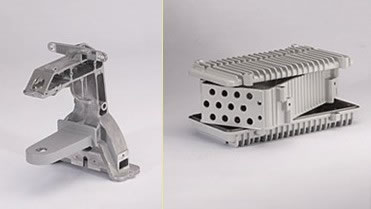

Aluminum Casting

The term "castings and forgings" refers in general to those metal items made in foundries and forges, respectively. Examples of castings and forgings include: automotive crankshafts, bearing caps, axle carriers, axle tubes, valve bodies, turbine housings, splines, suspension brackets, spring hangers, flanges, gear blanks and more.

Foundries and forges are both facilities in which whole metal parts are made, though they do so using very different techniques. As implied, foundries are used to make castings, while forges are used to make forgings. However, because the casting and forging products can be so similar, people often incorrectly refer to forges as foundries. Read on to understand the difference in their respective processes.

To make castings, which have mid to high tolerances, manufacturers use closed molds, high pressure, high heat and molten metal. During casting, manufacturers heat metals until they are molten and then pour them into dies or molds, where they take on that vessel‘s shape. Techniques manufacturers in forges use include hot and cold hammering and stamping of solid metal pieces. In other words, castings are made through the manipulation of molten metal, while forgings are made through the application of mechanical and thermal energy on solid metal.

Casting processes can be divided into categories including: permanent mold casting, grey iron casting, sand casting, rapid casting, investment casting and die casting. Forging processes can also be subdivided. Some of their categories include: hot forging, warm forging, cold forging, drop forging, open-die forging, impression forging and press forging.

All sorts of metals can be cast and forged. Metals that are typically used in both casting and forging include: steel, stainless steel, iron, aluminum and titanium. Materials used more exclusively in casting include: magnesium, copper, tin and zinc. In addition to regular metal casting, the casting process can also accommodate plaster, plastic resin, concrete and other chemical curing materials.

Castings and forgings each have their own sets of pros and cons. For example, while forgings are typically limited in size and weight, there is virtually no limit on the potential size or weight of castings. In addition, the casting process allows for the creation of much more complex and intricate parts. Also, because metal is molten during casting, it is much easier for manufacturers to add extra metals to the mix as they create new parts. So, castings are often made from custom alloys. This is rarely the case of forgings. Nevertheless, the process of forging allows manufacturers to create parts with tight grain structures. Because these grain structures give the forgings very high levels of wear resistance and mechanical strength, they are often just as strong as super expensive alloys. Also, forgings avoid several problems faced by castings, including: cavities, porosity, shrinkage and cold pour issues.

It's hard to say whether castings or forgings are cheaper in the long run, as the processes used to make each have their advantages and disadvantages. For the best advice, we recommend that you consult with an experienced casting and forging sales company or manufacturer.

Formed in foundries via a process with the same name, die castings are solid metal parts and shapes. Die casting works fairly simply. First, manufacturers heat metal until it is molten. Then, they force this molten metal into hollow forming shapes called dies, molds or die molds. Dies are cut from a hard metal like steel. Closed dies, which are used most often, are made when manufacturers cut an original die into two separate blocks, tool them back together with their cavities aligned and then spray the joined pieces with a lubricant. (The lubricant makes parts removal easier and helps regulate temperature.)

Formed in foundries via a process with the same name, die castings are solid metal parts and shapes. Die casting works fairly simply. First, manufacturers heat metal until it is molten. Then, they force this molten metal into hollow forming shapes called dies, molds or die molds. Dies are cut from a hard metal like steel. Closed dies, which are used most often, are made when manufacturers cut an original die into two separate blocks, tool them back together with their cavities aligned and then spray the joined pieces with a lubricant. (The lubricant makes parts removal easier and helps regulate temperature.)

While in the die, manufacturers apply a high pressure that helps force the metal to conform to the shape of the die. Once it has satisfactorily taken on said shape, manufacturers allow the metal to cool and harden. Sometimes, they follow the die casting process with secondary processes aimed at improve the quality of the casting in some way.

Typically, manufacturers perform die casting using one or more non-ferrous metals. Such metals include aluminum, bronze, copper, lead, magnesium, tin and zinc. While they can use steel as well, steel and steel alloys are usually reserved for the forge. Learn more about die castings.

Forgings, or metal forgings, are metal parts that are formed via the forging process. Forgings serve as important elements of many different vehicles and machines, such as: tractors, automobiles, airplanes, engines, missiles and material handling equipment. Forging is a popular process because it allows for design flexibility while it consistently yields extra strong parts with very few defects. In addition, forgings rarely require secondary processing.

