Balers

Balers are machines used to compress and bind different types of material into bales using binding materials like twine.

A note on the differences between "balers" and "compactors":

Balers and compactors are often sold by equipment manufacturers as identical or similar products. However, while compactors and balers do very similar work, their functions in industrial manufacturing and commercial retail are slightly different. The primary function of balers in industrial manufacturing is to compact and bind, or "bale" recyclable materials. Compactors are also used at times to compact recyclable materials, but they are primarily used to reduce waste via compaction. Despite these differences, you will hear the terms “baler” and “compactor” used interchangeably quite a lot.

Quick links to Balers Information

The History of Balers

Modern balers are descendants of the hay presses, invented in the mid-nineteenth century, in order to make it easier and more efficient to gather and stack hay. Most of the earliest hay presses were stationary units built into a barn and extending two to three stories into the hayloft. Typically, they worked using a team of horses that raised a press weight, then dropped it to compress the hay. Others used horse or mule-powered sweeps at the press bottom geared press or jackscrew. Before this, farmers and farm hands had to collect and stack hay by hand and with tools like rakes. Stationary hay presses led to portable hay presses.

The first mobile, man-powered (as opposed to horse powered) hay baler was invented in the 1860s. It required the participation of several workers. Throughout the late 1800s, inventors continued to improve the baler, making some that could work with just one person and other plungers. The b aler market lacked a consistent, standard model for several years, and did not stabilize until after the turn of the twentieth century.

The 1900s saw the rise of the mechanical baler, and in 1936, the first automatic baler, the round baler, was invented by a man named Innes. It featured a self-tie system that used Appleby-type knotters from a John Deere grain binder. In 1939, a man named Ed Nolt patented a modified version of this baling machine, which was more reliable. This model became the standard, and the round baler continues to be the most common type of baler used today.

From the hay baler came the industrial baler, which is used to compress and bind all sorts of waste material, particularly foil, cans, and paper products like paperboard, office paper, and newspaper.

As recycling becomes more central to industrial and manufacturing processes, baling and compacting equipment will play a large role in assisting the process of reducing the carbon footprint of the industry. Complete turn-key recycling and composting systems can be designed around a basic baling machine, allowing businesses to be environmentally responsible in their waste management.

How Balers Work

To work, workers manually feed or use automated systems to feed material in the bailer input area. Note: because bailers usually deal with high density volumes of bulk material, this input area is usually quite large. From the input area, the material is fed into a compression chamber, also known as the main cylinder, where scrap or waste material is pounded and squeezed until it is in a compact shape. Then the waste is bound in order to maintain the compact shape. The machine then automatically binds the compressed material using tightly wound wire, plastic or string.

Most industrial balers are powered by electricity; both types of balers use hydraulic systems to move the material, cutting back on energy expenditure and heat generation.

Balers are unique in that they are the only type of equipment out there on the market designed to compact and bundle material. They are essential tools that cannot be replaced with a viable alternative.

Baler Uses

Balers are used as a way to improve ease of handling, transportation to landfills or recycling plants, storage, or recycling of various materials. In addition, reducing the bulk of the waste reduces the money and effort required to dispose of it, leading to the company saving over time. Furthermore, using balers and compactors to reduce the waste cuts down the carbon dioxide emissions required in the process of recycling and further helping the environment. They are essential in the industrial, retail, consumer, waste management, recycling, and agriculture sectors.

In industrial, retail, and consumer sectors, including automotive manufacturing, plastics manufacturing, and food service, balers compress waste or byproducts. In farming and agricultural sectors, balers are used to compress harvested crops for purposes of transportation or feeding. Balers can press and bind virtually any material, including garbage, plastic, scrap cloth, and many other materials.

Benefits of Balers

Balers are important pieces of equipment in a wide range of industrial facilities. They play a huge role in waste management, saving companies time and money while also making recycling easy and minimizing trash that ends up in landfills.

- Baler Efficiency

- Efficiency is one of the biggest advantages of using balers. Average balers and compactors are able to pack around 10 cubic yards of trash or cardboard into 1 cubic yard. This means dumpsters or trailers can hold ten times the amount of trash as they would without such equipment. It also means employees will take fewer trips to receptacles (trips which are distracting and time-consuming) and fewer trips transporting trash or cardboard from your facility; that means big savings.

