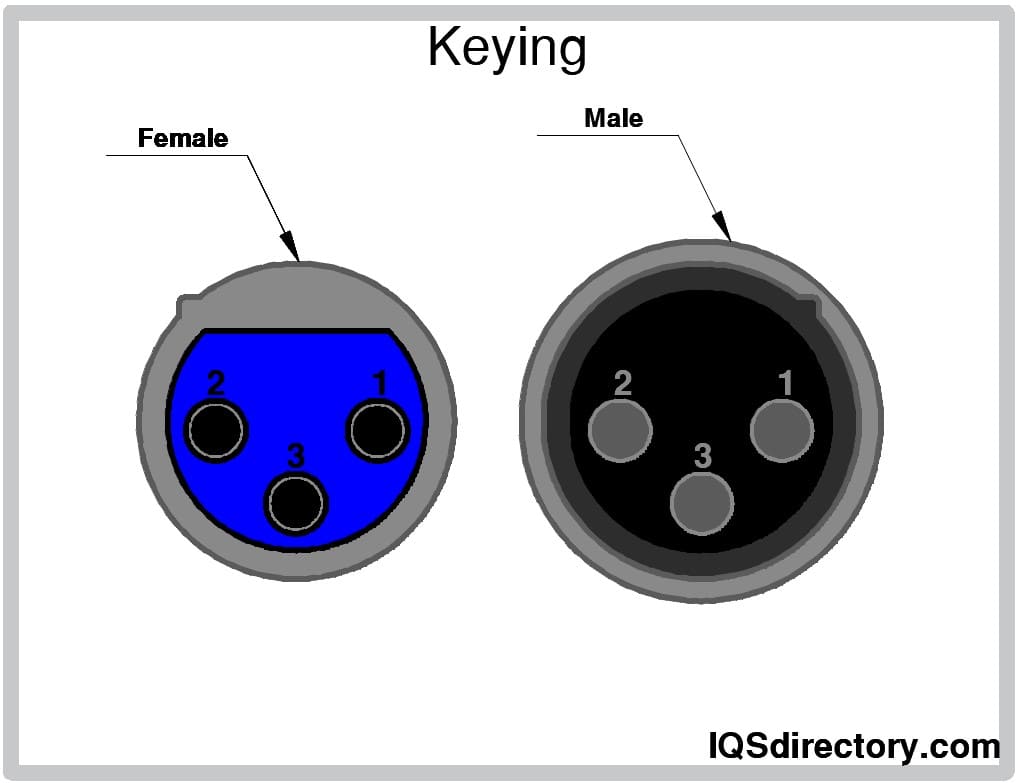

Two common features of connectors are locking and keying features. As mentioned above, the metal contacts of corresponding male and female connectors are what actually creates an electrical connection. Each contact of a particular connector must “mate” with the contact of a matching connector. Thus, many connectors have elements designed to “lock” this connection once it is achieved and prevent premature disconnections. Additionally, connectors are often designed with a specific mechanical feature that prevents “mating” apart from of a correctly-aligned appropriate connector. The term keying refers to this design aspect of connectors, which are typically manufactured in such a way that they will only work properly in one direction or orientation. Polarizing is a synonym for keying. The fragility of connectors makes this trait particularly important; forcing a connector into an incorrect position poses a probable risk of damaging the connector itself.

Electrical Connector Images, Diagrams and Visual Concepts

Electronic connectors are devices that joins electronic circuits for industrial machinery, consumer electronics, communications, and commercial appliances.

Electronic connectors are devices that joins electronic circuits for industrial machinery, consumer electronics, communications, and commercial appliances.

