Electrical Discharge Machining

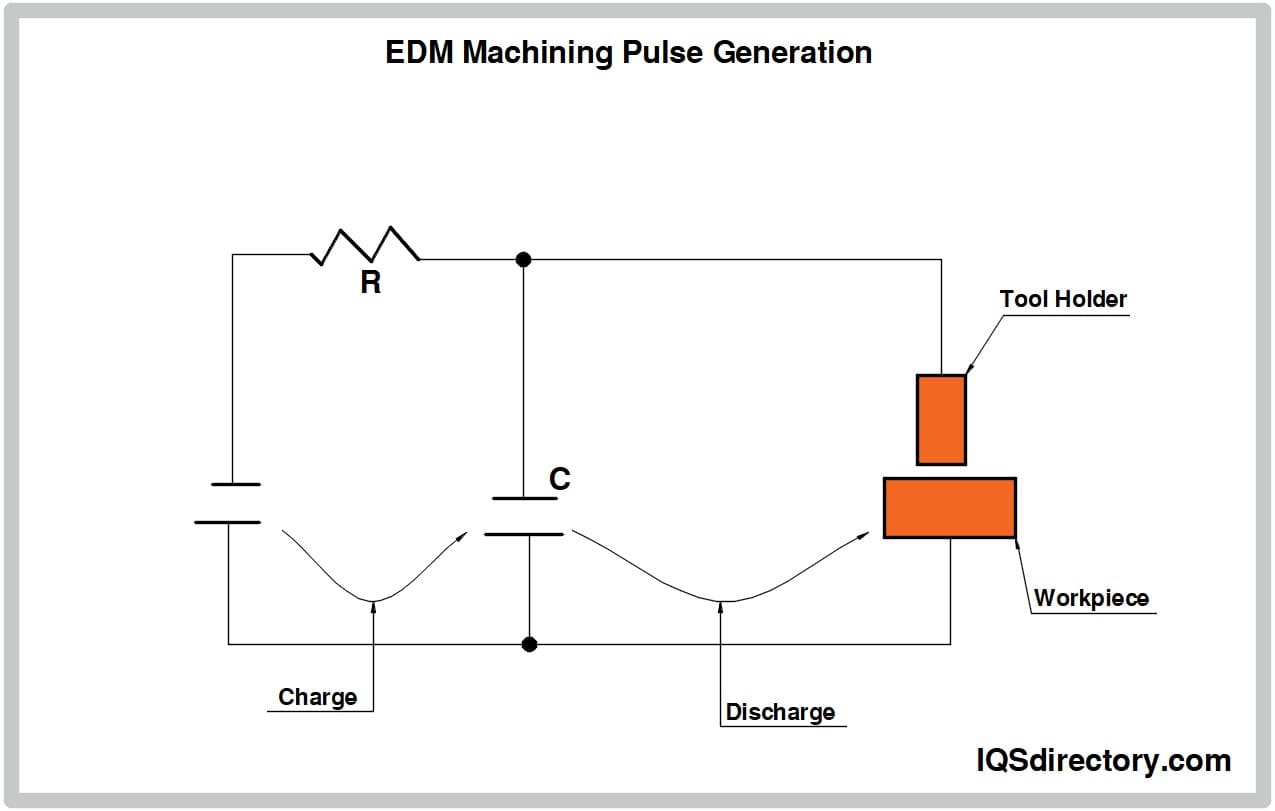

Electrical discharge machining (or EDM) is a simple manufacturing process in which electrical discharges are used to achieve a desired shape. EDM is also called many other names, like spark eroding, burning, spark machining, wire burning, wire erosion, and/or die sinking. In the EDM process, material is isolated from the work-piece by a sequence of quick repeating current discharges between two electrodes, divided by a dielectric liquid and prone to an electric voltage. Unless sufficient voltage is adjusted to help reach the ionization point, dielectric fluid will constitute an insulator when it converts to a conductor. Then the desired shape is formed by the spark discharge that corrodes the work-piece. Electrical discharge machines are normally grouped in categories: Die Sinker (RAM), Wire (Cheese Cutter), Hole Drilling (Hole Popper), but there are many different forms of EDM.