- Improved Workplace Environment

- Balers create a cleaner workplace, which in turn boosts employee morale. Higher morale equals increased labor efficiency and productivity, making for a better overall customer experience.

- Baler ROI

- Businesses can expect to see a quick investment return when they purchase a baler or compactor system.

- Sustainability of Balers

- Balers allow businesses to dispose of their waste in an environmentally responsible and sustainable way. In fact, complete turn-key recycling and composting systems can be designed around a basic baler. Furthermore, baled materials can be reused in the production of new objects. For example, scrap metal can be transported more efficiently to a factory where it can be recycled into new sheet metal and reused. In other instances, a baled material can be used in a different industry such as the use of fibers created from newsprint to be used in the production of shoe soles.

- Proper Care for Balers

- Keep your baler clean. Don’t even allow dust to build up, as dust can insulate and cause a rise in system temperature. Along those same lines, make sure that your system motors are cool and not in danger of overheating. Also, set up a maintenance schedule, according to the recommendation of your supplier, and inspect your baler often. Inspect cylinders, fluid levels, fluid temperatures, hoses, filters, conveyor parts, cooling devices, electrical components, etc.

- To improve usage, always make sure that your motor kW (kilowatt) speed stays steady. Don’t run it too fast or it could jam, clog, or even break. Anticipate your machine’s needs by maintaining an inventory of spare parts, so that you can quickly replace any components that fail.

Design of Balers

Balers typically consist of parts such as hydraulic cylinders, wheels, and arms. To produce a baling machine, manufacturers begin by cutting sheet metal. To cut it to size, they may use any number of processes, including punching, blanking, laser cutting, and shearing. After that, they take bar stock, used for frames, shafts, arms, etc., and cut it as well. After cutting the bar stock to length, they drill, punch, or mill holes and slots as needed. After this, they take various pieces and weld them together, typically via a robotic welder. Next, they clean and paint the welded pieces, and assemble, adding specific components where needed. Once that’s done, they go back through and add things like oil, tires, bearing grease, and warning labels. Finally, they inspect the baler machine and make any necessary adjustments to make sure that it’s up to snuff.

Balers are made up mostly of structural steel and sheet steel, which can be acquired from bar stock, sheets, or in rolls. The belts are made of nylon and polyester.

Balers come in several forms, each producing a different type of bale, either cylindrical or rectangular, of various sizes, bound by twine, strapping, netting or wire. Some balers are stationary, while others can be pulled behind a towing vehicle, like a tow truck or a tractor. The design of a baler varies greatly depending on its intended application. Hay balers, for example, have tines to move the hay and hydraulic arms to compress it, whereas many others do not. In addition, balers used with crops often have chopping features (lengths measured in millimeters (mm)). Chopping lengths vary widely, from around 14 mm or 20 mm to upwards of 100 mm. In addition, baler manufacturers offer a myriad of custom baler options, especially related to size. Smaller bales are lighter and easier to transport but the process of creating smaller bales will slow down the overall compression application. Customized balers may be worth it, in terms of long-term expenditure, if a specific size is required for transport or storage purposes. Industries that may benefit from customized sizing include restaurants, retail facilities, and warehouses to compact boxes, food scraps, and excess packaging waste.