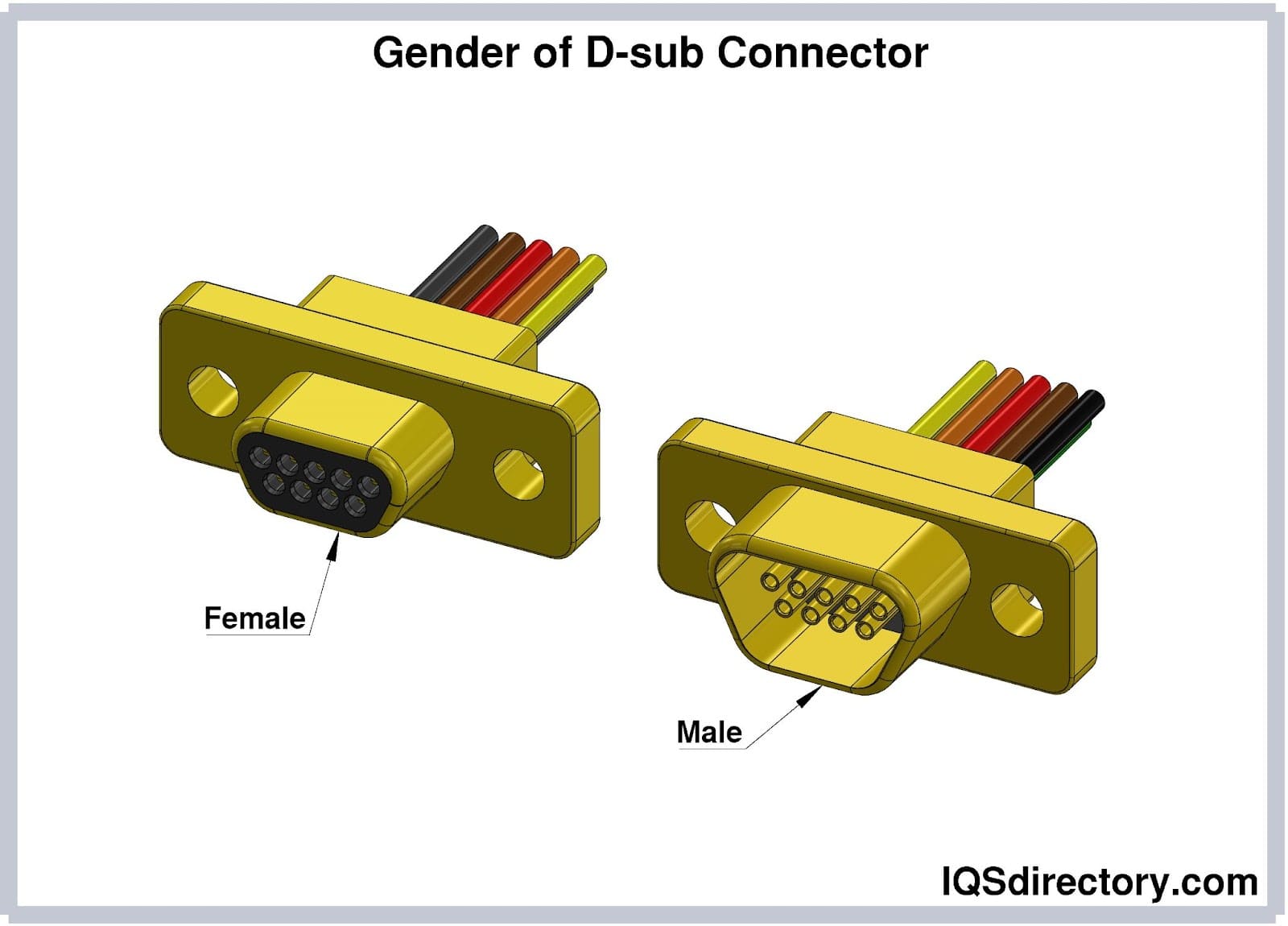

Electronic connectors have a male component or plug and female component or the socket.

Electronic connectors have a male component or plug and female component or the socket.

Keying, a feature of electronic connectors that avoids incorrect mating orientation to prevent mechanical and electrical damage to the pins from dangerous and incompatible connections.

Keying, a feature of electronic connectors that avoids incorrect mating orientation to prevent mechanical and electrical damage to the pins from dangerous and incompatible connections.

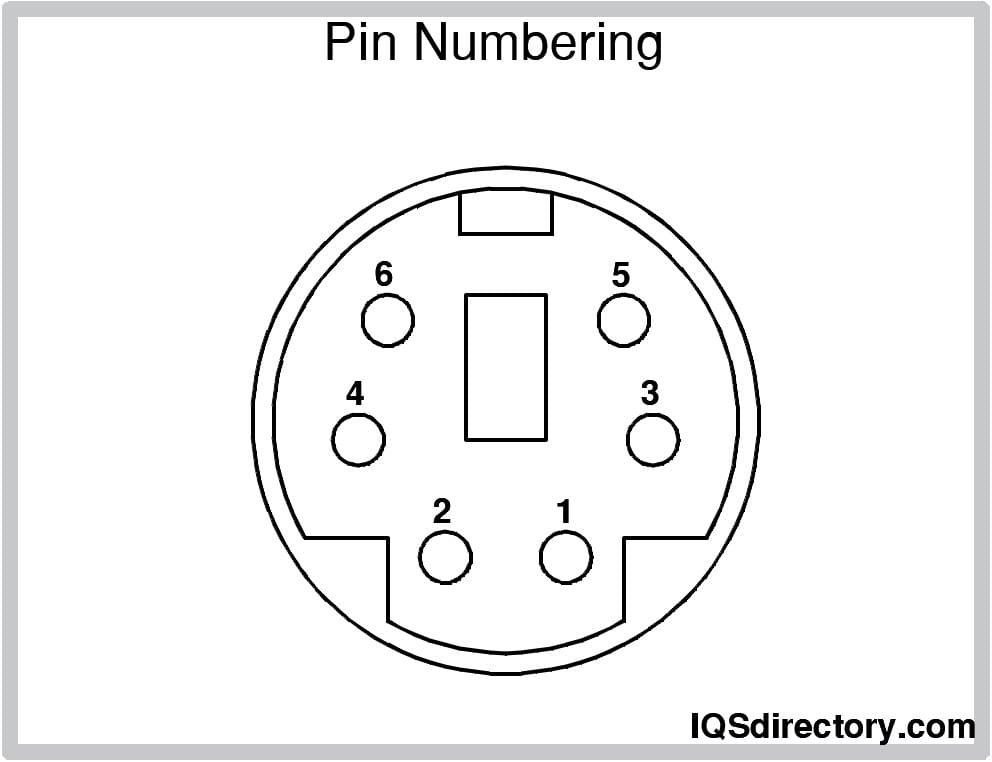

A number is assigned to a specific pin based on a sequence designated by a standard and in an anti-clockwise direction.