Quick Links to EDM Information

The History of EDM

Despite all types of EDM having particularly different history, applications, and methods, they perform on the identical principle of erosion by electrical discharge founded by Joseph Priestley in 1770.

- Die Sinker EDM

- Also known as RAM EDM and plunge EDM was independently invented and almost at the same time as someone else. In 1941, two inventors were placed with an assignment to find some way to try to boost tungsten breaker points' lifespan; these inventors were Russian inventors known as Boris and Natalya Lazarenko. They soon realized that it was possible to discipline a tungsten electrical contacts' erosion if they buried them in dielectric fluid. By 1943, their discovery soon refined a spark machining process based on this finding that ultimately became known as a resistor capacitor(R-C) circuit for EDM.

- During this time, Harold Stark, Victor Harding, and Jack Beaver, created an EDM machine for getting rid of broken drills and taps from aluminum castings. Originally, assembling their machines from feeble electric-etching tools, they weren't very rewarding. Stronger sparking units, linked with automatic spark repetition and fluid replacement with an electromagnetic interrupter arrangement made practical machines. Their machines were able to develop 60 sparks every second, largely increasing the cutting speed.

- Wire EDM

- Also known as Cheese Cutter EDM was invented practically a decade between the 1960s and 1970s as a new method for making dies from hardened steel. It was created in the Soviet Union, but later. Wire EDM that had the ability to follow lines from drawings were designed by Andrew Engineering. As the name indicates, Wire EDM will use a thin wire for an electrode. The wire shifts in a thoroughly organized pattern, analogous to a woodworker's scroll saw, which creates sparking to occur between the wire and the work-piece. The electrical discharge wears down by the wire and the work-piece, wire EDM machines use spools of wire that is steadily changing to pose a fresh discharge path in the cut.

Advantages and Disadvantages of EDM

There are many advantages to Electrical Discharge Machining:

It has the ability to create complex shapes that could be difficult to make with normal cutting tools.

- Provides a great surface finish.

- Electrical discharge machining solves the issue of hardness that is found in contact machining.

- The tool and work-piece have no contact in the process. Delicate materials and sections won't be damaged while being machined.

- Works well with small work-pieces. Normal cutting tools could damage parts from extra pressure.

There are a few disadvantages to Electrical Discharge Machining:

- It can be difficult to find expert machinists.

- There is a slow rate when it comes to material removal.

- Power consumption can be high.

- Making electrodes for RAM/Sinker could cause additional time and cost.

