Air Filters

Air filters are devices used to minimize or remove unwanted particles from the air. This may be air flowing within a ventilation system, or it might be air moving through an open indoor space. Industrial air filtration systems improve indoor air quality and extend the working life of machinery, engines and appliances.

Quick links to Air Filter Information

The History of Air Filters

The concept of air filters originated in the 16th century, when workers began wearing protective air respirators over their noses and mouths in order to prevent them from inhaling harmful fumes, vapors, gases or dust particles. Throughout the 1700s and 1800s, engineers like Alexander von Humboldt and Lewis P. Haslett worked on air-purifying respirators. Haslett’s invention, called “Haslett’s Lung Protector,” filtered dust using moistened wool and a one-way clapper valve.

In the late 1940s, the U.S. Army Chemical Corp and the U.S. Atomic Energy Commission worked together and came up with the first HEPA (High-Efficiency Particulate Air) filter. First called “collective protector filters,” they developed the HEPA filters in order to protect against radioactive chemical agents released while they worked on the Manhattan Project. After WWII ended, the U.S. government declassified HEPA filter technology, and manufacturers began producing it for residential and commercial use. While the first HEPA filters were made with asbestos components, by the late ‘50s, this ingredient was abandoned, as it is incredibly hazardous to health.

In the 1960s, after receiving complaints of defective filters, the Atomic Energy Commission introduced quality assurance testing. In 1963, a German mechanical engineer, Klaus Hammes, together with his brother Manfred, designed the first clean air filter for residential ovens. The filters consisted of a filter pad and magnets that allowed users to attach it to an air outlet. It trapped dust in the cold air as it entered the oven and heated, reducing “black dust buildup” found on oven walls. As consumers began to notice that filter use also decreased their allergy and asthma systems, the popularity of the Hammes system grew. After this, Hammes developed similar filter systems for other heating equipment, like radiators and forced air heating and cooling systems. In addition, with his son, Hammes developed the first cabin air filter for the American branch of Mercedes-Benz.

Over the subsequent decades, engineers continued to find new filter materials and construction materials. The more researchers learn about harmful particles and substances that exist in the air, the more air filters play an important part in society's long-term health. Today, air filters offer a wide range of filtration levels for innumerable environments.

Advantages of Air Filters

Air filtration systems have also become almost a necessity for all modern manufacturers, due to the rising level of pollutants in our environment. Plus, they help manufacturers and other businesses control their emission rates and reach their pollution control goals, as set out by the EPA.

Aside from this, they have many advantages over other purification methods. First, they are highly efficient. Second, they are incredibly simple and easy to maintain. Another great advantage of air filters is the fact that, in addition to removing harmful particles from the air, they also reduce odor in the air. Finally, they’re inexpensive and incredibly versatile.

Air Filter Uses

Air filters have use anywhere air needs cleaning; since air pollution can be found just about everywhere, air filters are in pretty high demand. Some of the biggest industry culprits include: wastewater and sewage treatment, oil and gas, paper and plastic, fertilizer, aerospace, pharmaceutical production, tobacco, transportation, rubber, chemical treatment, meat processing, automotive manufacturing, and more.

Within these industries, manufacturers and workers rely on clean air filters. However, they’re not the only ones. Clean air filters are also important for use in and around the home, where they’re found in furnaces, vacuum cleaners, air conditioners and humidifiers. Particularly beneficial is the use of air filters in domestic environments in which there are pets or excessive mold, mildew and dust that bring on allergic symptoms. Air filters help clean the air and remove these allergy-causing particulates, thus allowing homeowners and their families to breathe easier. The incorporation of filters into a circulation system is especially important for those prone to asthma or persons with breathing difficulties.

Also, in medical applications, filters can be used to remove bacterial and viral microbes and infections that are transported through air molecules.

Design of Air Filters

- Materials Found in Filters

- Air filter manufacturers make their products using a wide variety of materials. These include fabrics, paper, metal, plastics, and alternatives like charcoal.