A number is assigned to a specific pin based on a sequence designated by a standard and in an anti-clockwise direction.

Board-to-board connectors join two printed circuit boards either perpendicular or parallel configuration.

Board-to-board connectors join two printed circuit boards either perpendicular or parallel configuration.

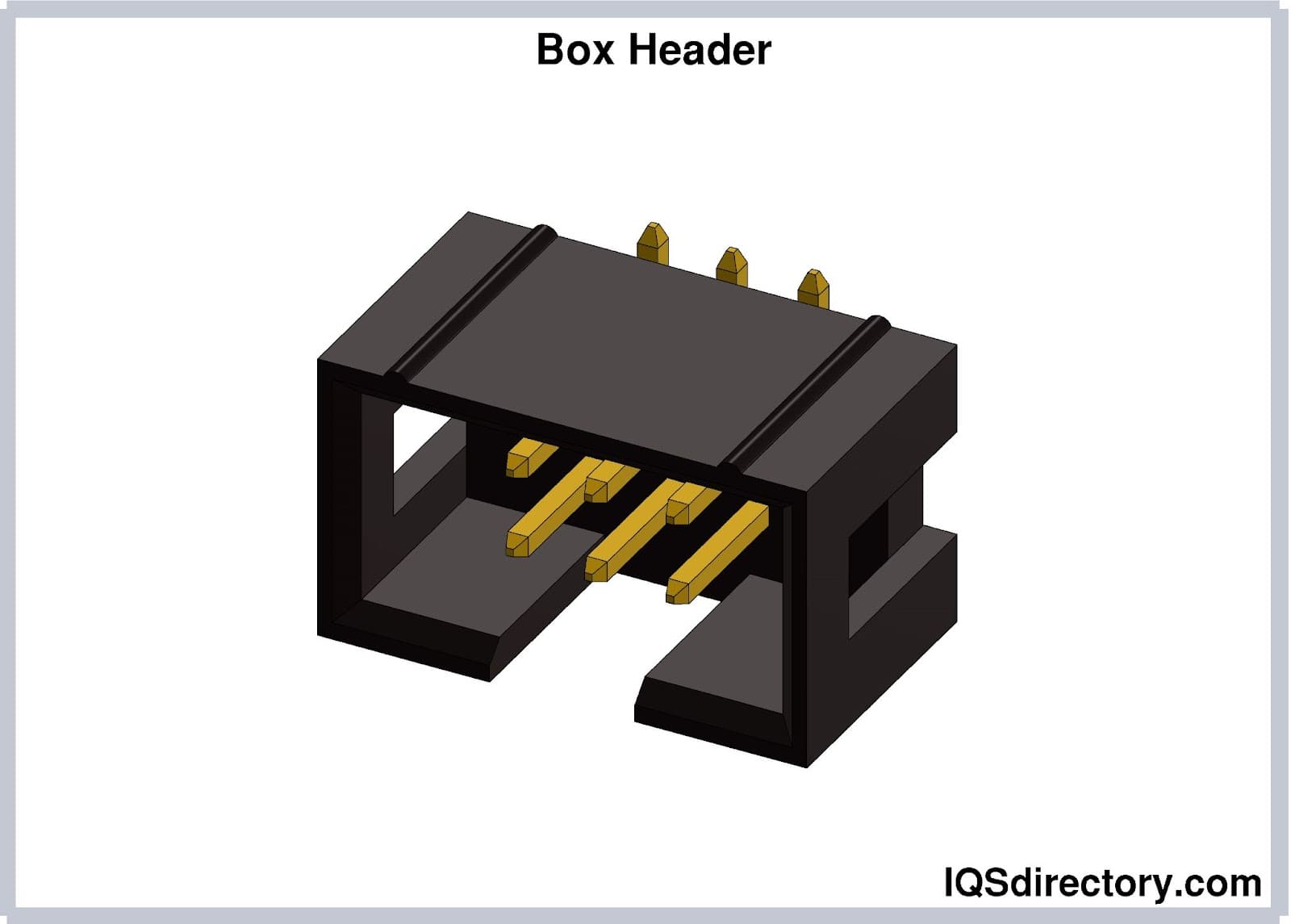

Box headers, the terminals are surrounded by their header.

Box headers, the terminals are surrounded by their header.