EDM Images, Diagrams and Visual Concepts

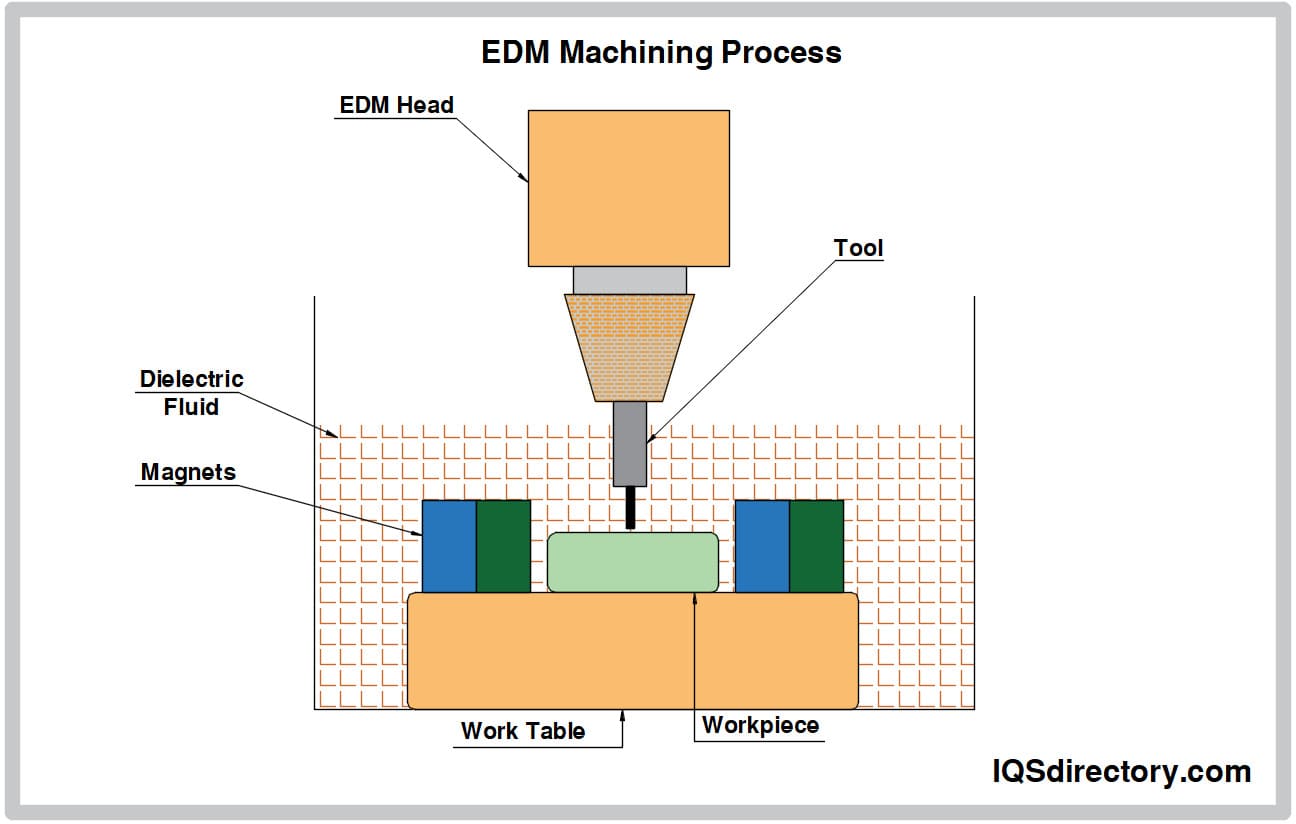

The basic funstions of an EDM machine to remove material using thermal energy.

The basic funstions of an EDM machine to remove material using thermal energy.

EDM machining process, the material is removed from the part to be machined and the electrode tool, the gap increases between the work and the tool, which must maintain a constant gap and arcing voltage to prevent a short circuit.

EDM machining process, the material is removed from the part to be machined and the electrode tool, the gap increases between the work and the tool, which must maintain a constant gap and arcing voltage to prevent a short circuit.