- The choice of which they are used depends entirely on the application. Fabrics, for example, are chosen for use with particulate matter passing through gas. Often, fabric filters, like filter bag houses, are used over and over again. Paper, on the other hand, is selected when customers are looking for a disposable filter option. Meanwhile, metals like stainless steel are useful as filter screens for heavier duty filtration requirements. Plastics are used in electrostatic filters to create the natural static charge from friction which attracts dust particles. You can find companies making these types of filters on IQS Directory. Finally, manufacturers choose filter materials like active carbon or charcoal for working with water. The carbon element causes chemical reactions within the filter itself to attract and remove harmful elements from the air.

- Filter Design Considerations

- When determining the most suitable type of filter to use for any given application, manufacturers consider a number of application-related factors. These include: required filtration efficiency (determined by: the size of the filter fibers, the density of the fibers in the filter and the velocity of the air that moves through the filter), the size and density of the particles to be captured, possible adhesive, and the available space and power limitations. Note that dense filters capture more particles, and therefore provide a higher level of air purification, but also require more power in order to push the air through the filter.

- Customization Air Filters

- Most manufacturers are more than willing to offer you custom options, including those related to: filter length, filter thickness, filter width and frame shape.

Air Filtration Images, Diagrams and Visual Concepts

Air filters are used to remove airborne particles, pollutants, and microorganisms hazardous to health and the ecosystem.

Air filters are used to remove airborne particles, pollutants, and microorganisms hazardous to health and the ecosystem.

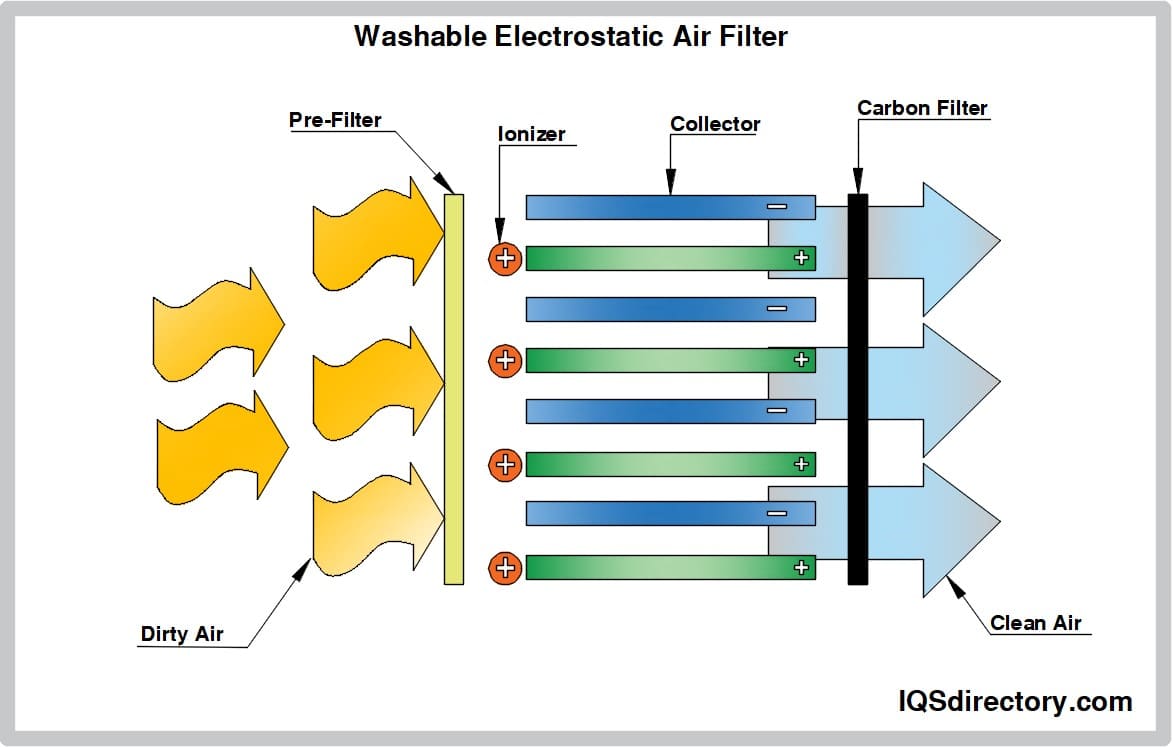

Washable electrostatic air filters operates electrostatic filter media, when the air encounter friction the media holds the particles with static electricity until the filter is washed.