Balers Images, Diagrams and Visual Concepts

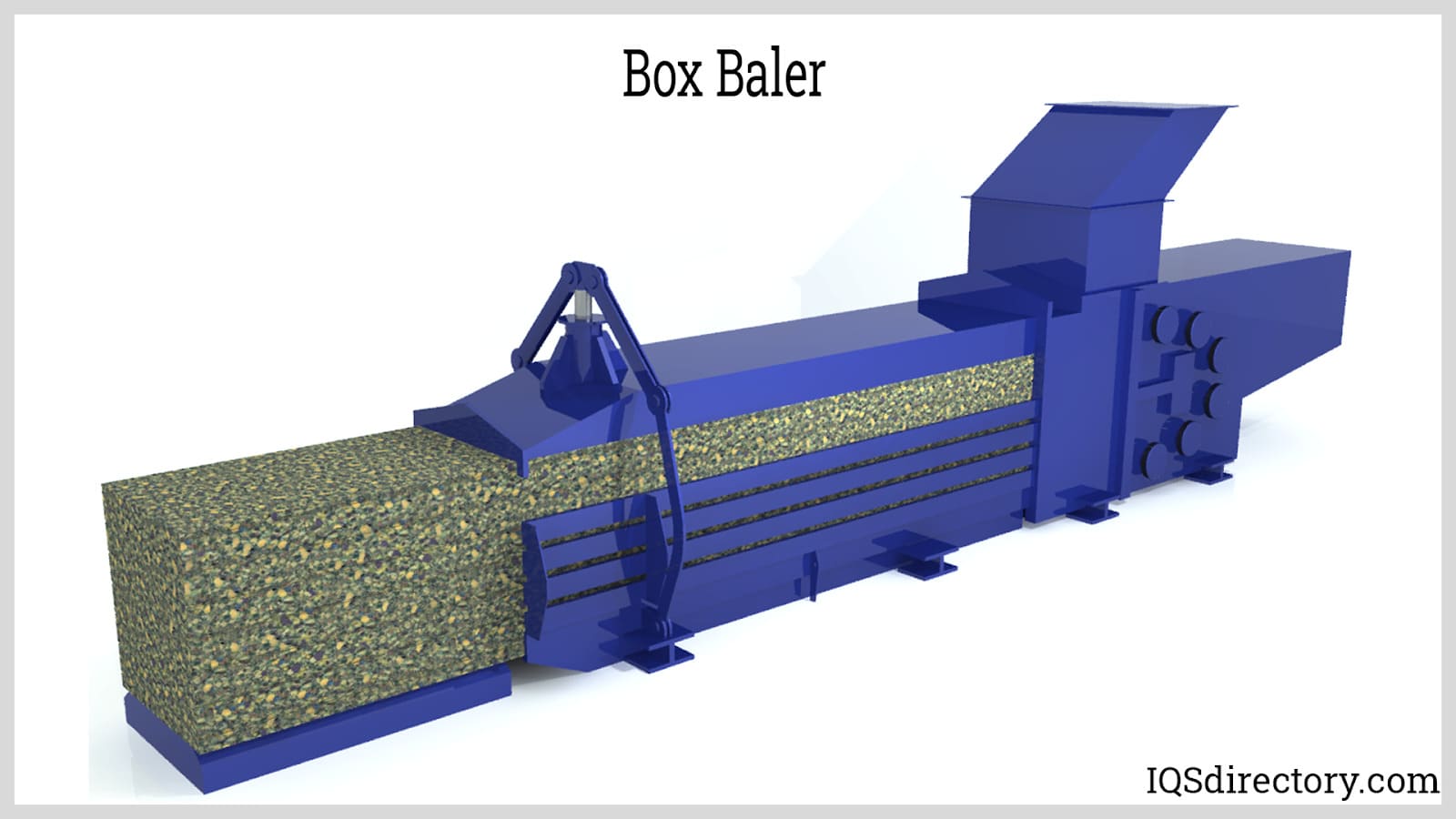

A compacting device which converts materials into rectangular bales.

A compacting device which converts materials into rectangular bales.

Converts textile material into bales for hauling and transportation efficiency.

Converts textile material into bales for hauling and transportation efficiency.