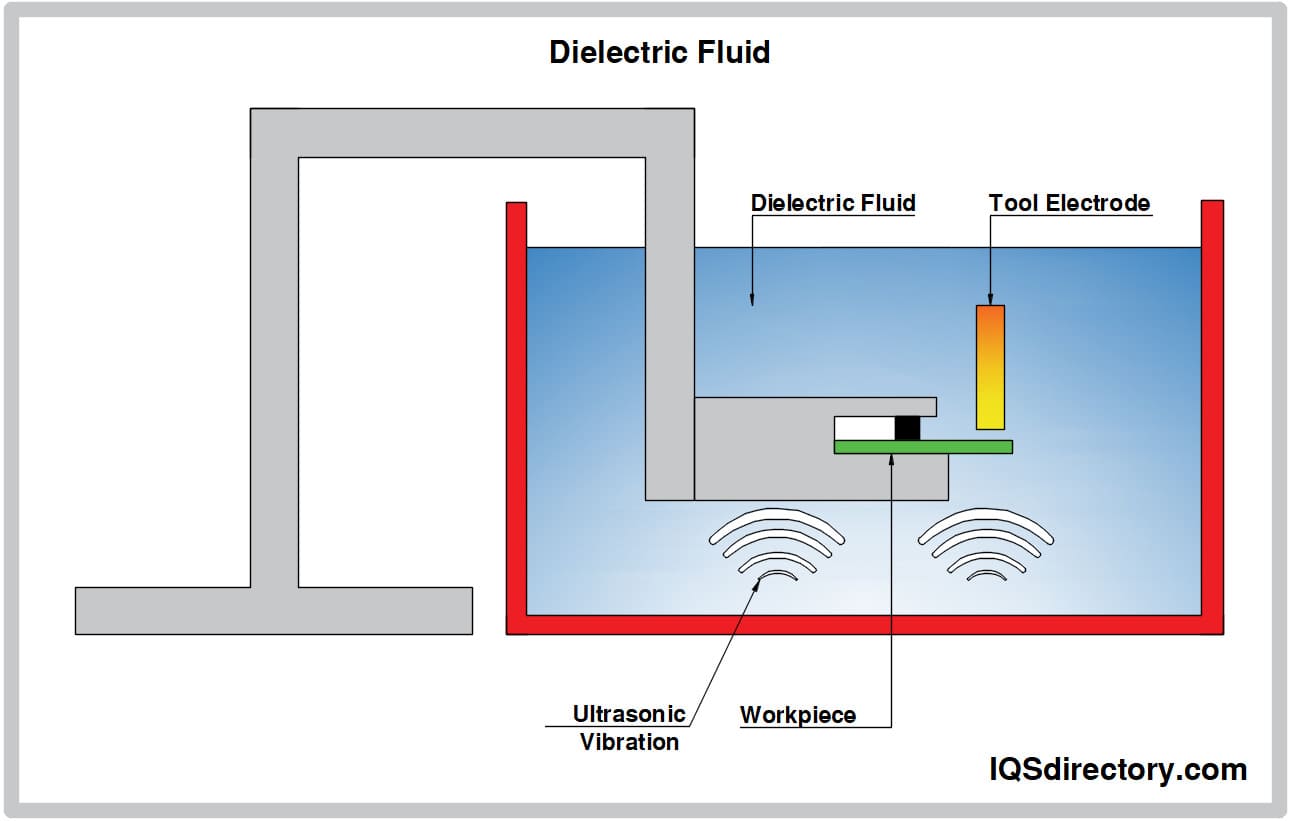

The different types of dielectric fluids are kerosene, paraffin oil, lubricating oil, transformer oil, or distilled water.

The different types of dielectric fluids are kerosene, paraffin oil, lubricating oil, transformer oil, or distilled water.

A proper circulation of the dielectric fluid at the gap that is between the workpiece and electrode tool in EDM machining.

A proper circulation of the dielectric fluid at the gap that is between the workpiece and electrode tool in EDM machining.