Washable electrostatic air filters operates electrostatic filter media, when the air encounter friction the media holds the particles with static electricity until the filter is washed.

Air filters are manufactured in different shapes and sizes to remove particles and pollutants from ambient air.

Air filters are manufactured in different shapes and sizes to remove particles and pollutants from ambient air.

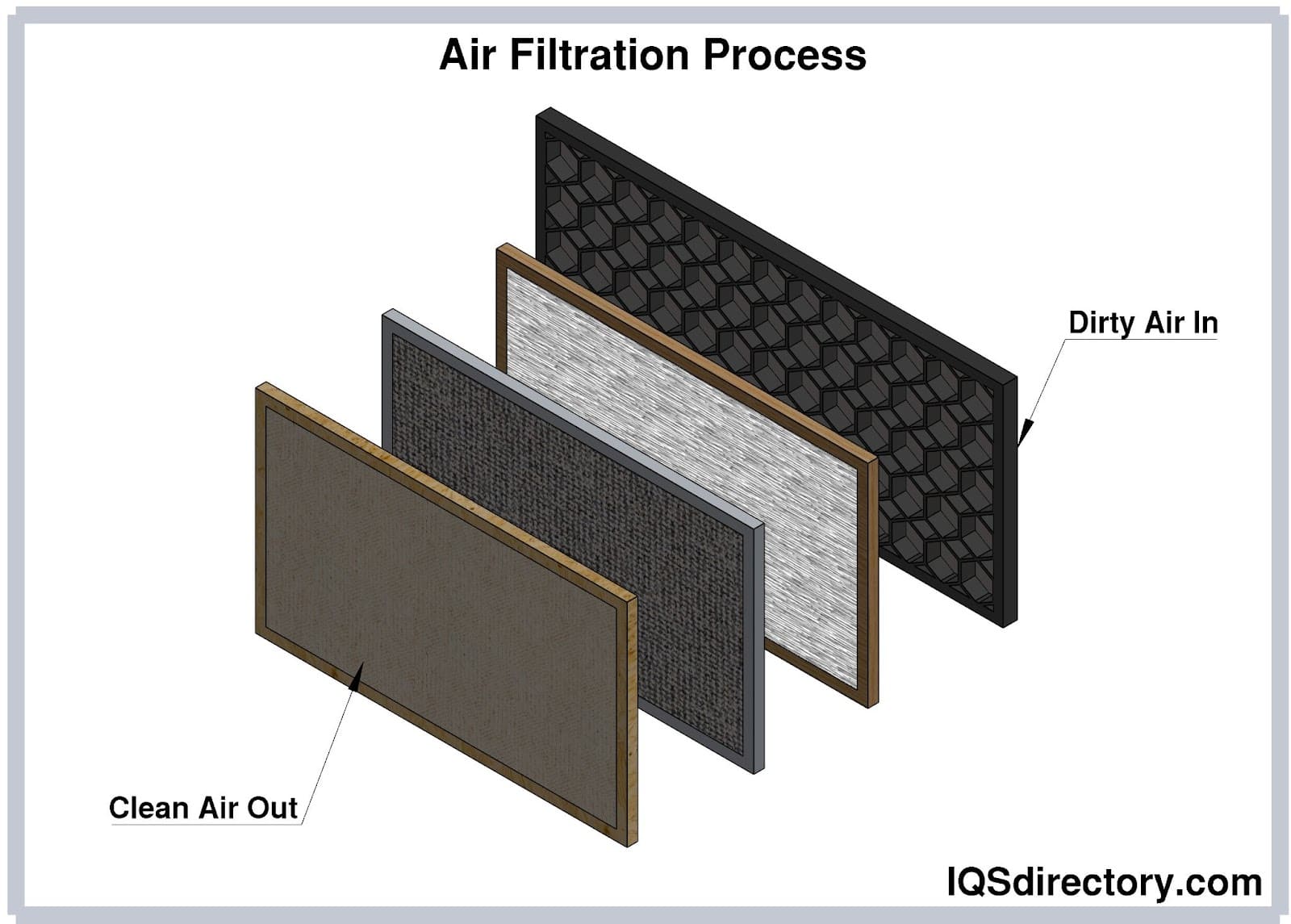

How air filters work by drawing unclean air to pass through a filtered medium with fine openings.