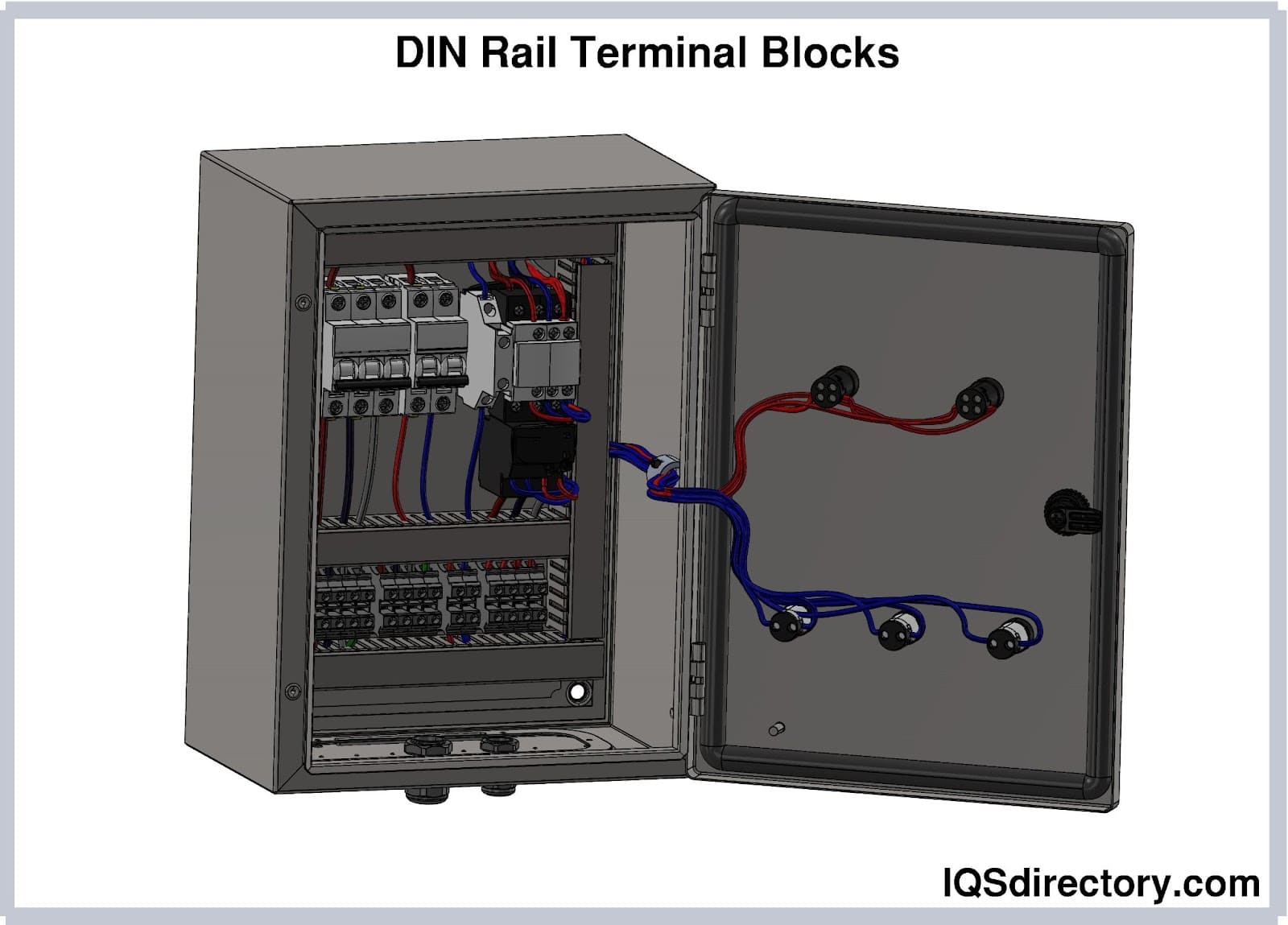

Terminal blocks are an insulated block that fastens or terminates two or more wires together.

Terminal blocks are an insulated block that fastens or terminates two or more wires together.