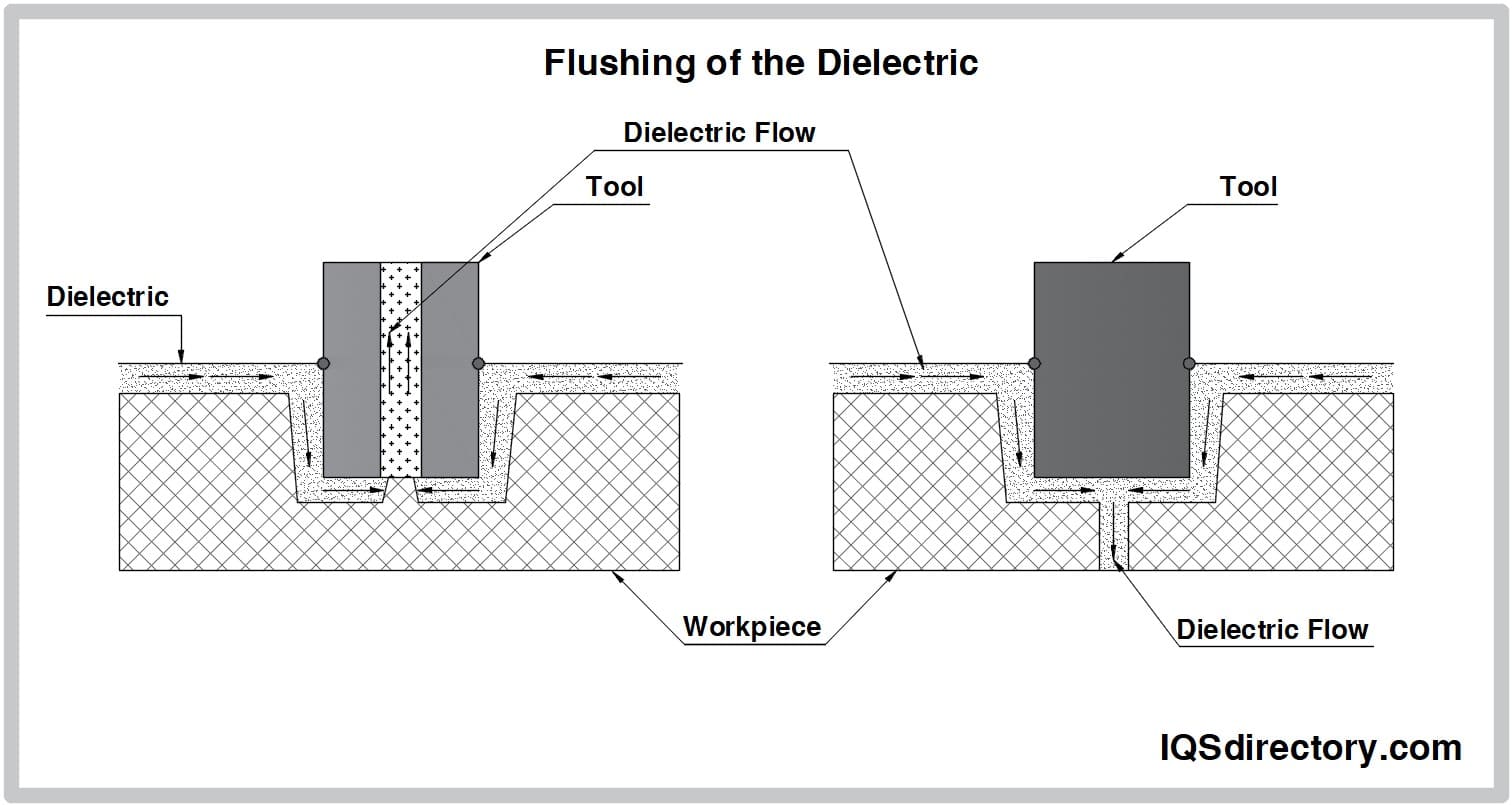

The tool and part machined, a spark is generated, in the presence of a dielectric medium, which removes material from the surface of the workpiece.

The tool and part machined, a spark is generated, in the presence of a dielectric medium, which removes material from the surface of the workpiece.