How air filters work by drawing unclean air to pass through a filtered medium with fine openings.

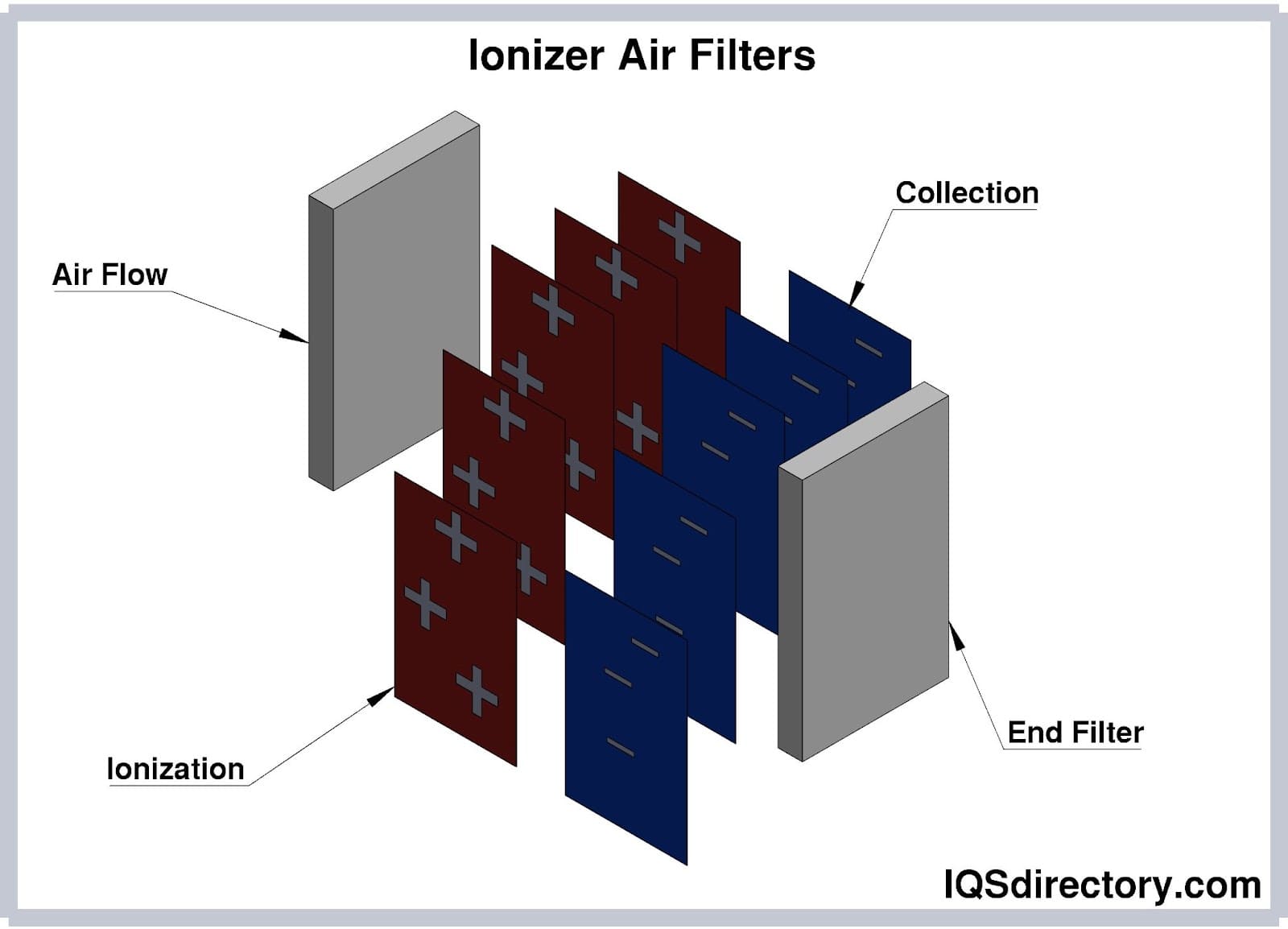

An ionizer air filters the air passes through a prefilter then an ionizer where the airborne particles are electrical charged.