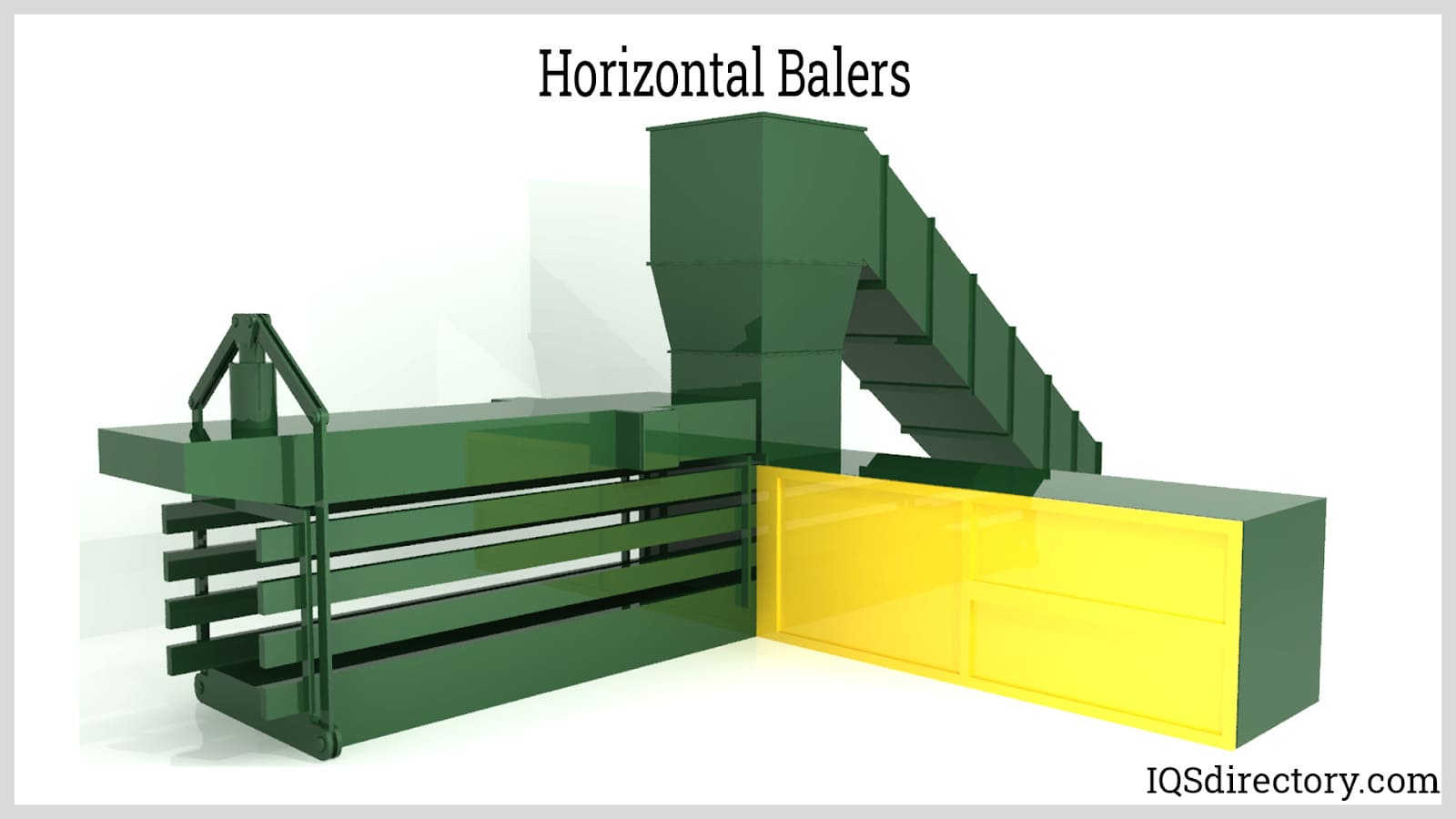

A baler that uses horizontal force to compress the materials.

A baler that uses horizontal force to compress the materials.