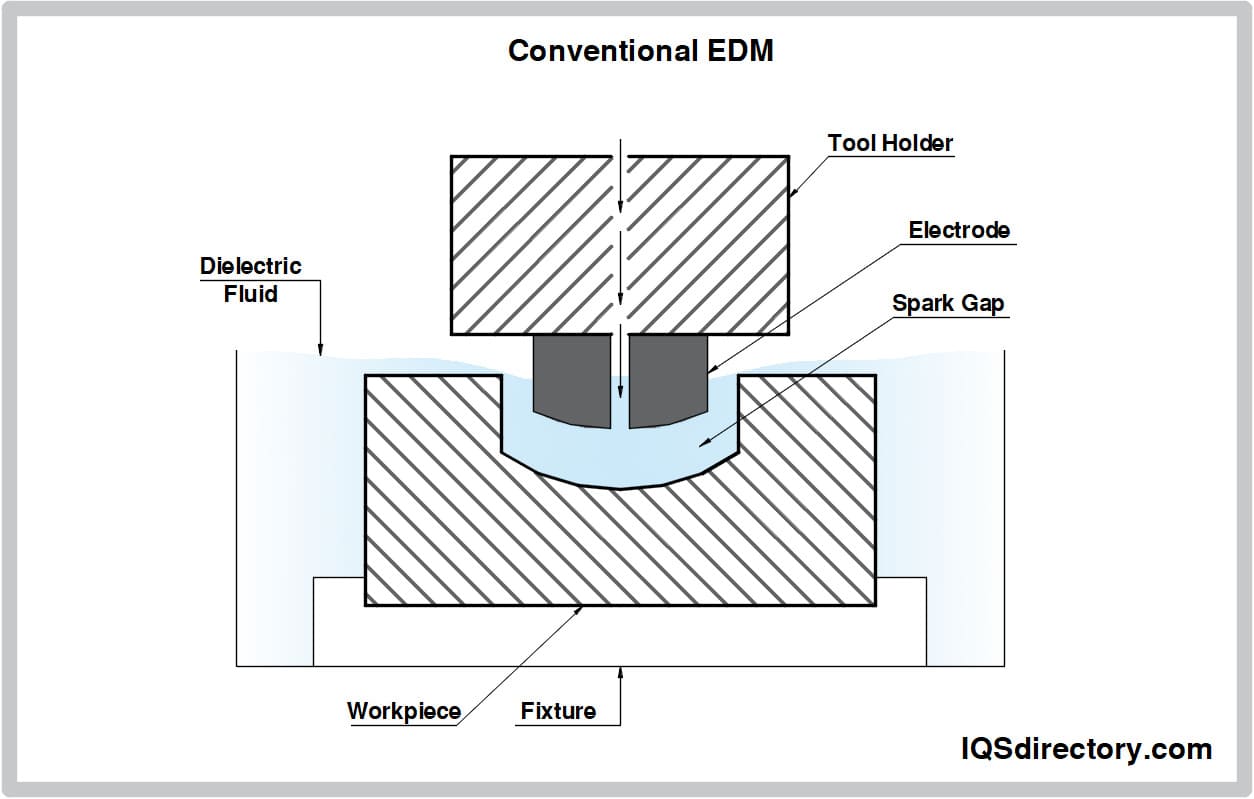

Conventional EDM makes use of machining to create a distinctive shape of an electrode, then sunk deep into the material to be machined.

Conventional EDM makes use of machining to create a distinctive shape of an electrode, then sunk deep into the material to be machined.

Wire EDM Machines uses deionized water to conduct electricity to cut through metal while preventing rust.

Wire EDM Machines uses deionized water to conduct electricity to cut through metal while preventing rust.

EDM Types

- Double Rotating Electrodes

- An EDM method that uses rotating electrodes to erode a revolving workpiece, creating different workpiece shapes by blending the comparative locations and angular velocities of the workpiece and the electrode.

- Electrical Discharge Grinding

- Uses a revolving electrically conductive wheel as the electrode tool for electrical discharge erosion. EDG is an alternative method for sharpening diamond and carbide tipped cutting tools, reducing the extreme cost of diamond grinding wheels.

- Electrical Discharge Machining

- Small hole processes use a tool electrode to gradually impress a mirror image of the electrode onto a workpiece.

- Micro Electrical Discharge Machining

- Miniature ram type machine that usually uses a diamond V-groove to spin the tool electrode up to 10,000 rpm. Electrode diameters as low as five microns are possible for the production of micro-holes and other shapes in thin, electrically conductive materials.

- Micro Wire EDM

- Use a tungsten wire electrode that has a diameter as small as 10µm to machine parts from .1 to 1 mm in size; the size of these parts makes it impossible to form them through normal semiconductor processes. These machines use a specially designed wire movement system, spark generator and monitoring system able to analyze and control extremely low energy levels.

- Sinker EDM

- Also known as plunge EDM and ram EDM, removes metal with rapid electrical discharges.

- Small Hole EDM

- Uses electrical discharges to create microscopic holes.

- Wire Electrical Discharge Machining

- A common EDM process that removes material with a wire electrode moving longitudinally through the workpiece. A CNC machine with special software maintains the movement of the wire electrode relative to the workpiece.

- Hole Drilling EDM

- The principal advantages of EDM make it fit for specific hole-making applications. If a pilot hole is already drilled in the work-piece, the wire can be threaded into it to finish the operation while using Wire EDM. Situations where this is not possible call for a particular EDM hole-making machine. The Hole Drilling EDM (also known as Hole Popper) uses a turning conductive tube for the electrode and a continuous flow of dielectric fluid to flush the cut. This EDM can be used to make the pilot hole needed for wire threading, as well.