An ionizer air filters the air passes through a prefilter then an ionizer where the airborne particles are electrical charged.

HVAC filters prevent particulates and other contaminants from entering the internal components of a HVAC system which could damage the system.

HVAC filters prevent particulates and other contaminants from entering the internal components of a HVAC system which could damage the system.

Air Filtration Types

In general, air filtration systems come in two categories: electrical and mechanical. However, there are many other types of air filtration systems that offer specific functionality, as described below.

- Flat-Paneled Fiberglass Filter

- These filters have a medium level efficiency with a rating between 1 and 4. The metal-like robust body protects the filter from breakage. These strainers are suitable for catching large airborne elements, but not small elements like dust or bacteria.

- Pleated Filter

- Disposable pleated polyester filters can catch small as well as large elements, and because of this functionality, they come with a rating from 7 to 13. This high efficiency level makes pleated filters an ideal choice for domestic and commercial use. They are very close to the efficiency level of HEPA filters but are available at cheaper rates.

- HVAC Filter

- High-efficiency Particulate Arrestance/Air filters are devices that have an efficiency rating between 14 and 16. They offer higher airflow resistance and support noiseless operation. HVAC filters are largely used in home or commercial heating ventilation and air conditioning systems (HVAC).

- HEPA Filter

- Offer the best air quality; as per industry standards, they can remove 99.97% of all elements from indoor air. These devices have an efficiency rating from 17 to 20. HEPA filters are frequently installed in HVAC systems, hospital operating rooms and pharmaceutical facilities, where they mostly remove allergens and other irritants from the air.

- ULPA Filter

- Similar to the HEPA filter is the ULPA (Ultra-Low Particulate Air) filter. It is also highly efficient, with precision filtration. ULPA filter varieties are used to eliminate allergens and maintain strict air quality guidelines.

- Inline Filter

- Or line filters, attach to pre-existing ductwork or tubing to remove impurities and liquids from an air stream.

- Membrane Filter

- Use thin microporous films to trap or retain particulate impurities from an air source drawn through them.

- Air Compressor Filter

- Or compressed air filters, remove water, oil, dust, vapors and other contaminants from a compressed air supply.

- Electrostatic Filter

- Provide an almost permanent filtration screen solution. What’s more, they do not require a power source in order to be most effective.

- Furnace Filter

- A type of air purifier installed inside both commercial and residential furnaces to catch dust, dirt, mold spore, pet dander and other potential allergens. These filters are easy to install and replace.

- Carbon Air Filter

- Specialty filters used to remove other contaminants such as gases and odors from air streams.

- Exhaust Filter

- Used to remove soot or other particulate matter from vehicle exhaust before it exits into the atmosphere.

- Cabin Air Filter

- A type of pleated-paper filter used with vehicles. To work, automotive manufacturers place them in outside passenger compartment air intakes.

- Oil Filter

- Designed to remove contaminants from oil in machinery, especially hydraulic machinery. Examples include engine oil, transmission oil, hydraulic oil and lubricating oil.

- Thermodynamic Sterilization

- These devices use heat of up to 200 degrees Celsius to sterilize an air flow. With this technique, about 99% of organisms, such as bacteria, allergens, molds and mildews, can be eliminated. Since thermodynamic sterilization devices do not catch or remove particulate matter or gaseous elements, these units are typically labeled as air purifiers versus air filters. Thermodynamic sterilization is safe and suitable for homes and offices, where noxious gases are not usually present.

- UV Germicidal Technique

- Ultraviolet Germicidal Irradiation (UVGI) employs UV rays to remove the contaminants from an exhaust stream. The appliance has a UV lamp and a fan that moves air toward a lamp, which treats the stream. After that, a filter traps and removes the dead bacteria from the air flow.

- Polarized-Media Electronic Air Cleaner

- This filtration technology uses an enhanced electronic medium to remove contaminants from an environment or airstream. These air cleaners fall in the category of both mechanical and electronic filters. The devices convert AC into DC to create a polarized field, in which the particles in the air flow are polarized, and caught by a fiber pad. With these systems, even the thinnest contaminant particles can be captured and removed. Additionally, these processes help chemical plants to create a breathable, odor-free, safe environment.