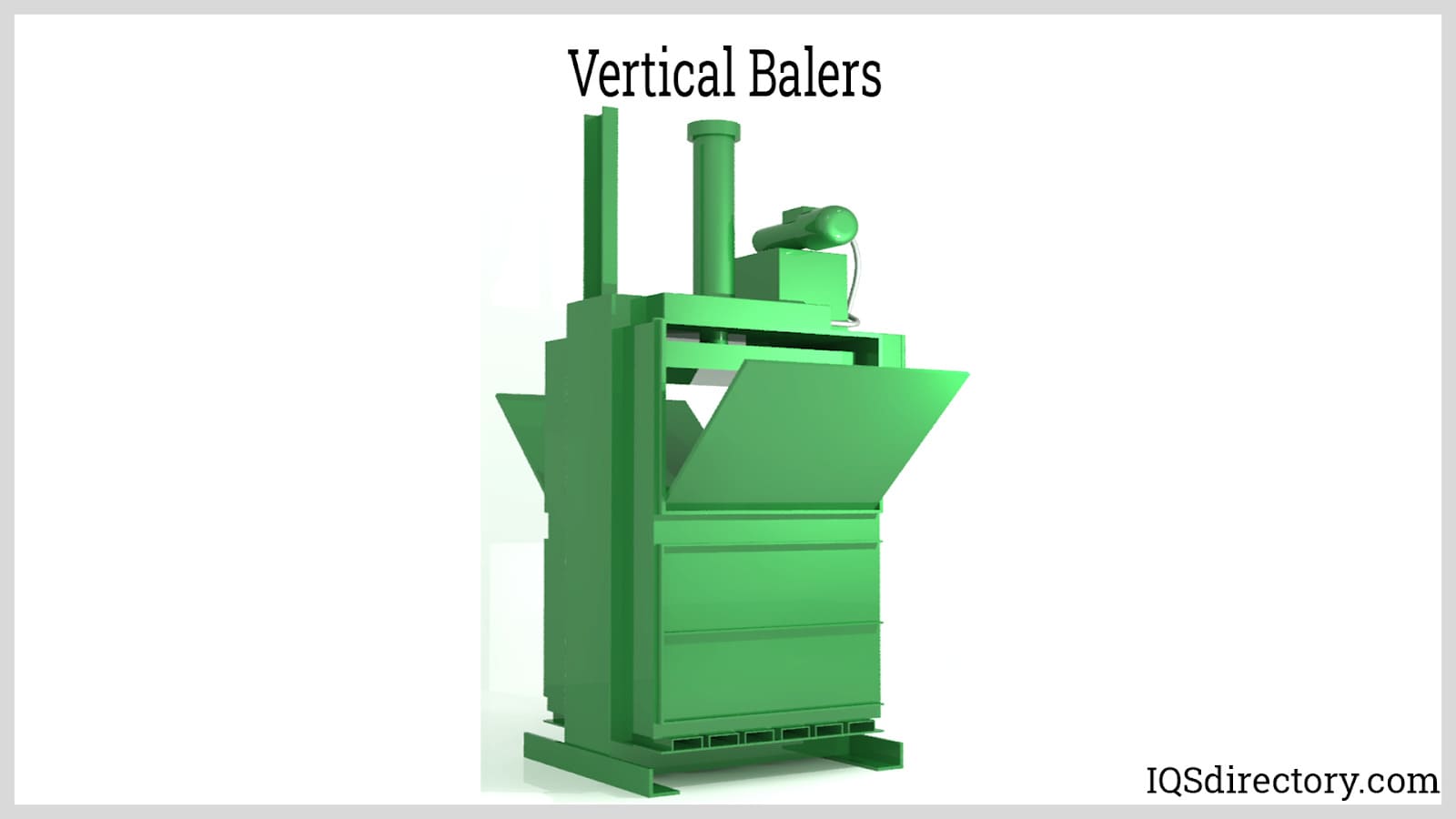

A baler that compresses materials by using vertical downward force.

A baler that compresses materials by using vertical downward force.