EDM Applications

- Metal Disintegration Machining (MDM)

- There are many manufacturers that produce MDM machines for the purpose of getting rid of broken tools from the work pieces. The process is meant to only remove the center of the bolt or stud that is leaving the hole intact.

- Small Hole Drilling

- Can be used in many different applications. For wire-cut EDM, it is used to create a hole through hole in a work-piece in which you thread the wire for the wire-cut EDM operation. Another EDM head used for small hole drilling is braced on a wire-cut machine and allows big hardened plates to have complete parts torn apart from them as needed and without already drilling. This process is used to drill rows of holes in the beginning and ending edges of turbine blades that are used in jet engines. Gas flows through these small holes and that allows engines to use higher temperatures than normally possible. The process is also used to make spinnerets for synthetic fibers, and many other other applications.

- Coinage Die Making

- The coinage die making process can be used to create dies for producing badges or jewelry, and blanking or piercing. For this to happen, the positive master could be made from sterling silver, because the master is somewhat eroded and normally used only one time. After that, the negative die is hardened and is used in a drop hammer and produces stamped flats from cutout sheets.

- Prototype Production

- Most of the time, the EDM process is used by tool, mold-making, and die industries, but it is now becoming a very common method making prototype and production parts. Particularly in aerospace, electronics, and automobile industries where production quantities are low.

EDM Materials

It is known that any work-piece that will be machined with EDM is going to be electrically conductive, however, there are more limitations when it comes to material used for EDM. For example, certain materials, like high nickel alloys and carbide material can sometimes be a challenge for EDM. The solutions to these issues all depend on the variation of electrode material that is used and slower EDM cycle times.

EDM is a thermal process and has possibilities to change the metallurgy of a work-piece by zones affected by heat, micro-cracking, and recasts; although, electrical discharge machining is known to be a stress-free machining process. Some commonly used materials: Brass, copper, copper tungsten, EDM graphite, and others.

One of the most important factors to consider when choosing the electrodes is the material's resistivity and its erosion resistance.

Dielectric Fluid

A RAM EDM machine normally uses hydrocarbon oil for the dielectric fluid, so both the work-piece and spark are buried. Wire EDM usually uses deionized water, where only a sparking area is buried. It doesn't matter if it is oil-based or water-based, the dielectric fluid used in EDM machines serves three important functions: it regulates the spacing of a sparking gap in between the electrode and work-piece; it cools the hot material to make the EDM chips; takes away EDM chips from a sparking area.

Overtime, the dielectric fluid breaks down due to age or contamination. When this happens, the possibility of unsteady discharge rises. Control electronics can satisfy it to an extent, but the only true solution is to constantly pump clean dielectric fluid through the cutting zone in order to flush it. It becomes more difficult for a machine to keep stable electrical thresholds in the sparking gap when more conductive particles are in the fluid.

The dielectric fluid lifespan depends on different factors, like the type, quality, and efficiency of your EDM fluid filters; there is no specific expiration date. However, you should replace an oil-based fluid if it is over five years old. The best way to figure out if your fluid should be replaced is by using a refractometer.

In order to choose the correct dielectric fluid requires many principles that should be taken into account: the degree of metal removal and electrode wear, and particle suspension, and more.

Things to Consider When Choosing EDM

Obviously, there are other ways to cut parts. When compared to conventional machining, electrical discharge machining has some advantages and disadvantages. When trying to decide if this process is the best for you, it all depends on your application.

Some simple electrical discharge machining features can help you decide if you should choose this machining for your material. It can usually be a little slower than some other machining methods, while also being more accurate and predictable.

- Considering Design

- If possible, relax the surface-finish for the part; which gives manufacturers the chance to make the part with less passes, with a high metal metal-removal rate and high current level.

- Design or prepare the part that the amount of stock removed by machine is very small. Use traditional techniques to get rid of a bulk of the stock with the finishing operations performed by machine. This incredibly reduces the cost and the time for every part.

- The manufacturer possibly could consider fixtures, like many parts can be stacked and machined all at the same time or one part can have many electrical discharge operations performed all together.

- When existing holes are supposed to be bigger or are being reshaped by the machine, going through holes are preferred rather than blind holes, because they allow easier flow of dielectric fluid through the area that is being machined.