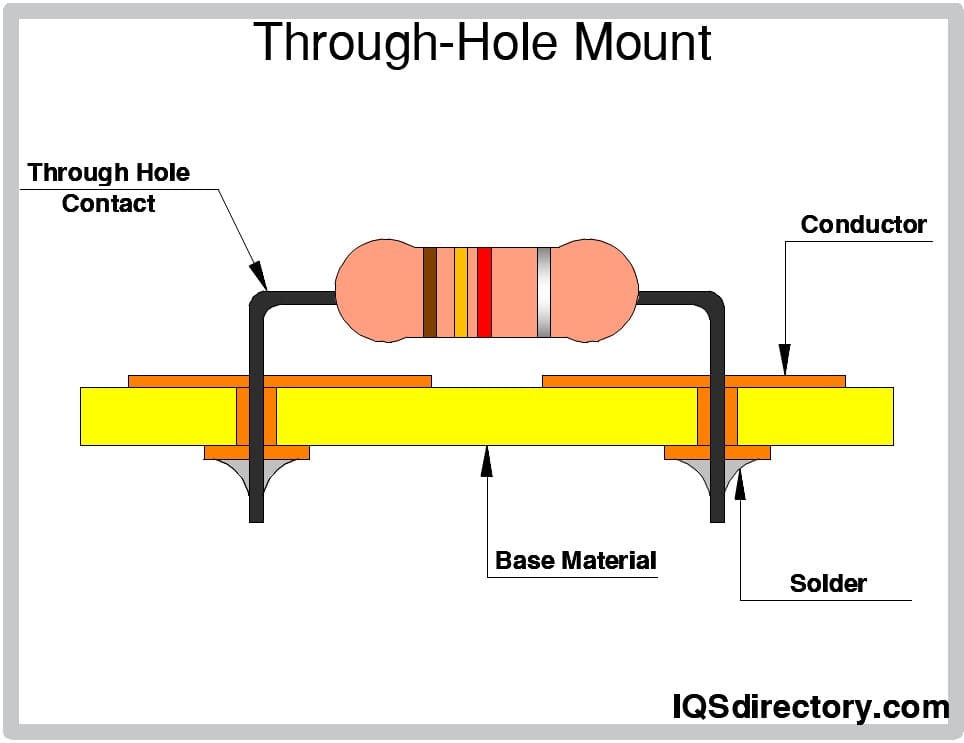

Soldering, the process of joining two or more electronic parts together by melting a solder around their contacts or terminals.

Soldering, the process of joining two or more electronic parts together by melting a solder around their contacts or terminals.

Types of Electrical Connectors

There are many different types of electrical connectors for many different types of appliances and purposes. Thus, products and product categories among electrical connectors are categorized by a number of different factors. One primary differentiator is the pinout (the collective number of pins on the male connection). Other factors that go into categorizing electrical connectors include the general physical construction, size, contact resistance, termination (e.g. how a connector is fastened to a wire), insulation between pins, strength, resistance to outside forces (vibration, pressure, water, etc.), number of reconnections that can be reasonably endured (e.g. mating cycles) and the ease of connecting and disconnecting. One helpful way of thinking about connector categories is discerning what type of electrical circuit a connector is designed to complete. As alluded to previously, connectors can connect devices to power sources, devices to each other, or internal parts within a device.

Some connectors are intended to connect directly to wires or to join wires together. Blade connectors use a flat conductive blade coupled with a blade-shaped receptacle in order to connect a single wire to a circuit. Ring and spade connectors have a similar purpose, but they connect wire using a bolt or screw inserted into a ring or spade cavity. Screw terminals are connectors designed to easily connect bare wires (usually of narrow wire sizes or gauges) to a circuit. Finally, terminal blocks provide a convenient way to connect single electrical wires to one another within an item of equipment. Automotive power electronics, such as a hundred-wire connector on an engine control unit, are examples of equipment that depend on connector terminals.

- AC and DC Power Connectors

- AC power connectors vary by gender, geometry and configuration and are used to transfer alternating current (AC) through electronic devices. AC power connectors, which range from simple AC inlets and outlets to sophisticated power entry modules, are used in a wide variety of industries within the commercial, industrial and residential sectors.

- Power (electrical) connectors is a broad term denoting connectors that link a device to a power source. These types of connectors exist in several different varieties and are mostly used for electronic or industrial equipment. It is important to note from the outset that power connectors can be divided into two different classes based on the type of power they provide. Alternating current (AC) refers to electrical voltage that is produced in cyclic waves, while direct current (DC) flows steadily. While DC is a strong power source, it is difficult to transport over any length of distance. AC does not face this difficulty, and thus it is the power source of choice for electricity grids and home power supplies. Power connectors are equipped with safety features (e.g. keying, grounding mechanisms) to guard against accidental electrocution.

- AC power plugs and sockets include the plugs on the ends of appliance cords and household wall sockets (usually a NEMA 5 socket). (When an electric cord is molded to two connectors, it is known as an electrical cord set or power cord.) These devices comprise the most familiar types of connectors to modern consumers, and they can be traced back to the commercial development of electricity in the late nineteenth century. Thomas Edison powered his innovative, efficient light bulb through DC (direct current). Inventor Nikolas Tesla pioneered the use of alternating current (which provides voltage through cyclic waves) around 1887, creating an alternative power model that did not suffer from the inability to transmit power over long distances (like DC). Ultimately, while DC connectors are still used today, AC connections gradually became the preferred power model for common use. Initially, household appliances depended on sockets and plugs specifically designed for lighting lamps. As consumer use of electricity continued to grow, different types of connectors were pioneered. Inventor Harvey Hubbell was at the forefront of plug/socket development in the United States. He created a 2-pin plug in 1903, flattened these pins 1904, and then reconfigured these pins into parallel positions to create a prototype that is widely used today. Harvey’s “Separable Attachment Plug” removed any need to directly wire an appliance to a household power supply. In the following decade (1928), Philip Labre developed a plug and socket with a third prong and hole (respectively) to provide a grounding mechanism for shorts in a circuit. Labre’s outlet provides an early example of “polarization”, intentional designing that allowed a plug to only be inserted in one way. This grounding, polarized outlet formed the basis for AC sockets commonly used today.

- Amp Connectors

- Range in amperage, which determines their application. Amp connectors can be applied to either AC or DC applications and are used as PV array, small power and battery, solar panel array and subarray connections, among others.