- Photocatalytic Oxidation Filter

- PCO filtration is a newer method that, apart from filtering air flow, can also help building management resources to save big on electricity consumption by restricting the unconditioned air from entering the duct and the environment.

- Ionizer

- The air filters that work on this technology ionize the particles in airflow that are then caught by an electrode, which is a negatively charged plate. This is a safe and robust technique for industrial and environmental scenarios.

Standards and Specifications for Air Filters

The American Society for Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) has proposed a rating standard to evaluate and rate the efficiency of air filtration systems. This rating system is named Minimum Efficiency Reporting Value (MERV), and the rating ranges from 1 (lowest), to 20 (highest). The purpose of these ratings is to assess the capability of filters to remove particles, to resist airflow, and to assess the durability of a product.

Things to Consider When Purchasing an Air Filter

There are a lot of air filter products out there, so it’s important that you have a reliable guide to help you find the filter you need. The best guidance comes from an established air filter manufacturer or supplier, and luckily for you, you’re only a few clicks away from finding one!

Here at IQS, we’ve gathered up the names, phone numbers and websites of the industry bests, and put them all in one place. Find the right provider for you by browsing their respective websites, found listed near the top of this page. As you peruse their sites, take note of three or four who you find most interesting. Then, reach out to these manufacturers, detailing your specifications and asking them questions about lead times, prices and customization services. Compare and contrast their answers, and then choose from them the manufacturer you believe will serve you best and with the most integrity–that’s the right one for you.

Proper Care for Air Filters

Air filters are generally able to function very well, as long as they handle the right kind of particulate for their design. If well maintained and regularly cleaned, many filters will outlast their intended replacement date and will provide years of reliable performance and cleaner air.

Filter Accessories

Air filter accessories include products like: adaptor flanges, hardware kits, valve covers, filter vent tubes and vent hose adaptors. Find out what products might work with your filter by talking to your supplier.

Air Filter Terms

- Adsorption

- The retention of gas, liquid or solid on a surface due to positive interaction/attraction between the surface and the molecules of the adsorbed material.

- Air Borne

- A term that refers to any particles or substances floating in the air.

- Air Stream

- A current of air.

- Allergen

- A normal substance that causes an acute defensive reaction in a person’s immune system.

- Arrestance

- An air filter’s ability to remove synthetic dust from the air during a test.

- Backpressure

- A backward surge of pressure from downstream to upstream of an air filter. Backpressure can be the result of closing a valve or air entrapped in a liquid system.

- Certified Energy Manager (CEM)

- International professional designation available through training and testing by the Association of Energy Engineers (AEE).

- CFC (Chlorofluorocarbon)

- Family of chemicals used as refrigerants, being tightly regulated and phased out of production due to stratospheric ozone depletion potential. Examples: R-11, R-12, R-113, R-114, R-115.

- Containment

- The prevention of an agent from being transmitted from one point to another.

- Contamination

- An unwanted intrusion, such as harmful airborne particles.

- Decontamination

- The removal of unwanted airborne particles to neutralize the air.

- Filter Medium

- The permeable material that removes particles from a substance being filtered. Oftentimes, the material used in filters is some type of foam or membrane.

- Filter Penetration

- Particles passing through an air filter without being removed from the air stream.

- Filtrate

- The product that is filtered.

- Indoor Air Quality

- A term that refers to the amount of pollutants in the air within a confined space.

- Ionizer

- A filament, grid or porous body in an ion engine or other device that strips an electron from the outer shell of a neutral atom to form a positively charged ion.

- Membrane

- A continuous matrix with pores of defined size.

- Negative Pressure

- Pressure in an area that is responsible for the inflow of air.

- Ozone

- A molecule containing three atoms of oxygen. Ozone is harmful to both humans and plants at ground level, but is crucial in blocking ultraviolet radiation in the stratosphere.

- Particulate

- A very small solid suspended in air or water that can vary in size, shape, density and electrical charge.

- Positive Pressure

- Pressure in an area that is responsible for the outflow of air.

- Pressure Drop

- In the case of air filters, a measure of the resistance of air to flow through a filter.

- Upstream

- The direction that is in opposition to the airflow.