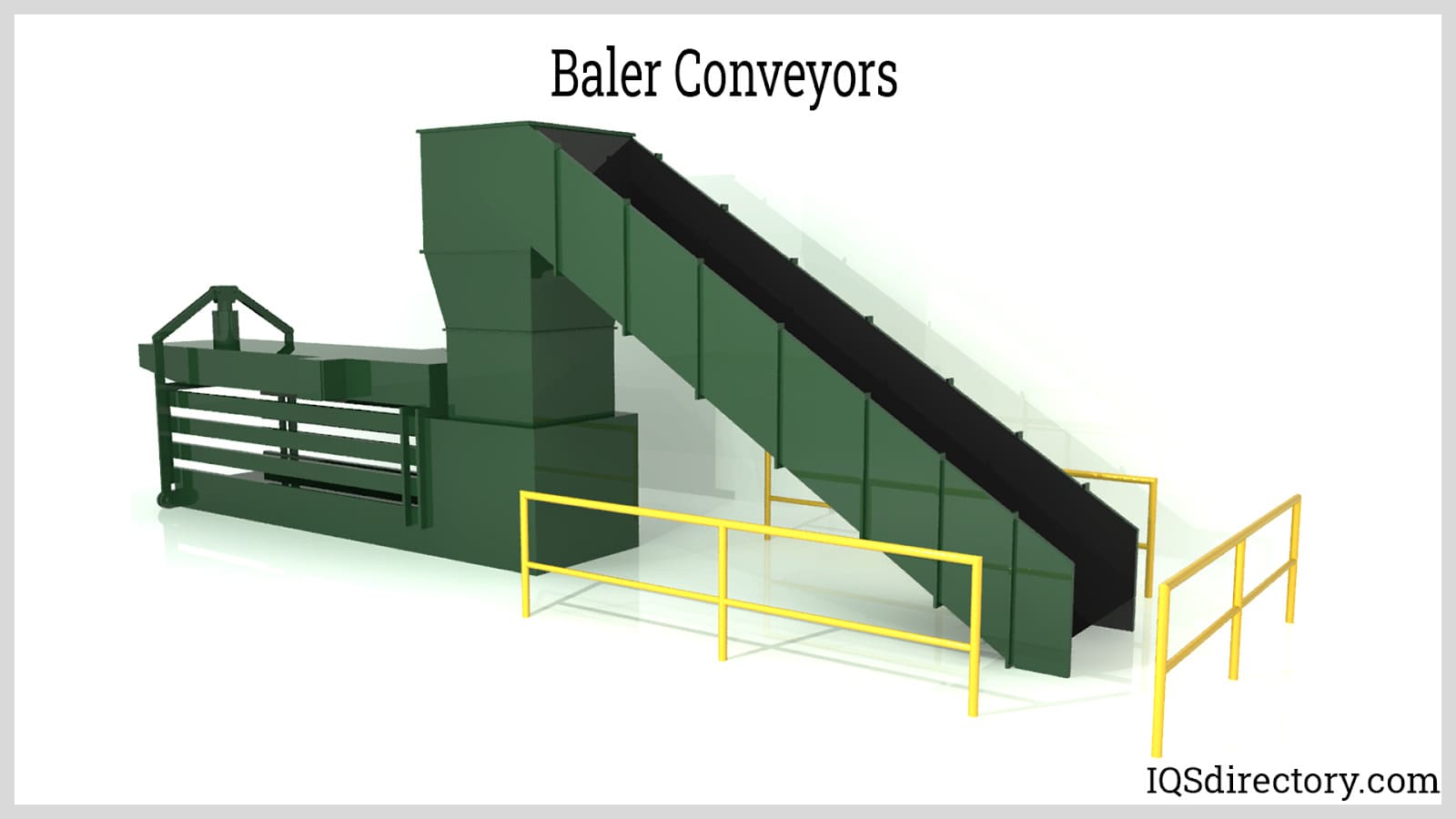

Baler conveyors are used for material feeding at a lower elevation.

Baler conveyors are used for material feeding at a lower elevation.

Types of Balers

- Vertical Balers and Horizontal Balers

- Depending on the intended application of a baler, there are two main structure types to choose from: vertical (also known as downstroke) and horizontal. Vertical balers are those that are loaded from the top, and vertical refers to the direction in which material travels in the baler. Vertical balers are often single load machines for material that is lighter in density and volume such as cardboard or plastic, and they need to be manually unloaded when the compaction process is complete. These are usually used for smaller waste reduction processes in facilities that do not produce large quantities of scrap. Vertical balers are typically more compact than horizontal balers and are available at relatively low-costs.

- Horizontal balers are designed for continual use and come with automated feed options but can also be hand-fed or mechanically fed. While horizontal balers take up more floor space, they have the advantage of increased load capacity and are able to compact materials such as cans, plastic containers, papers, and secondary fibers. Smaller vertical balers may require pre-shredding of materials, but horizontal balers are able to successfully compact most materials from food scraps to old vehicle tires without additional processes. Industries such as automotive or packaging use horizontal balers to make the process of removal and transportation easier.

- Heavy Duty Balers

- For use with waste products that require a lot of pressure in order to be compressed. Sometimes, this type of baler is referred to as a baling press or, when working with drums, a drum crusher. Baling presses usually have a bin, which collects materials, and a large plate, which comes down onto the material compressing it. Then, it is baled and ejected.

- Round Balers

- Used mainly for agricultural purposes, such as creating hay bales. When used to bale hay, they literally create round bales, thus the name.

- Specialty Balers

- Compact equipment include those balers and compactors that are made for highly specific purposes. For example, some specialized baling and compact equipment comes with the added feature of moisture extraction. Equipment like this is used for materials which contain residual oils and liquids.

- Cardboard Balers

- Does just what its name suggests–it compacts and bales cardboard. Cardboard balers are most often used as recycling equipment.

- Metal Balers

- Another specialty baler. It is made specifically to bail ferrous and non-ferrous metal. These balers are used in waste and recycle and scrap metal applications.