- Cable Connectors

- Make connections between cable cords and electronic components.

- Barrel Connectors

- Another type of connector that is common among consumer electronics. These connectors possess only two contacts and often coordinate with adaptors to use AC wall outlets. Furthermore, although AC connections tend to be more popular, various types of DC connectors also exist. Interestingly, charging portable electronics in a household environment uses DC, not AC, power. The “box” that is attached to many mobile charging cords performs an AC to DC conversion.

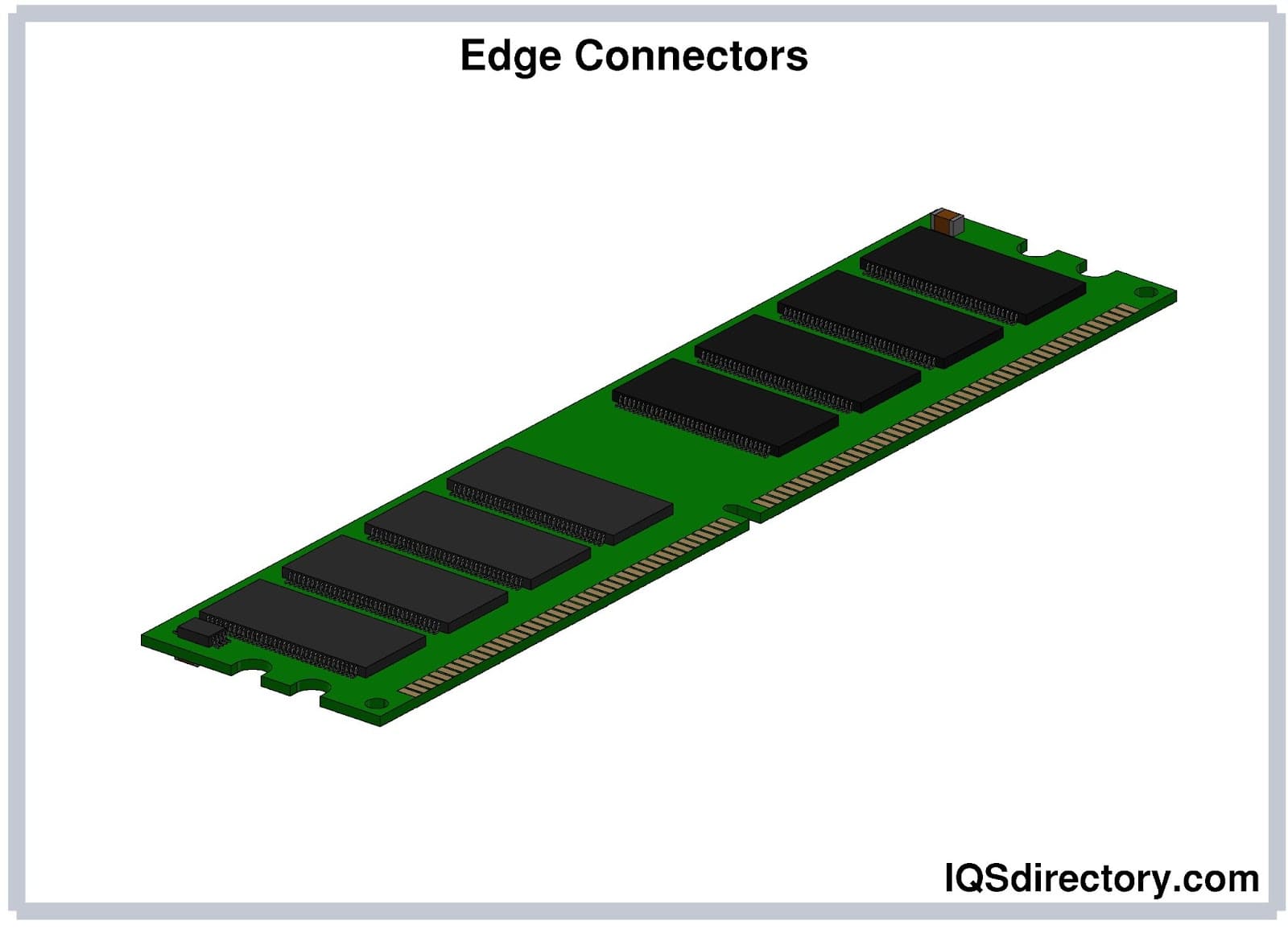

- Card Edge Connectors

- Used on personal computers to establish connections for parts, such as processors, motherboards and graphics ports. Card edge connectors have higher maximum heat capabilities than many other connectors, due to the heated internal environment of a PC.

- Coax Connectors

- Single-conductor cables that have braided shields. Coax connectors were used primarily in the 1980s for data transmission purposes but can still be found in many video applications today.

- Deutsche Industrie Normen Connectors (DIN)

- Connectors that are round multi-pin connectors. DIN and mini-DIN plugs, such as S-video connections, are considered audio connectors.