Forgings, or metal forgings, are metal parts that are formed via the forging process. Forgings serve as important elements of many different vehicles and machines, such as: tractors, automobiles, airplanes, engines, missiles and material handling equipment. Forging is a popular process because it allows for design flexibility while it consistently yields extra strong parts with very few defects. In addition, forgings rarely require secondary processing.

During forging, manufacturers use a compressing force to pressure metal to undergo plastic deformation and an alteration of its grain flow. This compressing force is delivered via a hammer and anvil.

There are two main forging methods: closed die forging (or impression die forging) and open die forging. Of these two, closed die forging is the most common. During closed die forging, manufacturers use the hammer and anvil to hammer preformed metal blanks (called ingots) into a die or set of dies. These dies serve as 3D negatives of the part that will be forged. To ensure thoroughness, the hammer and anvil completely cover the workpiece. This forces the metal to spill into all of the areas of the die.

Note that, during forging, manufacturers may preheat metal, but they never melt or pour it. Learn more about forgings.

Grey iron castings are castings produced in foundries from an iron alloy called grey iron. To get grey iron, metalworkers first mine iron ores and iron oxides. Then, they process them in a special kind of blast furnace called an electric induction furnace or cupola. To count as grey iron, the alloy must be 95% iron by weight, 2.1 to 4% carbon by weight and 1 to 3% silicone by weight. Sometimes, elements like manganese and/or sulphur are added to the mixture to alter its properties. Its variable properties include color, melting point, energy dissipation, thermal conductivity, resistance to wear and resistance to deformation. Grey iron is named after its graphite-gray coloring, which can be seen when it fractures. More than likely, this gray comes from the silicone. (Silicone produces graphite when it is heated.) The exact appearance of grey iron is determined by temperature and timing, as are most of its other properties.

Grey iron castings are castings produced in foundries from an iron alloy called grey iron. To get grey iron, metalworkers first mine iron ores and iron oxides. Then, they process them in a special kind of blast furnace called an electric induction furnace or cupola. To count as grey iron, the alloy must be 95% iron by weight, 2.1 to 4% carbon by weight and 1 to 3% silicone by weight. Sometimes, elements like manganese and/or sulphur are added to the mixture to alter its properties. Its variable properties include color, melting point, energy dissipation, thermal conductivity, resistance to wear and resistance to deformation. Grey iron is named after its graphite-gray coloring, which can be seen when it fractures. More than likely, this gray comes from the silicone. (Silicone produces graphite when it is heated.) The exact appearance of grey iron is determined by temperature and timing, as are most of its other properties.

To produce a grey iron casting, manufacturers follow standard casting processes. Grey iron castings are known for their strength and durability. Some of the industries in which they are used include: ventilation, architecture, transportation, agriculture, irrigation, automotive manufacturing, machinery construction, construction, transportation and electronics. Learn more about grey iron castings.

Investment casting is an industrial manufacturing process used to create exceptional detailed and complex industrial shapes and parts. It is derived from lost-wax casting, one of the oldest known metal-forming techniques.

Investment casting is an industrial manufacturing process used to create exceptional detailed and complex industrial shapes and parts. It is derived from lost-wax casting, one of the oldest known metal-forming techniques.

To begin the process, manufacturers create a wax model of the part that they want to create. In the end, this wax model will be a mold. Once they‘ve created the wax model, they attach it to a sprue. If they so choose, they can attach literally hundreds of these wax models to the same sprue. This is called a tree. Once they have done this, manufacturers dip the tree into a slurry compound. They do this several times before they sprinkle the tree with a sand-like abrasive material. This is called the investment. Once the investment is thick enough, manufacturers place it in an industrial oven, where they heat it to temperatures upwards of 1000 degrees Fahrenheit. This step melts the wax but keeps the investment intact. This investment serves as a hollow mold. To use the mold, manufacturers fill it with molten metal. They allow it to harden and cool and then they remove the shell and cut of the cast metal parts of of the sprue. Learn more about investment castings.

Sand Casting, or sand metal casting, is a process using sand as the molding material to produce metal castings. The term is also used to refer to the products produced by this process. Metals cast using the process include tin, cast iron, aluminum and steel, as well as copper and bronze. Sand casting is used to produce over seventy percent of all metal castings, some of these include metal tools, car parts and plumbing. These castings are produced in specialized foundries and factories, and the process is considered an economical option because it requires less technology and cost. Learn more about sand castings.