- Waste Compactors

- Also known as an industrial trash compactor, is a compactor designed specifically to work with waste materials and trash. These come in different varieties, such as vertical, horizontal, and portable, and may have varying features like an auto-tie capability.

- Industrial Compactors

- Reduce material size for more efficient transportation. They may be stationary or self-contained. A stationary industrial compactor is stationed in one spot while running but is pulled apart and removed for emptying. A self-contained compactor, on the other hand, stays joined during compaction and emptying, in order to minimize leaks.

- Plastic Balers

- Does just what its name suggests–it compacts and bales plastic.

- Scrap Balers

- Crushes, cuts, and bales a wide range of scrap metals.

- Waste Balers

- Used not only for the compression and easy disposal of waste, but also to help create a secure bundle in which to transport waste to a repurposing or recycling facility.

Baler Standards and Specifications

If not properly built, handled, and maintained, balers can be a danger to operators. So, make sure that your baler comes with an OSHA endorsement. Also make sure that they adhere to whatever ISO standards are relevant (agricultural machinery, harvesting and conservation standards, etc.) Any additional standards depend on your application, industry, and location. Find out more by talking it over with your supplier.

Things to Consider When Purchasing a Baler

Balers tend to be very durable and reliable pieces of machinery. Therefore, it is possible to source used balers that have been refurbished and still have a long lifespan at affordable prices. Refurbished balers can be a great solution for a company that is looking to save money, but not sacrifice quality.

There are a lot of great baler suppliers and manufacturers out there. So how do you know who to choose? We recommend that, first of all, you check out the websites of the companies we’ve listed above, and reach out to those that offer the services you require. All of those with whom we work are knowledgeable, experienced, and reliable. To figure out which one is for you, focus on their customer service skills. Which one among them shows you the greatest commitment to working within your timeline and budget? Which one is most willing to work to make your application the greatest success it can be? Once you figure out which manufacturer that is, start working with them.

Baler Accessories

There are a variety of accessories we may recommend for you, depending on the type of baler you are purchasing and your application. For example, for bundling, you should purchase accessories like galvanized steel baling wire, PET strap, or twine. Other accessories you might consider include: strapping tools, strapping dispensers, a pallet rack, a conveyor, an aluminum can grinder, an industrial shredder, corrugated cardboard shredders, floor scales, dollies, or recyclable bags.

Baler Terms

- Auto-Tie

- A device that automatically binds a bale with a wire or another tie material.

- Banana Effect

- The slight curving of a bale due to inconsistent density that causes the denser bottom portion to swell. This creates a trapezoidal bale shape that stresses the banding.

- Baler

- A machine used to pack together and bind secondary materials for storage and or shipment.

- Bales

- Compressed material that is bound usually by wire.

- Banding

- The material, usually wire or nylon, used for wrapping around bales to secure them.

- Compaction

- The increase in an object's or material's density by applied pressure.

- Density

- The per unit size or space or the concentration of a material.

- Feed Width

- The width of the opening where material is inserted into the shredder.

- Ferrous

- Iron-based metals like steel.

- Hammermills

- These are high-speed rotor equipped machines with large hammers for crushing material into reduced sizes with up to 6,000 horsepower of force. Hammermills come in various sizes and material reducing capabilities.

- Hydraulic Press

- Press that applies force with a piston that uses liquid.

- Impact Crusher

- A machine that has large rotors with hardened steel bars at various intervals to pound concrete or other material fed to the machine. The pieces are then hurled against a hard steel wall, which further breaks them down.

- Incline Conveyor

- A conveyor that moves at an upward angle.

- Industrial Shredders

- Equipment for the processing and reduction of solid chemicals, materials and other solid products.

- Landfill

- An area where waste is disposed of, then covered beneath a layer of earth. Landfills are usually equipped with a liner to reduce soil and water pollution from any contaminating seepage, thus the term “sanitary landfill.”

- Pneumatic Press

- A press that applies pressure from a piston that uses gas and or air.

- Recycling

- A resource recovery method involving the collection, separation and processing to specification of scrap materials and their uses as raw materials for the manufacture of new products.

- Scrim

- A very loosely woven fabric, i.e. netting, used as support or backing.

- Secondary Materials

- A term commonly used as a synonym for materials in the recycling process.

- Throughput

- The amount of material conveyed in a specific amount of time.

- Waste Exchange

- A network that connects companies, which produce waste, with companies who can use the waste in their production.