- D-Sub Type Connectors

- Can be considered "predecessors" of USB connectors in the sense that they were originally created to connect early computer models. Although they are increasingly rare among consumer electronics, they are still used in commercial equipment. They derive their name from the metal “D” shield surrounding the multiplicity of metal pins. D-sub type connectors can be found in places such as network ports, electrical systems used for aircraft, and computer video outputs.

- Electrical Connectors

- Transmit electricity between a power source and devices that rely on electric power to run.

- Fiber Optic Connectors

- Type of Electronic connectors, in which the material used to construct the connectors is a type of optical fiber.

- IEC Connectors

- Commonly used to provide (AC) power for desktop PCs and provide a good example of variations on “male/female” terminology with reference to connectors. In this case, male pins are located inside IEC computer sockets and are on the receiving end of the “female” IEC plug. This highlights the fact that the gender of a connector is ultimately determined by physical considerations (specifically, the presence of pins/extensions) and not merely the direction in which the piece moves.

- Military Connectors

- Type of electronic connector that has been manufactured according to military specifications, commonly abbreviated as MIL-SPEC.

- Modular Connectors

- Connectors in which identical or similar sections can be assembled to provide the ideal connector size or type for the application.

- PCB Connectors (Printed Circuit Board)

- Refer to a type of electronic connector that is used to transmit electrical signals between either two printed circuit boards or a printed circuit board and another type of electric circuit.

- Phone Connectors

- Are 1/4 inch in diameter and were originally used for telephone connections. Mono phone jacks are used for a number of microphones, while stereo phone jacks are often used for connecting headphones to audio components. Some connectors are designed for circuits that transmit audio and visual signals. Phone connectors include the male pins attached to the ends of headphones. The male versions are marked by tip-ring-sleeves (TRS), and overall this type of connector is used to transmit various audio output signals (e.g. on MP3 players). HDMI and RCA connectors compose another family of connectors that are heavily used for audiovisual purposes. Banana (or bullet) connectors consist of one crimped plug designed for making a single connection within a corresponding jack. They are usually used for testing within the electronic world (e.g. with power supplies).

- Pin Connectors

- A type of electronic connector that utilizes pins, which are short, straight, stiff pieces of wire that are designed with a blunt head and a sharp point, in order to connect two or more electrical circuits. Pin headers comprise special types of “internal” connectors that differ significantly from other types discussed thus far. The male pins on these connectors usually consist of one or more rows soldered to a printed circuit board (PCB). They fit with multiple female receptacles often attached to ribbon cable, a color-coded “wire” composed of many individual wires. (Ribbon cables are just one example of cable assemblies, a common arrangement in which multiple wires and cables are combined to form one overall unit.) Ribbon cables and pin header connectors are particularly useful for forming circuits among internal electronic peripherals (e.g. connecting a disk drive to its drive controller).

- Power Connectors

- Transmit power between sources and devices that rely on power to function.

- Radio Frequency (RF) Connectors

- A connection type that is designed to function at radio frequencies. Variations of RF connectors include BNC, TNC, N, SMA, SMB, SMC and F connectors. Radio frequency (RF) connectors operate within radio frequencies and are often combined with coaxial cables. They are mostly for telecommunications equipment (e.g. Wi-fi devices, TV receivers) and are marked by reinforced mechanisms (e.g. braces) that enable high mating cycles. Registered jack (RJ) connectors are a standard, “modular” type of connector that is also located heavily within the telecommunications industry. Since they are mostly designed to facilitate data flow, they possess numerous conductors or contacts and only modest capacities for carrying electrical current. 8P8C connectors belong to this family and are found at the end of Ethernet cables.

- RCA Connectors

- By far the most commonly used audio connections. RCA connectors are used for coaxial and composite-video cables.

- Speaker Cable Connectors

- Provide secure, corrosion-free contact without the risk of fraying wires. Speaker connectors include banana plugs, binding posts, screw terminals, spades and spring clips.

- Universal Serial Bus (USB) Connectors

- Are a type of computer connection with a maximum data transfer rate of about 12 megabits per second. USB 2 is an upgrade to the original USB connector, offering a higher data transfer rate among other benefits. USB connectors (short for Universal Serial Bus) comprise a well-known set of device-to-device connectors. They appeared during the Information Revolution of the 1990s in order to facilitate connecting computers and other devices. They are designed for transmitting data as well as power. USB connectors possess a minimum of four contacts, which are flat and sturdily engineered to withstand frequent connections and disconnections. USB connectors are also equipped with metal shields and plastic molding for strain relief purposes. The most common type of male/female USB connectors fall into the USB-A category. Other categories of USB connectors are linked to differences based on size. Specifically, USB-B connectors are sturdier but larger types of connectors, while USB mini and USB micro connectors are designed for portable, compact applications (e.g. laptops, digital cameras, mobile phones). Today, various USB connectors can be found on and for all types of electronic equipment (e.g. printers, tablets, etc.).

- Wire Connectors

- Used to connect one or more conductive wires to various electrical circuits.