- Considering Manufacturers

- As many manufacturers grow and expand their company, they are taking full advantage of the new machinery that is going to help their business succeed. The electrical discharge machining is a process that is not always mentioned, but learning about the many uses it offers can help it become more popular.

- You should find a contract manufacturer that has much experience and they should have some very popular opinions when it comes to their superior customer service. You want a manufacturer who is confident in doing the job and makes sure they do the job to fit the customer's liking.

- Even though the equipment needed can be quite an investment, the company should be investing money into their EDM equipment and machines. Look for manufacturers who are going to provide you with quality and precision.

EDM Terms

- Altered Metal Zone

- A mechanically altered zone on a metal surface that is created by the EDM process.

- Billet

- An uncut block of graphite provided by a manufacturer.

- Burning

- Slang term for the EDM process.

- Capacitor

- An electrical unit that stores electricity.

- Center Flow

- Dielectric fluid that is pumped through the workpiece or electrode for flushing purposes.

- Crater

- Small holes on the workpiece surface left over from the EDM sparks, also referred to as pits.

- Dielectric Fluid

- A non conductive liquid that fills the space between the electrode workpiece and insulates it until the needed space and voltage are reached. At that point, the fluid ionizes, becoming an electrical conductor, and causes the current or spark to flow to the workpiece; it also cools the material and flushes away the particles produced by the spark.

- Diametrical Sparking Distance

- The difference in size between the electrode and the size of the crater the electrode makes.

- Discharge

- The spark in the electrical discharge machining process.

- Edge Finder

- An apparatus initiated by electricity that helps accurately locate the workpiece in relation to the electrode. When any part of a workpiece comes to within about 0.0001 inches of any position alongside the electrode, a buzzer or signal light will alert the operator.

- EDM Drilling

- A specialized tooling process that creates holes in metal parts and products by using electrical energy in the form of sparks to erode the metal.

- EDM Machining

- Uses electrical energy to shape and form metal parts.

- Electrode

- The tool used in the EDM procedure, which must be made from an electrically conductive material. The shape and form of the electrode is a mirror of the completed shape desired in the workpiece with dimensional compensation for the overcut.

- Eroding

- The elimination of material through electrical discharge machining.

- Finish

- The surface texture in the EDM process, usually expressed as min Ra (U.S.).

- Finish Cut

- The last cut done on a workpiece. The finer the finish preferred, the more time the finish cut will take, so the rough cuts should be planned to leave just the material the finish cut will remove in order to attain both the final size and finish needed.

- Flushing

- The forcing of dielectric fluid through the gap for the removal of detritus resulting from EDM.

- Gap Voltage

- A measurement of the voltage at two different points in one complete cycle. The open gap voltage is the voltage read across the electrode and workpiece space prior to the spark; the working gap voltage is read across the space as the spark current discharges.

- Graphite

- One of four types of carbon, used for electrode material because of its high resistance to heat. Graphite is the most common electrode material and the simplest to machine.

- Heat Affected Zone (HAZ)

- The layer below the recast layer. Its metal properties change due to the increased heat exposure.

- Off-Time

- The time between the sparks in the EDM process.

- Overcut

- The variation between the size of the electrode and the size of the cavity since an EDM crater is always bigger than the electrode machining it. There are two different types of overcut to take into consideration: total overcut, also known as diametrical overcut (the most common), or overcut per side.

- Peak Current

- The highest amount of current that is available from every pulse of the power supply.

- Recast Layer

- A layer that results from melted metal solidifying on the surface of the workpiece.

- Roughing (Hogging) Cut

- An EDM method that eliminates the most material in the least amount of time.

- Spark

- The electrical discharge between two conductors.

- Spark Gap

- The space between the workpiece and the electrode at the point of discharge.

- Spark Intensity

- The energy that is contained in each spark.

- Surface Finish

- Comparative smoothness or coarseness of a machined workpiece surface, typically measured in min Ra in the U.S.

- Wear

- Erosion the electrode undergoes during the EDM process.

- Workpiece

- Any metal part to which an electrical discharge machining process is applied.