Caring for Electrical Connectors

Although most mechanical products require attentive care, electric connectors particularly require it. This can be largely traced to the type of connections electrical connectors are meant to establish: electrical and temporary. Electrical connections are prone to chemical threats (due to their dependence on metal) while temporary connections are prone to mechanical stresses (due to the frequent establishing and disestablishing of connections). Metal contacts in connectors can suffer from processes like soiling or oxidation. Depending on the type of connector, chemical threats can be even more pronounced due to the environment the connector operates in. For example, connectors on mobile devices or for hospital equipment can be exposed repeatedly to harsh natural environments or a plethora of chemicals for sterilization purposes. Frequent cycles of physically connecting and disconnecting male/female connectors wears out connectors over time via vibration, abrasion, etc. Since connectors vary so widely, best practices include closely following official care procedures (both preemptive and maintenance-oriented) for specific connectors as well as periodically reassessing the chemical and mechanical health of your particular equipment.

Choosing Connectors and Suppliers

When choosing a connector for your specific application, several factors should be taken into your analysis:

- Technical Specifications

- Connectors are carefully crafted pieces that rely on precision and customization. It is always important to make sure that different types of connectors can actually work with each other, since connector appearances can be particularly deceiving. One example of this is related to the pitch of connectors. Pitch refers to the distance between the centers of separate contact pieces on connectors (both male and female). If the pitch of a male and female connector is similar but not identical, then they will not be compatible.

- Performance Specifications

- Consider carefully the conditions you desire to use a connector under and select accordingly. Different connectors are designed to operate on different electrical currents, voltages, and temperatures. Other design aspects of connectors can affect performance as well. For example, a low pitch (i.e. low distance between the centers of contacts) may result in electrical interference (a phenomenon known as arcing in this context).

- Durability

- Mating cycles is an important term in connector terminology; it refers to the period of time a connector can reasonably be expected to last under normal usage (due to mechanical stress, etc.). This period of time is highly variable between different connectors. Consider how long you require a specific connector combination to last for your specific purposes and use data sheet information to select accordingly. For example, a permanent electronic installation that does not require frequent plugging/unplugging does not need connectors with long mating cycles.

- Versatility

- Since connectors are designed to facilitate temporary circuits, it is likely they will be used in contexts where the overall design or architecture of circuitry will change. Consider connectors that possess extra contacts and are adaptable to future changes in their mechanical environment.

- Because of the vast variety of electrical connectors, as well as the many different contexts in which they prove critical, it is important for manufacturers to make them easy to distinguish and assemble for consumers (as well as inexpensive). The vastness of the connector industry also highlights the importance of choosing a reliable custom manufacturer or electrical connector supplier who can provide critical input on the selection and application of specific connectors. When choosing a connector supplier, normal concerns such as a company’s business reputation, financial stability, commitment to state-of-the-art equipment, and such like should not be ignored.

Electronic Connectors Terms

- Action Pin Contact

- A style of contact that has a split pin which provides gas tight retention when used in conjunction with a printed circuit board.

- Angular Misalignment

- Loss at a connector resulting from the skewing of fiber end face angles.

- Back Mounted

- A type of configuration in which the connector is attached to the interior of a box or panel, along with its flanges for mounting.

- Body

- The largest or main section of a connector to which all other parts are attached.

- Bulkhead

- A connector that is inserted into a panel cutout from the component side of the panel.

- Center Fastener

- A fastening device located in the center of a pair of mating connectors. On one connector there is a threaded screw that attaches to the threaded bushing on its mating connector.

- Connector Plug

- A device that terminates an electrical or optical cable.

- Connector Receptacle

- The stationary half of a connection that mates with a plug. Connector receptacles are mounted on a panel or bulkhead.

- Contact

- An electrically conductive piece used in multi-circuit connectors.

- Contact Durability

- The number of withdrawal and insertion cycles a connector must be able to withstand, while remaining within performance levels of certain specifications.

- Dust Cap

- A device that is attached to connectors to provide protection from foreign debris and dust.

- Extraction Tool

- A tool that is used to remove a contact from a connector.

- Flange

- A projection that extends from a connector and contains holes for mounting a connector to a panel or mating connector.

- Guide Pin

- A device that provides alignment when connecting mating connectors. Guide pins also prevent contact damage due to the mismating of connectors.

- Holding Strength

- The capability of a connector to stay assembled to a wire or cable under tension.

- Interface

- The surfaces of a multi-contact connector that face each other while the connector is assembled.

- Jack

- A connecting mechanism into which a plug is inserted to make circuit connections.

- Jumper

- A short fiber optic cable that has connectors on either end.

- Loss

- The amount of signal power lost due to defects in connectors, splices or fibers. Loss is expressed in decibels (dB).

- Panel Mount

- A method used to attach a connector to a panel, board or frame.

- PC (Physical Contact)

- A term that refers to an optical connector whose fiber ends physically touch, which minimizes backreflection and insertion loss.

- Sealing Plug

- A plug that is used to seal unoccupied contact cavities. Sealing plugs are especially critical in environmental connectors.

- Withstanding Voltage

- The voltage that a connector is able to withstand for a minute without showing signs of electrical breakdown.